-

SCAM WARNING! See how this scam works in Classifieds.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Bud Toaster - (currently: Model 14, version 3)

- Thread starter Hippie Dickie

- Start date

well, if you mean for the cube, the only 3-D printers i've seen use a fairly low temperature plastic (melt & extrude) -- perhaps too low temperature. it is an intriguing idea, however.

The CNC router i have in mind would be much faster and could do 100 cubes at a go.

maybe casting would be better.

but i have to get the next 20 done and beta tested first.

The CNC router i have in mind would be much faster and could do 100 cubes at a go.

maybe casting would be better.

but i have to get the next 20 done and beta tested first.

Just thought I'd check up on the progress ... this one has been interesting me for a while ... ever consider just selling kits with all the parts for those DIY that want to give a go at building their own? Might even get some refinements from the community this way that could help your idea progress even further  ... obviously would have to be sold with non-redistribution rights so only for personal use and advancement of the vaporizer community in general.

... obviously would have to be sold with non-redistribution rights so only for personal use and advancement of the vaporizer community in general.

... obviously would have to be sold with non-redistribution rights so only for personal use and advancement of the vaporizer community in general.

... obviously would have to be sold with non-redistribution rights so only for personal use and advancement of the vaporizer community in general.i have definitely decided not to do a kit. i think it would be counter productive to have someone fail to get the kit working, and then blame me for that, bad word of mouth, ... just too much could go wrong if out of my hands.

And if you really want to DIY, the parts list and assembly instructions are in this thread. code is available on my SkyDrive.

re: progress. i have had a major break through in the final design element for the power cells. i think this will allow me to proceed with fabricating the first 10 units. i'll post at length about this after i get to try the new design. sometime this week.

And if you really want to DIY, the parts list and assembly instructions are in this thread. code is available on my SkyDrive.

re: progress. i have had a major break through in the final design element for the power cells. i think this will allow me to proceed with fabricating the first 10 units. i'll post at length about this after i get to try the new design. sometime this week.

i have definitely decided not to do a kit. i think it would be counter productive to have someone fail to get the kit working, and then blame me for that, bad word of mouth, ... just too much could go wrong if out of my hands.

And if you really want to DIY, the parts list and assembly instructions are in this thread. code is available on my SkyDrive.

re: progress. i have had a major break through in the final design element for the power cells. i think this will allow me to proceed with fabricating the first 10 units. i'll post at length about this after i get to try the new design. sometime this week.

Totally understand ... (I wouldn't be one to blame you if I messed it up, however, I totally get it). I did find the schematics etc after making my post (should have looked more carefully) so if I find some time and decide to tinker then I'll use that as a starting point. You really have done some awesome work here .... it's interesting to see the work broken down and the ingenious design behind your heating element/chamber ... pretty cool!

Abysmal Vapor

Supersniffer 2000 - robot fart detection device

Awesome !i have definitely decided not to do a kit. i think it would be counter productive to have someone fail to get the kit working, and then blame me for that, bad word of mouth, ... just too much could go wrong if out of my hands.

And if you really want to DIY, the parts list and assembly instructions are in this thread. code is available on my SkyDrive.

re: progress. i have had a major break through in the final design element for the power cells. i think this will allow me to proceed with fabricating the first 10 units. i'll post at length about this after i get to try the new design. sometime this week.

Can I get one,

please?

miles to go before i sleep ... uh, sell.

G'day HD

I have repackaged my clone in some indonesian rainforest. Thought I'd share.

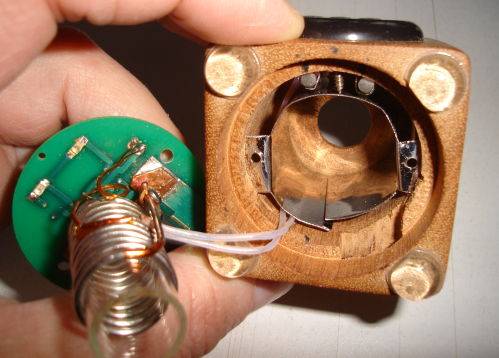

This is still temporary, there is a lot of wasted space inside, the oven chamber is much longer than yours too for no particular reason. And the electronics is mounted on the bottom, with rubber feet as a workaround. The glass is also less than ideal, but I have some 15 and 12mm test tubes on the way.

I have some ideas for the battery situation. As shown above, I'm trying to integrate it into the vape, ideally mounted inside the wood (or whatever) enclosure. The ultimate plan is to have a battery charger circuit on board and construct a charging cradle for the vape to live on.

This just seems like the more ideal solution. people shouldn't have to worry about the battery, how to plug it in and support its weight separately etc. I suppose dealing with batteries is something you have done a lot of thinking about?

A charging cradle also means that the vape only has to last about 2-3 sessions, so a much smaller battery can be used, making the entire thing a more hand-held size.

With the right circuit, a full charge could be achieved in half an hour.

And I'm sticking with the 12V system as it means lower current, cheaper, smaller components and batteries etc. I worked out 1.25ohm (15 turns of 19AWG) will deliver 80W at 10V and 8A. this power will be delivered by a LiCo 3-cell (11.1V) pack, either 800mAh or 1300mAh, both rated >30A constant 60A burst. They are cheap and tiny!

I'll probably make another thread documenting this project in the near future.

Anyway, I have some glassware on the way from a local seller on ebay. 12mm vials are hard to come by, so I thought I'd try using 12mm test tubes instead, drill holes around the bottom edge.. was there some good reason you are using vials?

Is this the sort of drill bit you are using? I know nothing about drilling glass except the hints you have given in this thread.

Cheers

I have repackaged my clone in some indonesian rainforest. Thought I'd share.

This is still temporary, there is a lot of wasted space inside, the oven chamber is much longer than yours too for no particular reason. And the electronics is mounted on the bottom, with rubber feet as a workaround. The glass is also less than ideal, but I have some 15 and 12mm test tubes on the way.

I have some ideas for the battery situation. As shown above, I'm trying to integrate it into the vape, ideally mounted inside the wood (or whatever) enclosure. The ultimate plan is to have a battery charger circuit on board and construct a charging cradle for the vape to live on.

This just seems like the more ideal solution. people shouldn't have to worry about the battery, how to plug it in and support its weight separately etc. I suppose dealing with batteries is something you have done a lot of thinking about?

A charging cradle also means that the vape only has to last about 2-3 sessions, so a much smaller battery can be used, making the entire thing a more hand-held size.

With the right circuit, a full charge could be achieved in half an hour.

And I'm sticking with the 12V system as it means lower current, cheaper, smaller components and batteries etc. I worked out 1.25ohm (15 turns of 19AWG) will deliver 80W at 10V and 8A. this power will be delivered by a LiCo 3-cell (11.1V) pack, either 800mAh or 1300mAh, both rated >30A constant 60A burst. They are cheap and tiny!

I'll probably make another thread documenting this project in the near future.

Anyway, I have some glassware on the way from a local seller on ebay. 12mm vials are hard to come by, so I thought I'd try using 12mm test tubes instead, drill holes around the bottom edge.. was there some good reason you are using vials?

Is this the sort of drill bit you are using? I know nothing about drilling glass except the hints you have given in this thread.

Cheers

Outstanding! You are now a member of the very exclusive Bud Toaster Builders Club.

re: glass drilling

that's the right kind of bit, but a bit pricey. bits only last about 12 holes before the shaft snap or the tip gets too dull. and i destroyed several before i could get that good. Try Kingsley North (.com) in MI. They have several grades -- the package of 10 for $12 work okay.

i use a dremel in a drill-press stand, spinning around 10,000 rpm. i fill the glass (tube or vial) with water and have the drill surface under water. messy and tedious to do. yesterday i was drilling some 16mm tubes to get back into the mindset.

i make a hole pattern template using copper foil (0.010 i'm guessing) which i drape over the end of the vial/tube -- otherwise the drill bit wanders and snaps. i use a wood block to hold the glass and the template is fastened to the wood -- flat for the vials and with a 1" bulge for the tubes to stick into.

i do 4 holes in the end of the vial and 7 holes in the end of the toke tube.

re: glassware

i got my first bunch of vials from American Science & Surplus (sciplus . com). after that, i bought a pack (144 pieces) from a labware supply company. Sciplus has 5 packs of the 16mm x 150mm tubes.

when i got my custom cut glassware from India, i got some 12mm x 35mm test tubes to try as an alternative to the vial. my first test was not successful. i think that 1/8" gap between the bottom of the vial and the inside bottom of the oven tube is critical for the vape to work (maybe even patentable). test tube inside test tube eliminates that gap.

just one test and i haven't pursued it any further because i really like the flat bottom vials anyway.

however, using the vial, i need to grind some notches (i do 6) equally spaced around the bottom edge of the vial (another possibly patentable design feature) so air can get into the bottom of the vial -- otherwise, pushing down on the top of the vial with the toke tube will seal the bottom of the vial in the oven and block air flow. (that description probably makes no sense)

i use a 16mm x 150mm (6") test tube for the toke tube. i use a 12mm x 100mm (4") tube for concentrates, with a single 1/4" hole in the side, rather than the bottom.

re: batteries

at the increasing rate of battery development, i think entirely new chemistries will be available before it's legal to sell paraphernalia. MIT now has a technology that recharges in a minute -- so it could recharge between tokes.

i am wedded to the A123Systems technology -- mainly for the safety factor. i know it works. i haven't looked at the other lithium chemistries.

re: longer oven tube

i was thinking about this just yesterday wrt the Cloud design. going from a 1.5" oven to a 6" oven would provide an incredible amount of vapor extraction. but it would get very hot. i don't know if the stainless steel heat shield would be enough thermal barrier.

Anyway, great job.

re: glass drilling

that's the right kind of bit, but a bit pricey. bits only last about 12 holes before the shaft snap or the tip gets too dull. and i destroyed several before i could get that good. Try Kingsley North (.com) in MI. They have several grades -- the package of 10 for $12 work okay.

i use a dremel in a drill-press stand, spinning around 10,000 rpm. i fill the glass (tube or vial) with water and have the drill surface under water. messy and tedious to do. yesterday i was drilling some 16mm tubes to get back into the mindset.

i make a hole pattern template using copper foil (0.010 i'm guessing) which i drape over the end of the vial/tube -- otherwise the drill bit wanders and snaps. i use a wood block to hold the glass and the template is fastened to the wood -- flat for the vials and with a 1" bulge for the tubes to stick into.

i do 4 holes in the end of the vial and 7 holes in the end of the toke tube.

re: glassware

i got my first bunch of vials from American Science & Surplus (sciplus . com). after that, i bought a pack (144 pieces) from a labware supply company. Sciplus has 5 packs of the 16mm x 150mm tubes.

when i got my custom cut glassware from India, i got some 12mm x 35mm test tubes to try as an alternative to the vial. my first test was not successful. i think that 1/8" gap between the bottom of the vial and the inside bottom of the oven tube is critical for the vape to work (maybe even patentable). test tube inside test tube eliminates that gap.

just one test and i haven't pursued it any further because i really like the flat bottom vials anyway.

however, using the vial, i need to grind some notches (i do 6) equally spaced around the bottom edge of the vial (another possibly patentable design feature) so air can get into the bottom of the vial -- otherwise, pushing down on the top of the vial with the toke tube will seal the bottom of the vial in the oven and block air flow. (that description probably makes no sense)

i use a 16mm x 150mm (6") test tube for the toke tube. i use a 12mm x 100mm (4") tube for concentrates, with a single 1/4" hole in the side, rather than the bottom.

re: batteries

at the increasing rate of battery development, i think entirely new chemistries will be available before it's legal to sell paraphernalia. MIT now has a technology that recharges in a minute -- so it could recharge between tokes.

i am wedded to the A123Systems technology -- mainly for the safety factor. i know it works. i haven't looked at the other lithium chemistries.

re: longer oven tube

i was thinking about this just yesterday wrt the Cloud design. going from a 1.5" oven to a 6" oven would provide an incredible amount of vapor extraction. but it would get very hot. i don't know if the stainless steel heat shield would be enough thermal barrier.

Anyway, great job.

but it would get very hot. i don't know if the stainless steel heat shield would be enough thermal barrier.

What about Aerogel? http://www.aerogel.com.au/

i haven't looked at aerogel in a while -- kind of expensive?

here's my thinking on insulation --- any kind of physical substance (even aerogel) is going to heat saturate in this small enclosed cube. i find an air gap (currently 1/8") outside the stainless steel heat shield to be very effective. i might go for two heat shields and two air gaps if the heat was excessive.

And, after all, what is the insulation trying to do? merely (it seems to me) capture air in a matrix and prevent it from moving, colliding, and transferring thermal energy. a vacuum would be better.

There is no air flow inside the cube, so the matrix - aerogel or whatever - is superfluous.

Also, @yayvape, i have many more construction photos in my album on icmag . com:

http://www.icmag.com/ic/album.php?u=98947

here's my thinking on insulation --- any kind of physical substance (even aerogel) is going to heat saturate in this small enclosed cube. i find an air gap (currently 1/8") outside the stainless steel heat shield to be very effective. i might go for two heat shields and two air gaps if the heat was excessive.

And, after all, what is the insulation trying to do? merely (it seems to me) capture air in a matrix and prevent it from moving, colliding, and transferring thermal energy. a vacuum would be better.

There is no air flow inside the cube, so the matrix - aerogel or whatever - is superfluous.

Also, @yayvape, i have many more construction photos in my album on icmag . com:

http://www.icmag.com/ic/album.php?u=98947

Thanks for the direction hippy. Unfortunately I'm on the other side of the world so those $12 bits become $60 after shipping  However, I did find a place on ebay selling 0.7mm bits for a similar price.

However, I did find a place on ebay selling 0.7mm bits for a similar price.

I also found this: DIY Ultrasonic drilling, seems pretty neat.. basically zero wear on the drill bit, ultrasound and the abrasive fluid do all the work. bit of a project to build one though. (he builds it from a $30, 50W ultrasonic driver, and a relatively simple 120V mosfet inverter, much like what you would find in a PC power supply)

The big advantage is that it will work with very small holes.. much smaller than a diamond drill bit.

Same site details a neat method of cutting test tubes (how are you cutting yours? do you seal the end after cutting of leave a sharp edge?). There is also a page on a diy spot welder (nichrome to copper connections maybe?)

My test tubes came today but have to wait another week or so for the drillbits planning on making a few units for some close friends, if I don't break all the test tubes

planning on making a few units for some close friends, if I don't break all the test tubes

re: Air gap introduced by the flat bottom vial

The only reason I can think of for this improving performance is that it might give the air a chance to evenly mix before entering the vial. air coming down one side could conceivably be cooler than the other if the vial is pushed to one side of the chamber.. I don't imagine this effect would have a huge impact though.

oh and airflow between shield and wood will occur due to convection. There will also be some heat flow due to radiation, airogel would block both of these things quite well. but its totally overkill. ceramic/glass fibre insulation is probably a better option.

does your cube warm up much with use? mine will get slightly warm to the touch after 15min continuous. I'm using an aluminium shield (roof flashing) with no intentional air gap.

However, I did find a place on ebay selling 0.7mm bits for a similar price.

However, I did find a place on ebay selling 0.7mm bits for a similar price.I also found this: DIY Ultrasonic drilling, seems pretty neat.. basically zero wear on the drill bit, ultrasound and the abrasive fluid do all the work. bit of a project to build one though. (he builds it from a $30, 50W ultrasonic driver, and a relatively simple 120V mosfet inverter, much like what you would find in a PC power supply)

The big advantage is that it will work with very small holes.. much smaller than a diamond drill bit.

Same site details a neat method of cutting test tubes (how are you cutting yours? do you seal the end after cutting of leave a sharp edge?). There is also a page on a diy spot welder (nichrome to copper connections maybe?)

My test tubes came today but have to wait another week or so for the drillbits

planning on making a few units for some close friends, if I don't break all the test tubes

planning on making a few units for some close friends, if I don't break all the test tubes

re: Air gap introduced by the flat bottom vial

The only reason I can think of for this improving performance is that it might give the air a chance to evenly mix before entering the vial. air coming down one side could conceivably be cooler than the other if the vial is pushed to one side of the chamber.. I don't imagine this effect would have a huge impact though.

oh and airflow between shield and wood will occur due to convection. There will also be some heat flow due to radiation, airogel would block both of these things quite well. but its totally overkill. ceramic/glass fibre insulation is probably a better option.

does your cube warm up much with use? mine will get slightly warm to the touch after 15min continuous. I'm using an aluminium shield (roof flashing) with no intentional air gap.

First off, thank-you for that website link. That dude does cool work. It also addresses my passion for alternative energy. i am determined to take my house off the grid “soon”. i like the Sterling Engine – i live by a river so the heat sink is available, just need a heat source.

Re: cutting test tubes.

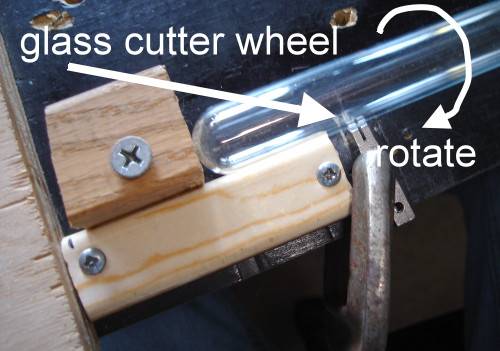

i use a similar technique, but without the lathe. i spin the tube against the cutter from a standard window glass cutting tool. Then I heat the scratch with a BIC lighter for about 30 seconds, then wipe and wrap the scratch with a wet cloth, and snap the tube. i often have to clean up the cut with a grinding wheel. My gf has a stained glass studio so I have access to some useful tools.

i found a glass supplier in India (on alibaba.com) that does custom cut-to-length work. There is so much wasted glass when I cut a 6” tube that I like keeping the waste at the factory to be recycled. The cut end is unpolished so I hit the end with a propane torch for about 60 seconds and that removes the sharp edge and anneals the edge.

I thought this could be done by machinery but evidently it is being done by hand. I really hate this manufacturing step and I am happy to outsource it. The polishing is not too bad – they did polish the first batch but it was very inconsistent and the vial won’t fit in 50% of them. They also silkscreened a logo on the glass before I learned to tell them to leave it blank (nasty chems in the ink which might outgas at vape temp). That whole first batch (1000 tubes) is unusable.

Re: drilling glass

If I ever get into production I think a laser drill is the way to go. I’ll try to outsource this – not ready to get my own laser. I’d rather have a 3D printer.

Re: air gap

I think the 1/8” air gap creates a heat reservoir under the vial. I should do more tests to see what is going on. i had a discussion in the Solo thread with Tintest who made a metal disc to fit in the Solo which provided a similar 1/8” gap between heater and herb – he claimed that it provides better extraction, and that agrees with my results in the Bud Toaster.

I see what you are saying about the air convection inside the cube. I hadn’t considered that. Thanks. My results are like yours – slightly warm to the touch on the outside after two 7.5 minute sessions in a row.

I use the air gap (between heat shield and wood) to run the LED light pipes and the wires from the thermometer display to the thermometer probe. And my shield has two tabs that the bottom cover screws into – inside the air gap.

Re: cutting test tubes.

i use a similar technique, but without the lathe. i spin the tube against the cutter from a standard window glass cutting tool. Then I heat the scratch with a BIC lighter for about 30 seconds, then wipe and wrap the scratch with a wet cloth, and snap the tube. i often have to clean up the cut with a grinding wheel. My gf has a stained glass studio so I have access to some useful tools.

i found a glass supplier in India (on alibaba.com) that does custom cut-to-length work. There is so much wasted glass when I cut a 6” tube that I like keeping the waste at the factory to be recycled. The cut end is unpolished so I hit the end with a propane torch for about 60 seconds and that removes the sharp edge and anneals the edge.

I thought this could be done by machinery but evidently it is being done by hand. I really hate this manufacturing step and I am happy to outsource it. The polishing is not too bad – they did polish the first batch but it was very inconsistent and the vial won’t fit in 50% of them. They also silkscreened a logo on the glass before I learned to tell them to leave it blank (nasty chems in the ink which might outgas at vape temp). That whole first batch (1000 tubes) is unusable.

Re: drilling glass

If I ever get into production I think a laser drill is the way to go. I’ll try to outsource this – not ready to get my own laser. I’d rather have a 3D printer.

Re: air gap

I think the 1/8” air gap creates a heat reservoir under the vial. I should do more tests to see what is going on. i had a discussion in the Solo thread with Tintest who made a metal disc to fit in the Solo which provided a similar 1/8” gap between heater and herb – he claimed that it provides better extraction, and that agrees with my results in the Bud Toaster.

I see what you are saying about the air convection inside the cube. I hadn’t considered that. Thanks. My results are like yours – slightly warm to the touch on the outside after two 7.5 minute sessions in a row.

I use the air gap (between heat shield and wood) to run the LED light pipes and the wires from the thermometer display to the thermometer probe. And my shield has two tabs that the bottom cover screws into – inside the air gap.

the real hold up (for me) is the legality of paraphernalia -- that is, it isn't. my gf would be super pissed off if i had to go do a Tommy Chong. (me too!)

we all need to collectively kick congress in the ass to make a change. Tell them: "Bitches, it's all about the jobs."

we all need to collectively kick congress in the ass to make a change. Tell them: "Bitches, it's all about the jobs."

the real hold up (for me) is the legality of paraphernalia -- that is, it isn't. my gf would be super pissed off if i had to go do a Tommy Chong. (me too!)

we all need to collectively kick congress in the ass to make a change. Tell them: "Bitches, it's all about the jobs."

I am feeling you HD! Wondering whether its worth it with all thats happened round here lately to a great guy we know!

I have stopped in here from time to time to see your progress and you have made much, I wish you well!

Hmm you may be waiting a while. Maybe move your sales operation to canada or something

Another update from me, I don't think the last one was deserving of the "Bud Toasters builders club" but this one is definitely getting there.

The glassware is up to scratch with the real thing. only exception being a round bottom inner vial (with 0.5mm holes drilled around the bottom)

I have only had a chance to test with damiana, but it seems to pull a wicked vapour. I think the smaller gap between inner vial and heating tube helps a lot.

Many test tubes were harmed in the creation of this prototype. its actually a serious issue, I can not get a clean break. I am trying exactly as you suggested, score the tube using the rig described (I am using linseed oil to prevent chipping) then heat over a yellow flame and snap with a damp rag. the 16mm tubes never follow the score perfectly, always a chip in the wrong place. I ruined 4 tubes and didn't get a single one without a chip (I ended up using a chipped one, as I didn't want to ruin my last test tube doing the same shit.)

The 12mm ones just seem to shatter into pieces with the force required to snap them. If I try cooling the tube more in the rag, they crack length-ways down the tube.

It's extremely frustrating! I understand why this is your least favorate part of construction..

Drilling was a breeze, I had some 0.5mm carbide bits around which work really well, each one can drill about 15 holes before I notice it getting blunt. Got a bunch of diamond bits on the way though.

So I ended up with one good set of cut, ground-down, drilled tubes (as pictured above), then the cat jumps up on the desk and knocks over the vape, vial falls to the floor.. fffffffffffffuuuuuuuuuuuu

I have enough tubes for exactly one vape, assuming you have some magic hint which will prevent me from breaking any more test tubes. (one can hope)

Another update from me, I don't think the last one was deserving of the "Bud Toasters builders club" but this one is definitely getting there.

The glassware is up to scratch with the real thing. only exception being a round bottom inner vial (with 0.5mm holes drilled around the bottom)

I have only had a chance to test with damiana, but it seems to pull a wicked vapour. I think the smaller gap between inner vial and heating tube helps a lot.

Many test tubes were harmed in the creation of this prototype. its actually a serious issue, I can not get a clean break. I am trying exactly as you suggested, score the tube using the rig described (I am using linseed oil to prevent chipping) then heat over a yellow flame and snap with a damp rag. the 16mm tubes never follow the score perfectly, always a chip in the wrong place. I ruined 4 tubes and didn't get a single one without a chip (I ended up using a chipped one, as I didn't want to ruin my last test tube doing the same shit.)

The 12mm ones just seem to shatter into pieces with the force required to snap them. If I try cooling the tube more in the rag, they crack length-ways down the tube.

It's extremely frustrating! I understand why this is your least favorate part of construction..

Drilling was a breeze, I had some 0.5mm carbide bits around which work really well, each one can drill about 15 holes before I notice it getting blunt. Got a bunch of diamond bits on the way though.

So I ended up with one good set of cut, ground-down, drilled tubes (as pictured above), then the cat jumps up on the desk and knocks over the vape, vial falls to the floor.. fffffffffffffuuuuuuuuuuuu

I have enough tubes for exactly one vape, assuming you have some magic hint which will prevent me from breaking any more test tubes. (one can hope)

alas, no magic -- you should see my box of broken tubes. It just takes a lot of practice. Did you look for YouTube videos?

i also BIC the tube at the score location for about 60 seconds before i score it, but i don't know if that makes a difference.

is it legal to manufacture and sell paraphernalia in Canada?

Edited to add a video. This was done in Oct 2011:

i also BIC the tube at the score location for about 60 seconds before i score it, but i don't know if that makes a difference.

is it legal to manufacture and sell paraphernalia in Canada?

Edited to add a video. This was done in Oct 2011:

i keep forgetting you live in a civilized country ... so close, yet so far away.

alas, no magic -- you should see my box of broken tubes. It just takes a lot of practice. Did you look for YouTube videos?

well I guess I'll just need to break more tubes. I couldn't find much on youtube, only that lathe video.

well I guess I'll just need to break more tubes. I couldn't find much on youtube, only that lathe video. do you score the tube on the first run? or go over it a couple of times to make a deeper (but more chipped) score? maybe I need a sharper glass cutter (mine is the same style as what you use, but I don't know how old it is)

When you wrap the tube in the damp towel, does it kinda fall apart? or you actually have to put some force in? because the heating/cooling doesn't seem to have any effect for me.

As a last resort I might try putting a tube in the bench drill and use a dremel and cutoff wheel.

@Video

Nice video too man, that is some dense vapor. can't wait to get some bud and test mine!

Have you thought about moving the buttons to the side or top? seems impractical to turn the cube over, or reach under just to turn the thing on.. Or just have it automatically start when plugged in?

I was going to implement a pretty simplistic interface, 6 or 7 led's forming a bar display with something like 5C increments centred around 185C (370F), the led's above this temp will be coloured green (or bicolour maybe) so having the same effect as your green led, indicating when the vape is ready.

Then it will have a single pushbutton (which should be pretty optional to use) this starts the vape (for the built-in battery model), and restarts it after it turns off.

For most people, that's how the vape is operated, but if they want to play around with the temperature, a long hold will change to a temperature setting mode, the LED's will display the set temp, single pushes change the temp, long push sets it.

I have 7 spare pins for UI.. I could do an LCD or 7-segment displays (using a BCD converter chip or something) but I can't find anything quite small enough.

Do you reckon 5C increments is good enough? its not like you really care if its 185 or 187..

What about this LCD? Even though it's an eleven pin parallel interface, you can use a serial backpack to turn it in to a SPI interface. What microcontroller are you using?

@CentiZen - that is a nice LCD display. i don't have any spare i/o pins in this design. maybe next iteration.

i'm using a Microchip 12F683 in a 8 pin SOIC package.

re: cutting tube

yes, i go over the score 6 or 10 times so it is fairly deep. the cloth is a 6"x6" piece of cotton t-shirt, very wet, but not dripping. i heat the score with a BIC for 30 seconds, then wipe around the score with the damp cloth. sometimes it will separate at this time. else, wrap the score with the cloth (so i won't cut myself on the sharp edge) and use two hands to snap at the score. the damp cloth causes a thermal shock around the score. i have a glass polishing wheel to smooth a jagged edge.

the "factory setting" is 380°F. i rarely adjust it, but the +5°F (click left button) and -4°F (click right button) allow quick and precise adjustment. it remembers any change in setting and returns to that for the next session. holding the right button for 2 seconds, then release, starts the vape. holding the left button for 2 seconds, then release, resets to factory setting.

because of the circuit board is round and where it is located, the buttons have to be on the bottom. it really hasn't been a problem. i definitely don't want it to automatically start when plugged in.

if i go to a square/rectangular circuit board (to get the buttons out the back) i would need the cnc router to do the bottom opening in the cube. But, buttons on the bottom are out of the way and don't accidently get clicked when holding the cube.

i'm glad you liked the video. only mediocre herb. good herb produces much denser vapor.

although the heater gets up to vape temp in 30 seconds, the vial needs to heat for another 60 seconds before the vapor will be satisfyingly dense.

i'm using a Microchip 12F683 in a 8 pin SOIC package.

re: cutting tube

yes, i go over the score 6 or 10 times so it is fairly deep. the cloth is a 6"x6" piece of cotton t-shirt, very wet, but not dripping. i heat the score with a BIC for 30 seconds, then wipe around the score with the damp cloth. sometimes it will separate at this time. else, wrap the score with the cloth (so i won't cut myself on the sharp edge) and use two hands to snap at the score. the damp cloth causes a thermal shock around the score. i have a glass polishing wheel to smooth a jagged edge.

the "factory setting" is 380°F. i rarely adjust it, but the +5°F (click left button) and -4°F (click right button) allow quick and precise adjustment. it remembers any change in setting and returns to that for the next session. holding the right button for 2 seconds, then release, starts the vape. holding the left button for 2 seconds, then release, resets to factory setting.

because of the circuit board is round and where it is located, the buttons have to be on the bottom. it really hasn't been a problem. i definitely don't want it to automatically start when plugged in.

if i go to a square/rectangular circuit board (to get the buttons out the back) i would need the cnc router to do the bottom opening in the cube. But, buttons on the bottom are out of the way and don't accidently get clicked when holding the cube.

i'm glad you liked the video. only mediocre herb. good herb produces much denser vapor.

although the heater gets up to vape temp in 30 seconds, the vial needs to heat for another 60 seconds before the vapor will be satisfyingly dense.