woah, new forum layout. shiny.

Made some progress on my bud toaster copy, it is now in usable form

I managed to jam the arduino code into a attiny84 (I'm not actually using any of hippies code, nor schematic/PCB design), made a little PCB and a wooden structure to support the heater and heatshield I actually still have 4 spare GPIO pins to play with

Features I have put in so far:

-led to indicate when set temperature is reached, and the vape state of operation, also a red led on the FET output

-auto off after 7min

-low voltage power down (so I don't destroy the batteries by overdrawing the cell voltage below 3V, ie 9V for a 3cell. led flashes at a different rate than for usual timeout)

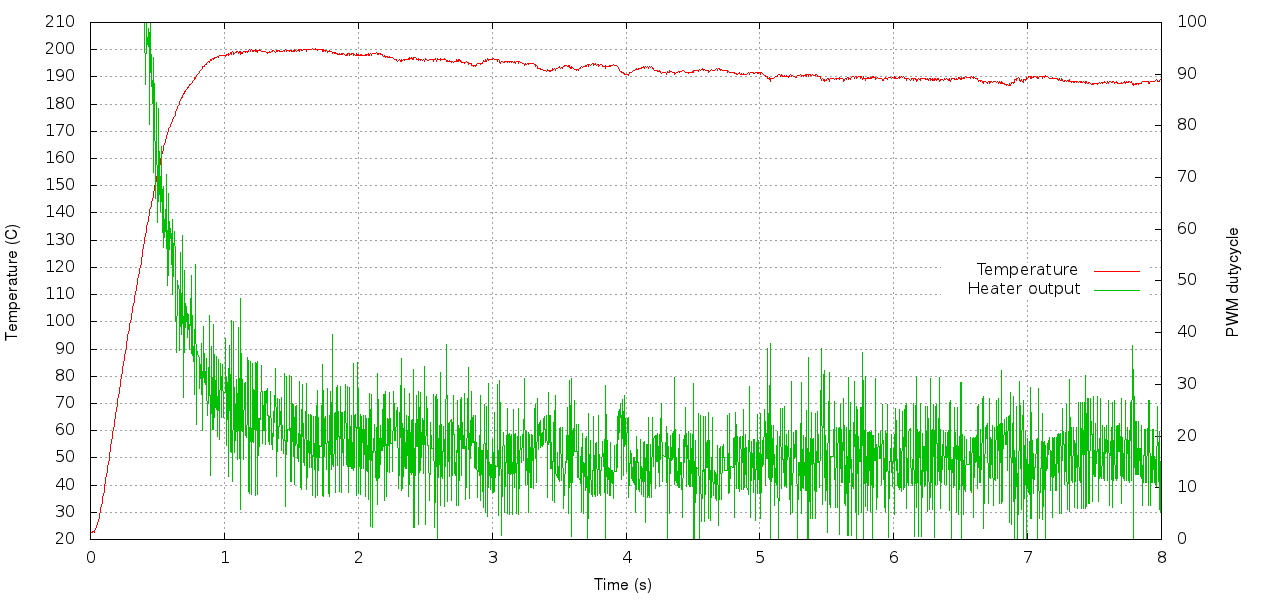

I still want to add temperature adjust buttons (although I wouldn't use it), serial debugging, to graph temperature and power output swings

The PCB was hacked up a bit after the design, I put headers on there so I could easily remove wires to change around the rest of the structure, swapped out a through hole FET with surface mount, just blob soldered on the original pads hehe, works fantastically, about 7A peak from a 3-cell lithium, heats up within about 30sec, seems to do pretty damn well at vaporising. (its the best device I have ever used) and its so easy to use.

anyone reading who cbf building one.. if hippy ever sells them, buy!

lol I'm pretty much reviewing your design

So, I'm happy with it, could look a bit better, and I gotta get that heatshield out of finger-reach. no burns yet. If I was going to make another, I would definitely change some things on the PCB, use SOIC package for the micro instead of that leadless package. I don't want to talk about soldering leadless smd chips haha.

Hippy, I hope you don't mind me sticking this in ur thread, I was tossing up making a new thread but I thought it'd fit in here.

now for some photography (click for big)

) with the rubber end removed, which is perfect size. the bottom hole is small enough that not much falls through (3.5mm) but I have a stainless mesh that goes over the end, this also allows more airflow around the bottom of the vial

) with the rubber end removed, which is perfect size. the bottom hole is small enough that not much falls through (3.5mm) but I have a stainless mesh that goes over the end, this also allows more airflow around the bottom of the vial