Went for a new compacting of the China-offering. Found something interesting in a mistake. I completely spaced the center leg of the two coils. I had it in mind this was just a series pair of coils. It is in fact a center-taped coil with separate cores. What was interesting is that is drew zero current.

That means everything balances on this center tap. At the same time I did some measurements across the 470 ohm control-power resistors. They loose between 8-10.5V!

The compact size lent itself to yesterdays version. Let's see how hard it will be to power that center leg in this con figuration.

Got some ideas about a DIY switch too.

I corrected my brain fart from yesterday and the circuit lives. Took it a few tries to get it to fire and it even went through a reset routine of some kind [balancing routing]. The power died to the LED and came back after some 2-3 seconds. Once the caps got their fill, its been working great.

Now that I've improved the conductive path, this thing's become a beast! And not in a good way. It gets freakin' hot! Two things have changed; 1) I compressed the coil, and 2) have very little voltage loss from the power supply to the IH. Still requires 10 seconds to click-2.

What I was hoping to achieve with the tighter coil is to focus the energy to the bowl. I suspect it is doing that and lessening the heating of the cooling fins. And I will reiterate again - MOMENTARY SWITCH! You don't want to leave this on for long. It will burn you! Sessions with cutting power except to heat the VC is still palmable.

I am now delivering 11.5V at full load of the available 12V. I am on the edge of a 2 amps current draw without load. With a stainless steel VC, I get almost 8 amps of current flow. I also noted that when I turned the voltage down, current went up, and the unit actually went through a reboot cycle. That is so odd since there is no processor.

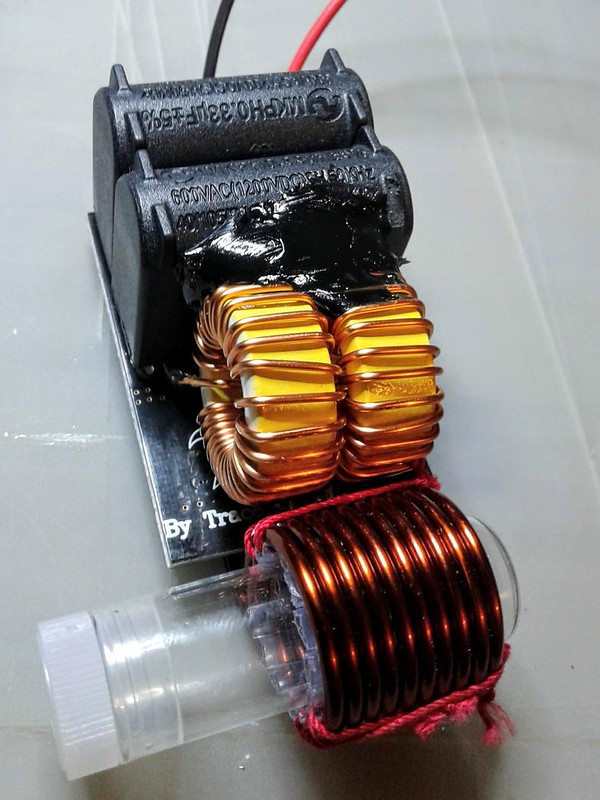

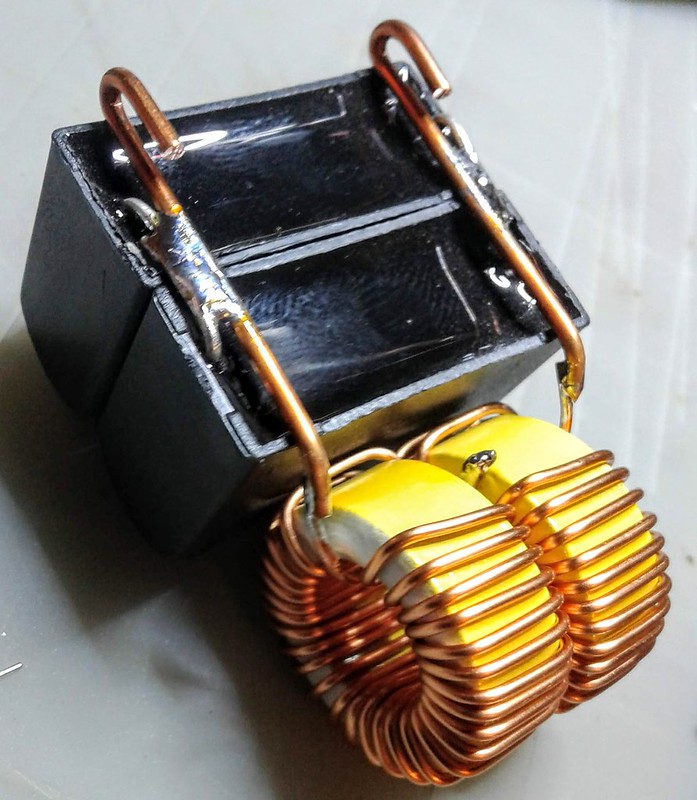

As to the build. Again, the goal was compact design and a compact coil. I have no idea how badly this thing causes internal losses due to this configuration. These coils have magnetic fields that can affect other functions.

The final size ended up being 3"x 1.5"x1.38". The bare wire shown in the images is 14 awg. 16 awg should be sufficient at these short runs.

Pairing the caps;

Merge coils;

The center-tap I forgot - This joins up with the +in pad. Sorry for the shitty image quality.

And the final merging to the board; There is room to reach in for the coil's center-tap lead-wire.

Shape and locate the coil to your liking and solder it to the board. Add power wires and done.

Now to get some switches.

For a real-time IH, the power will need to be reduced significantly. This means less turns on the inductors. Less coil turns and less diameter, and fewer wraps around the ferrite core. I have one more circuit coming and I'll see what it takes to get this down to 1/2 the output.

These thing do work proportionally to the power provided.

These thing do work proportionally to the power provided.