BE CAREFUL with PBW with coloured hopper mouthpieces!!!!!

I would limit soak times to 5 minutes (10 minutes at a MAXIMUM, but that is probably unnecessary anyway).

My recommended procedure as it stands, I'm still experimenting (and I hardly clean my mouthpieces, it's happening tomorrow though, plus I think I have two loose screens to deal with)

- Hot water rinse. Hold the MP under a running hot tape, use a scraping tool to rid the screen of the bigger chunks of gunk. You can get a little gunk out from the mouthpiece hole too.

- Add boiling (from kettle) water to a glass with a 1/4 tsp PBW (concentration is high at this level, so between a 1/6-1/2 teaspoon is good, it really won't make a lot of difference either way [perhaps])

- Soak for 1 minute, take out and repeat step 1. Using a pipe cleaner to scrub is effective.

- repeat step 3 until clean

- Rinse (hold under running water for 30 seconds, make sure to flush the top end thoroughly

- Blow air through either end to dispel water, and let it sit to allow the mouthpiece to dry

I'm going to go ahead and say AVOID PBW with coloured hoppers

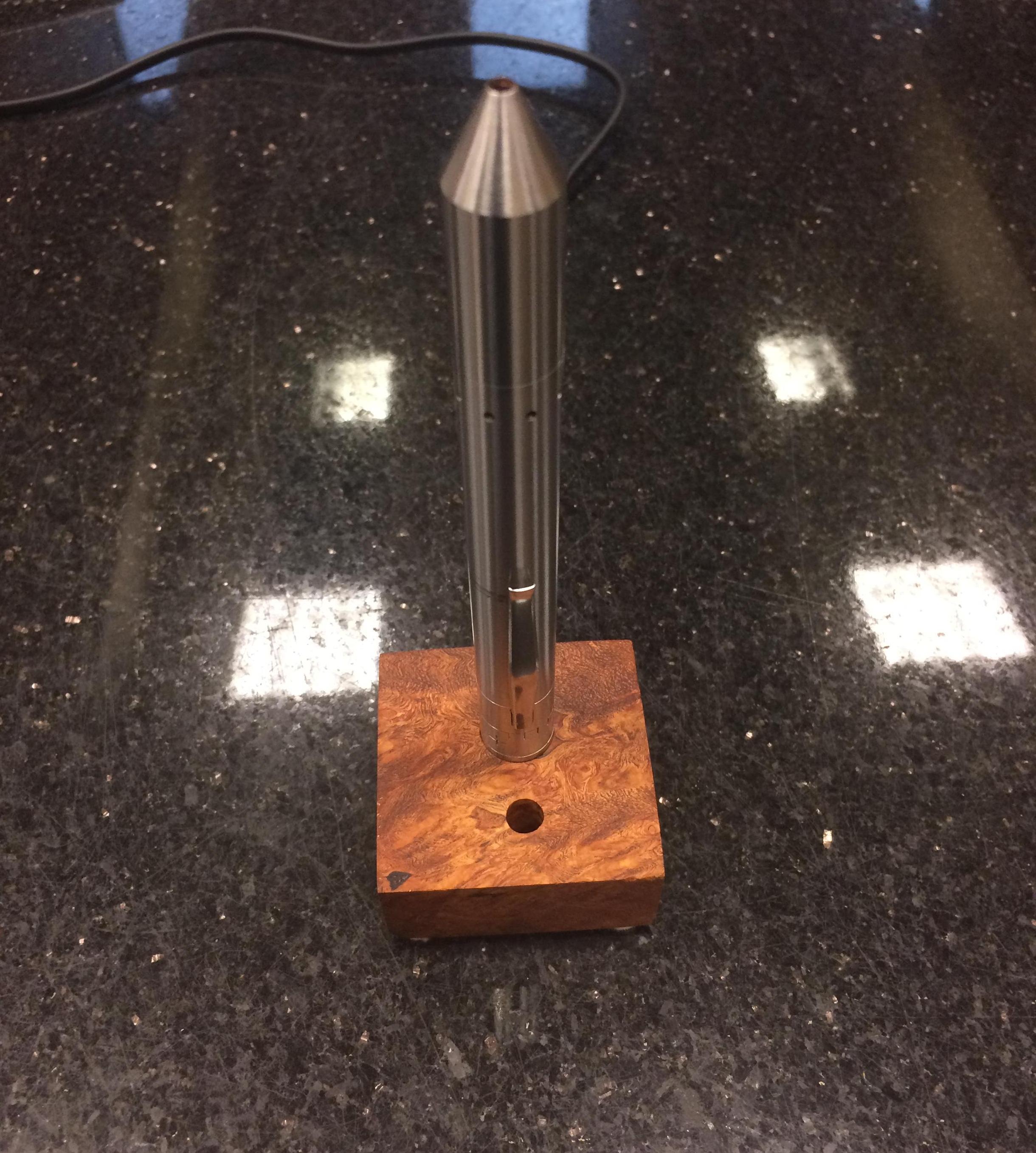

All the pieces in the pic were once the same colour, now I have a really awesome gold and I've started to discolour my other mouthpiece too.

I think my recommendation of 1/4 teaspoon is too much, I didn't soak either of these MP's long at all (except for the gold one, which was mostly affected last time I cleaned it).

I think a 1/10th tsp would be a better concentration, but possibly less again would be better.

Anyway, I gave the mouthpieces a dunk in my PBW solution for about 30s-1min a pop after a hot water rinse and scrape.

I took them out after less than a minute and hot water rinsed for a bit, then replaced them in solution.

After the second rinse, they were very clean, there were still minor traces of resin and gunk in the threads and conical section, but after this very short amount of time (from reasonably dirty MPs) most was gone. Stirring the PBW solution will help get rid of more than this, but I was trying to keep soak times at a minimum.

After I'd PBW'd I used a tiny bit of IPA to dissolve the remaining resin. Filling the MP halfway with IPA over a sink with a thumb over the MP hole and a bunch of shaking, with both ends sealed, caused the MP to become almost entirely clean. I couldn't get any more resin out with a cloth or tooth pick, scraping around either side of the screen.

The whole process took about 3 minutes, but I have allowed over half an hour for drying.

It's vital to blow through the MP from the hopper end to help it dry, a fair bit of liquid gets partially trapped in there.

I also had to use fine-nose tweezers to screw either screen down so it would tighten flush with the hopper body.

What a pain! The GH should definitely have come with a screen tool, tweezers are bullshit.

They work, but not as easily as a proper tool would (a tool would be mindlessly easy compared to the fiddly and time consuming tweezer method).

Overall, all I can say is it makes a lot of practical sense to stick with the bare metal finished hoppers, so you can more easily soak the MPs with solution that actually works.

IPA as a rinsing medium is much better suited, and overall it makes the maintenance as simple as it could be.

I also just plucked a very old lump of blue tack off the wall and used it to clean the threads.

Now back to business

My point was about "destructive" language being used so that it becomes normalized. It's especially insidious when it's used out of context. "I wasn't talking about women, I was talking about..." but if a woman who had been physically abused had read that, I wonder if she would see it as OK.

My point was about "destructive" language being used so that it becomes normalized. It's especially insidious when it's used out of context. "I wasn't talking about women, I was talking about..." but if a woman who had been physically abused had read that, I wonder if she would see it as OK.

What's the second smaller hole for?

What's the second smaller hole for?