there a way to measure what psi or clamping force you are getting from a specific setup?

http://shop.1asecure.com/prod.cfm?ProdID=369918&StID=10442#.VjPaSberTIU

http://shop.1asecure.com/prodindex.cfm?StID=10442

there a way to measure what psi or clamping force you are getting from a specific setup?

For sure brother, I know you didn't get one, I was referring to where you indicated that you found it acceptable above.this may sound dumb, but os there a way to measure what psi or clamping force you are getting from a specific setup?

like is there a meter that can be pressed to tell this?

im wanting to know how many pumps on my hydraulic jack are needed to get to the to the pressure that is ideal.

again i dont know of anything like this but figured it couldnt hurt to ask.

just wanted to add... i do not have a dnail press. im going with a DIY hydraulic press.

Dammmmmmnnnnn that gauge costs as much as the whole setup lol. Too bad. I'd love one if it was closer to $50 or less.

Dammmmmmnnnnn that gauge costs as much as the whole setup lol. Too bad. I'd love one if it was closer to $50 or less.

Perhaps man, but the performance was known, it is clearly acceptable to a number of users (bubbleman, 2clicker for examples) and it functions as advertised.

Suggesting that a clamp could further improve performance is not the same as suggesting that there is a problem, given that noone ever suggested that you would get the goods out with one squish on one of these presses in the first place. The use of a clamp suggestion simply increases performance, rather than rectifying a problem as such.

For sure brother, I know you didn't get one, I was referring to where you indicated that you found it acceptable above.

DIY

http://www.practicalmachinist.com/v.../project-diy-force-gauge-testing-vise-301601/

Crush some wood? I have read 1/2" plywood starts to deflect at 1000psi but I am still looking for the link.

http://www.woodworkweb.com/woodwork-topics/wood/146-wood-strengths.html

Here 100,000lbs crushing a baseball. I thinks @shark sandwich had some numbers here.

http://i.imgur.com/98ppWA0.webm

Fuck yeah man! Lookin bomb diggity! Can't wait to see it in action. Now I kind of want one like this too. Looks slick!ha my bad. misread yer post. carry on.

good shit.

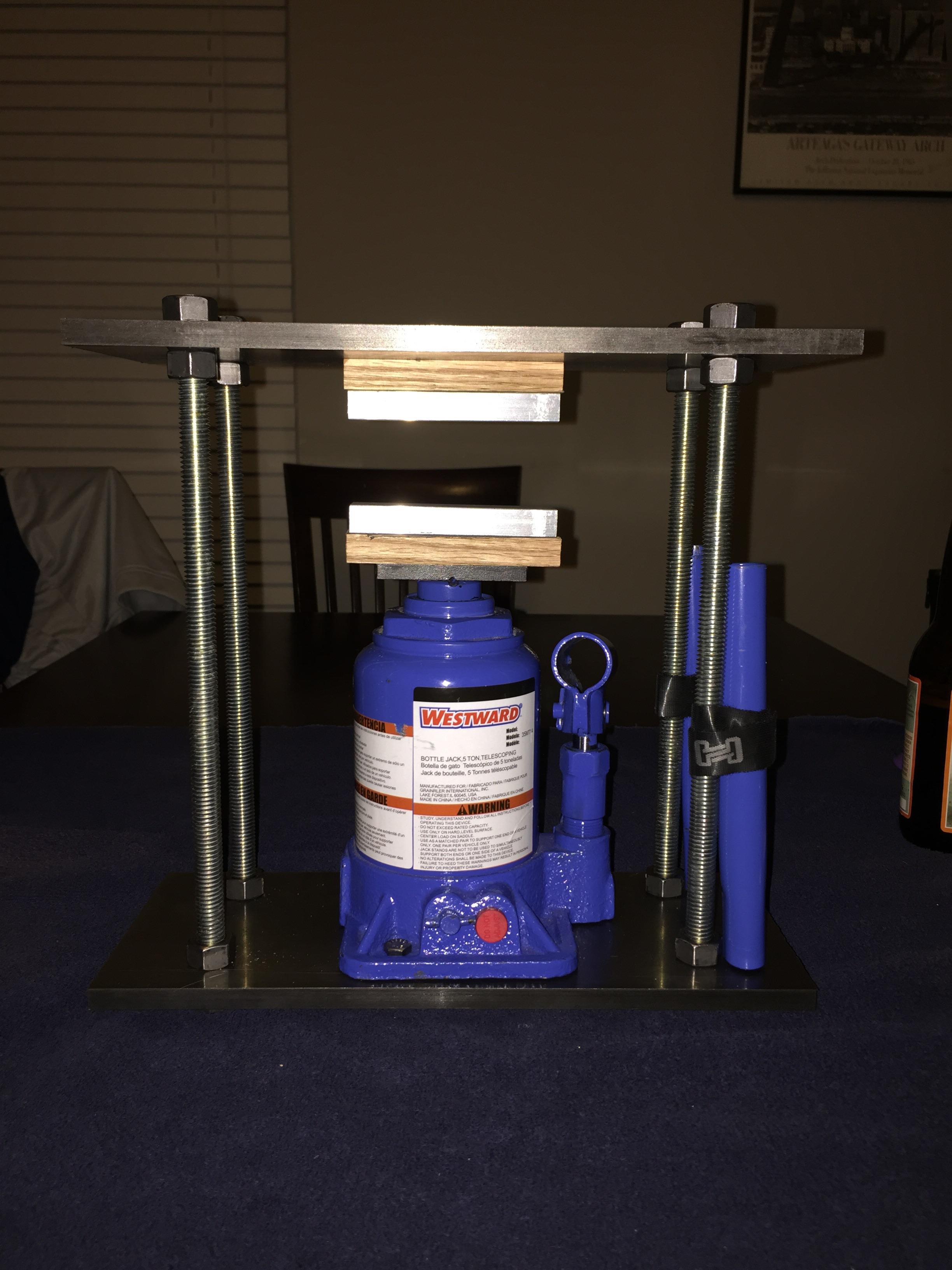

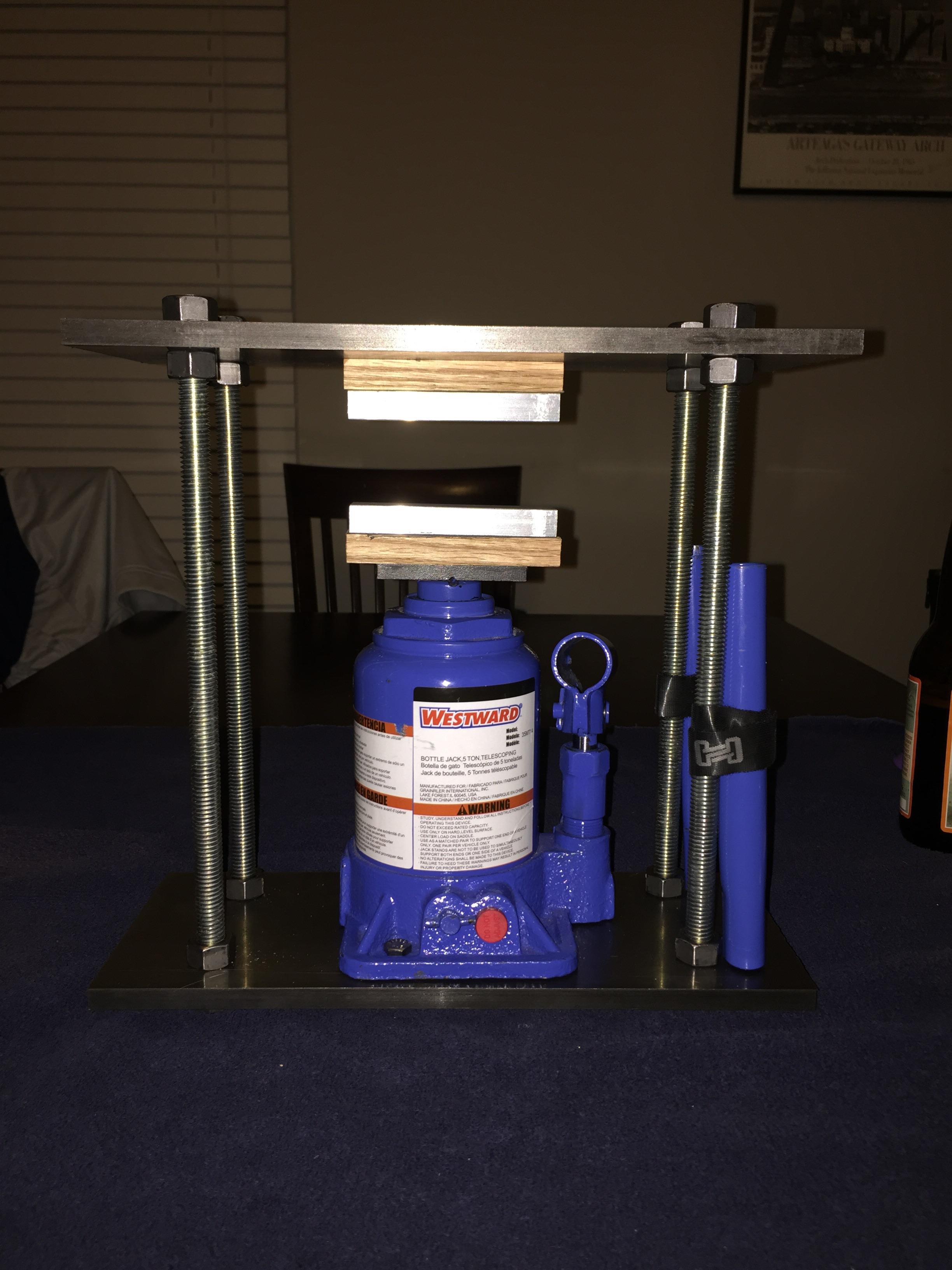

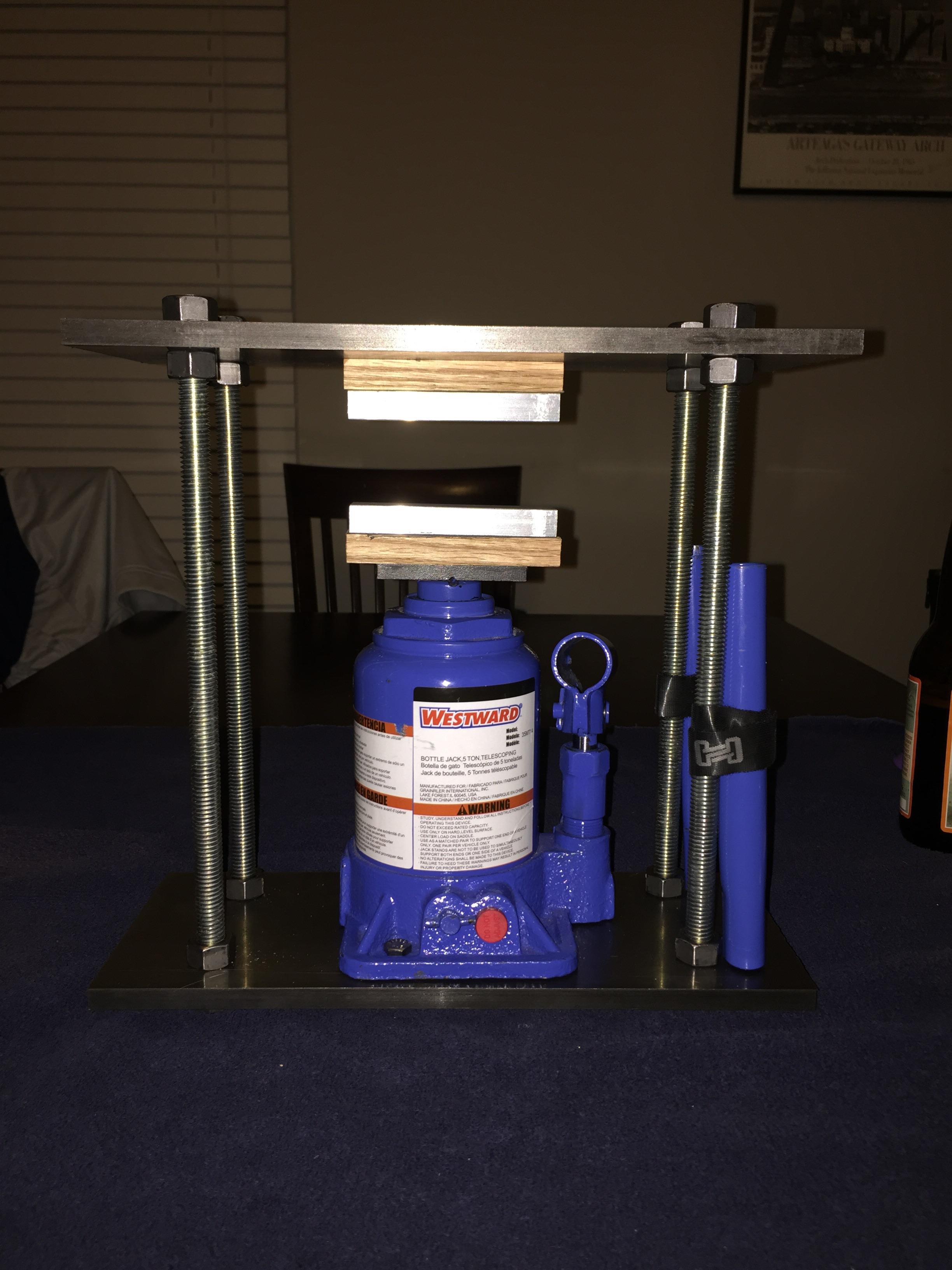

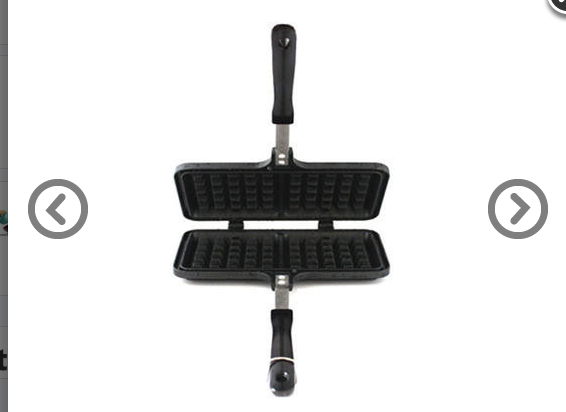

my new hydraulic press is almost ready. its pretty fucking stout. lol. thats 3/8" steel and 1/2" threaded rod. the jack is 5tons max.

looking like sunday before i can warm her up. need to hydrate the dry flowers im working with in the meantime.

just playin. I aint that mad. I probably would have taken it off anyways because the yellow is ugly on it hahaha

just playin. I aint that mad. I probably would have taken it off anyways because the yellow is ugly on it hahaha

That looks sweet! I've seen some like that with springs on the bottom plate to help release it after the pressing, not sure if it's an issue but something to consider if you run into it.ha my bad. misread yer post. carry on.

good shit.

my new hydraulic press is almost ready. its pretty fucking stout. lol. thats 3/8" steel and 1/2" threaded rod. the jack is 5tons max.

looking like sunday before i can warm her up. need to hydrate the dry flowers im working with in the meantime.

I got my dnail press in today. Just had time to unpack it and heat it up to make sure it works.

Ill try to get shorter bolts tomorrow or Sunday to do the spring removal mod. I think I'll pick up a crowbar too so I can clamp the handle down with a little more ease. Then I'll do a review ASAP.

First impressions: it seems well built like I'm sure most t shirt presses are. I like the dual digital temp controllers too. For $335 it isn't too bad. Nice to look at anyways lol.

The only assembly required is to mount the second heater and connect the heater cable. It took 4 bolts and that's it. Took less than 2 minutes and they provided the tools needed so that was nice.

Here is everything I got. They tossed in a d-nail reusable grocery bag thing, 2 25u micron screens, a couple stickers, and a hat pin thing.

I think to help keep the heat directed into the aluminum plate and prevent the case from being dangerously hot to the touch.Any idea why the piece of cotton (insulation?) is there?

They probably don't want anyone doing what SoilGrown did to his large press.One interesting thing I noticed was the instructions say not to overload pressure as this may damage the unit. However the letter from the d-nail owner suggests adding clamps to increase pressure. This seems strange to me. So don't increase pressure with the options on the machine itself that are specifically designed to work together, yet adding external pressure from clamps is okay... Why wouldn't external pressure damage the unit as well? Just doesn't seem right.

Anyone ever check this out? Seems awesome! Check out their instagram. They seem so simple, but effective. http://tarik-rosin-extraction.myshopify.com

...my new hydraulic press is almost ready. its pretty fucking stout. lol. thats 3/8" steel and 1/2" threaded rod. the jack is 5tons max.

I got my dnail press in today.

Looks sweet brother! I haven't squished anything in weeks now, been exclusively dabbing full melt bubble hashes but I want to step up my rosin setup in a major way soon.Too bad I can't embed Instagram posts!

https://instagram.com/p/9hCpLWIUCB/ <- quick clip of pressing out a small quarter gram bud of Mango on a pnuematic press. About 200-210°F and 8 seconds of squish.

Or this @2clickerwhat do you all think of an alternative to wood in regard to insulating the plates from the press?

If you can rig the plates of one up to an arbor press it would work well. Your starting material as always is what dictates the quantity and quality. One of the automated presses will really help though. And you get higher returns with bubble so it would be easier to get more oil from it. I've pretty much ditched BHO in favor of rosin, but I don't dab that much so it's easier for me to transition.Still BHO for me , thinking of making the switch. Interested to see more Dnail press results. After trying my girls flat iron it's hard to imagine that I would get as good of a yield, but it was no double sided press either. I do enjoy the flavor a lot, although I use nug for BHO so it's pretty tasty too. Got Full melt bubble on the way as well!