lol what?! i just liked 20ish new messages!

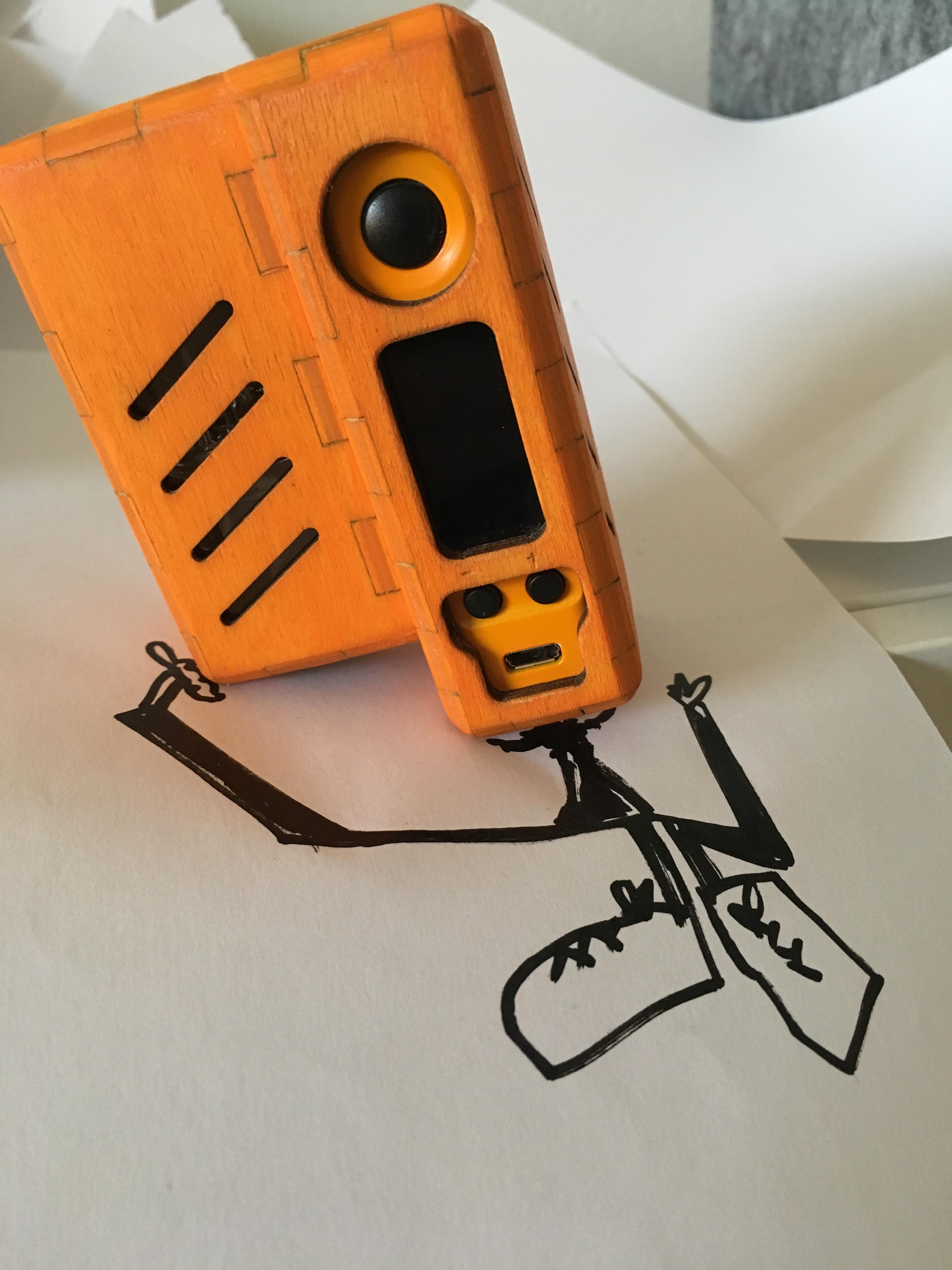

@vapen00b so glad, that it finally landed! stunning pics! you make it look way cool! that brown stem looks great for it. please report about other stems you might be able to try on the tubo

i also need to share a very recent story!

@stickstones contacted me 2 days ago, saying he ran into a problem. i freaked a bit!

when he was going a bit harder on his tubo, the display kept telling weak battery, ending in a low battery message mid draw, even tho his several batteries were charged full.

we were guessing and checking a few things. at one point we even suspected heater degradation, a f-ing worst case scenario

.

i sent some instructions on reflashing the firmware, but since it resets all values we ended up skyping to try to get the first tubo in the wild back on track.

long story short: its working again! i am very releaved!

from a video he made of the issue, i suspect the resistance got altered somehow and caused the mod thinking it cant reach temperature. so it tried to push everything it got but ended up going too heavy on the battery.

looking back, adjusting said resistance should have done the trick as well. i do stand by my heater, but my oldest prototype (that gets abused very hard and survived plenty of stress tests) is only 5 months old so i really cant say much about long term reliabilty.

anyways i am working on a little informative site for exactly such information.

so glad all worked out!

BTW: regarding warranty: i am no asshole, but at this price i cant go replacing units easily, if anything should ever happen, you will have to argue hard with me

officially the evic is only warrantied for 90days by joyetech. i am thinking about including an outspoken/written warranty for everything done by me, but this will reflect directly on the price!

To the degree temp control and the aesthetic is what sold me on it. Cannot resist.

to be fair: i send it out with 5degC/10degF temperature increase. anyone can go to 'menu>interface' and set 1C5F to on, to have 1degC and 5degF steps.

the reason i chose not to have it preset like this is that you can change temps a lot faster in say 5degC steps instead of clicking the button a lot.

and since we are being fair. the temps are often not spot on the set temp, you will see over and undershooting while drawing of up to 5degrees.

Oh i forgot, are the heater coils steel too?

Hm.

What are those heating coils made of, I heard they were SS Clapton wire coils... ?

Curious.

yes, they are three parallel coils of twisted 316L stainless steel.

Sorry mate but I got to disagree. First, temp control via resistance change check it to me less accurate than using a dedicated sensor. The measurements on the evic VTC mini are pretty wild to start with...

i have to kind of disagree here. i have some thermocouples here and they do work but are slow in temperature measurement and cant be read to many times per second. maybe with thermistors the closed loop would work better, but then we go again, where do you place the sensor? still you have a rather big delay in feedback compared to the here in place system.

by calculating temps from resistance (which can be measured very accurately by the device imo, 0.001ohms, given connections are tight etc) the coils stay at the same temps regardless of draw speed. the coil is both, sensor and heating element!

there is still some variable on the way to the herb and in the herb. but like this you can be sure that the temps will be a tiny bit lower a little away from the coil. in a way i find this control superior to a bigger closed loop system with proper temperature sensor, mainly because of delay.

.

.