-

SCAM WARNING! See how this scam works in Classifieds.

-

The Frolic by Limelight Giveaway has started!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rosin Technique....Easy DIY Solventless

- Thread starter darkrom

- Start date

I readily believe that material humidity plays a big part, but the temps required to produce steam/vapour would surely boil off terps (and maybe THC too?).

I lose a bout 5 - 8% of something , somewhere ...

Water, terps or thc?

Still recovering up to 26% of something back though.

Edit: I just got my order from dnail cancelled and refunded.

. Thanks dnail!

. Thanks dnail!

Last edited:

Monsoon

Well-Known Member

Any moving parts would need to be inside the chamber to maintain the seal but you could probably build a small chamber around just the plates and the press head.it would only need to be a chamber big enough to fit something like @2clicker or @BoogerMan type press...

killick

But I like it!

Man, I wish I had access to shipyard machine shop tools these days, now that I have a whole nuther use for them... Just leaving some bud in titanium foil on the dockyard crane train track as he drives over with a load of steel would provide a decent return for no cost at all, outside of maybe arrest and stuff...

BoogerMan

Well-Known Member

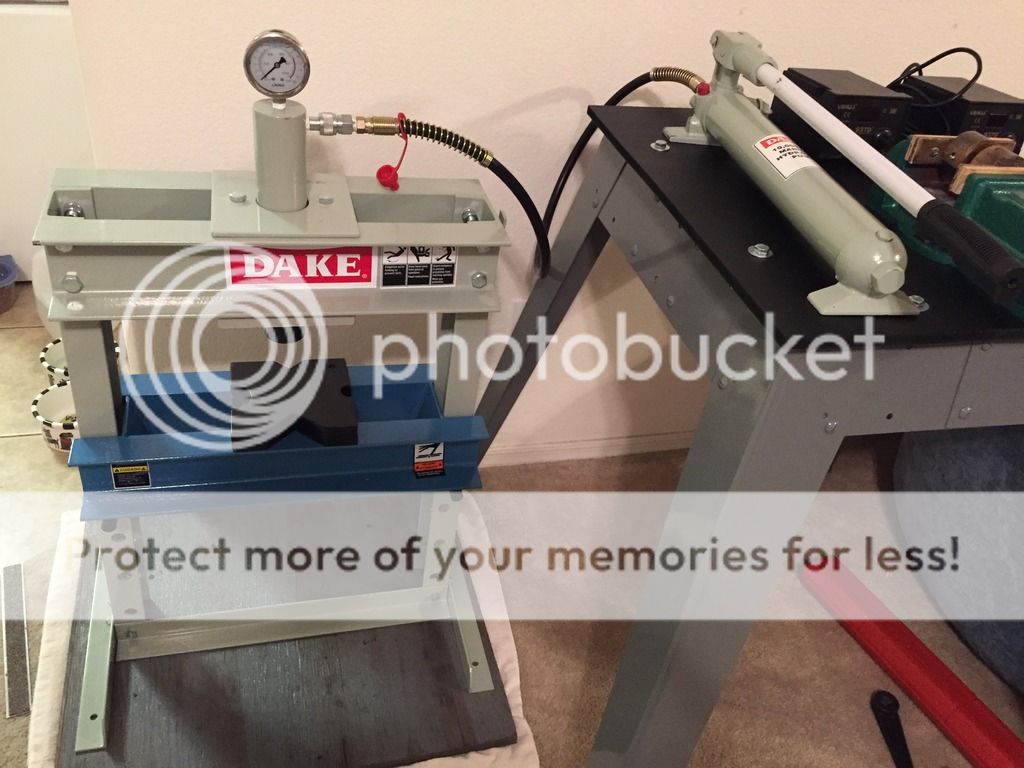

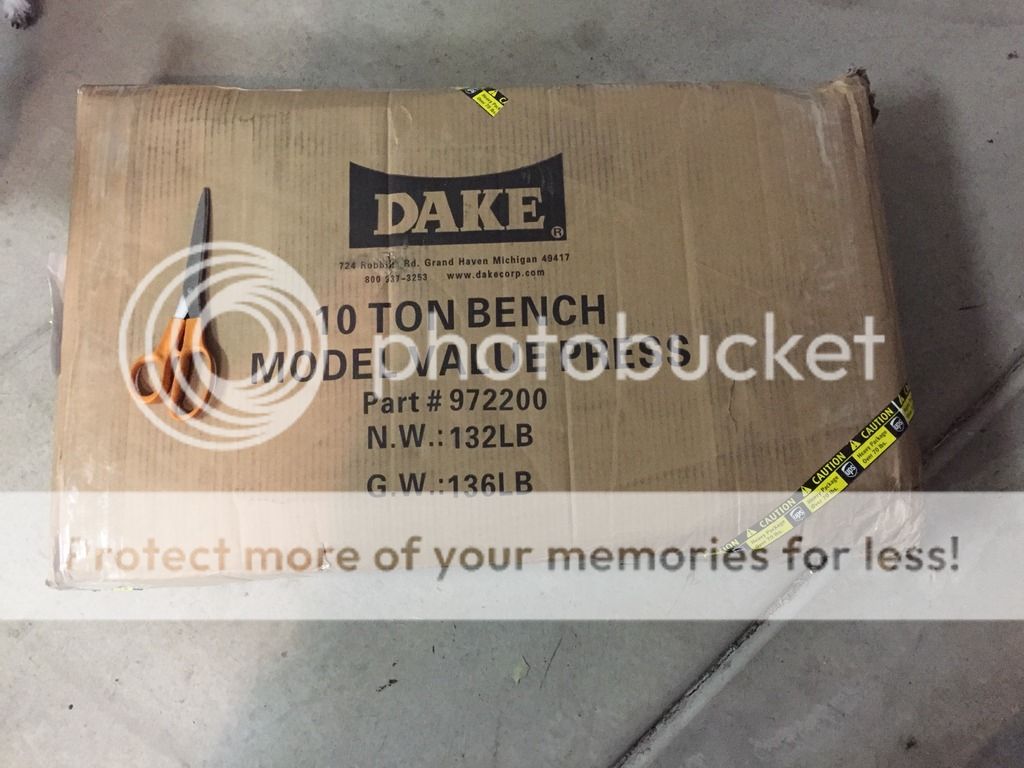

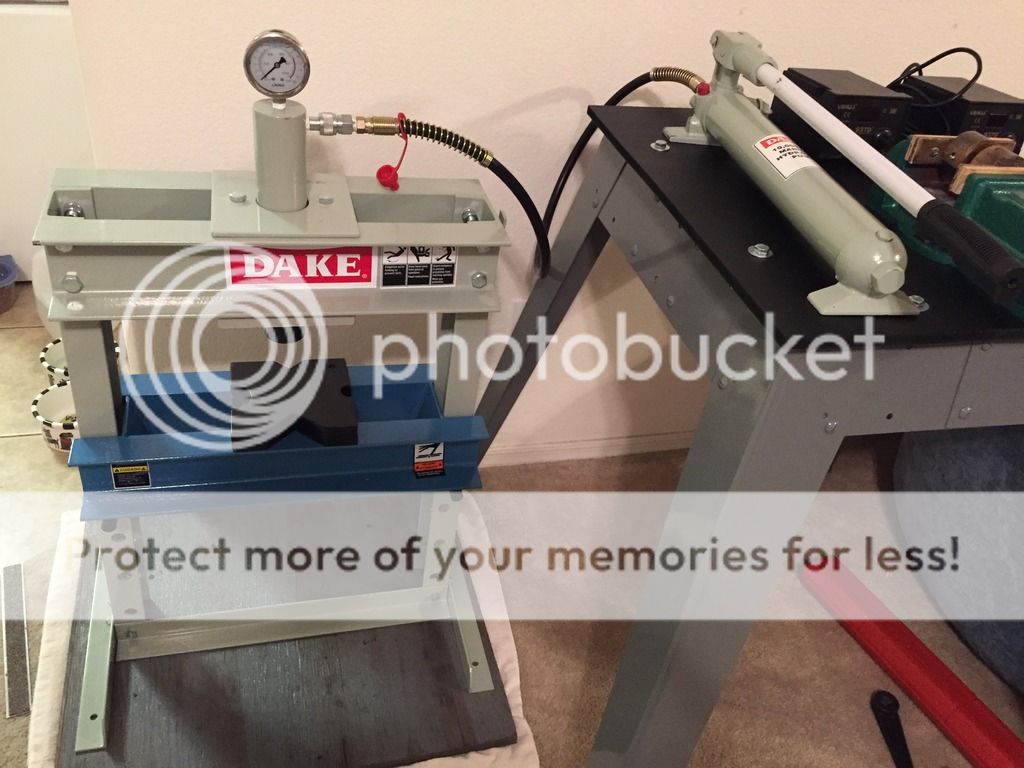

@2clicker here is the H press from Amazon. PS it should be delivered today and I got off work early so I definitely will not miss the UPS man! H press pics tonight!!!!!

Dake B-10 Model Manual Utility Hydraulic Bench Press, 10 Ton Capacity, 23" Length x 18" Width x 36" Height

https://www.amazon.com/dp/B00DWB1MTM/ref=cm_sw_r_awd_eq4nwb1G0RRSM

Oh fuck yeah! I saw one of those vacuum rooms for sale at my local Walmart. Looks like I should probably go buy one

But seriously that would be pretty sweet to have an entire vacuum room.

If someone comes up with a functional rosin press vacuum, I will be very impressed! Seems a little out of my league as far as DIY goes.

Can any of the knowledgable chemical/material guys chime in about this titanium foil as a replacement to parchment. I'm very interested!

Dake B-10 Model Manual Utility Hydraulic Bench Press, 10 Ton Capacity, 23" Length x 18" Width x 36" Height

https://www.amazon.com/dp/B00DWB1MTM/ref=cm_sw_r_awd_eq4nwb1G0RRSM

I think I've seen vacuum pressing come up in the Facebook group too, I guess the problem right now is actually making such a setup. I'm sure it's doable but I don't think it will be cheap or easy. I'm thinking the easiest way to do it right now is with a smaller version of this and a spacesuit so you can be in the room under vacuum.

Oh fuck yeah! I saw one of those vacuum rooms for sale at my local Walmart. Looks like I should probably go buy one

But seriously that would be pretty sweet to have an entire vacuum room.

If someone comes up with a functional rosin press vacuum, I will be very impressed! Seems a little out of my league as far as DIY goes.

Instead of parchment, how about titanium foil?

It comes in many different thicknesses, and is affordable.

No worries about contamination, and it might allow very high pressure/very low temp presses to preserve terps.

If bought thin enough to bend, even absolute shatter that wants to ping away could be gathered with ease.

http://www.titaniumgoat.com/windscreens.html

Can any of the knowledgable chemical/material guys chime in about this titanium foil as a replacement to parchment. I'm very interested!

Last edited:

@BoogerMan

I've previously recommended titanium foil as a reusable pressing material.

The right thickness should be physically resilient, and able to dissipate enough heat to work well. Various thicknesses are available on Amazon. I'm working on a new set of blocks and haven't been pressing much lately, so I haven't had a chance to try more alternative materials.

I imagine either .001" or .005" ti foil should work pretty well. Here's a video that gives an idea of what the different thicknesses are like:

I've previously recommended titanium foil as a reusable pressing material.

The right thickness should be physically resilient, and able to dissipate enough heat to work well. Various thicknesses are available on Amazon. I'm working on a new set of blocks and haven't been pressing much lately, so I haven't had a chance to try more alternative materials.

I imagine either .001" or .005" ti foil should work pretty well. Here's a video that gives an idea of what the different thicknesses are like:

Last edited:

CharlieBelmont

Well-Known Member

+1 here for dnail full refund. Thanks for posting that they were allowing it. They were very gracious about it, no hassle what so ever. Now to decide what to do again...

Monsoon

Well-Known Member

Do you foresee any issues with the oil sticking to the foil? Like how non-stick is titanium or does it matter for rosin?@BoogerMan

I've previously recommended titanium foil as a reusable pressing material.

The right thickness should be physically resilient, and able to dissipate enough heat to work well. Various thicknesses are available on Amazon. I'm working on a new set of blocks and haven't been pressing much lately, so I haven't had a chance to try more alternative materials.

I imagine either .001" or .005" ti foil should work pretty well. Here's a video that gives an idea of what the different thicknesses are like:

Been searching for hydraulic presses and found this one which is similar to @BoogerMan's except it's benchtop size. They apparently also sell a similar one at Canadian Tire so if you live in Canada you can probably avoid shipping fees and just drive it home from your local store. Dimensions for the press are 27 x 18 x 42 inches and it weighs 116lbs. If BoogerMan is happy with his new setup, I think I'll go with that one. It's only $270 (+15% tax

) for 10 Tons of pressure, it should fit okay in my apartment and I can get my friend to drive it home for me.

) for 10 Tons of pressure, it should fit okay in my apartment and I can get my friend to drive it home for me.TankHankerous

Well-Known Member

Here is a cool video of the Dake Press in action. This gave me a better idea of how it works and the background music wasn't bad either.

BoogerMan

Well-Known Member

Do you foresee any issues with the oil sticking to the foil? Like how non-stick is titanium or does it matter for rosin?

Been searching for hydraulic presses and found this one which is similar to @BoogerMan's except it's benchtop size. They apparently also sell a similar one at Canadian Tire so if you live in Canada you can probably avoid shipping fees and just drive it home from your local store. Dimensions for the press are 27 x 18 x 42 inches and it weighs 116lbs. If BoogerMan is happy with his new setup, I think I'll go with that one. It's only $270 (+15% tax) for 10 Tons of pressure, it should fit okay in my apartment and I can get my friend to drive it home for me.

I think my bench press is actually smaller than that one

Mine is 23" x 18" x 28" (36") -- L x W x H (*)

*it is 28" to the top of the H and 36" to the top of the pressure gauge.

@TankHankerous thanks for the vid! That was definitely a good one.

It took about 2.5 hours to set up. Many parts are extremely heavy. They aren't lying about the 136 lbs shipping weight haha). Having a friend to help is a plus but it can be done by yourself (if you can lift 30-50 lbs by yourself). My back is sore as fuck so please excuse any typos as I'm heavily medicated

Heaviest box of its size I have ever lifted!

It was packaged nicely. However something ended up moving around and scratched up a few pieces and broke some small notches off the release knob (pics in a sec). Not a huge deal because it still works. I'll contact Dake and I'm sure they will send me a new one free. It's a $5 part I bet.

The small damage. It's supposed to have 4 fins but 2 broke off. I'll get a replacement

Everything in the box

The small box above contained these plates (very heavy)

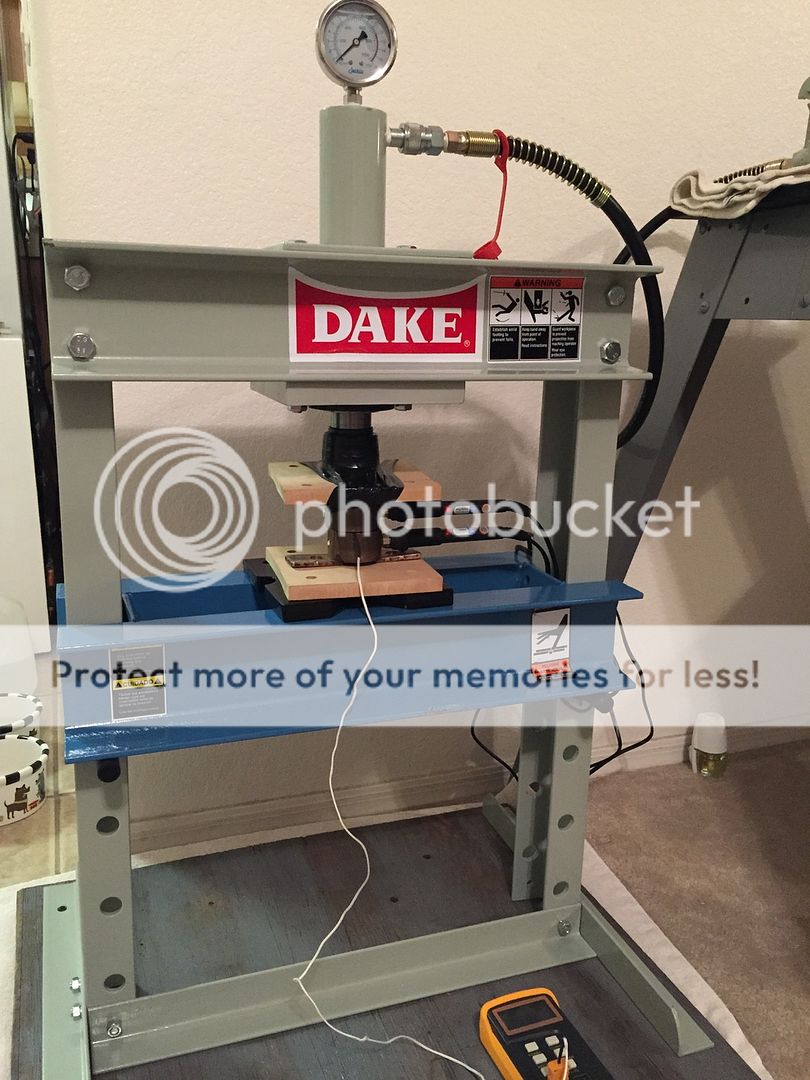

All put together

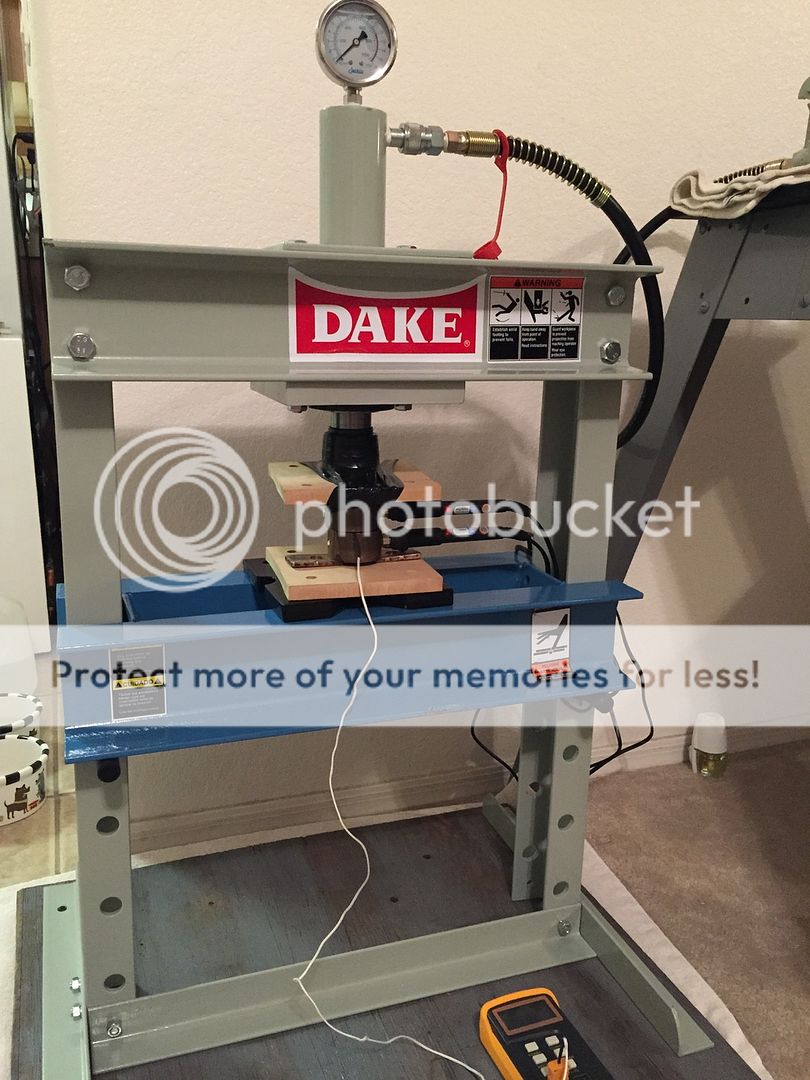

What 5 tons of pressure does to 1/2" mdf

Taped my vise jaws in it while I wait for my new jaws

Heating up now. Up to 210F. Let's have a H press shall we?

(No vid tonight. Wayyyy toooo hungry haha. Maybe tomorrow or Saturday. Rosin pics in a min)

(No vid tonight. Wayyyy toooo hungry haha. Maybe tomorrow or Saturday. Rosin pics in a min)

I think I like this H press a little better than the vise press. Having the plates horizontal (instead of vertical like on the vise) makes it easier to align the bud in the center and once it is centered you can let it go and it will stay there (if you let go of the paper before tightening the vise it will slide down and become off centered. You know, Gravity and all... Lol).

Anyways, quick points:

Vise is cheaper and smaller (unless you don't already have a work bench).

H press is much heavier and takes more effort and strength to set up.

H press is easier to align parchment.

H press takes less physical effort to operate because of the hydraulic pump compared to a torque wrench.

Pressure gauge on the H press is amazing.

Both are very efficient.

H press wins in my book if you have the money, space, and strength to put it together

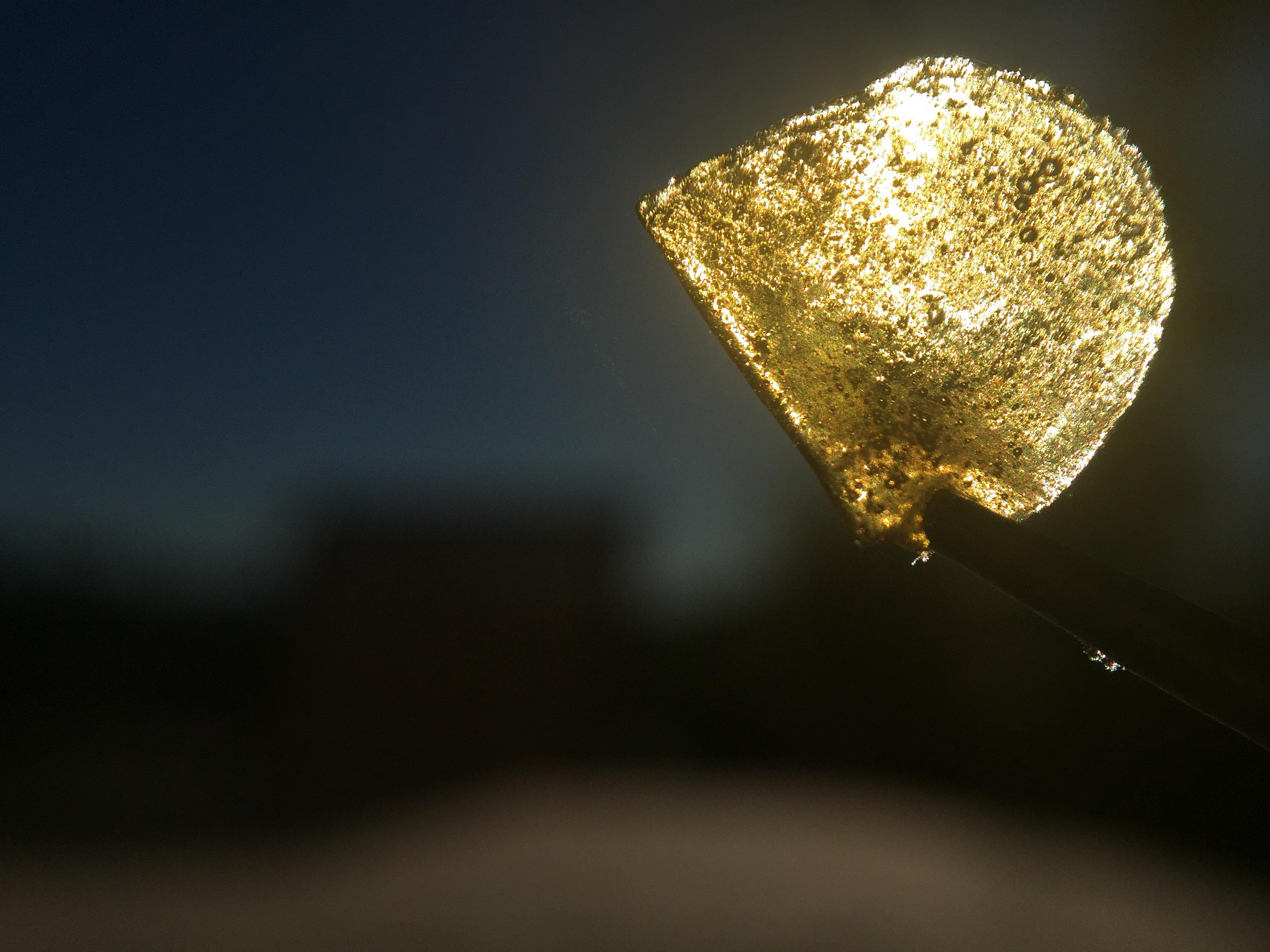

Pressed at 230F at 3 tons (6,000 lbs) of pressure. Surface area of my Cuni roundbar @Joel W. plates is 3.14 sq. inches. So I'm pressing at about 1910 psi.

I didn't weigh anything (I will this weekend) but it looks like the same yield as the vise.

I don't see a need to go much higher psi then this. I may try 5 tons to see if I can eliminate a second press but that may destroy the parchment. We will see...

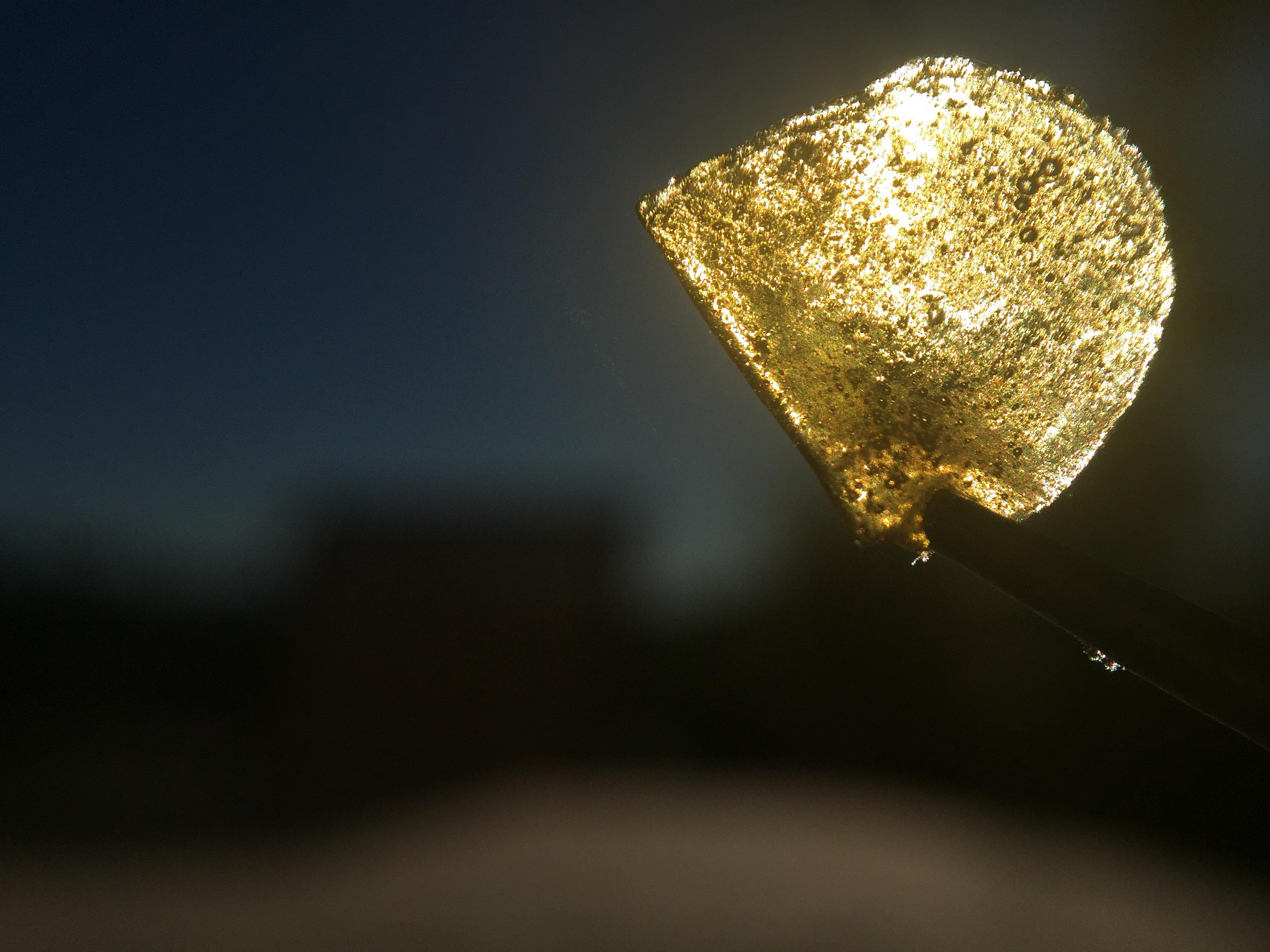

First squish

Second squish

Last edited:

MileHighLife

Blower of glass, grower of grass

Looking good @BoogerMan  After watching the video of that press and finding a few videos on the Harbor Freight presses I think I'm going to have to splurge and get the Dake.

After watching the video of that press and finding a few videos on the Harbor Freight presses I think I'm going to have to splurge and get the Dake.

Quick question for you experienced rosinators. What's an ideal plate size to press nugs and get the resin to flow out of the heat zone? I was thinking 1.5" x 1.5"?

After watching the video of that press and finding a few videos on the Harbor Freight presses I think I'm going to have to splurge and get the Dake.

After watching the video of that press and finding a few videos on the Harbor Freight presses I think I'm going to have to splurge and get the Dake.Quick question for you experienced rosinators. What's an ideal plate size to press nugs and get the resin to flow out of the heat zone? I was thinking 1.5" x 1.5"?

BoogerMan

Well-Known Member

ThanksLooking good @BoogerManAfter watching the video of that press and finding a few videos on the Harbor Freight presses I think I'm going to have to splurge and get the Dake.

Quick question for you experienced rosinators. What's an ideal plate size to press nugs and get the resin to flow out of the heat zone? I was thinking 1.5" x 1.5"?

I'm really happy with how it operates. And it's going to look so clean with the new plates and round wood insulators

I'm really happy with how it operates. And it's going to look so clean with the new plates and round wood insulators  Definitely a keeper for a while. I think my RAS (Rosin Acquisition Syndrome) is cured for now.

Definitely a keeper for a while. I think my RAS (Rosin Acquisition Syndrome) is cured for now.Yeah 1.5x1.5" or 2x2" would be good. The smaller the plate the less herb you can squish. That size allows you to press about 1g max. I usually do about 0.5-0.8g at a time.

Last edited:

Monsoon

Well-Known Member

That setup is sweet, can't wait until you've been able to properly test it out (as are you I'm sure)! You should whip up some lotion when you get a chance to keep on hand for those aches and painsI think my bench press is actually smaller than that one

Mine is 23" x 18" x 28" (36") -- L x W x H (*)

*it is 28" to the top of the H and 36" to the top of the pressure gauge.

@TankHankerous thanks for the vid! That was definitely a good one.

It took about 2.5 hours to set up. Many parts are extremely heavy. They aren't lying about the 136 lbs shipping weight haha). Having a friend to help is a plus but it can be done by yourself (if you can lift 30-50 lbs by yourself). My back is sore as fuck so please excuse any typos as I'm heavily medicated

Quetzalcoatl

DEADY GUERRERO/DIRT COBAIN/GEORGE KUSH

Morning press of Tahoe OG.

Pressed at 230F at 3 tons (6,000 lbs) of pressure.

So do your irons still slip in and out easy after that pressure?

BoogerMan

Well-Known Member

So do your irons still slip in and out easy after that pressure?

Yeah they seem to still slide in and out okay.

I'll keep an eye on the iron holes to make sure they aren't getting squished.

Are you afraid cuni may not be able to handle 3 tons of pressure?

I will be able to play with different pressures tonight so if I can back off the pressure a little to get the same yields I will.

Are you afraid cuni may not be able to handle 3 tons of pressure?

Yes, you are in uncharted waters here, as I have not taken them to that much pressure, as far as I know of.

So far, so good...Squish on good Sir!

BoogerMan

Well-Known Member

I've got a good idea!

I'll measure the thickness of those 2x2" Cuni square plates I have and then do multiple 5 ton presses on them (no heat since I can't really heat these up easily). After multiple presses I'll remeasure the thickness to see if they got flatter. I know heat softens up the metal, but since I can't use any heat on the small square plates, I figured bumping up the pressure to 5 tons should maybe be similar to 3 tons with heat? Maybe not lol.

Sound like a good test?

If you can think of anything else or any other way to test, let me know

I'll measure the thickness of those 2x2" Cuni square plates I have and then do multiple 5 ton presses on them (no heat since I can't really heat these up easily). After multiple presses I'll remeasure the thickness to see if they got flatter. I know heat softens up the metal, but since I can't use any heat on the small square plates, I figured bumping up the pressure to 5 tons should maybe be similar to 3 tons with heat? Maybe not lol.

Sound like a good test?

If you can think of anything else or any other way to test, let me know

The 2"x 2" plates should be .098" thick now. I am not sure that will be a good indicator on how the round bar will react but feel free. When I send you your new set of blocks next week, I will include an extra "test" block for you to crush with your steel press, That should give us an idea of safe max working pressure.

I just watch the rosin flow and I put a little more unnecessary pressure on it when it stops flowing, just for good measure.

I just watch the rosin flow and I put a little more unnecessary pressure on it when it stops flowing, just for good measure.

Last edited:

BoogerMan

Well-Known Member

Yeah you're right. The flat plates won't be a good comparison since the roundbar is so much thicker. Awesome thank you for sending a test block!!! That will be great.

I found some info on this site about Compressive Strength (CS) of CuNi (table near the bottom). However it doesn't say if it is for 90/10, 70/30, etc and at what temp these measurements were taken (I'm guessing room temp? Maybe 70F )

)

http://www.nickel-alloys.net/copper_nickel_alloys.html

Anyways it says the Min CS is 85 and Max is 550 MPa (Mega Pascals).

Doing a little math (aka google),

85 MPa = 12,328 PSI

550 MPa = 79,770 PSI

I know adding heat softens metal so I'm sure the min and max MPa drop when using 220F temps, but still, it seems like the CuNi should hold up at about 2,000 PSI that I was using last night (I hope it will hold up at least lol).

I found some info on this site about Compressive Strength (CS) of CuNi (table near the bottom). However it doesn't say if it is for 90/10, 70/30, etc and at what temp these measurements were taken (I'm guessing room temp? Maybe 70F

)

)http://www.nickel-alloys.net/copper_nickel_alloys.html

Anyways it says the Min CS is 85 and Max is 550 MPa (Mega Pascals).

Doing a little math (aka google),

85 MPa = 12,328 PSI

550 MPa = 79,770 PSI

I know adding heat softens metal so I'm sure the min and max MPa drop when using 220F temps, but still, it seems like the CuNi should hold up at about 2,000 PSI that I was using last night (I hope it will hold up at least lol).

BoogerMan

Well-Known Member

Sorry I can't edit the above.

Found more good info on Copper-Nickel (CuNi) Compressive Strength.

http://www.copper.org/publications/pub_list/pdf/7014.pdf

Page 10 informed me that 90/10 CuNi is C96200.

I then found table 10 on page 80. This table gives the compressive strength which is defined as "The stress required to produce the indicated percent permanent engineering strain (Set) in a 0.125-in. (3.2-mm) thick compression specimen."

90/10 CuNi C96200 is under the 10% Set section and has a Compressive Strength of 255 MPa (36,985 psi).

Unfortunately, it doesn't say on the table what temperature these strengths were tested out (it might say somewhere in the body of the article but I am not sure).

I am still unsure of what the 10% Set means. Is it saying that if 36,985 psi is applied to 90/10 CuNi, then there will be 10% permanent engineering strain? (Whatever that is lol).

lol).

Found more good info on Copper-Nickel (CuNi) Compressive Strength.

http://www.copper.org/publications/pub_list/pdf/7014.pdf

Page 10 informed me that 90/10 CuNi is C96200.

I then found table 10 on page 80. This table gives the compressive strength which is defined as "The stress required to produce the indicated percent permanent engineering strain (Set) in a 0.125-in. (3.2-mm) thick compression specimen."

90/10 CuNi C96200 is under the 10% Set section and has a Compressive Strength of 255 MPa (36,985 psi).

Unfortunately, it doesn't say on the table what temperature these strengths were tested out (it might say somewhere in the body of the article but I am not sure).

I am still unsure of what the 10% Set means. Is it saying that if 36,985 psi is applied to 90/10 CuNi, then there will be 10% permanent engineering strain? (Whatever that is

lol).

lol).2clicker

Observer

I've seen a few people mention Mash Mesh as being good, might be worth looking into those

i have been talking to the mash mesh people a bit and they are cool as hell. anyway, i was asking about their mesh and the thread used to sew them together. they advised that its the same material as the mesh itself. silk screen mesh. they are also a silk screen supplier. so i mentioned SS mesh to them and they advised that thay have been experimenting more with SS mesh. of which i like the idea of. ive got a bunch left for solvent extraction that wont be used anymore.

Instead of parchment, how about titanium foil?

It comes in many different thicknesses, and is affordable.

No worries about contamination, and it might allow very high pressure/very low temp presses to preserve terps.

If bought thin enough to bend, even absolute shatter that wants to ping away could be gathered with ease.

http://www.titaniumgoat.com/windscreens.html

really like the idea of this stuff. may have to try it out.

@BoogerMan

I've previously recommended titanium foil as a reusable pressing material.

The right thickness should be physically resilient, and able to dissipate enough heat to work well. Various thicknesses are available on Amazon. I'm working on a new set of blocks and haven't been pressing much lately, so I haven't had a chance to try more alternative materials.

I imagine either .001" or .005" ti foil should work pretty well. Here's a video that gives an idea of what the different thicknesses are like:

good shit

I think my bench press is actually smaller than that one

Mine is 23" x 18" x 28" (36") -- L x W x H (*)

*it is 28" to the top of the H and 36" to the top of the pressure gauge.

@TankHankerous thanks for the vid! That was definitely a good one.

It took about 2.5 hours to set up. Many parts are extremely heavy. They aren't lying about the 136 lbs shipping weight haha). Having a friend to help is a plus but it can be done by yourself (if you can lift 30-50 lbs by yourself). My back is sore as fuck so please excuse any typos as I'm heavily medicated

Heaviest box of its size I have ever lifted!

It was packaged nicely. However something ended up moving around and scratched up a few pieces and broke some small notches off the release knob (pics in a sec). Not a huge deal because it still works. I'll contact Dake and I'm sure they will send me a new one free. It's a $5 part I bet.

The small damage. It's supposed to have 4 fins but 2 broke off. I'll get a replacement

Everything in the box

The small box above contained these plates (very heavy)

All put together

What 5 tons of pressure does to 1/2" mdf

Taped my vise jaws in it while I wait for my new jaws

Heating up now. Up to 210F. Let's have a H press shall we?(No vid tonight. Wayyyy toooo hungry haha. Maybe tomorrow or Saturday. Rosin pics in a min)

I think I like this H press a little better than the vise press. Having the plates horizontal (instead of vertical like on the vise) makes it easier to align the bud in the center and once it is centered you can let it go and it will stay there (if you let go of the paper before tightening the vise it will slide down and become off centered. You know, Gravity and all... Lol).

Anyways, quick points:

Vise is cheaper and smaller (unless you don't already have a work bench).

H press is much heavier and takes more effort and strength to set up.

H press is easier to align parchment.

H press takes less physical effort to operate because of the hydraulic pump compared to a torque wrench.

Pressure gauge on the H press is amazing.

Both are very efficient.

H press wins in my book if you have the money, space, and strength to put it together

Pressed at 230F at 3 tons (6,000 lbs) of pressure. Surface area of my Cuni roundbar @Joel W. plates is 3.14 sq. inches. So I'm pressing at about 1910 psi.

I didn't weigh anything (I will this weekend) but it looks like the same yield as the vise.

I don't see a need to go much higher psi then this. I may try 5 tons to see if I can eliminate a second press but that may destroy the parchment. We will see...

First squish

Second squish

nice! cant wait to see the new plates on it.

Quick question for you experienced rosinators. What's an ideal plate size to press nugs and get the resin to flow out of the heat zone? I was thinking 1.5" x 1.5"?

my plates are currently 1.5" x 3.75" and i plan on trying to make some bags or use SS mesh to press with. my idea was to make a filter that leaves an 1/8" border around the filter in relation to the plate. i imagine, after seeing bubblemans return on his dnail press, that with hydraulic force behind it will work very well. if not then im going to cut some 1.5 x 1.5 squares of the aluminum my plates are made of and stack them to my current plates. shouldnt need smaller heaters or new holes since aluminum is such a great heat conductor. will simply have to turn the heaters up a tad higher than where I currently run them. of which is already very low.

lol... so in short... 1.5" x 1.5" does sound like an ideal size for squishing nugs.

EDIT*** the spring return works perfectly!!! ill post some pics tonight

also, anyone know of a thin material that can handle some heat and lots of pressure? not wood. i need to cover these magnets i have embedded into my wood insulators. they keep popping out. ive used jb weld and gorilla glue and they wont hold but more than a few days. looking for something that the magnets will still work well THROUGH. like 1/16" thick plexi or something. any ideas?

@shark sandwich @farscaper @BoogerMan @Joel W. ???

Last edited:

i have been talking to the mash mesh people a bit and they are cool as hell. anyway, i was asking about their mesh and the thread used to sew them together. they advised that its the same material as the mesh itself. silk screen mesh. they are also a silk screen supplier. so i mentioned SS mesh to them and they advised that thay have been experimenting more with SS mesh. of which i like the idea of. ive got a bunch left for solvent extraction that wont be used anymore.

really like the idea of this stuff. may have to try it out.

good shit

nice! cant wait to see the new plates on it.

my plates are currently 1.5" x 3.75" and i plan on trying to make some bags or use SS mesh to press with. my idea was to make a filter that leaves an 1/8" border around the filter in relation to the plate. i imagine, after seeing bubblemans return on his dnail press, that with hydraulic force behind it will work very well. if not then im going to cut some 1.5 x 1.5 squares of the aluminum my plates are made of and stack them to my current plates. shouldnt need smaller heaters or new holes since aluminum is such a great heat conductor. will simply have to turn the heaters up a tad higher than where I currently run them. of which is already very low.

lol... so in short... 1.5" x 1.5" does sound like an ideal size for squishing nugs.

EDIT*** the spring return works perfectly!!! ill post some pics tonight

also, anyone know of a thin material that can handle some heat and lots of pressure? not wood. i need to cover these magnets i have embedded into my wood insulators. they keep popping out. ive used jb weld and gorilla glue and they wont hold but more than a few days. looking for something that the magnets will still work well THROUGH. like 1/16" thick plexi or something. any ideas?

@shark sandwich @farscaper @BoogerMan @Joel W. ???

drill the holes a touch deeper and sink them in the wood and top it with some superglue to fill the hole after the magnet is installed.

has anyone seen these little guys?

http://www.ohiopowertool.com/p-747-...edMztRnf86wFWN6mOTLRj4aA3x1yT-m_mhRoCxeLw_wcB

only has a 3/4" stroke but its super small so making a matching frame would be small too. shity expensive price though.

@2clicker

A block I made had the same issue of magnet detachment recently.

Jb-weld is the best adhesive for this application, and I don't think it's the source of the problem. Your blocks have automatic heat control, so there's no way it's a thermal failure of the adhesive.

The problem is most likely a lack of adhesion to the smooth surface of the magnet. You could either embed the magnet in jb-weld, or rough the outside of the magnet with sand paper or a rotary tool, or do both.

If you decide to use a cover sheet instead, I'd recommend PTFE instead of plexiglass. It's great for things like this- it has a good mix of toughness, temperature resistance, and affordability. The sheet could be screwed in place, but the screws must be set carefully to avoid damage during compression cycles.

A block I made had the same issue of magnet detachment recently.

Jb-weld is the best adhesive for this application, and I don't think it's the source of the problem. Your blocks have automatic heat control, so there's no way it's a thermal failure of the adhesive.

The problem is most likely a lack of adhesion to the smooth surface of the magnet. You could either embed the magnet in jb-weld, or rough the outside of the magnet with sand paper or a rotary tool, or do both.

If you decide to use a cover sheet instead, I'd recommend PTFE instead of plexiglass. It's great for things like this- it has a good mix of toughness, temperature resistance, and affordability. The sheet could be screwed in place, but the screws must be set carefully to avoid damage during compression cycles.

Last edited: