YungLeaner

Well-Known Member

By being located in Oregon and by Eric Holder issuing an order for the federal government to stop interfering with cannabis business in legal states.how do you get past the illegality of cannabis paraphernalia???

By being located in Oregon and by Eric Holder issuing an order for the federal government to stop interfering with cannabis business in legal states.how do you get past the illegality of cannabis paraphernalia???

By being located in Oregon and by Eric Holder issuing an order for the federal government to stop interfering with cannabis business in legal states.

Hmm looking over your web site it looks like this is just the box controller and you can pickup the coil if you want with a choice of woods in the box?

Going from Industrial to actually trying to be Cannabis related might be worth the extra $$

We manufacture the controller unit itself (and the hardwood enclosure), not the heater or nail (but your choice of heater in included). I'll be posting again in an hour or so with a much more in depth description of the enclosure manufacturing process (as well as some exciting updates...and photos). After choosing your wood (at the beginning of check-out) you'll then choose a coil/heater.Hmm looking over your web site it looks like this is just the box controller and you can pickup the coil if you want with a choice of woods in the box?

Going from Industrial to actually trying to be Cannabis related might be worth the extra $$

We manufacture the controller unit itself (and the hardwood enclosure), not the heater or nail (but your choice of heater in included). I'll be posting again in an hour or so with a much more in depth description of the enclosure manufacturing process (as well as some exciting updates...and photos). After choosing your wood (at the beginning of check-out) you'll then choose a coil/heater.

<snip>

We are working on tunings for both Ti & Ceramic Domeless nails at the moment using a HIVE Ceramic Nail (w/ a 16mm Coil) and a Highly Educated INFINITi Nail (w/ a Flat Coil). We are planning have tunings for SiC, Quartz, and Sapphire by the time we ship.

We are hoping to offer a wide range of high-end nails to go with our units by launch. We're in talks with some really great folks about stocking some pretty next-level bundles on the store (which will of course be available to our current customers as upgrades, as well). That way the only thing you'll need to add the mix is a rig of your choice!

We are definitely looking into offering packages that include nails by the time we launch. We want it to be ready to go out of the box for the customer whether they have a nail already or not (or if they want to upgrade their entire set up then and there).Sounds pretty amazing then maybe we can order a nail to pair it up also? Obviously it would be from choices like above.

Although I have been thinking about http://jredglass.com/product/14mm-female-20mm-diamond-e-knot/

Halloween Update

We're happy to announce that we expect to have real world images of every enclosure option on the site (and here on FC) very soon. Every one of them has been milled and started the assembly/sanding process.

We are almost ready to show off quite a few functioning prototypes as well. They'll soon be in the hands of a few folks here on FC so we can get some good real world feedback.

We officially have a rough dab log up and running (including automatic dab detection). We've also been making huge leaps almost daily in temperature stability across the board.

The Hex-Nail is now essentially 'learning' what a dab is as we stress test the prototypes. We couldn't have gotten to this point without taking what we learned and building ground up again from a software perspective. It's been a grueling month...but the fun is about to begin.

More photos will be up very soon. Stay tuned!

MID-OCTOBER UPDATE

Our team has been pretty heads down since we made the jump to Portland, but we're finally ready to start give those of you chomping at the bit a some exciting info.

So...what's been going on since we launched our pre-order site a month or so ago?

Well for one, we have upgraded our CNC capabilities in a big way. This has allowed us to finalize our production case design (v3)! We have a lot more control than before allowing us to create an incredibly strong, durable enclosure. We ended up going through around 5 different designs (and 3 major revisions) before landing where we did, but all that work has definitely paid off.

Our finishing process has also been set in stone (or wood, as it were). A lot of experimentation has gone into this one, but all of us here at Hex-Nail have a deep appreciate good wood. Heh. Our final process includes over 10 rounds of sanding, and 3 rounds of oil application, and 3 rounds of waxing. This whole process is done entirely by hand. Every enclosure is unique and true to the original characteristics of each wood we've decided to use.

There is no stain. There is no paint. Just a strong application of elbow grease and pride in what we do.

Without further adieu...Here are a few shots of what we've been working with...

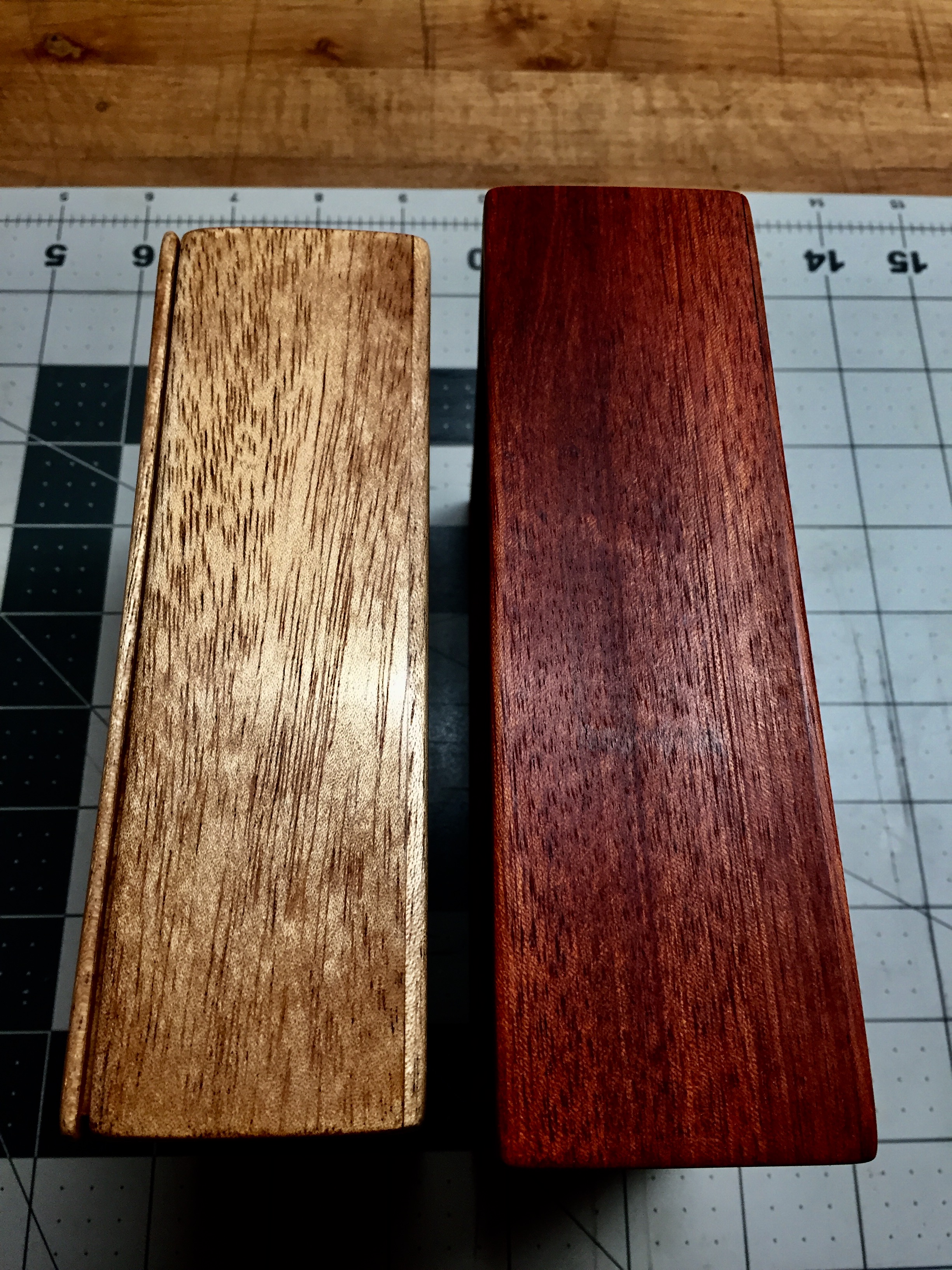

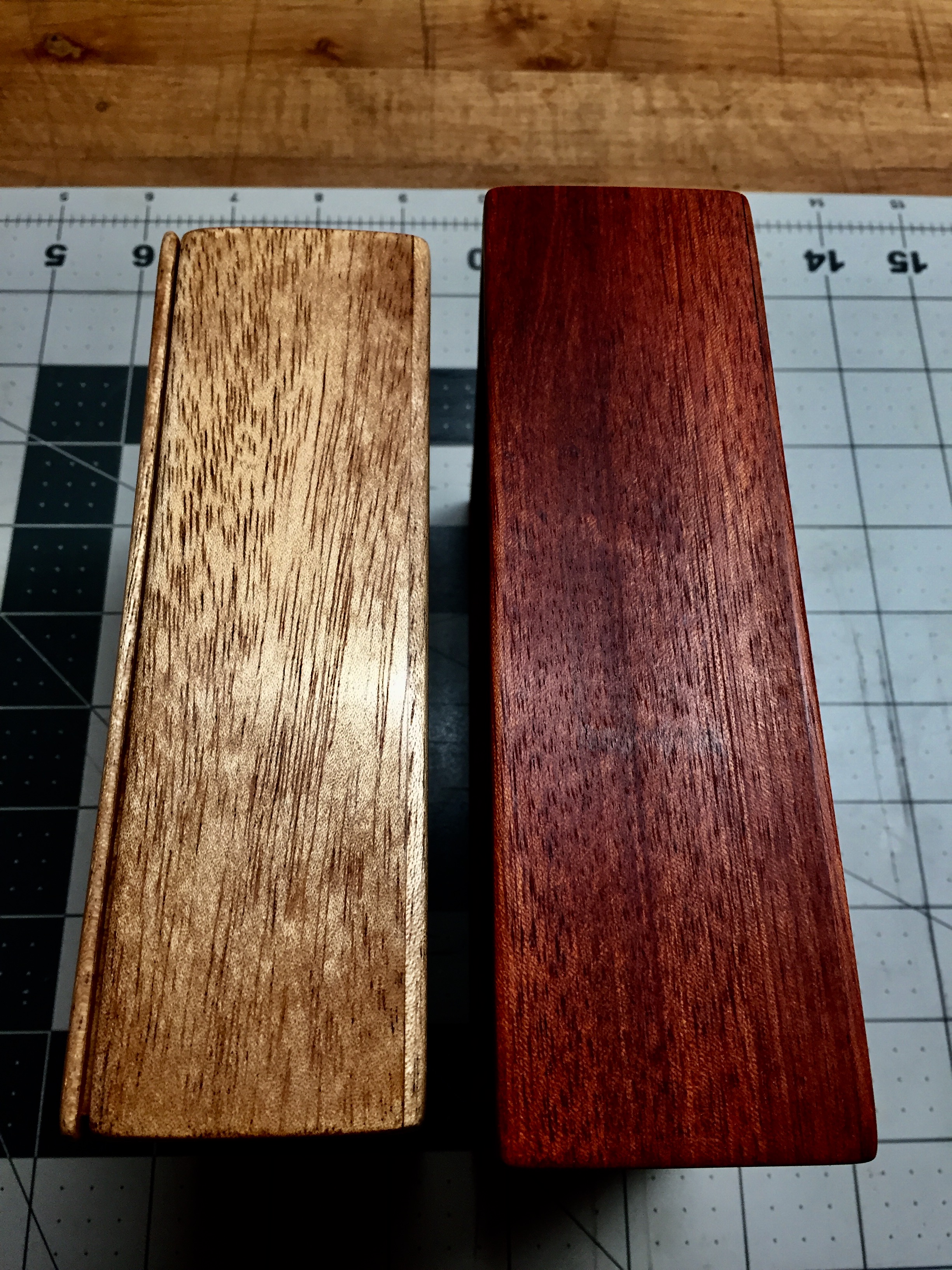

1) Close-up of our V1 (original) Prototype African Padauk Enclosure. The finish was good, but further refinement has allowed us to bring out more natural chantoyance and a much more even grain finish.

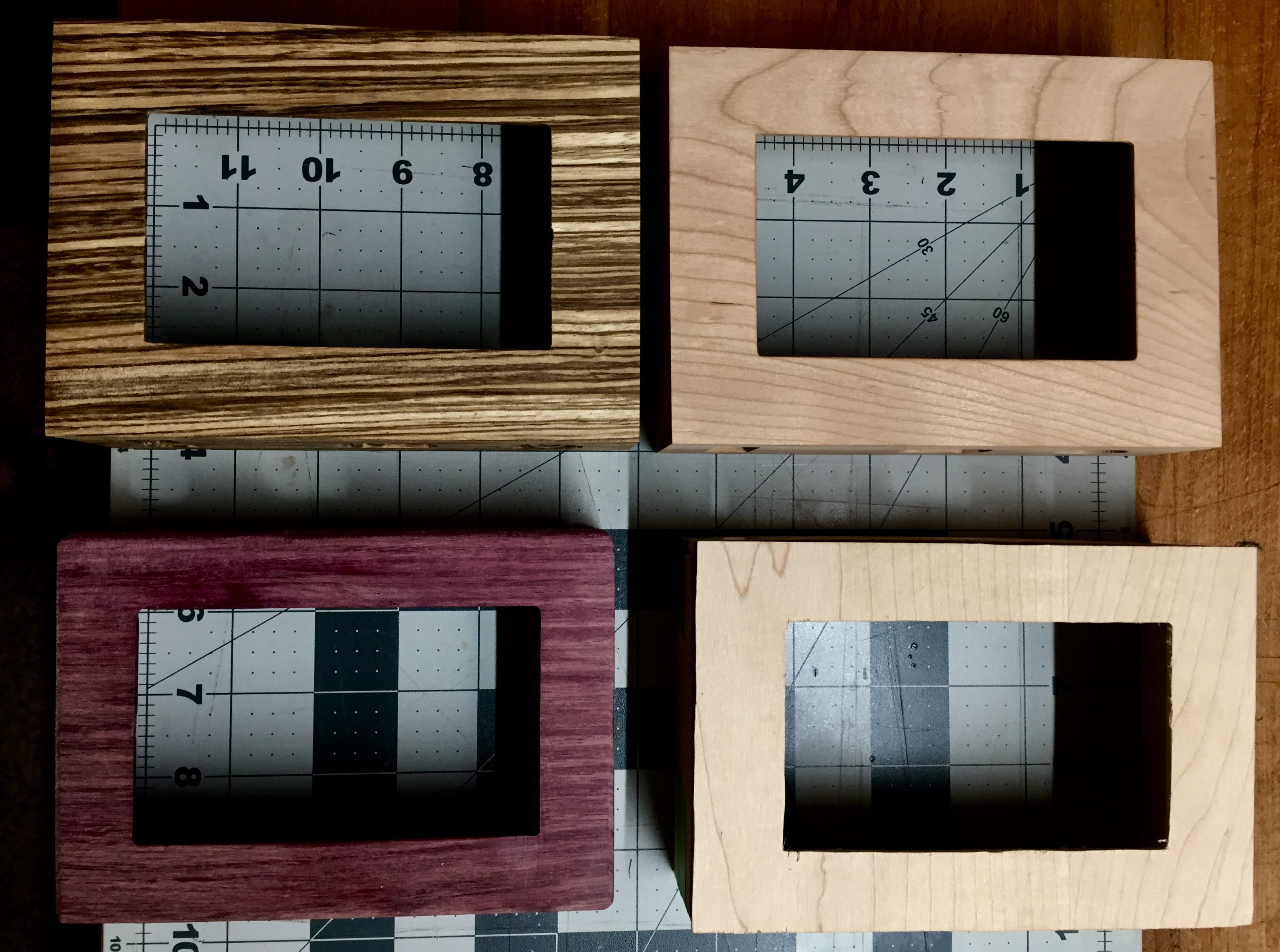

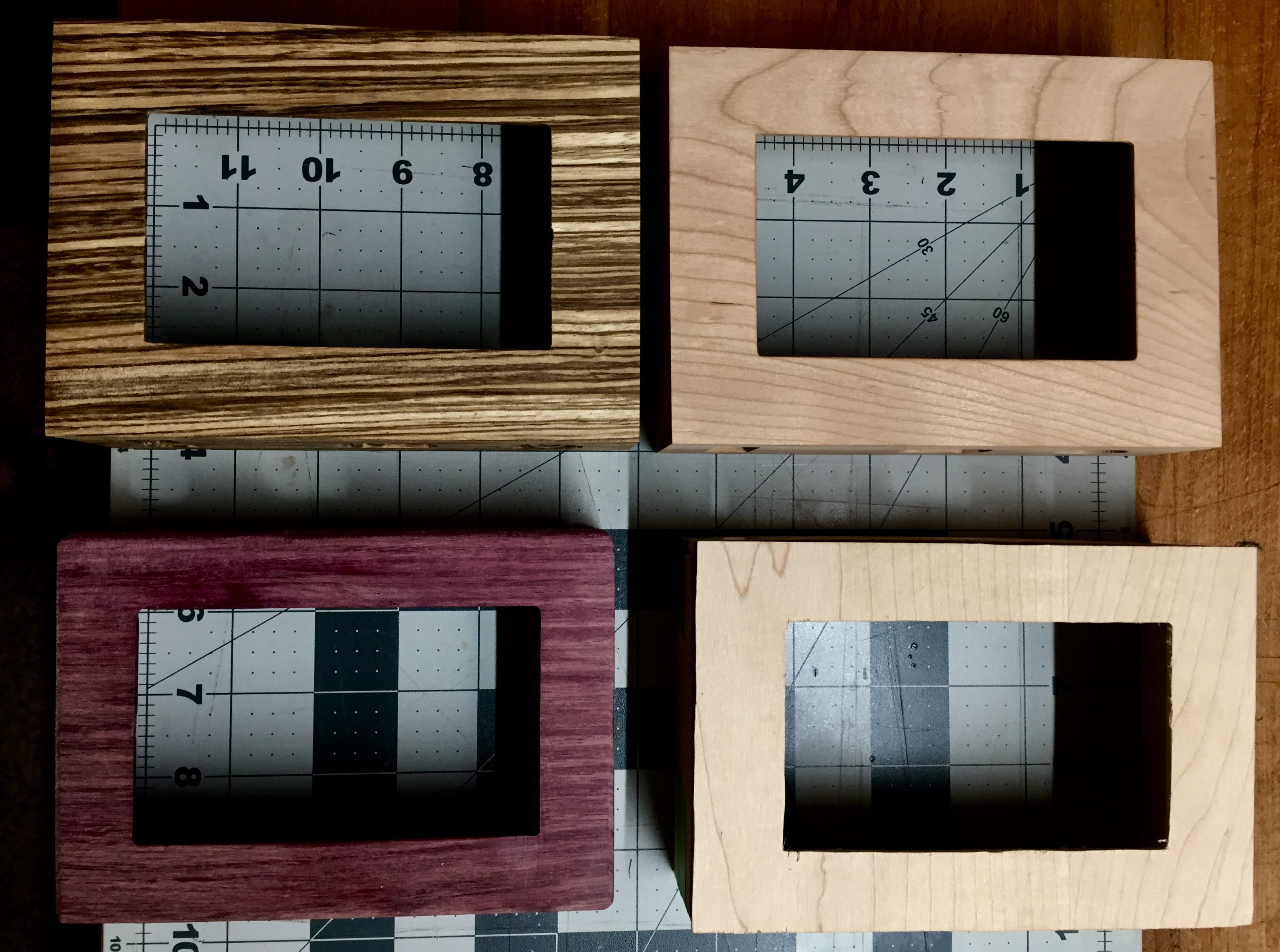

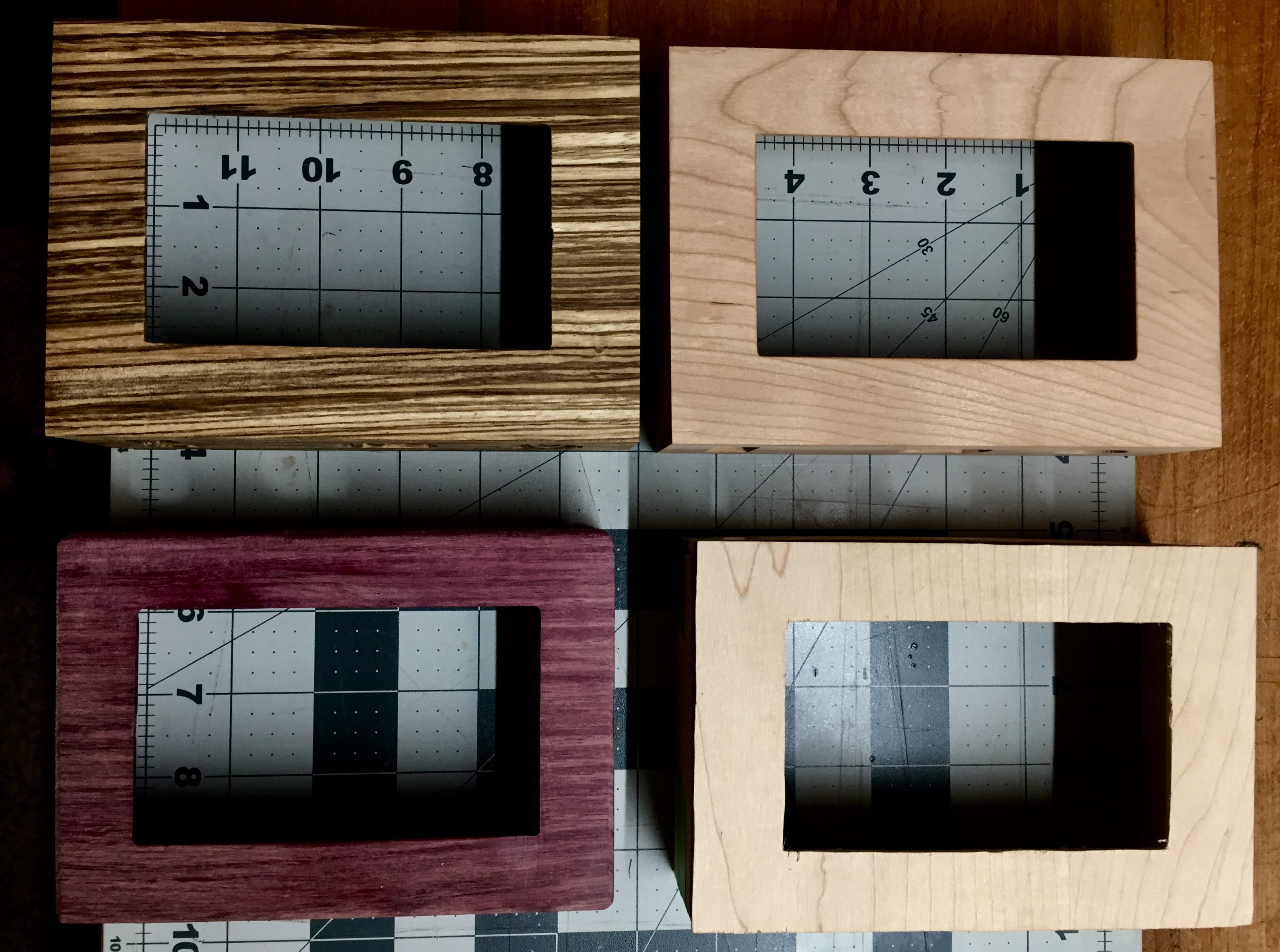

2) Pictured here are a few of the raw woods (no oil or wax has been applied) along with a mix of our enclosure refinements. The top 2 are our V3 enclosure (Zebra & Cherry). The bottom 2 are our V2 design in Purpleheart & Maple.

3) Raw shots of our V3 'hidden' bottom for each enclosure design. The Hex will be on the interior of the box (Serial Number, Manufacturing Date & Info will be on the visible back).

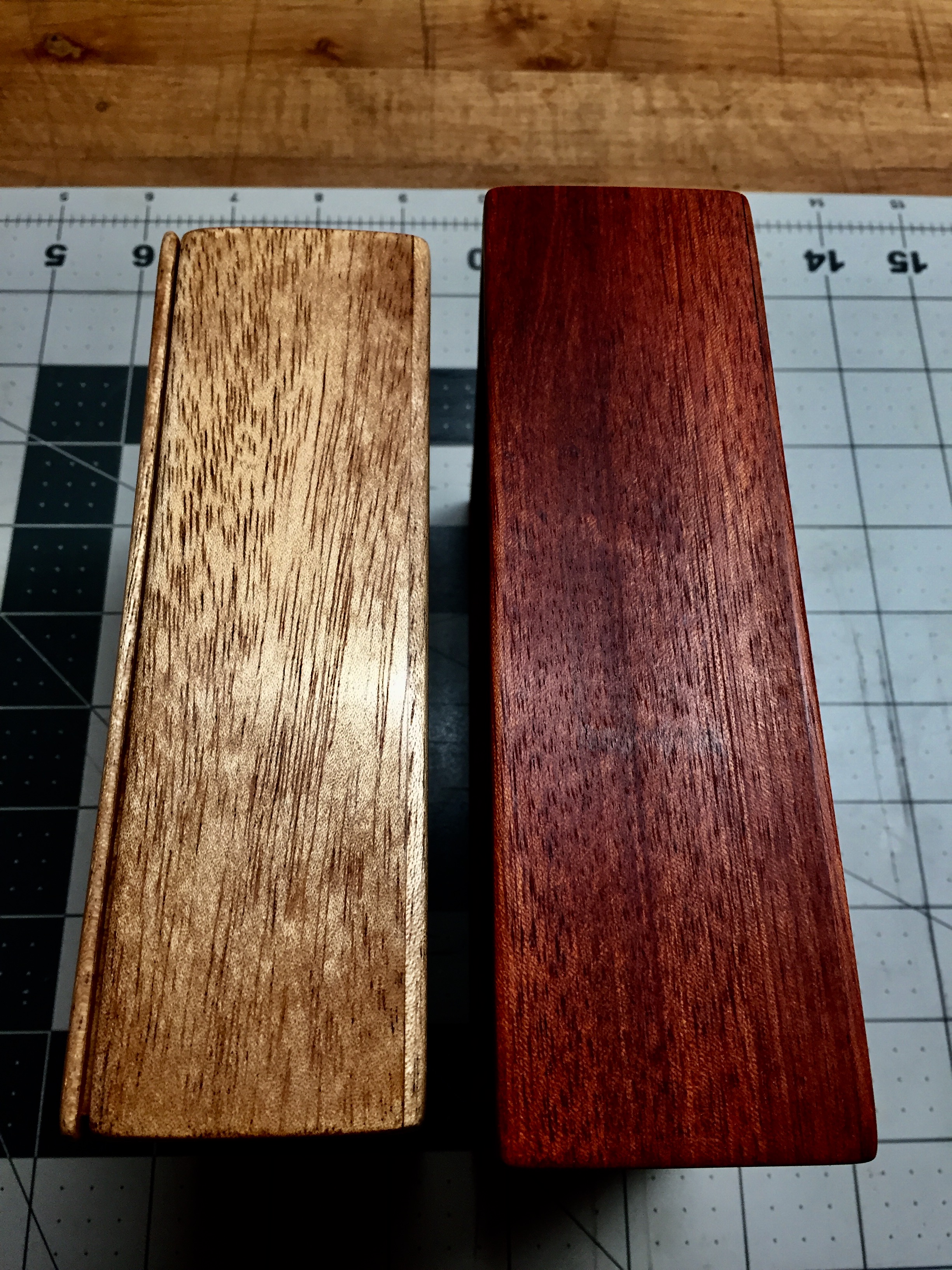

4) On the left is a finished V2.5 Enclosure in Mahogany. The right is our V3 in Redheart. The V2.5 was a little smaller, but had a seam at the base. The V3 added refined construction and an even further refined finishing process has been started on the V3.

5) Close-up shots of the enclosures shown above (4). Grain differences between woods become more and more apparent the closer you look, but the thing to note here is that the V2.5 is 100% 'finished'. The V3 hasn't even started the waxing and buffing process yet. It adds significant time to the construction of each unit overall, but we just couldn't let it go. The end result seen with a little extra manual labor was just too noticeable to deny.

----

We should have a few finalized prototypes to start showing off soon, and we'll definitely have plenty of sexy new wood shots over the next couple of weeks as we get an enclosure for each offering finished.

Stay tuned, everyone. It's about to get fun really, really soon. Remember, pre-orders are open and the more orders we have by launch means we can include even more fun goodies in everyone's shipments. Giving back to our loyal customers is a big priority for us.

MID-OCTOBER UPDATE

Our team has been pretty heads down since we made the jump to Portland, but we're finally ready to start give those of you chomping at the bit a some exciting info.

So...what's been going on since we launched our pre-order site a month or so ago?

Well for one, we have upgraded our CNC capabilities in a big way. This has allowed us to finalize our production case design (v3)! We have a lot more control than before allowing us to create an incredibly strong, durable enclosure. We ended up going through around 5 different designs (and 3 major revisions) before landing where we did, but all that work has definitely paid off.

Our finishing process has also been set in stone (or wood, as it were). A lot of experimentation has gone into this one, but all of us here at Hex-Nail have a deep appreciate good wood. Heh. Our final process includes over 10 rounds of sanding, and 3 rounds of oil application, and 3 rounds of waxing. This whole process is done entirely by hand. Every enclosure is unique and true to the original characteristics of each wood we've decided to use.

There is no stain. There is no paint. Just a strong application of elbow grease and pride in what we do.

Without further adieu...Here are a few shots of what we've been working with...

1) Close-up of our V1 (original) Prototype African Padauk Enclosure. The finish was good, but further refinement has allowed us to bring out more natural chantoyance and a much more even grain finish.

2) Pictured here are a few of the raw woods (no oil or wax has been applied) along with a mix of our enclosure refinements. The top 2 are our V3 enclosure (Zebra & Cherry). The bottom 2 are our V2 design in Purpleheart & Maple.

3) Raw shots of our V3 'hidden' bottom for each enclosure design. The Hex will be on the interior of the box (Serial Number, Manufacturing Date & Info will be on the visible back).

4) On the left is a finished V2.5 Enclosure in Mahogany. The right is our V3 in Redheart. The V2.5 was a little smaller, but had a seam at the base. The V3 added refined construction and an even further refined finishing process has been started on the V3.

5) Close-up shots of the enclosures shown above (4). Grain differences between woods become more and more apparent the closer you look, but the thing to note here is that the V2.5 is 100% 'finished'. The V3 hasn't even started the waxing and buffing process yet. It adds significant time to the construction of each unit overall, but we just couldn't let it go. The end result seen with a little extra manual labor was just too noticeable to deny.

----

We should have a few finalized prototypes to start showing off soon, and we'll definitely have plenty of sexy new wood shots over the next couple of weeks as we get an enclosure for each offering finished.

Stay tuned, everyone. It's about to get fun really, really soon. Remember, pre-orders are open and the more orders we have by launch means we can include even more fun goodies in everyone's shipments. Giving back to our loyal customers is a big priority for us.

; specifically your emphasis on temperature stability, emphasis USA made, quality construction, and customer service.

; specifically your emphasis on temperature stability, emphasis USA made, quality construction, and customer service.So, first of all, thank you for your interest in the Hex-Nail. I'll take this reply as an opportunity to call this an update (as I was hoping to post one here later today).Very nice! I have been rather outspoken in the past about what I consider to be excessively gold plated expensive enail controllers for basically a simple thermocouple feedback loop temp controller vice something like a Auber or High5.

HOWEVER, there are a few things I really like about this proposed unit: 1) trying to accommodate medical patients and not just "doods doing dabs"; specifically your emphasis on temperature stability, emphasis USA made, quality construction, and customer service.

I would like to know a little bit more about your temp stability. Nothing about your algorithm which I assume is proprietary but:

Also, I believe I read in the thread that you use 5-pin XLR. Can you please confirm the pinouts, are you "d-nail" type compatible with pins 1 & 2 = AC power, 3 & 4 TC +/-, 5 = ground?

- What is your stability goal at steady state?

- What is your under/over shoot goals when hit with a dab?

- Can you explain please the display we saw in the videos, in particular the graph in the upper left (I'm assuming one line shows set point and the other actual TC temp....maybe a smoothed down and integrated view of the temp graph to the right?

With regard to your wood enclosure finish. Very nice. I'm a shotgunner and shotgun stock making is a long respected craft/art form to include what is often called "in the wood oil finish". This is the process of sanding oil into the grain to fill it with numerous coats until the grain is filled. So, you ain't up there with Purdy or Boss but it looks pretty darn good. One product we found, after long experience, that we liked for the quality of the finish and the ease of working it is Laurel Mountain Forge's Permalyn finish. Permalyn is actually a polymeized polycarbonate so I don't know if this meets yours/folks requirements for non-toxic/non-out gassing finishes but my experience is that this is very stable stuff.

http://store.laurelmountainforge.com/index.php?main_page=index&cPath=69

Look forward to more news about your product.

Now, this is good for gunstocks

So, first of all, thank you for your interest in the Hex-Nail. I'll take this reply as an opportunity to call this an update (as I was hoping to post one here later today).

FIRST WEEK OF NOVEMBER UPDATE

(11/6/16)

To address the intro...

Yes, we started this company (and building of this device) as patients, for patients and we never want to lose site of the potential for steps forward in the medicinal space. Finding Cannabis when I needed it the most in my life (living day to day using a cane or walker, and rarely leaving the house due to physical pain) changed it completely. Being able to help patients better manage their intake (especially as potency and purity in concentrates improve) is always at the forefront of our work.

But ain't nothin' wrong with dudes doin' dabs, either. Haha. Being part of the Recreational Cannabis Community as well as the Medicinal Cannabis Community has opened a lot of great doors for me. New friendships, business ventures, and exposure to things like art and music the community often seen as 'just stoners' puts into the world is invaluable to what we do as well.

You got us at Hex-Nail pretty pegged on the rest.

- Stability & Customizability are the foundation the HN-01 is founded on.

- The dedication to supporting USA suppliers, manufacturers, etc. comes from our personal experiences struggling to support ourselves (or growing up in a family with similar issues) in America. Supporting our community and helping it grow is at the heart of Hex-Nail as a company. Being able to work with people face-to-face and easily inspect our materials before accepting them is huge. Being able fix problems immediately is always our preference and we need quick, easy access to quality material to do that.

- Dedication to quality construction comes from our backgrounds as craftsmen ourselves. We appreciate and see the quality that can be had over a machined finish/assembly when a little elbow grease, a human eye and love are used instead. Everything post-milling is done by hand, and we aim to keep it that way.

- And the dedication to customer service comes from years of experience. Issues we've run into or had to fix in our own lives (or careers). We don't like to wait, we don't like to get tied up in red tape, we don't like never seeing a response from our inquiry (or only ever getting one from a computer).

We will always do our absolute best to make sure our customers have as little to deal with as possible. We also highly value our customer's input. We try to listen, instead of letting it all pile up in the mailbox (so to speak).

-----

And now for something completely different...your questions!

1) Our goal is to maintain a steady nail temperature (which is set by the user) within the margin of error for a K type thermocouple (3.6 F) regardless of fluctuations in the temperature of the coil itself by quickly and selectively altering power sent to the coil using our predictive algorithms.

2) Overshoot and undershoot goals are +/- 1% absolute with a recovery time of less than 10 seconds back to the set temp of either the coil or nail (with essentially no settling time)

We're already seeing numbers close to this at this point in development.

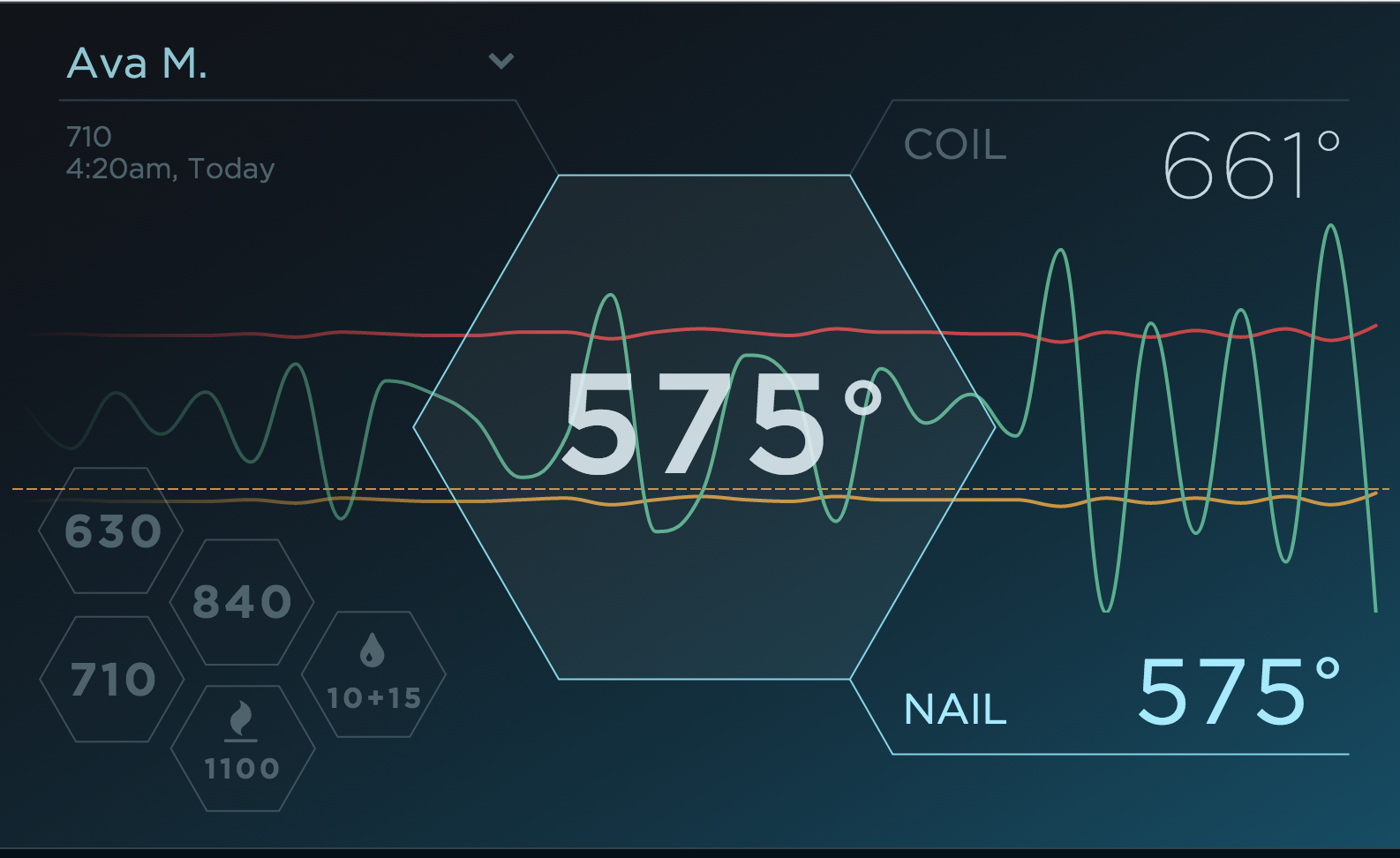

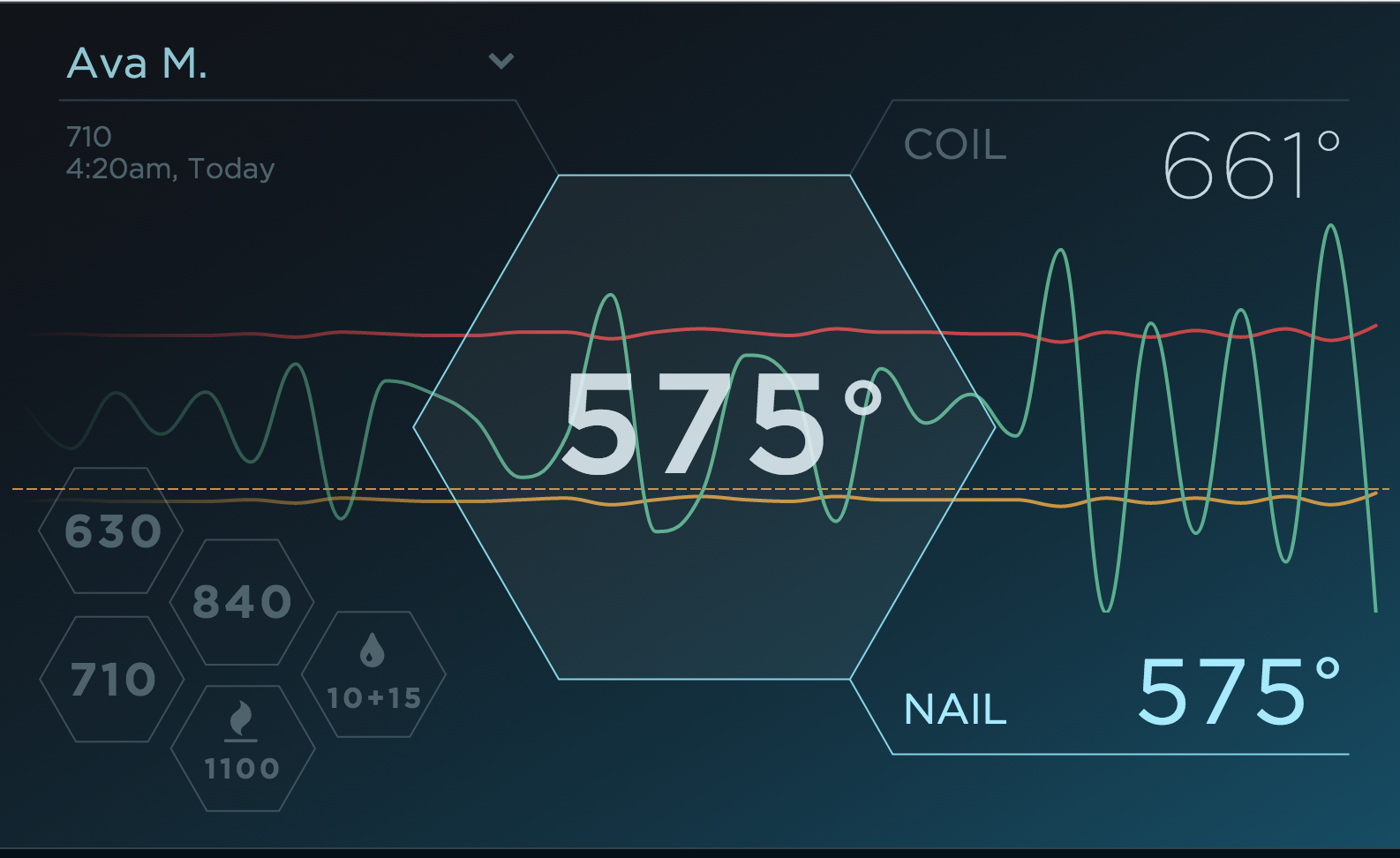

3) With the original UI in the videos (just to break it down a little) we were showing 3 things on the graph (but it's really hard to tell): Set Temp (not very visible), Current Temp (the visible red line), and changes in power (the most active, green line).

Our new UI (which we will be uploading videos of later today) reflects this goal in a much more legible way. It provides real-time graphs of power sent to the coil, coil temperature, and nail temperature (calculated via our proprietary algorithms and models) simultaneously. Users can choose to track to calculated nail temperature, or to the coil itself.

Here's a preview of the re-vamped UI:

(there's more to be done, but we've had good response to this newer design both in our own use and the eyes of a few folks we've shown it to)

And to explain this a little more I'll just go over what you see here.

Top Left:

+ Profile Name

Set by user in the initial set-up (profile pictures will also be available)

+ Most Recent Dab

Placeholder info for now, though we do have tracking working it's not implemented in the UI yet

+ Drop Down Menu

This will be the source for your settings which will include things like Presets for Temps., extras like Cleaning Mode or Glob Mode, Coil/Nail Temp. Tracking Select, Mode settings, User Select, Security, etc.

Bottom Left:

+ Presets

Seen here are temperature presets (630, 710, 840) along with Glob Mode [10(%)+15(S)] and Cleaning Mode (Set to 1100 degrees for our stress tests, at the moment).

+ 'Glob Mode'

Increase power by a set percentage for a set period of time (when selected) the next time a dab is detected. This can be set for the folks that drop half gram slabs on the daily, or someone who just needs a little more along with their coffee in the morning by the user.

+ 'Cleaning Mode'

Fairly self explanatory, but it will increase your nails temperature to a (user set) point at which it will be easiest to clean/burn off any leftover material on the nail itself. This will vary depending on the material of the nail itself. Lots of folks don't want to go blasting Sapphire with 1100 degrees. Heh.

These are totally customizable to accommodate user preference.

Top Right:

+ Coil Temperature

Currently dimmed since we're tracking to the nail temp., but is updated in real-time.

Bottom Right:

+ (Calculated) Nail Temperature

Currently illuminated since we've selected to track to it. It stays at your set temperature and does not change when selected (same goes for Coil Temp. when tracked to)

Center:

+ Graph & Lines

- Red: Current Coil Temperature

- Green: Power Fluctuation (Which is represented as a percentage 'needed to maintain temp.' by the line)

- Dotted Line: Set Temp

- Orange: (Calculated) Nail Temperature (which tends to run mostly parallel with coil temp. when at steady state)

+ Current (Tracked) Temperature

Which updates in real-time along with the (dimmed) Coil Temp.

-----

Oh, and yes, we are wired in standard 'D-Nail Compatible' fashion. We wanted to ensure to most universal fit for all of our customers.

As for the finishing suggestions...thank you! We've been getting a lot of hands on experience with different stuff and we will definitely give this a look for final finish consideration. I would like to say that we have improved the finish greatly from the previously posted shots. It now includes multiple rounds sanding in oil, as well as sanding (and buffing, at the later stages) wax into the grain.

I'm pretty proud of our latest finished results and I'm excited to post new shots of some completed enclosures soon (along with the videos, if proper lighting permits).

May I assume this is Ava writing back to me from Hex? If so, thank you so much, Ava. You answered my questions very thoroughly, I like the answers very much, and I appreciate your taking the time to post this back to me and the forum.

Now, I posted my last entry under the gun as I needed to get out of the house and rushed....and it shows in some of the barely legible, completely unedited, sentence I wrote. My apologies for the sloppy writing. And I wasn't even baked. LOL

Now, also...I agree...ain't nothing wrong with "doods doing dabs" and I am one from time to time. But I'm also an older medical patient, and retired engineer/program manager in a tech field, and the kind of information you shared with us is exactly the stuff I was looking for.

By the by, I like the new UI and it makes sense to me with your short explanation. Its rather intuitive which is the holy grail, right?

I also very much like that you can establish a set point on TC feedback or a calculated value for dab surface and that this is operator selectable. Are there any user tweakable parameters in your dab surface calculation? Can you explain this a bit more? I assume its not just a simple offset value (like -10 F) that can be user set. What are the user input for dab surface temp calculations...what would I, as an operator, need to tell the unit so it can reasonably accurately estimate dab surface temp?

Again, thanks so much for your replies. You have really piqued my interest.

Cheers

Glad to hear I could help (and that we could shake things up a bit for ya, too).

UI

We're hoping the UI works out well, but we haven't had a bad response yet! The more we refine it and add little things the more it sort of starts to show it's utility side, too. We've really been enjoying using it.

Less 'dead space' on the screen was the goal with the new UI, and we managed to do that while still simplifying it. But keep in mind we're planning to make the UI very customizable. We'll even be adding more features and UI options through software updates as we get feedback from the community post-launch.

Tuning

It's not a simple offset by any means. Things change greatly every couple hundred degrees regarding heat loss, etc. We've been primarily testing the thermal properties of Titanium & Ceramic the last few days (not to mention the efficiency of different coil types. Flat, 16mm, etc).

Our goal with nail temp. calculations is to have a tuning model for Titanium, Ceramic, Quartz, SiC, Hybrids (ex. Ti w/ Quartz Dish) & Sapphire based on a pool of different data collected from various nails made from each material.

As a user, all you'll need to do to take advantage of this is pick your nail material (which you can change at any time). Initial Set-up will ask for this information, but you'll even be able to do things like set Presets per nail type as well.

Say you have a Quartz Nail and a Titanium one. Quartz you like at 500, Ti at 600. With the push of a button you'll be able to change the temperature and tuning parameters of the Hex-Nail to help you quickly swap between nails.

We want this tuning combined with our noise reduction to be accurate enough to show the flaws in a user's chain, rather than require them to worry about tuning the nail itself.

Perfection has to be built from the bottom up. If your nail isn't as accurate as possible you've already shot yourself in the foot, ya know?

Oh, and here's a little fun I had while milling some enclosures today. Premiering on FC first. Heh. We're pretty fond having the nail on the TV.

Maybe subscribe to our new YouTube channel, while you're at it.

Thanks! I think you might find coming up with tuning parameters for hybrids (e.g. Ti/SiC insert) as different models of these bangers/nails seem to be built very differently, I would presume would have very different thermal dissipation characteristics, and then there is the whole issue of coil fit which impacts thermal transfer to the dab surface fairly significantly, it seems. Good luck, like what I'm seeing so far, look forward to more reports.

I guess if I have one more piece of unsolicited advice to give it would be to do burn-in, parts reliability screening, whatever you need to give the unit rock solid reliability figures. There is already too much stuff out there in the vape ecology where sufficient attention to reliability/durability/maintainability has been given.

Cheers

We absolutely agree on burn-in and stress testing.

Every. Single. Unit. Will be stress tested for a minimum of 48 hours (on-time) while the internals are maxed out. We are definitely going to do our best to make sure that every nail is reliable well before it leaves our doors on it's way to yours.

Boy burn-in testing has changed since my father introduced it at Storage Tek years ago. (I'm not claiming he introduced it to the industry) we used to burn in Power Supplies for 2 months straight

48hours feels a bit light; however at least your stressing it. Some people just automate clicking the button for 7 days straight and make sure it works.

Testing has always been a passion of mine; thanks to my father.