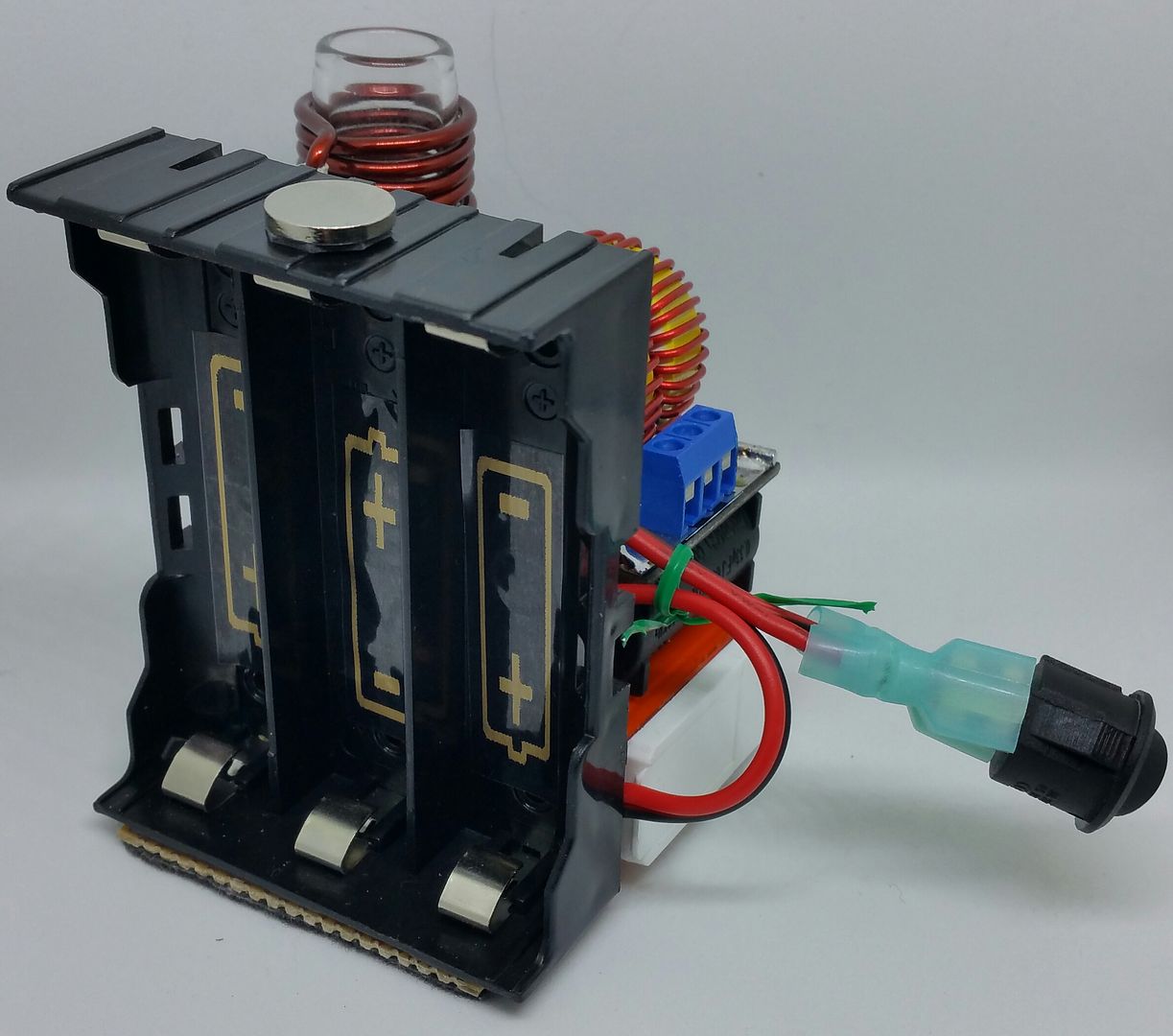

I did a couple of quick tests with my IH setup, the load was an empty Dynavap M, the batteries and connectors being the only hardware difference between the tests. I did my best to keep the load insertion depth the same across each heat cycle.

A. 12v lead acid car battery.

State of charge - 12.56v

Current draw at idle - 1.32A

Current draw with load - 5.3/5.8A

First heat cycle to click - 5.5 sec

2nd - 4.1 sec

3rd - 3.5 sec

B. 14.4v nicad cordless drill battery pack.

State of charge - 14.9 v

Current draw at idle - 1.54A

Current draw with load - 4.4/4.7A

First heat cycle to click - 9.5 sec

2nd - 7 sec

3rd - 7.5 sec

The NiCad was slower than I thought it would be, with less draw at load than the LA. Nothing got unusually hot, although when i have time i'll run the test again with more cycles. At the moment it looks like the NiCad might be a suitable power supply.

I also learnt that if you put the loaded, running IH too close to your mobile phone(was using it as a stopwatch) It makes the phone do weird things.