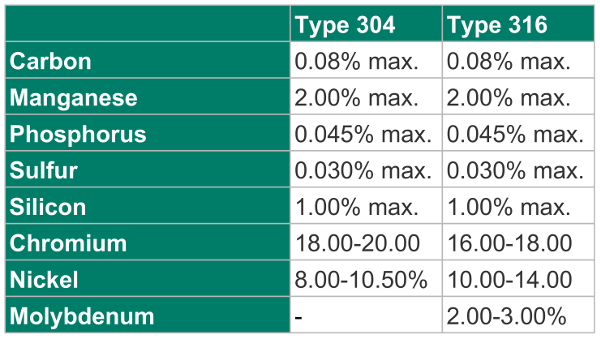

The Dynavap uses 316l for the tip/ body. The L means it has a max allowable carbon of .03%. The cap is 304.

While they use the same chemicals, alloys are extremely complex. The tiniest variances completely change the characteristics of the material…like to a mind blowing degree. I used to do a lot of soldering and the differences an extra percent of one metal, or the difference of doping in inclusions of thousandths of a percent of an additional metal is stark.

Metallurgy is borderline witchcraft lmao.

Edit: As far as the vapor goes, the path travels through the inside of the cap before entering the tip. So I’d imagine nearly 100% of the vapor comes in contact with the disks. The only air that wouldn’t contact the discs is the the dilution air entering through the airport.

it doesn't matter if the cap is made from ss304 or ss316

the inside of the cap doesn't come close to a lot of air, very small amout of air each time

hence the chance it will oxidize it is very very very small

the outside of the cap maybe can get oxidize after a lot of years in a humid envirnment

but hey, you don't store your cap in the shower, right?

and the humidity in your room is not 90%+ all the year

plus you can store it in some tube etc'

but the inside of the cap? the amount of air passing it is so low that it won't get be rusty after 10++ years or so

i think 20+ even

amounts are everything here. think about how small the amount of air the cap touches during the years. very low amount.

it's closed all the time with the Tip. and even you draw, well, yea, air comes inside, but again, VERY small amounts comparing to the point it will be reacted with air....

think about your shower's handle or so. not only it's stored in the shower, a lot of air is passing on it during the years, and still ss304 handles will last years. the inside of the cap? decades, or more, it will take it to react with oxygen.

the disk inside the cap is 100% safe for decades

PS boiling point of ss304 is 1000C+ so 200C of the Dynavap is nothing for this material...

, no Simrell ti bowl for Ed’s TnT Woodsense, lika vera much, worked nice in my Roffu.

, no Simrell ti bowl for Ed’s TnT Woodsense, lika vera much, worked nice in my Roffu.