jambandphan03

in flavor country

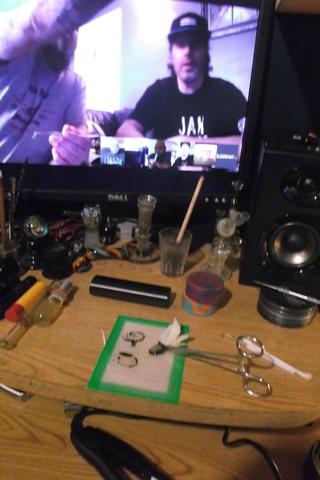

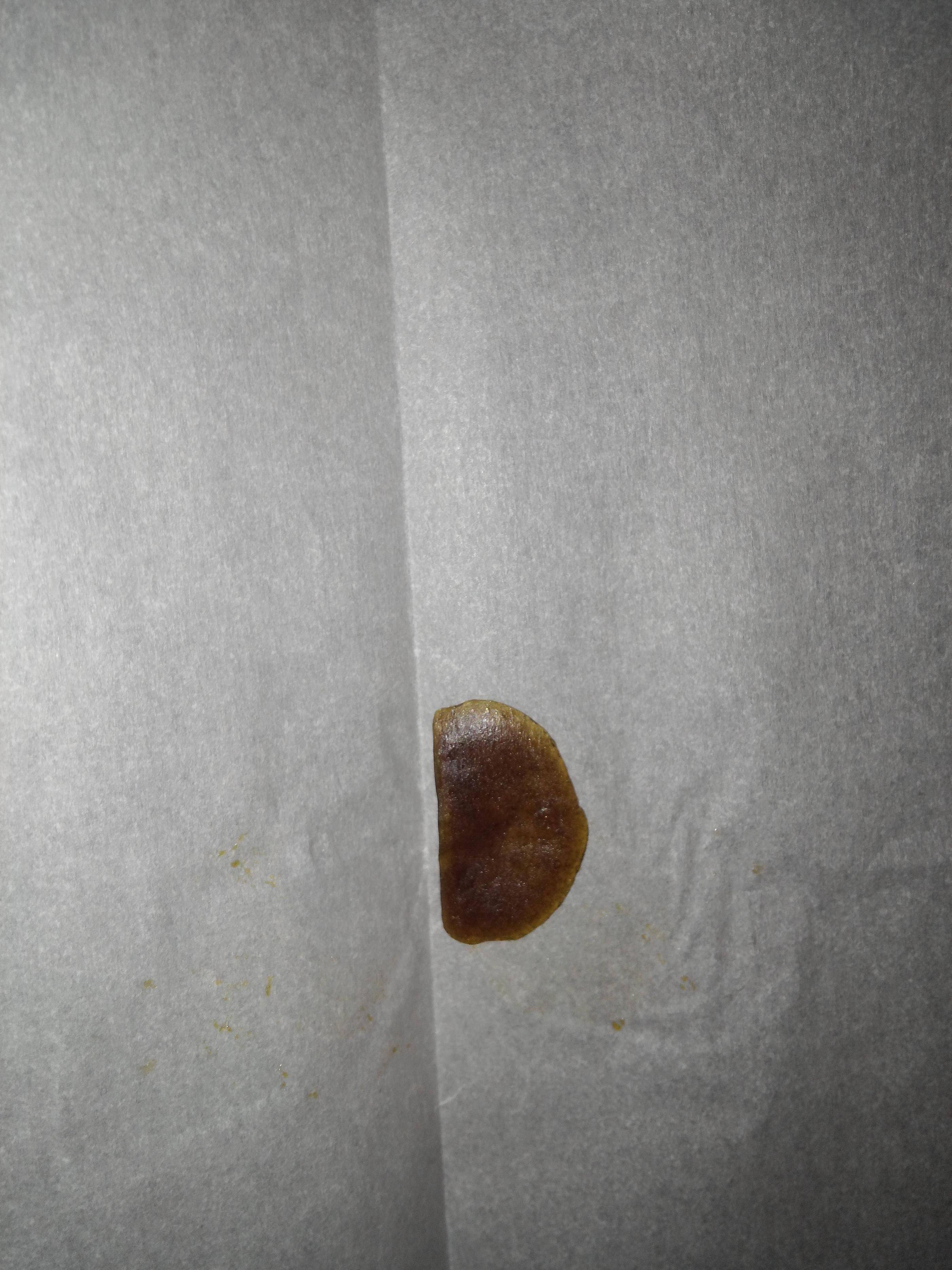

I squished some 5 year old bubble hash I've had put away, and got a pretty nice yeild of some really dark shatter... during Hash Church  This pic is my first press, I gave it a couple more, got oil each time... put the left over hash puck in an alcohol soak that I have for future topical use. This hash was already almost black and hard as a rock, took some time to press flat.

This pic is my first press, I gave it a couple more, got oil each time... put the left over hash puck in an alcohol soak that I have for future topical use. This hash was already almost black and hard as a rock, took some time to press flat.

This pic is my first press, I gave it a couple more, got oil each time... put the left over hash puck in an alcohol soak that I have for future topical use. This hash was already almost black and hard as a rock, took some time to press flat.

This pic is my first press, I gave it a couple more, got oil each time... put the left over hash puck in an alcohol soak that I have for future topical use. This hash was already almost black and hard as a rock, took some time to press flat.