ROUND ONE UPDATES (Jan. 1, 2017)

(Includes Info On: Shipping, Hurdles, Extras, etc.)

(tl;dr & shipping info @ bottom of the post)

First off, I want to offer my sincerest apologies for not communicating more throughout the build process of Round One. I know how it feels to be left in the dark and it's frustrating as all heck. All of us have been working 'round the clock and sleeping around 2 nights a week for the last month and losing time happens more than I'd like it to.

------

I think we've officially started to refer to Round One internally as 'The Little Engine That Could'.

We've hit quite a few bumps in the road so far during Round One. The holidays really messed with us and we should have anticipated more issues concerning that right off the bat (both from a personal and business sense). Everyone here decided to basically ignore the holidays completely and just keep chugging along to try to offset some of the minor delays we're experiencing.

We stocked up on at least one of every replacement part we could think of, but we still had a few small delays with MORE replacements we needed over the last 2 weeks. We're planning to upgrade one of our (adding yet another) mill to HQ as soon as we can in 2017.

We took a lot of time to find the right wood supplier. We were confident they had reliably great product while building our prototypes (which nearly every piece was perfect for) but our largest shipment of wood for Round One had to be sent back. The whole first batch of coils we ordered also had to be sent back due to both quality and safety concerns (but we have since found a new supplier we're

much happier with). So yet again, due to the holidays, we got set back quite a bit during these exchange processes.

(I mean, seriously, what the hell is this?)

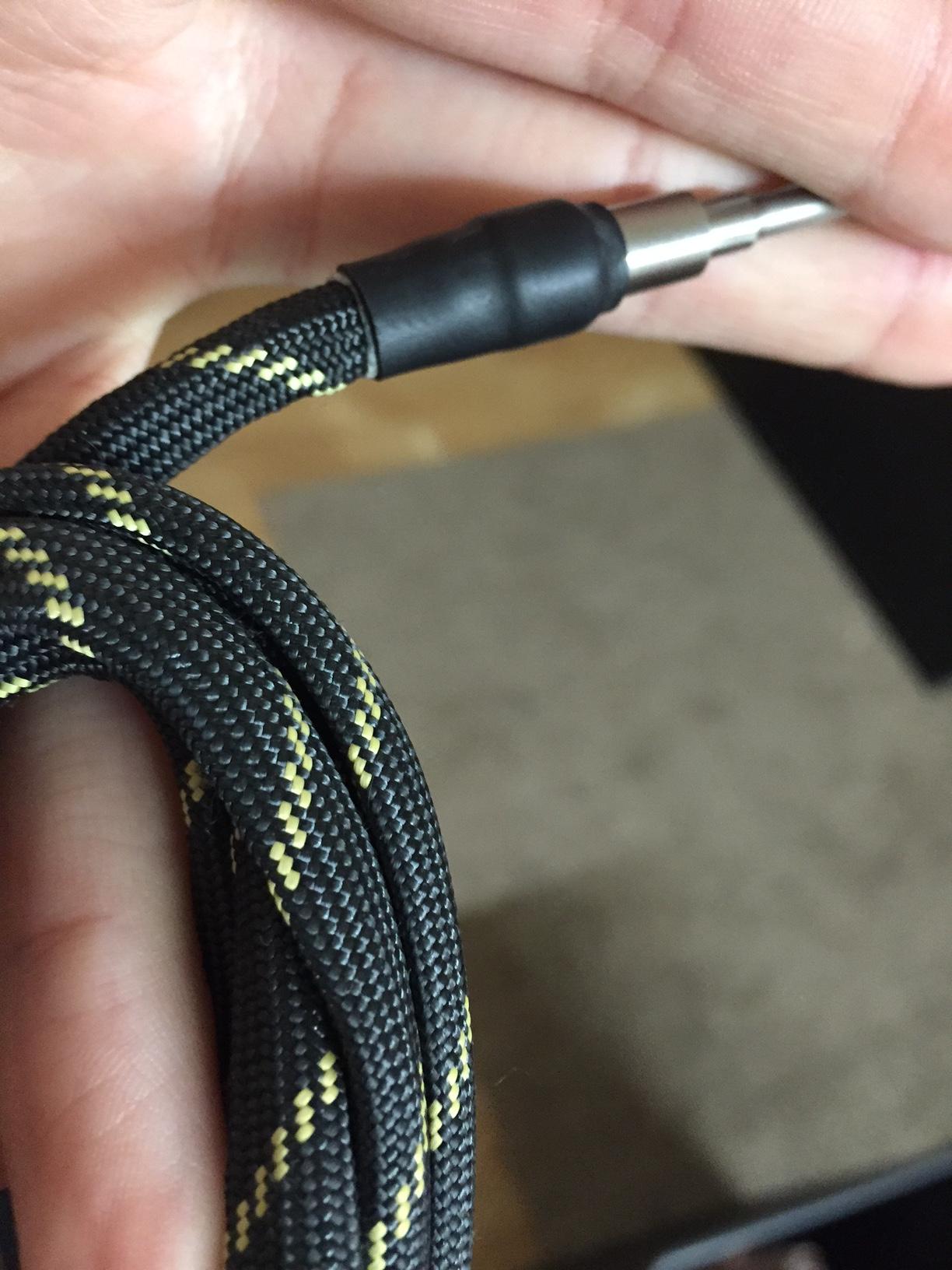

(Or this? btw, this had seen new heat shrink 3 times by day 3 and the plug was replaced on day 3 as well. Then the ground ripped out.)

We tried to mill some of the slightly less warped stock but ended up scrapping a few hundred bucks in wood alone when we started to worry about the enclosures cracking once the finishing process started (or them literally just breaking in half during milling). It's been...frustrating to say the least.

We offset this somewhat by finding another local supplier for about half of the replacements we needed and just buying them outright, but we still took a pretty decent time hit there since the wood is basically the front end of the entire process.

And here's some shots of our new coils, which are lightyears ahead of our first shipment or the one above (which was bought from a local shop before our others had arrived as a 'back-up').

The shrink is reinforced, the coils are actually wrapped in a friggin' ROUND SHAPE, they're Nichrome instead of Kanthal (Duh), and have Kevlar sleeves (thank god). The plugs are also MUCH higher quality than our previous stock.

------

We also invested a decent chunk of change into hiring and flying out a contractor I've known for a long time from Texas to help us further optimize our wiring schematics and help us throughout the assembly portion of Round One. His flight ended up coming in 2 days late, and his checked bag of tools took 3 more days to get here due to issues with lost luggage.

We were ecstatic to finally get him here though. He's been a miracle the past couple of weeks and the extra day or two we took redrawing the schematics with him was well worth it (he even found a way to add another hardware failsafe into the design without adding more 'noise'). In an attempt to take a load off our very over-worked developer (Liz, more straight from her below) he's taken over most of the internal manufacturing.

After that discovery we also wanted to put in another layer of software protection / auto-limiting functionality. Safety is one of our biggest concerns since I'm sure quite of few of y'all have units going on a regular basis throughout the day the same way we do here. We don't want anyone to have to worry about leaving their nail on in another room, etc. Though who's to say that's not just our personal paranoia peaking through?

Our mounting hardware for the bottom of each unit has been changed as well to try and ensure better durability & longevity for each unit.

The delay in milling a lot of our Bloodwood orders set us back on testing and burning in a lot of units as well, but we also want to make sure we end up with every customer getting a good, solid controller. The last thing we want is for someone to receive a unit that just falls apart on them the next day. We are burning in each unit with their respective coils as well. After watching a lot of different coils break in and change (thermally) from our various testing throughout Round One we see this as a necessity to try and maintain solid temps 'out of the box' and verify proper function. Both coil and controller will getting a minimum of 48 hours burn-in before being shipped out. Period. Burn-in is also, of course, a big extra safety check, too.

I've compiled our final checklist for each unit (which will be included in your orders) to make sure we have at least 2 people check each unit in and out before shipping. They will be initialed after each inspection. This list will also serve as our Certificate of Authenticity so it will contain serial # and other relevant info about each unit (along with notes on any fun manufacturing tidbits like knots, eyes, and unique grain patterns in each enclosure, etc.). Each screen will be calibrated before sending it out. Little finishing touches like that are some of the minor things that slipped past us the last couple of weeks.

------

I waited on this update to get more info (re: code monkey stuff) from our developer on how the software is progressing as well so (for the first time) here's a little info straight from her.

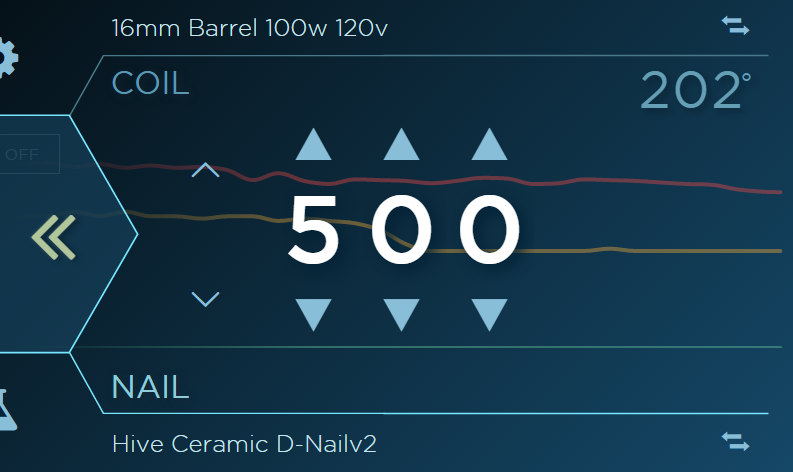

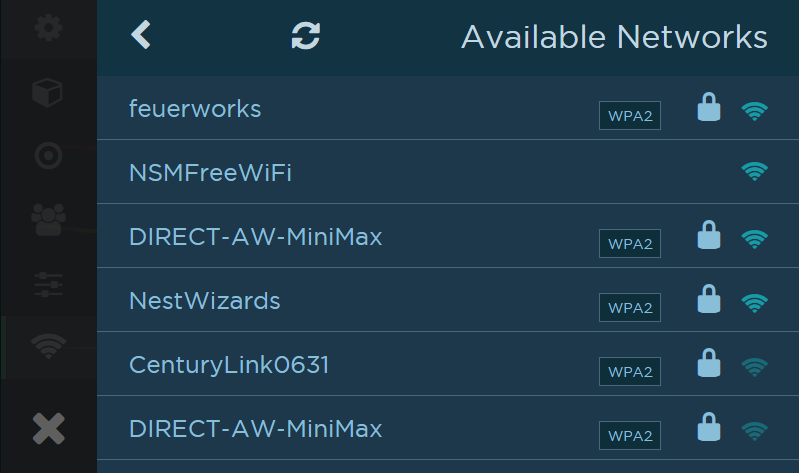

Here's a small preview of how some of the interface has changed / improved over the course of Round One as well. Bear in mind some of these shots are out of date and were taken after a ground-up rewrite of the entire system to improve stability and performance.

------

The last thing I want to address are the extras we were planning to sent out with units. Don't worry, any of you that ordered early, or chose exclusive swag over partial refunds to help us out financially during the bulk purchasing will

absolutely still be getting some really fun (and useful) stuff...we just need to send it later this month once all of our unit orders are taken care of. I hope this doesn't disappoint anyone too much and I can promise I'm gonna try to get even more fun stuff done for everyone once we get the orders out.

We've got a few things planned, but just so you get an idea of what's coming here's a few of of the ideas I've been (literally) milling over here and there since Round One began...

Matching (Hardwood) Dabbers

- The body will be made of the chosen wood for each order

Controller (45 Degree Angle) Stands

- Various materials will be used. We'll also be looking into making mounting brackets at some point for direct mounting to walls, etc.

Signed Prototype Design Enclosure Pieces

- Round One will be a huge accomplishment for us and we want all of our supporters to have a piece of what they helped make happen besides just the unit itself.

And of course we'd love to send some of the usual 'stoner swag' like shirts, dab mats, pins, and stickers, too.

------

tl;dr - We will be sending units out in small batches as we wrap-up each inspection and burn-in over the course of this (and next) week. Overall, in spite of a 'Santa's List'-esque set of issues we've run into outlook is positive and we can't wait to get these in your hands. Multiple year's worth of development, planning, testing, and prototypes are finally coming into focus and we ask that you bear with us just a little longer.

TRACKING NUMBERS WILL BE PROVIDED IN BATCHES AS SOON AS EACH ONE SHIPS. THIS IS YOUR LAST CHANCE TO EDIT YOUR SHIPPING ADDRESS (IF NEED BE).

If anyone has any other questions please either message me here or e-mail us directly at: ava@hex-nail.com (or) liz@hex-nail.com

The Sublimator is an obvious other candidate here but that is going to be included from the look of it.

The Sublimator is an obvious other candidate here but that is going to be included from the look of it. I'm sure by then there'll have been plenty of time to bring in support for all of the e-nail stuff I like to use!

I'm sure by then there'll have been plenty of time to bring in support for all of the e-nail stuff I like to use!