Prophecy

Well-Known Member

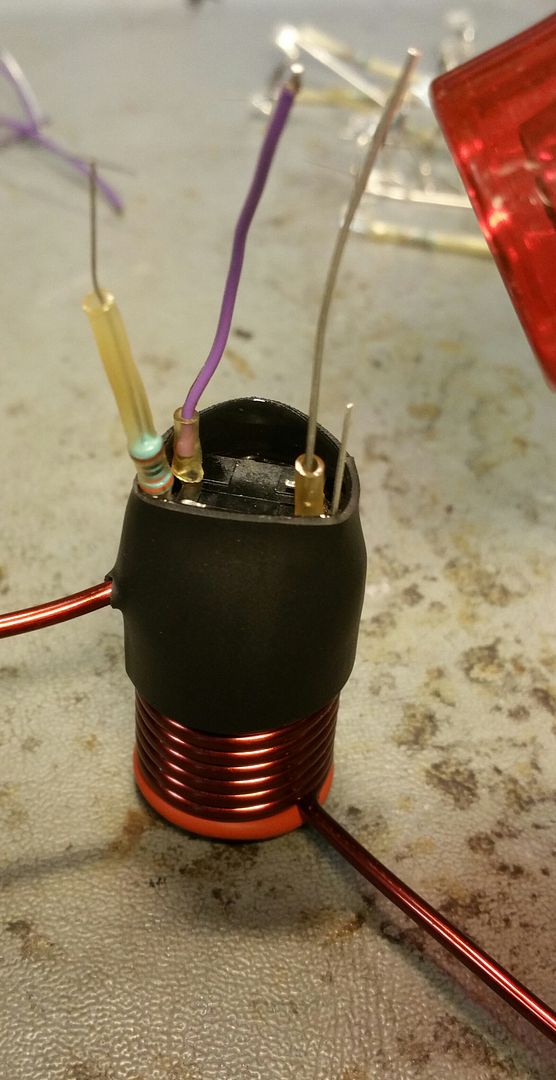

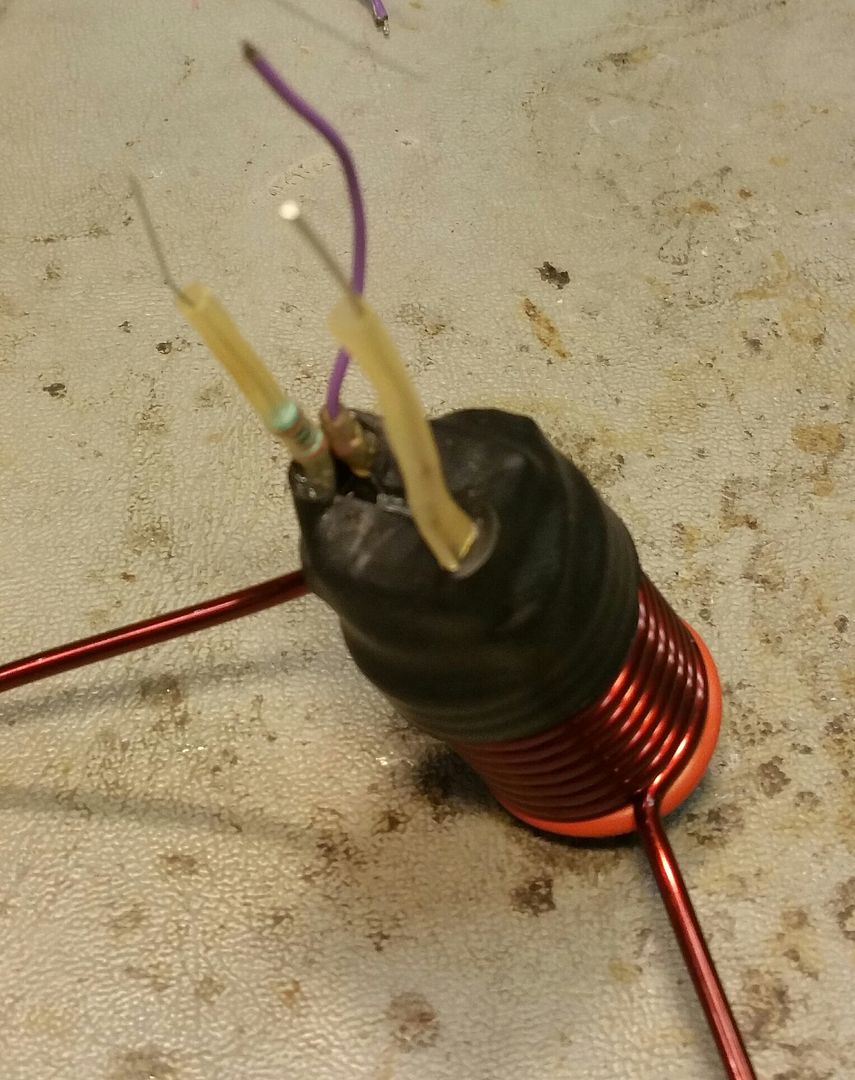

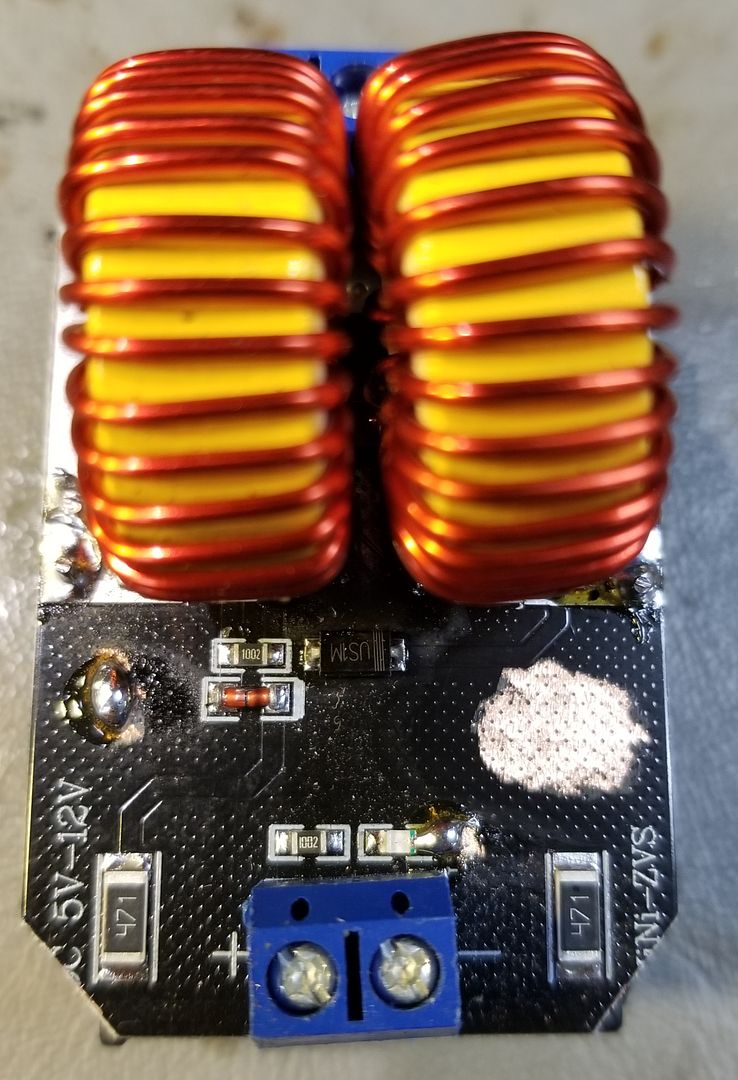

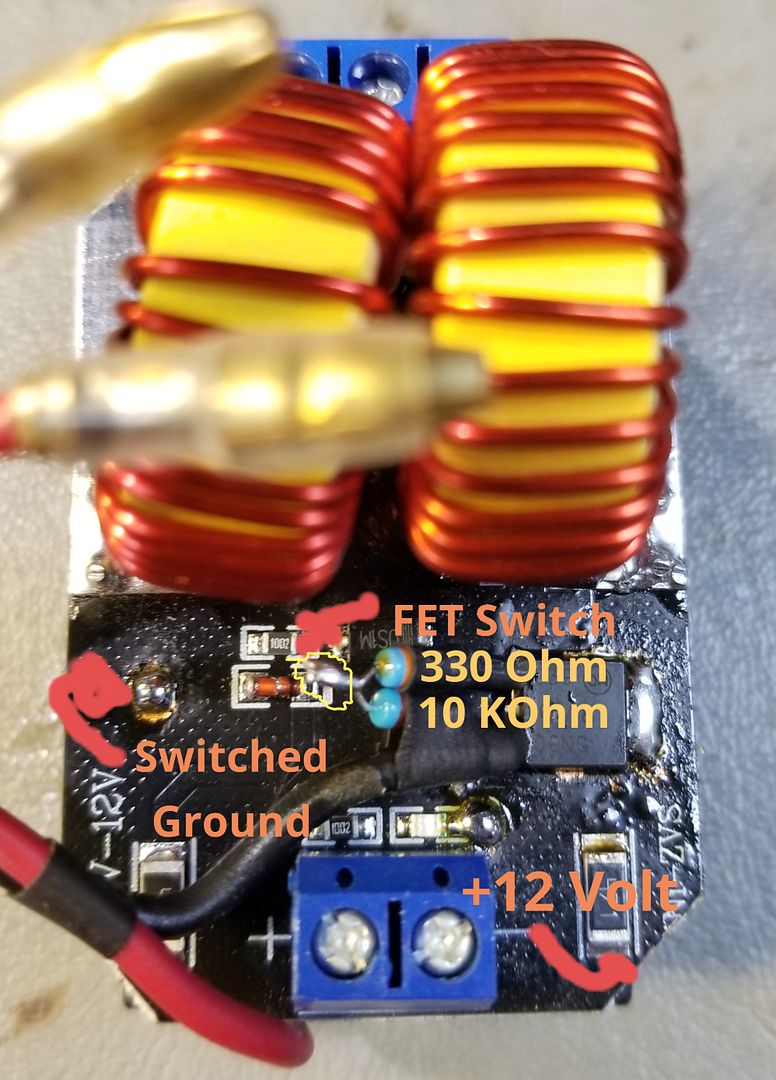

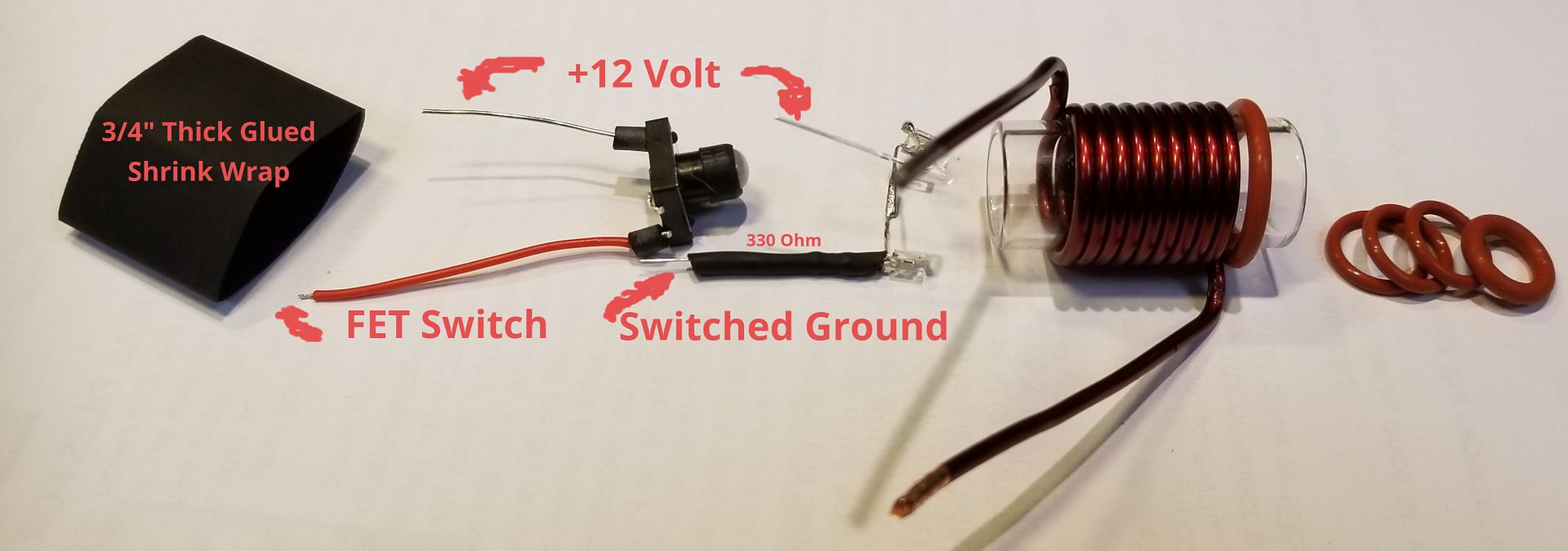

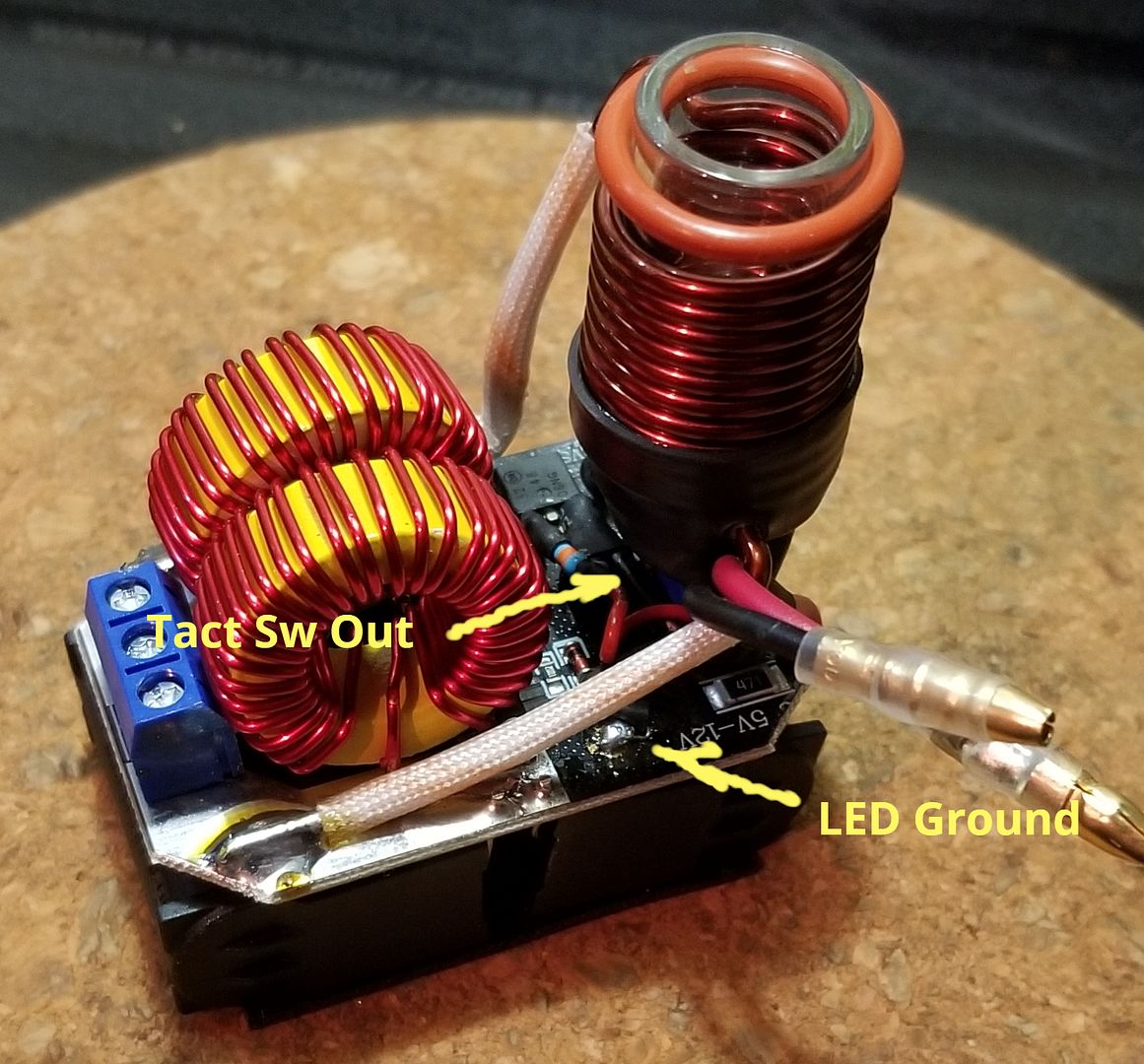

Today my tactile switch in the glass tube from my skeletor IH broken down, the whole plastic from the switch went down see the picture.

Must say I used the IH daily for 15 months multiple times a day, but in the last week the switch had a wobbling feeling too, always when I pushed my vapcap in the glastube I had to move my vapcap back and forth while pushing down to engage the IH.

Is there any fix to resolve this issue?

In this moment I'm glad that I have also a Portside Mini

Must say I used the IH daily for 15 months multiple times a day, but in the last week the switch had a wobbling feeling too, always when I pushed my vapcap in the glastube I had to move my vapcap back and forth while pushing down to engage the IH.

Is there any fix to resolve this issue?

In this moment I'm glad that I have also a Portside Mini

Thanks

Thanks

However the little feet on the bottom & the magnet on top of the portside have all come off. Well, the mini was fine until last week when my significant other used it for a few minutes & someone lost them all lol. Anyway I did a little searching through the thread but couldn't find any info about good replacements for these and/or a good adhesive to use, especially for the magnet. Any help would be appreciated!

However the little feet on the bottom & the magnet on top of the portside have all come off. Well, the mini was fine until last week when my significant other used it for a few minutes & someone lost them all lol. Anyway I did a little searching through the thread but couldn't find any info about good replacements for these and/or a good adhesive to use, especially for the magnet. Any help would be appreciated!