Prophecy

Well-Known Member

WOW he making anymore?

I will ask him when you interested. Will Send you an PM when I have more information on that.

WOW he making anymore?

Thanks @Pipes! Love my Caldron but wish i would have brought it with me on a recent cross country trip. The car adapter will be a game changer for next time.

Update: love it! (Never going to be a question)Received my psm this morning!!)

Update: love it! (Never going to be a question)

took the psm through 4discharge cycles and then did a test on the battery. I was able to get 49 clicks from it. In most cases I would finish a bowl in 2 clicks, but on occasion it needed a third. I did this over 4 sessions so in some cases the tip was cold, sometime warm but I feel like 40-50 clicks can be expected, depending on type of use.That’s 10-20 bowls depending how I push it.

I’ve been using a Ti tip... maybe a gen 6or7... 5fin. When I used my OG M (16?) tip, it took much longer so I would expect far fewer clicks per charge. With that said, now that I have a sense of what to expect I won’t be depleting the battery so no more tests.

It is one of the best purchases I've made in vaping.

It is one of the best purchases I've made in vaping. The PSM is kinda heavy and a little awkward shape for carrying around and this case smooths out those issues. I have only used it with the strap, but I can imagine circumstances where the belt loop may also be useful. Definitely worth considering if you want to bring your PSM with you out and about. I am much more likely to use my VC out of the house when I have the PSM with me.

The PSM is kinda heavy and a little awkward shape for carrying around and this case smooths out those issues. I have only used it with the strap, but I can imagine circumstances where the belt loop may also be useful. Definitely worth considering if you want to bring your PSM with you out and about. I am much more likely to use my VC out of the house when I have the PSM with me.So I need some advise from my fell FC'ers.

I recently acquired my first IH which is the Alpine 2020. Unfortunately, I don't have much fait in the longevity of the heater. However, I am now hooked on the functionality of an IH. I am considering buying another IH to be my main driver both at home and on the go. I am between the JoJo and maybe a PSM. For those of you who have either one can you please fill me in on the pros and cons of each.

Specifically the PSM, how long does the battery last? Is it a durable unit? What do you like and dislike about it? The PSM seems to be a popular Ih with plenty of positive reviews.

I appreciate you input.

Would this be a suitable car charger for the PSM?

Amazon.com : TalentCell 12V Lithium Battery Pack Car Charger, 12.6V/1A DC 5.5mm x 2.1mm Car Charger Adapter for 3S 12V Rechargeable Li-ion Batteries, Black : Home Audio & Theater

Amazon.com : TalentCell 12V Lithium Battery Pack Car Charger, 12.6V/1A DC 5.5mm x 2.1mm Car Charger Adapter for 3S 12V Rechargeable Li-ion Batteries, Black : Home Audio & Theaterwww.amazon.com

Please and Thank You

View attachment 1590

recently received my PSM, and it fits PERFECTLY in this Steadfast leather coozie available from Etsy. Happy vaping, fam

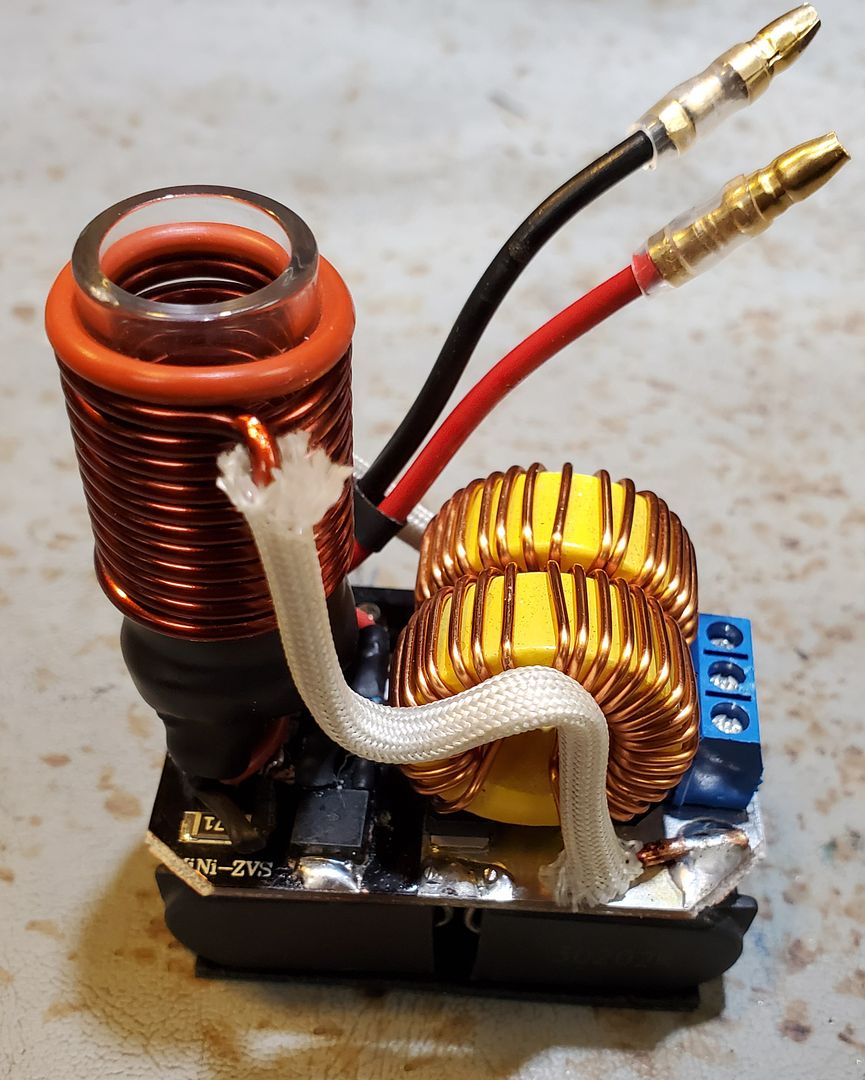

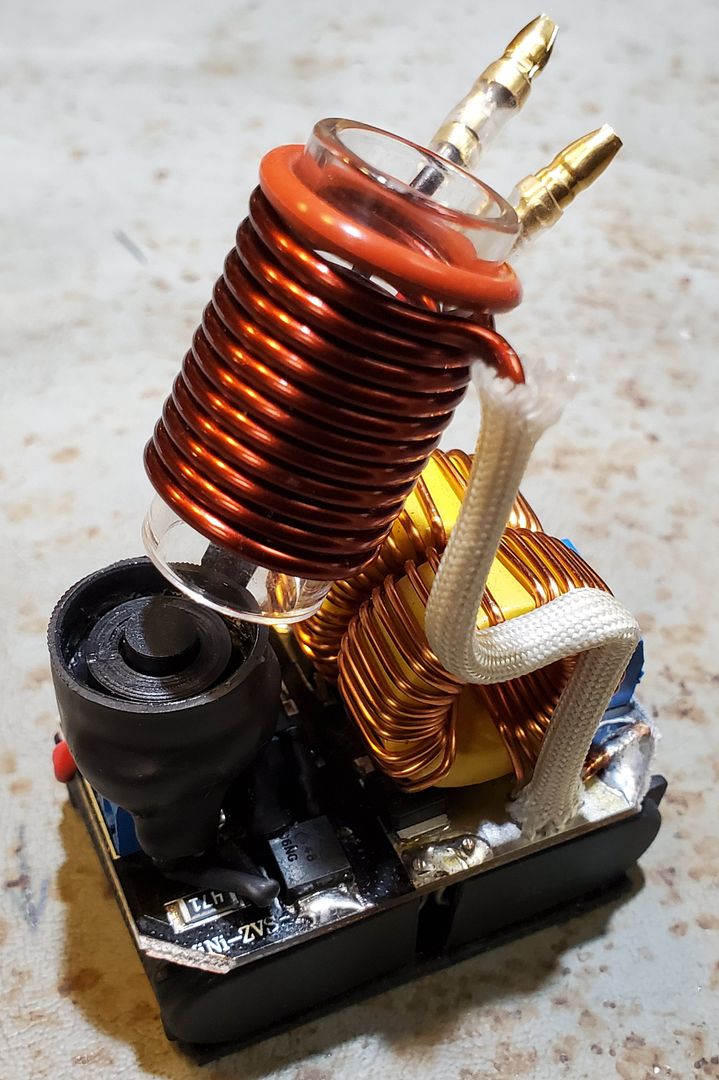

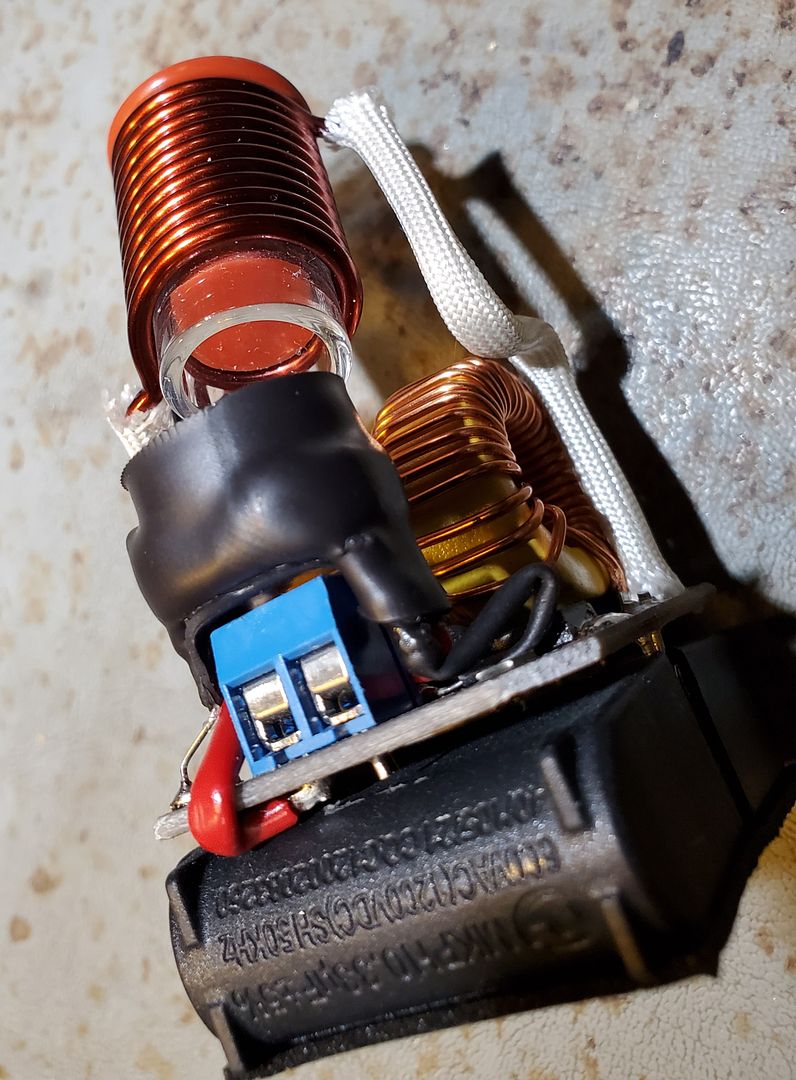

I have an announcement about a new activation switch mechanism I've introduced into my IH heaters. I started shipping new units about a week ago so some will already have or getting this new design.

The current switch scheme is all held in place with the shrink wrap tubing and has virtually no serviceability. Also, those Orings and the pearl heat shield have been the Achilles heel of the whole driver assembly. Understandably, as it is the only moving part. I’ve changed this design 3 other times over the years and think this is the best to date.

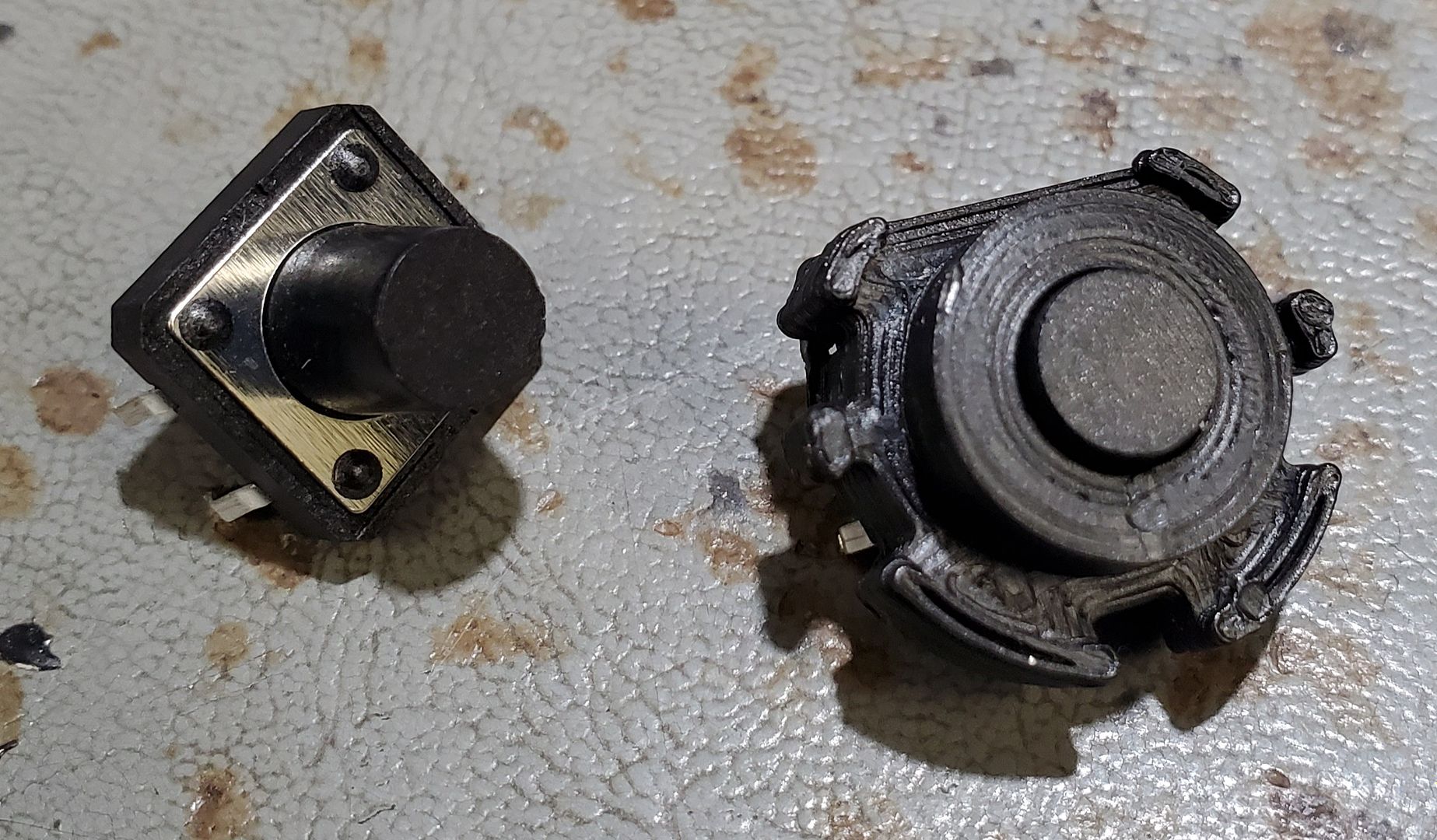

After lots of pondering over how to improve the mechanism. The main step was to make a holder for the switch and LEDs and align the works to the glass tube. I got myself a 3D printer just for this task.

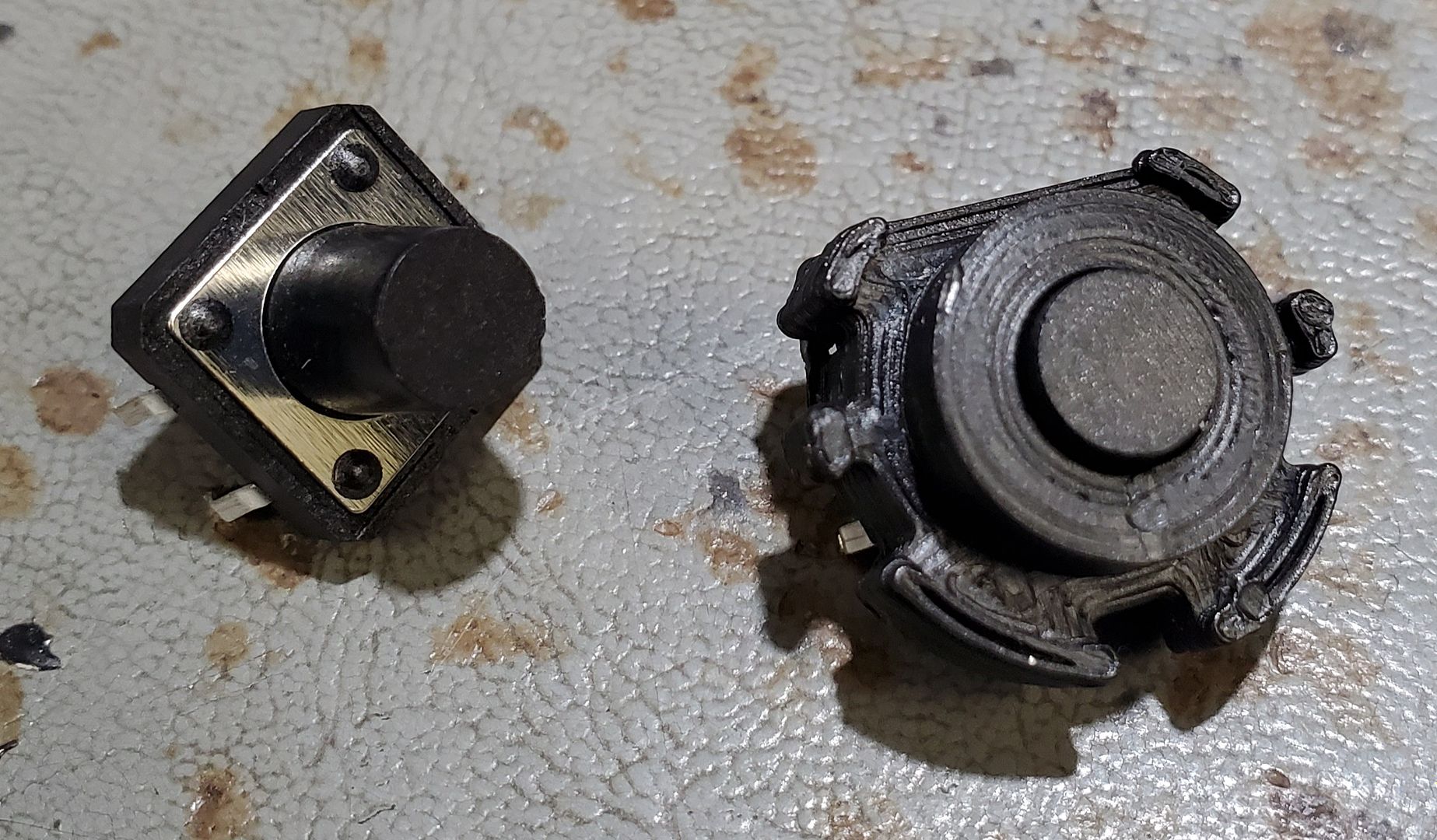

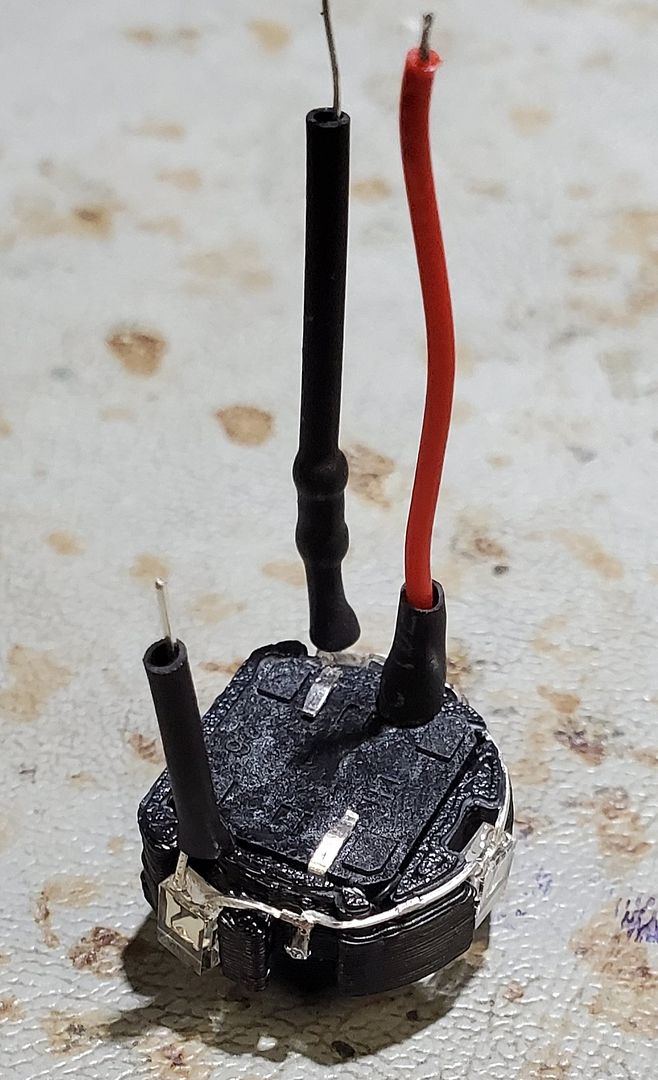

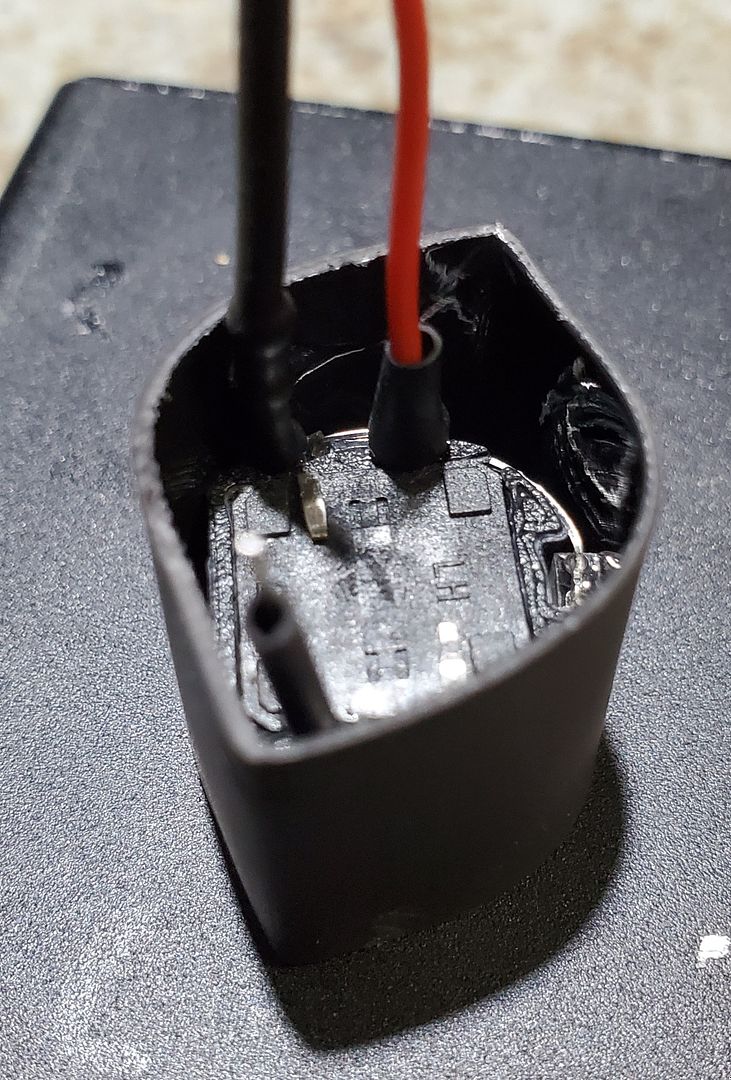

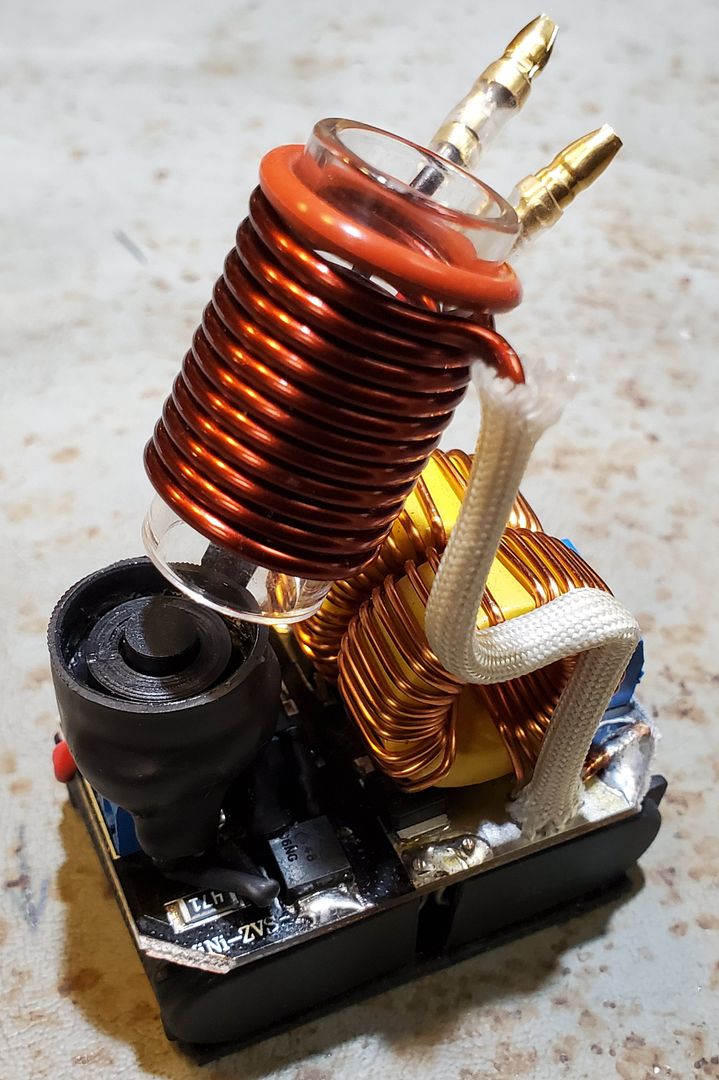

Here are a couple of pics that show the new tactile switch holder part.

This part cradles the switch on one side, holds the LEDs along the sides as well as holds the glass all with the one little piece. This ensures all parts are aligned and secure.

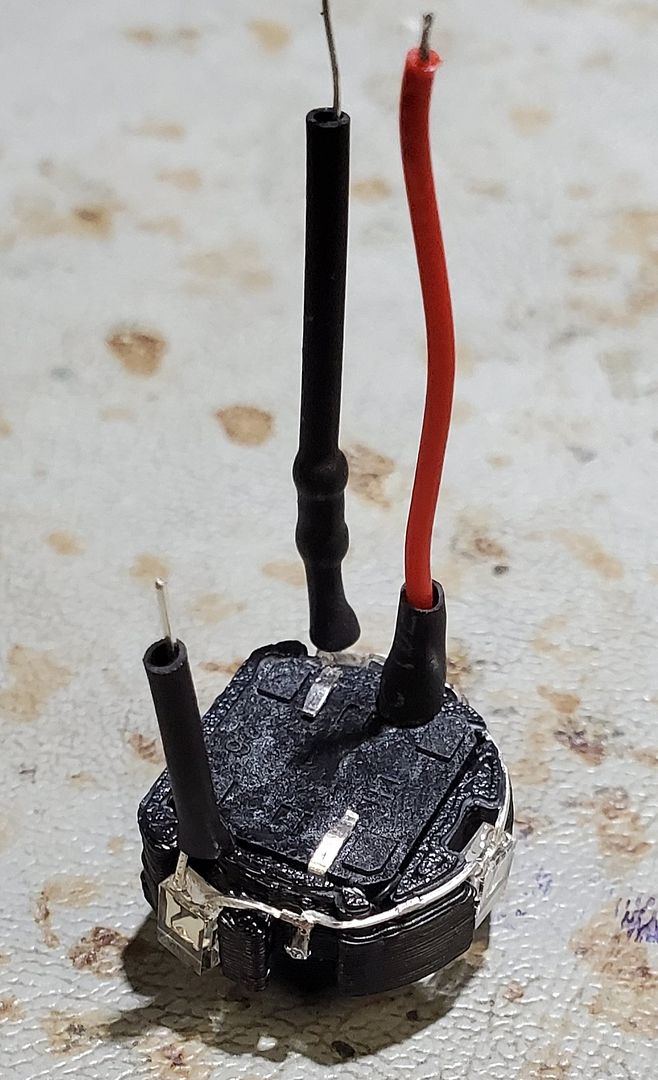

Makes my life a little easier as the LEDs fit into channels and the leads twisted, soldered and tucked away. Same wiring as before. The + side of the diode string is joined to one side of the switch. This attaches to V+. The red wire is the switch out which goes to the FET gate. And finally, the – of the diode string which has a resistor attached inside shrink wrap goes to switched ground. Nothing new, just a cleaner package. Fits snugly into the glass tube.

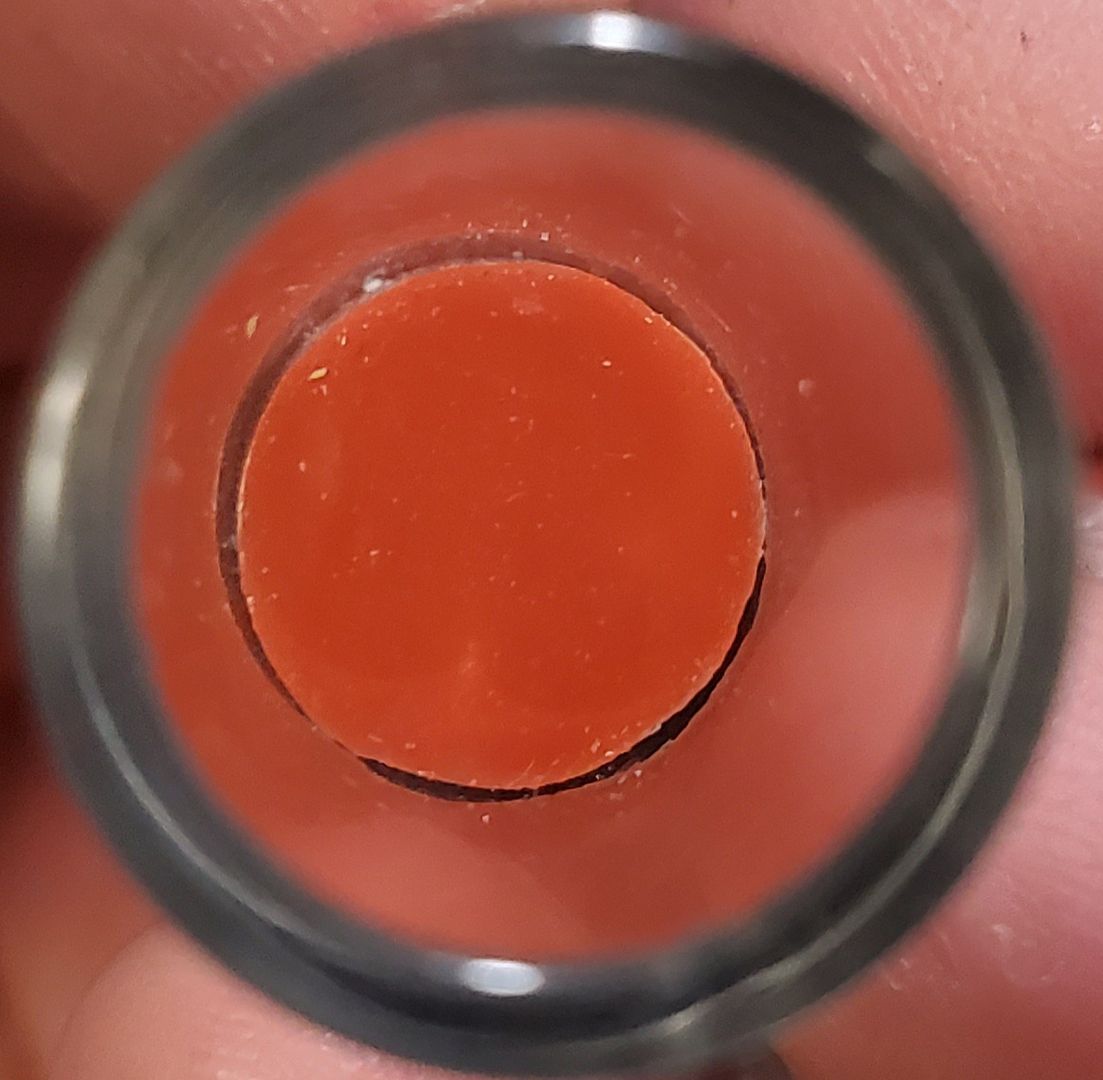

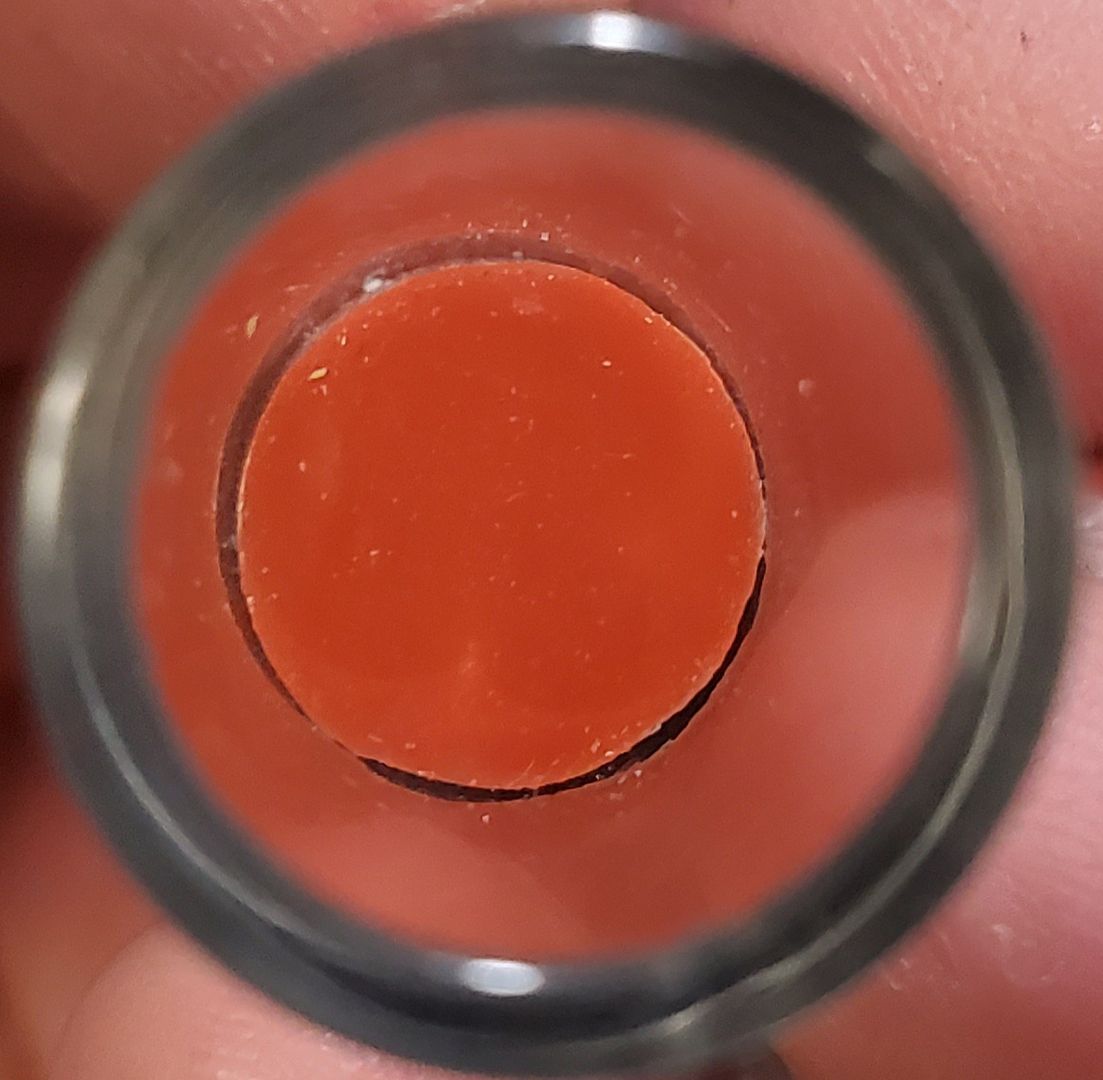

Now here is the biggest change. Kinda mimics the silicone oven glove or cork which has been discussed a few times. In which, one would cut a piece out, and use it for either a spacer or to protect their cap from dents.

These new disks are very dense high temperature, 3 mm thick silicone pads. Rated for 220C continuous use. However, they will melt if a cap is pressed in well past the click and beyond combustion which I’m hoping is a very rare event. Those who use concentrate will have to keep this in mind. They do stay nice and shiny under normal use.

These disks slide into the tube and rest on top of the switch. Now due to tolerances in the glass tube as well as punching out these disks, they are manually selected while assembling such that they have some friction to keep from falling out as well as not being too tight, thus possibly causing the IH to stay on. I can foresee this being the next issue if one isn’t doing cleaning from time to time. Cleaning will be fairly easy as you can just fish out the heat shield and clean it and the glass with Q-tips and ISO. Sizing these disks down if too tight is also easy as you just rub the side of the disk, like an eraser so to take some diameter or high spot down. Doesn’t take much.

The other caution is to NEVER use the heater without this disk in place. The top of the switch will melt very quickly. I’ve started including an emergency spare disk tucked away between those big ass choke coils. I’m sure some will lose or manage to melt theirs.

No O-rings… Ahh!

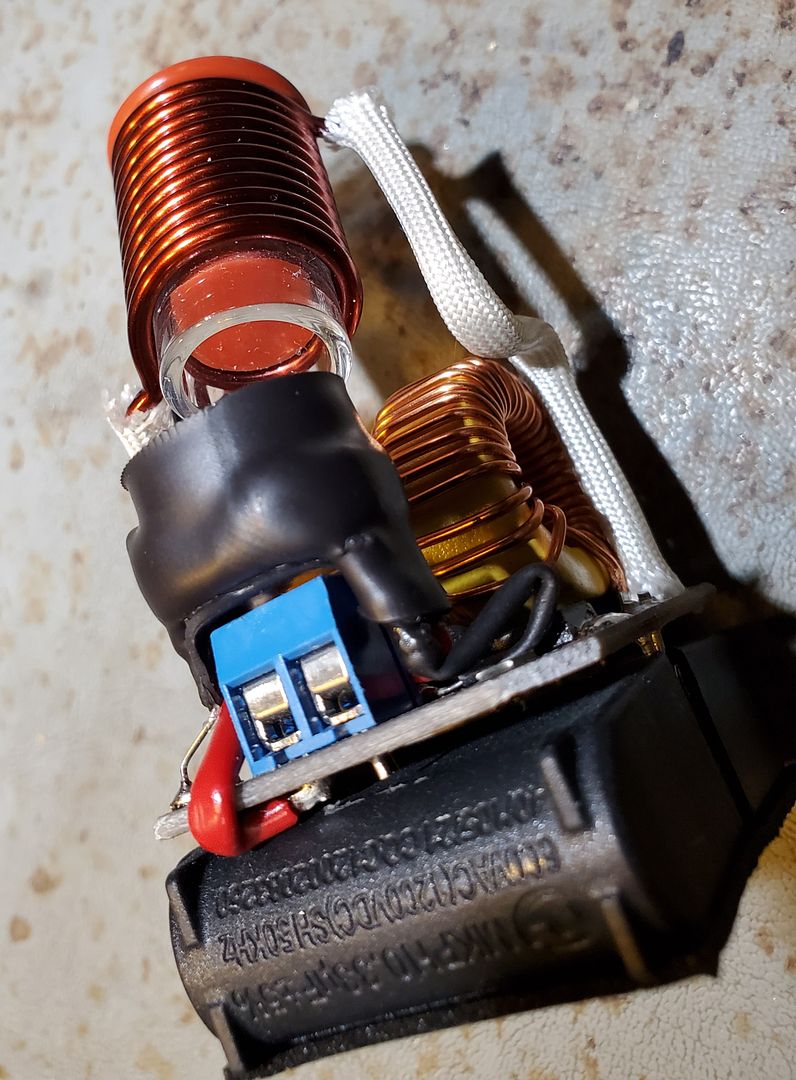

Still have to hold the switch in place from the bottom. That ¾” shrink wrap is great stuff!

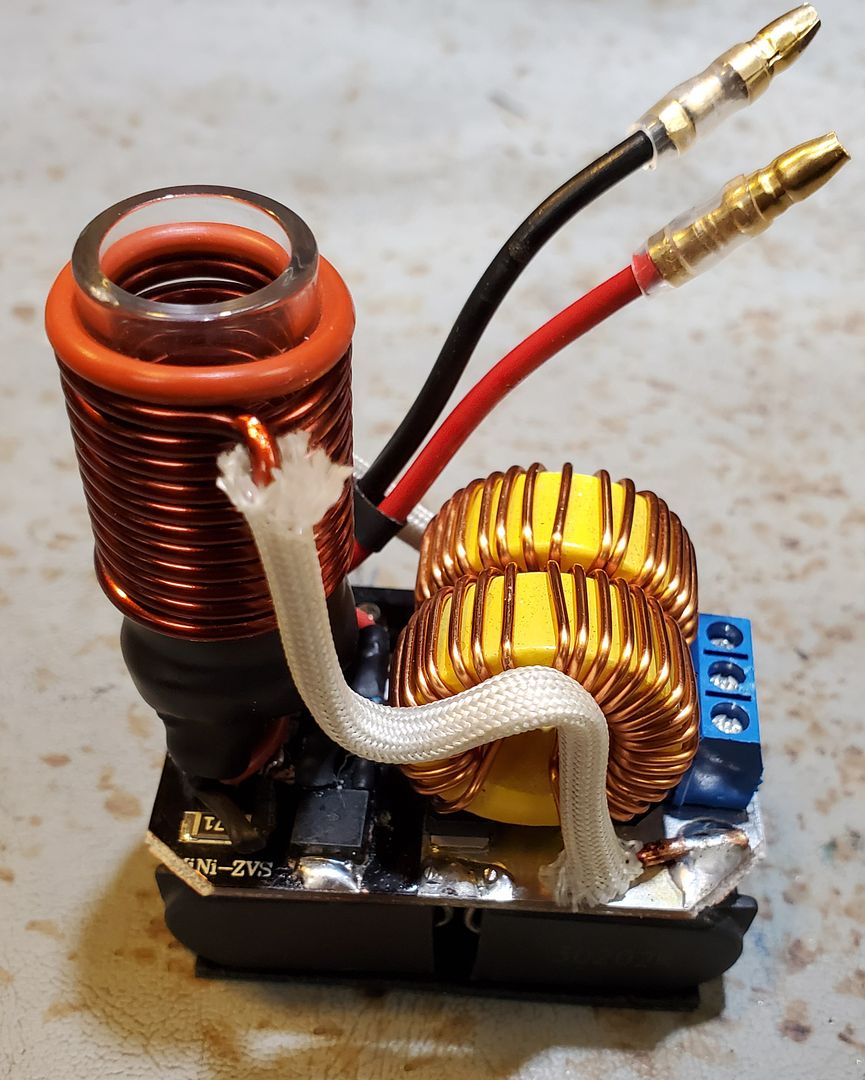

Here it is all ready less the coil. It’s removable BTW. You’ll see a couple of pics down.

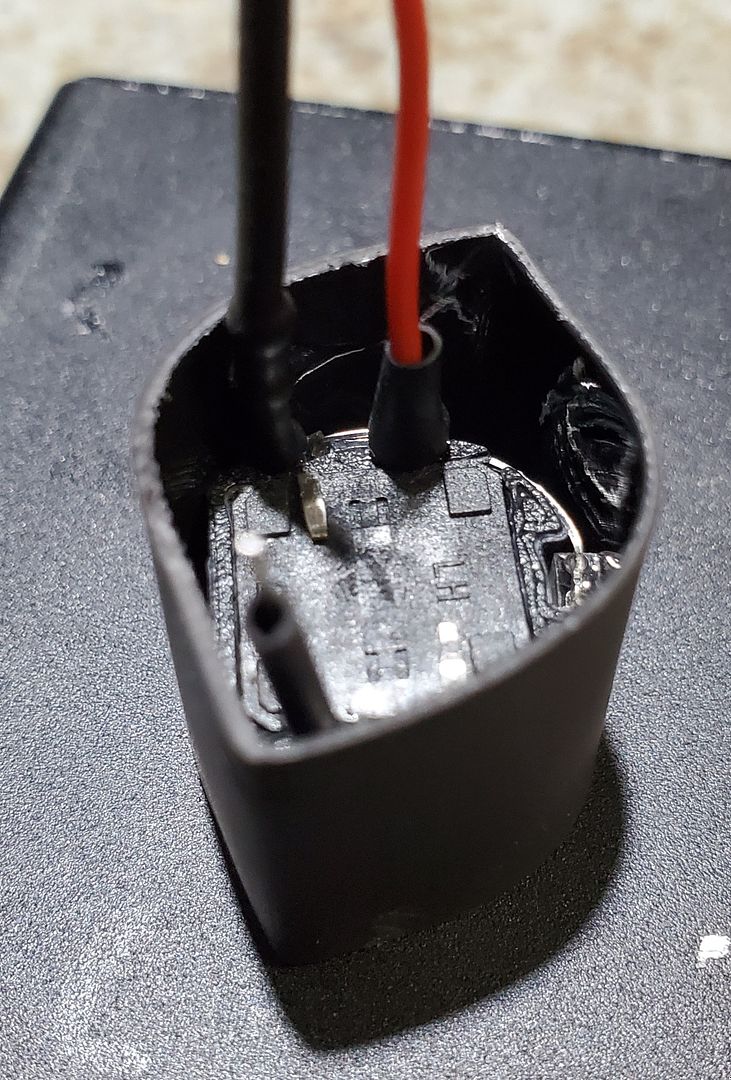

All assembled. Pretty much the same look as before.

What’s this…?

Yes, as a last resort for troubleshooting, glass replacement, or even cleaning, one can grasp the bottom portion and hold against the board, while pulling the upper portion off. Giving the glass a twist to start helps. Also, a drop of water between the coil and glass helps to act as a lubricant if needed.

So it doesn't look much different but has lots of hidden advantages. That new silicone heat shield is great and doesn't melt within the temperature we use. I’m also including a spare that is hidden away between those big coils so they don’t get lost until it may be needed.

The advantages are:

The overall stability of the mechanism.

Has some adjustability by coil not being locked into place.

Better consistency as I no longer have to judge spacings etc.

And no more complaints about dented caps.

The only disadvantage is the possibility of accidental major overheats may melt the heat shield. Fixable by flipping it or replacing it. Can also be replaced DIY with 2 layers of a silicone oven mitt cut to fit.

For current owners, you can accomplish the same “feel” by using a disk cut from an oven glove.

I have had 2 other reports about this. After some digging, it seems that there is no melting happening, no visible or sticky substance. The conclusion seems that there is a little pull from the formulation of the silicone pad. This is a very small pull and only effecting ones that have a very loose-fitting cap. It's hard to remember to tilt some before lifting so the best solution is to make the cap slightly out of round so it holds tighter to the bowl. This is not an uncommon practice for other reasons as well.