-

SCAM WARNING! See how this scam works in Classifieds.

-

The Frolic by Limelight Giveaway has started!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rosin Technique....Easy DIY Solventless

- Thread starter darkrom

- Start date

EpicNameGuy

Well-Known Member

Nice! I'm waiting for his new 4x4 frame personally

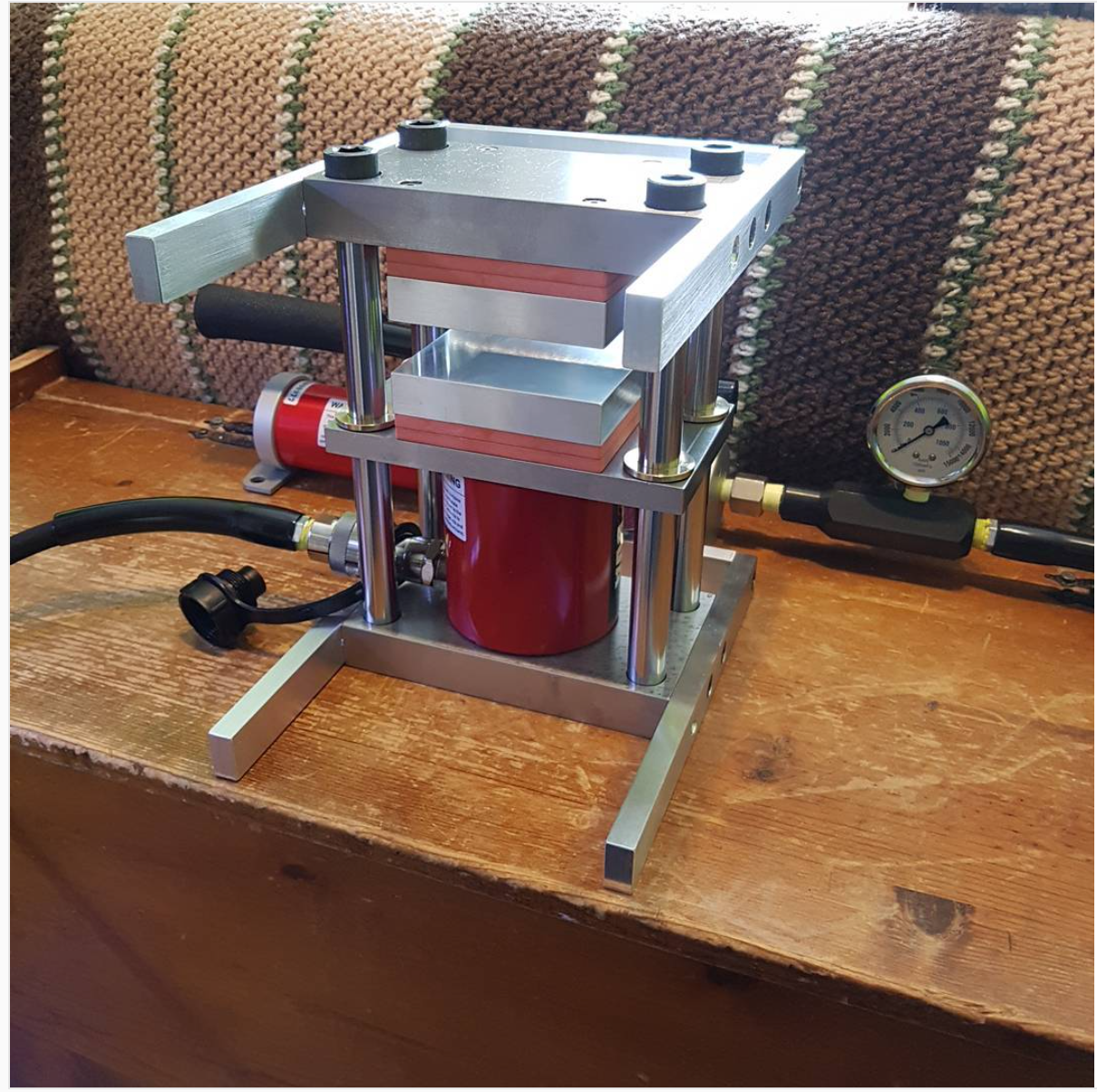

TimeWizard is killing it right now! Im so pumped to try out some true drip tech without having to spend 5 grand on an elysian press. He's got a lighter and more compact design than elysian and it packs the same 20 ton ram so it has higher PSI's too. I'm in love with this thing I could go on and on

I believe TW's press comes with a 10-ton. It has an option for 20-ton if you buy the parts and install it yourself. Could be wrong but that's the last he told me.

Caelar900

Well-Known Member

@EpicNameGuy In the comments section on one of his more recent posts, I think of the finished 4x6, he said that he would be selling the frames and hydraulics separately. He would sell the preassembled frames with either 4x6 ($1200) or 4x4($1000) plates and controllers included and installed. You would need to buy the low profile hydraulics kit separately though which is about $600. Both models are designed to work with either 10 or 20 ton kits. I know sunfire said on one of the posts that he thinks the 20 would be overkill for the 4x4 but I respectfully disagree

@Oilslick... are you guys working on any new oil storage solutions?

some of us here are worried to use silicone due to it being porous and can cause issues to the oil being stored. in turn issues for the end user.

anything coming that isnt silicone?

O yes! The very latest is the FEP sheet which is very similar to PTFE but scary nonstick and more durable, and clear.

Even distillate can sit in it for months. Add this hits the market it is going to change everything again.

Terpene rich concentrates, and a budding connoisseurship in the community have made this so much more relevant than it would have been even a few years ago.

Caelar900

Well-Known Member

The very latest is the FEP sheet which is very similar to PTFE but scary nonstick and more durable, and clear.

Is this a material that you guys are going to be using for solid storage solutions (pucks and such)?

We have an entire Willy Wonka room full of cool things we haven't revealed, and likely won't ever. Fep and ptfe containers are among them...until there's a market for a hundred dollar slick stack.Is this a material that you guys are going to be using for solid storage solutions (pucks and such)?

Two years ago there was no mass awareness or market for terpene preservation...so never say never.

Caelar900

Well-Known Member

Mass market, probably not anytime soon, but I would definitely take one!until there's a market for a hundred dollar slick stack.

or 5....

The Beagle

That wasn't a microdose

@Oilslick do you have an official distributor for the EU? I've got a roll of you new paper and it was not exactly cheap to get here but I found out on this thread that it's not suitable for hot pressing (BTW, I know it's more a seller fault than yours but it's absolutely not clear by the packaging nor product description that's not ok for rosin).

Doktor Dub

Well-Known Member

A very good Idea would be to print all suitable uses clearly on the Products - don t want to be a Smartass, but that would solve some Problems and would be good for Oilslick as a Company.

You aren't being a smartass art all! Appreciate that input, we get it allot.A very good Idea would be to print all suitable uses clearly on the Products - don t want to be a Smartass, but that would solve some Problems and would be good for Oilslick as a Company.

With the various ways people employ our products it's tough to clarify every use without "giving instructions to commit a felony" (fed talk) on the packaging.

For instance: Slick Sheet (ptfe) is by far the favorite for directional flow (burrito tech) rosin. It's also wonderful for low psi kief extraction. In those circumstances it's fantastic for rosin.

We sell thicker PTFE on a bulk roll just for that market. Around 10000 feet a month right now.

If you put that same PTFE in a 20t+ press with a small bag of flower...crank the temps..it will deform and be..not so good for rosin.

In almost every case we are limited by what we can put on the package (legally) and sell everywhere in the world. And to our dismay...folks will use whatever we make for whatever they will.. even against our advice (don't blast into silicone pads!)

These days we keep a live chat going on the website 12 to 18 hours a day. And take phone calls through one department just for technical use questions.

I welcome anybody to get in touch with their most detailed questions for answers in private, or on forms like these. Oilslick generally prefers not to push an agenda onto the extraction community...but instead to listen and learn what it needs. As this community grows we've learned that whatever we write on the box, someone will come along and surprise us. Often to our benefit...sometimes to our delight...And sometimes to our consternation

Vapodudule

Well-Known Member

I would like to stress on the safety of rosin tech in general.

Everyone will agree that we chase any solvant to be a danger but we brought other dangers:

-heat: this danger is pretty common

-pressure: the one we can look at in the eye very close. the problems will occur right now or in a long time where fatigue stress and breakage play. I specifically imagine a teeth, bolt or plate breakeage under pressure that could throw hot metal pieces very fast in your face looking your squish.

It brings me to means of prevention: gloves and safetyglasses.

WEAR SOME SAFETY GLASS, ROSIN IS DANGER ALSO!

cheers.

Everyone will agree that we chase any solvant to be a danger but we brought other dangers:

-heat: this danger is pretty common

-pressure: the one we can look at in the eye very close. the problems will occur right now or in a long time where fatigue stress and breakage play. I specifically imagine a teeth, bolt or plate breakeage under pressure that could throw hot metal pieces very fast in your face looking your squish.

It brings me to means of prevention: gloves and safetyglasses.

WEAR SOME SAFETY GLASS, ROSIN IS DANGER ALSO!

cheers.

Last edited:

jl420

Well-Known Member

I have a question concerning using Oil Slick mats for Rosin pressing. I've been using RAW parchment paper which does a pretty decent job but I get alot of tears and I always feel I'm missing spots. I run my press at 240 C and press time is usually 10-15 seconds now when I use the Oil Slick mats should I increase heat and press time? Any info is always greatly appreciated...

Caelar900

Well-Known Member

I dont think you'll see many people pressing with the pad/slab/duo's around here anymore... It was a thing there for a while back in the early days but most people use oilslick's other products now as they are known to just work a bit better. I recommend these.

But to answer your question. Yeah, the silicone is going to take a little longer to equalize to the plate temperature so a little extra time or heat or both can be used to compensate for this. Like I said there was quite a bit of discussion about this near the begging of the thread. A quick search for Oil Slick mats yields about 9 pages worth of results lol.

P.S. From what I remember just don't fold them!

P.S.S. Are you really pressing at 240 Celsius? Are you using a hair iron? If not you should really try turning down your temps a smidge.

Hope this helps and happy squishing!

But to answer your question. Yeah, the silicone is going to take a little longer to equalize to the plate temperature so a little extra time or heat or both can be used to compensate for this. Like I said there was quite a bit of discussion about this near the begging of the thread. A quick search for Oil Slick mats yields about 9 pages worth of results lol.

P.S. From what I remember just don't fold them!

P.S.S. Are you really pressing at 240 Celsius? Are you using a hair iron? If not you should really try turning down your temps a smidge.

Hope this helps and happy squishing!

Last edited:

Looks like Caeler has it covered. In brief, silicone is flexible...it stretches when pressed, and will eventually break.I have a question concerning using Oil Slick mats for Rosin pressing. I've been using RAW parchment paper which does a pretty decent job but I get alot of tears and I always feel I'm missing spots. I run my press at 240 C and press time is usually 10-15 seconds now when I use the Oil Slick mats should I increase heat and press time? Any info is always greatly appreciated...

Super soft squish of keif? Probably ok. We just don't recommend.

just to edit what i think Caelar was meaning to link to. I actually just ordered these myself based on comments from @Oilslick

Sorry to ask what will be repeat questions, but there's a lot more here than I could ever read! Just did my first press. .5g total/two small nugs, pressed in parchment with pressure clamp and Remington only produced one modest dab. Is that right or low? Will try some different flower later, but wanted to check for any obvious pointers. Straightener was set at 300, as I'd read lower is better. Anyone advocate for bumping the heat a bit for higher yield? I held for a count of five seconds or so, should I go longer? ALso it seems like grinding your nug before flattening would help to my mind, but I haven't seen people doing that?

Thanks

Thanks

herbivore21

Well-Known Member

I would never press silicone mats with high pressure, I've had my oil slick mats flake and the green part delaminate over time before just from using the mat as a surface for my rig with no heat or pressure applied!!! Everyone here knows I regard oil slicks products as the best such products too! Silicone has its limits is all. I only use such mats to keep my rig on now, I do not put concentrates on silicone mats at all for any period of time - especially not sticky full melt!Looks like Caeler has it covered. In brief, silicone is flexible...it stretches when pressed, and will eventually break.

Super soft squish of keif? Probably ok. We just don't recommend.

The old school slick wrap is best IME for rosin even if I understand that to be a matrix of cellulose with silicone (@Oilslick can no doubt clarify this). Obviously this is only good for single use, I would never repeatedly press on the same collection material no matter what it is. PTFE is good but you gotta be really on top of your technique as I find that PTFE can tear/crack at the wrinkles/folds during pressing easily. IME nothing is perfect for rosin collection yet, but then I haven't yet used the new Oil Slick rosin paper

Sorry to ask what will be repeat questions, but there's a lot more here than I could ever read! Just did my first press. .5g total/two small nugs, pressed in parchment with pressure clamp and Remington only produced one modest dab. Is that right or low? Will try some different flower later, but wanted to check for any obvious pointers. Straightener was set at 300, as I'd read lower is better. Anyone advocate for bumping the heat a bit for higher yield? I held for a count of five seconds or so, should I go longer? ALso it seems like grinding your nug before flattening would help to my mind, but I haven't seen people doing that?

Thanks

300 is too high. The lowest setting on my Remington is 310 and this is what i do. Let it get up to temp, turn it off, and let it cool while fold your parchment and presquish your nug (about 30 secondsish). Get as much pressure as physically possible and press for closer to 30 seconds. Higher temperatures cook out the good flavors and always seem to come out a lot more gooey IME. Grinding is a bad idea, I believe because you want to keep the trichomes intact as much as possible and would definitely end up with material in your rosin.

On another note, this happened last night...

http://imgur.com/a/Rw5tL

@%#$@%% why can i not embed an image??

Last edited: