so i did my first press with my new pneumatic setup last night with great results! pressure was def an issue before and is not even a thought now. well other than applying too much pressure, but i should get the hang of its limits after more testing.

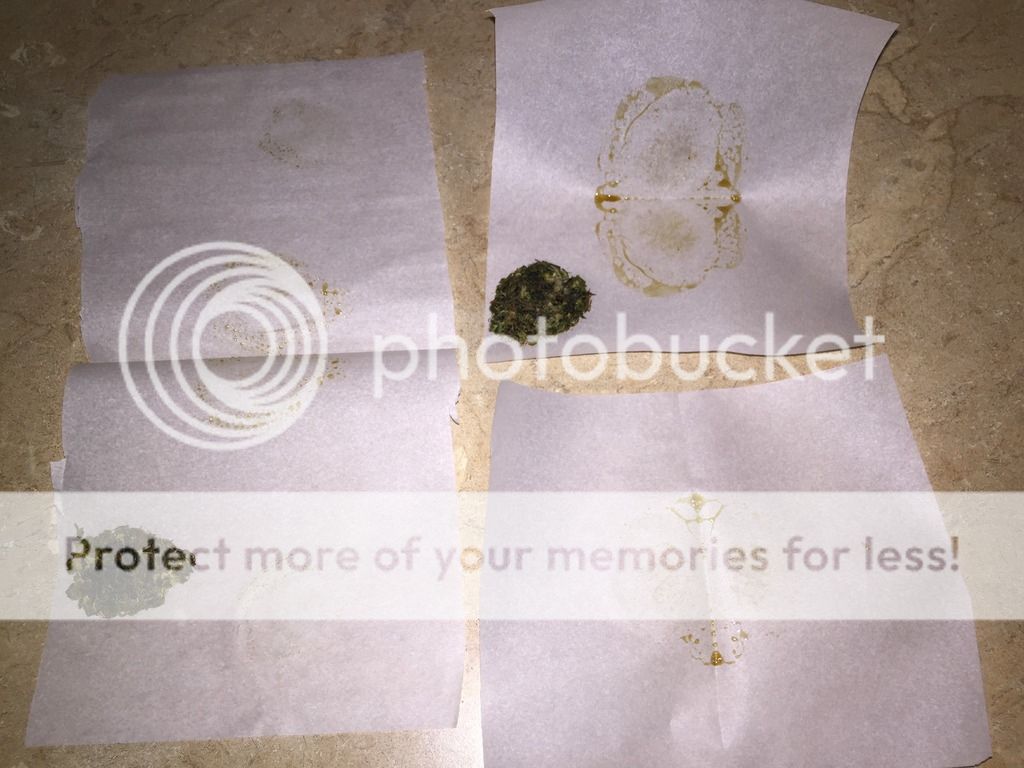

i will post some pics later when i can snap some. the finished press looks pretty damn cool. and i can show my press results. im low on material so i wanted to experiment on a small amount. so i pressed .15g of dry flowers. i did this press late night and did not worry about attempting to hydrate the dry flowers in any way. this time around i pressed for 1min 15 secs (had a distraction at the time

) and the return was about double from the hobby vise run. and the puck did not come out sticky at all. it was pretty dry. so i folded it onto itself a couple of times and repressed getting more tasty rosin out, but not as tasty as the first. i was not able to weigh the return because it was still sappy. i was pressing at 200-210F. between the first two presses i got about 1 decent dab and a half maybe. tasted amazing and was very potent. then i pressed again for another min, but got nothing. so i thought the flowers were tapped. to make sure i got all/most of it i crumbled the puck up and put it in my solo. turned it up to 4 and got no vapor. turned it all the way up to 7 and got about 2 - 3 nice pulls before nothing. so there was still some left in there, but i imagine a more hydrated flower and even more pressure would get that last bit out. since this was my first press with this set up i was going easy on the pressure. i tightened her until the jack started to resist and then gave it another full pump. clearly i could keep pumping away so i imagine i only tapped into maybe 1 of the 5 tons the press can put out. moving forward i am going to be using fresher/more moist material and i will be testing the pressure for real. and im already thinking of ways to improve it.

and run into it i did! so after the press i would turn the pressure relief and it would start to depress the ram all by itself... for about a 1/4" and then stopped. lol

now this isnt a huge deal, but will be a PITA if im trying to do many presses at once. so right now i have to use my hands to push the ram all the way back down. honestly it doesnt need to go all the way back down so for now its fine. i can always presmash the flowers just a bit to get them in there until i can figure out a way to set this thing up with springs like you are talking about. i have a good idea on how to accomplish that already so i will update it to reset the ram after releasing pressure. more to come on this.

yep that is red oak. its got those magnets embedded in them so maybe that will help with any crushing issues? either way if they get crushed then ill make new insulators. that phenolic sheet looks great! thanks for the link. i wonder how thin of a piece would be similar to the insulating performance of the red oak im using...? if you do get a sheet let me know. i would be interested in a couple of 4" x 1.5" pieces. or maybe i could split it with you? let me know if you do get some. any way to get some #s on their performance. obviously the thinnest that would work for us would be ideal. i wonder if 1/8" thick would work well...?

yep its solid and weighs about 45 lbs... lol. the top and bottom plates are 3/8" steel rated with 65,000 PSI tensile strength and 55,000 PSI yield strength. the threaded rods are rated with a 45,000 PSI yield strength and there are 4 of them. id think that is plenty stout to handle the bottle jacks max pressure of 10,000 PSI. and since i really only need to use 3 of the 5tons then we are talking 6,000 PSI. i should be able to pump that fucker until my arm falls off before it ever warps in any way.

thanks partner. coming from such a seasoned hash maker as yourself that means a lot! i purchased the frame parts (plates and threaded rods) in 1' lengths of which were used. so no cutting there which helped. i did however have to drill all the holes in the steel plates. and that was a task no doubt. especially since i was drilling them out with a Milwaukee 18V brushless cordless drill.

the key here was to use pilot holes and step up each bit a bit to get to the final 1/2" hole. i started with 1/8" then 1/4" then 5/16" and finally the 1/2". so that part took time with using cutting oil and all that jazz. it was fun tho. so ease of construction was semi difficult for me. im no metelworker, but generally pretty handy so i figured it out as i went along. oh and i had to drill 1/4" holes (2 of them) in the base of the jack to mount to the bottom plate. that shit is fucking on there!

ill have updated pics of how it looks with everything installed later tonight. oh and PM me with your new plate ideas if you dont mind. i am already thinking about jb welding 1.5" x 1.5" square pieces of the aluminum plates to the plates im already using. that way i get the benefit of the square plates. or possibly a 1.5" round plates. oh boy... when does this shit ever stop???

) and the return was about double from the hobby vise run. and the puck did not come out sticky at all. it was pretty dry. so i folded it onto itself a couple of times and repressed getting more tasty rosin out, but not as tasty as the first. i was not able to weigh the return because it was still sappy. i was pressing at 200-210F. between the first two presses i got about 1 decent dab and a half maybe. tasted amazing and was very potent. then i pressed again for another min, but got nothing. so i thought the flowers were tapped. to make sure i got all/most of it i crumbled the puck up and put it in my solo. turned it up to 4 and got no vapor. turned it all the way up to 7 and got about 2 - 3 nice pulls before nothing. so there was still some left in there, but i imagine a more hydrated flower and even more pressure would get that last bit out. since this was my first press with this set up i was going easy on the pressure. i tightened her until the jack started to resist and then gave it another full pump. clearly i could keep pumping away so i imagine i only tapped into maybe 1 of the 5 tons the press can put out. moving forward i am going to be using fresher/more moist material and i will be testing the pressure for real. and im already thinking of ways to improve it.

) and the return was about double from the hobby vise run. and the puck did not come out sticky at all. it was pretty dry. so i folded it onto itself a couple of times and repressed getting more tasty rosin out, but not as tasty as the first. i was not able to weigh the return because it was still sappy. i was pressing at 200-210F. between the first two presses i got about 1 decent dab and a half maybe. tasted amazing and was very potent. then i pressed again for another min, but got nothing. so i thought the flowers were tapped. to make sure i got all/most of it i crumbled the puck up and put it in my solo. turned it up to 4 and got no vapor. turned it all the way up to 7 and got about 2 - 3 nice pulls before nothing. so there was still some left in there, but i imagine a more hydrated flower and even more pressure would get that last bit out. since this was my first press with this set up i was going easy on the pressure. i tightened her until the jack started to resist and then gave it another full pump. clearly i could keep pumping away so i imagine i only tapped into maybe 1 of the 5 tons the press can put out. moving forward i am going to be using fresher/more moist material and i will be testing the pressure for real. and im already thinking of ways to improve it.

the key here was to use pilot holes and step up each bit a bit to get to the final 1/2" hole. i started with 1/8" then 1/4" then 5/16" and finally the 1/2". so that part took time with using cutting oil and all that jazz. it was fun tho. so ease of construction was semi difficult for me. im no metelworker, but generally pretty handy so i figured it out as i went along. oh and i had to drill 1/4" holes (2 of them) in the base of the jack to mount to the bottom plate. that shit is fucking on there!

the key here was to use pilot holes and step up each bit a bit to get to the final 1/2" hole. i started with 1/8" then 1/4" then 5/16" and finally the 1/2". so that part took time with using cutting oil and all that jazz. it was fun tho. so ease of construction was semi difficult for me. im no metelworker, but generally pretty handy so i figured it out as i went along. oh and i had to drill 1/4" holes (2 of them) in the base of the jack to mount to the bottom plate. that shit is fucking on there!

when it isnt pneumatic at all. its hydraulic. yikes.

when it isnt pneumatic at all. its hydraulic. yikes.