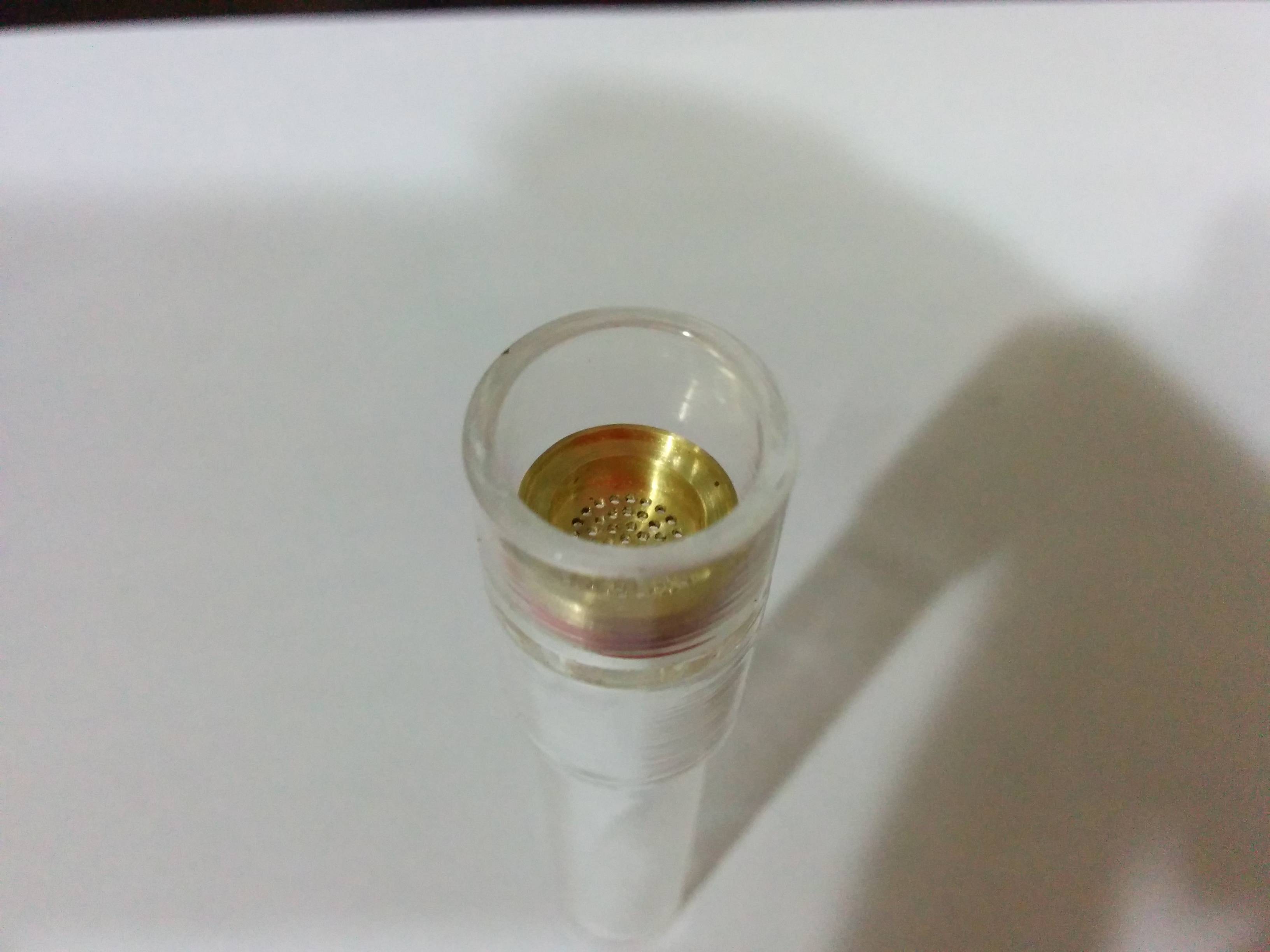

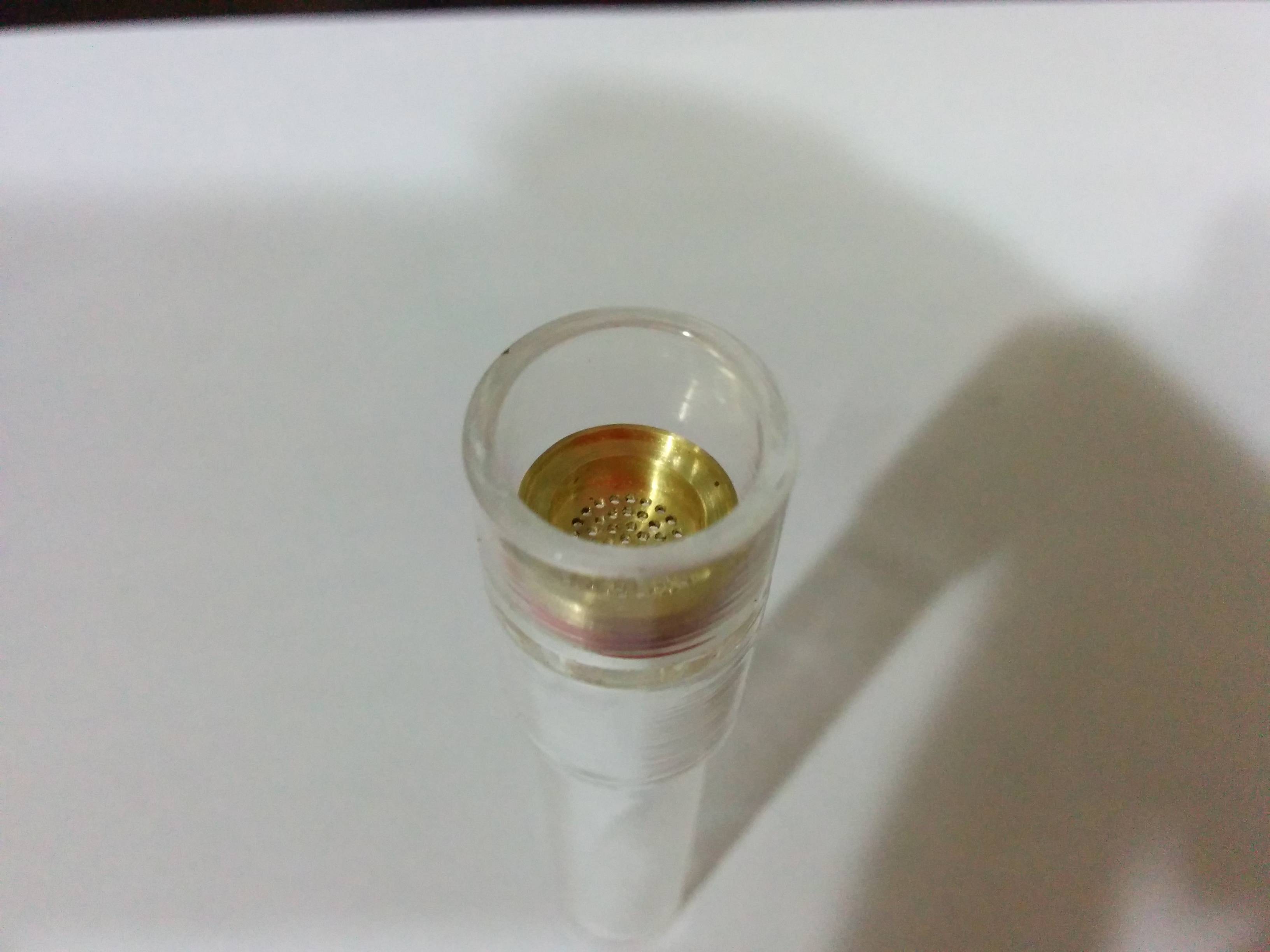

Holes are small enuf that sticky resin will create blockage lickity split.

That well could be, hopefully hole size was experimented with an a useful size selected. It doesn't help that the material used (brass) is a great heat sink. That is it'll be cooling the vapor (a good thing) but in doing so so rapidly will also increase local condensation.

Hopefully, due caution was used in material selection WRT to safety. Typically you'd use "free machining brass" for such things otherwise since it (as the name implies) is easier to machine. However, the traditional way to do this is to add

Lead to the brass. This is why the rules for making plumbing fixtures were changed, we were poisoning each other washing our dishes and getting drinks from sinks and stuff.

Therefore, I recommend if you get one of these attractive looking guys you also get a Lead test kit (hardware stores, Amazon, etc) and test for Lead. A cheap, simple, effective 'swipe test'.

OF