-

SCAM WARNING! See how this scam works in Classifieds.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

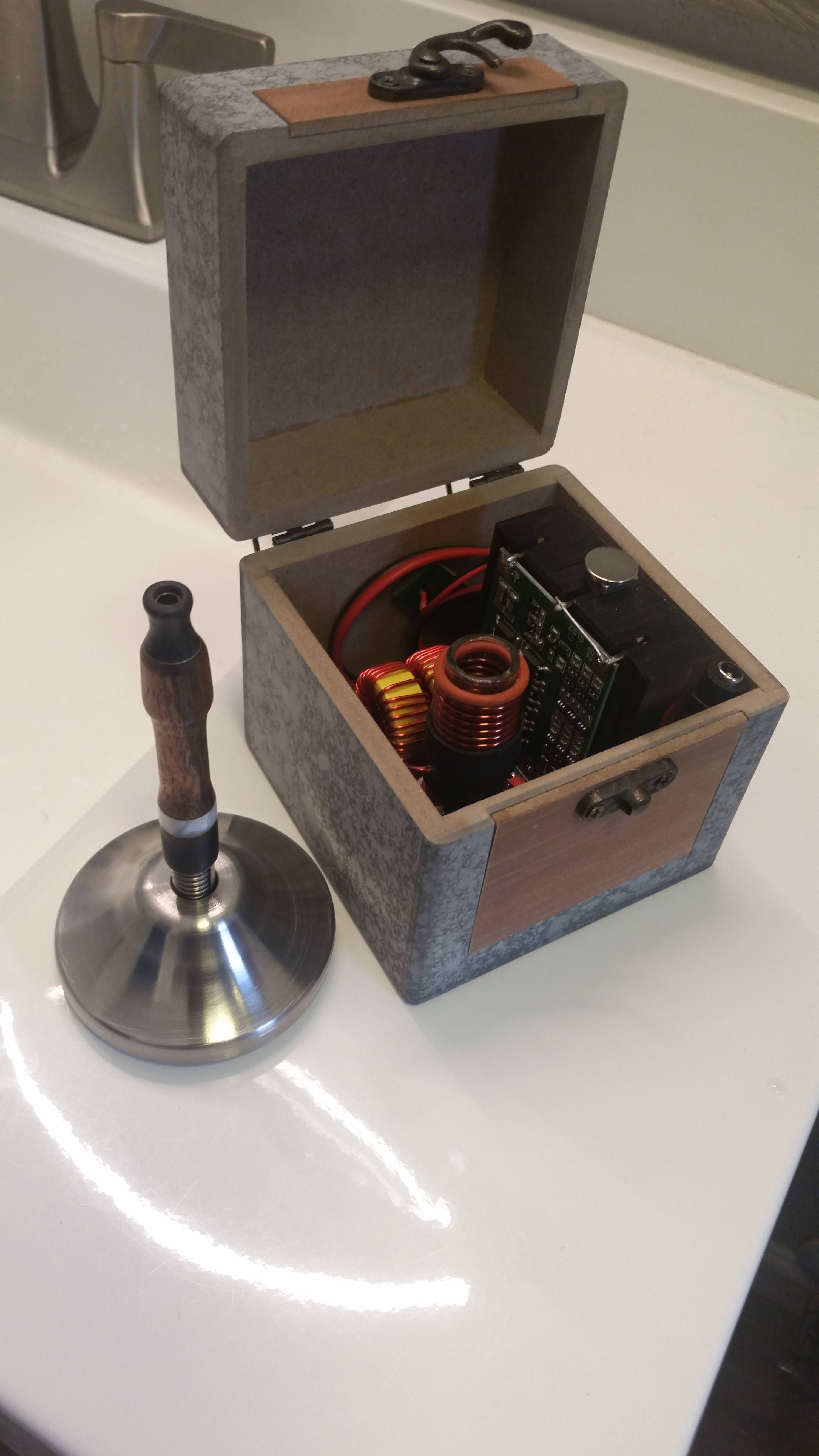

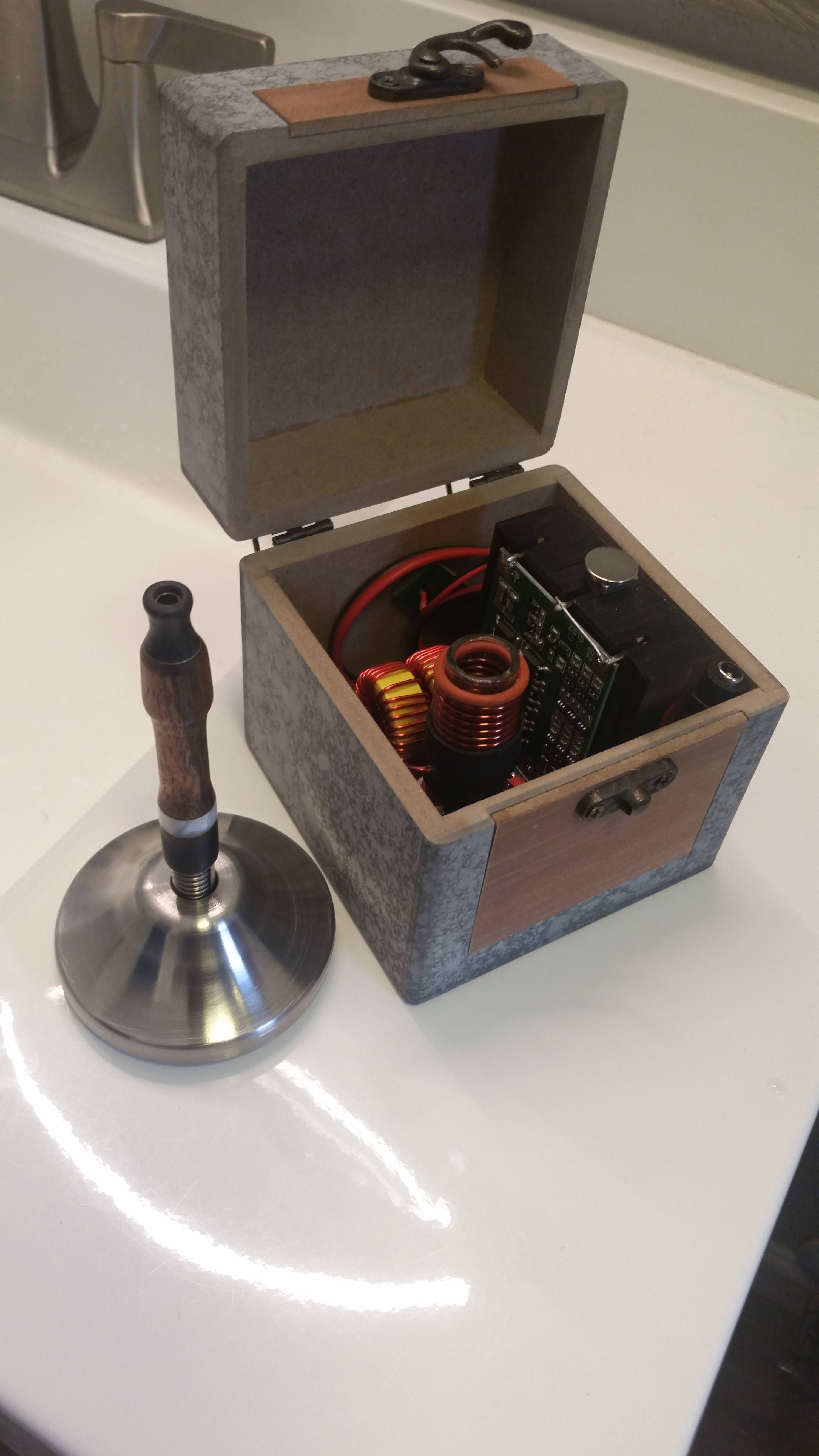

VapCap Induction Heater for Desktop and in Car Use

- Thread starter Pipes

- Start date

-

- Tags

- dynavap induction heat vapcap

You should have gotten a tracking number with the shipping notification. If you can't find it, shoot me a PM and I'll dig it up. Use USPS for their tracking information now as has likely left Canada.

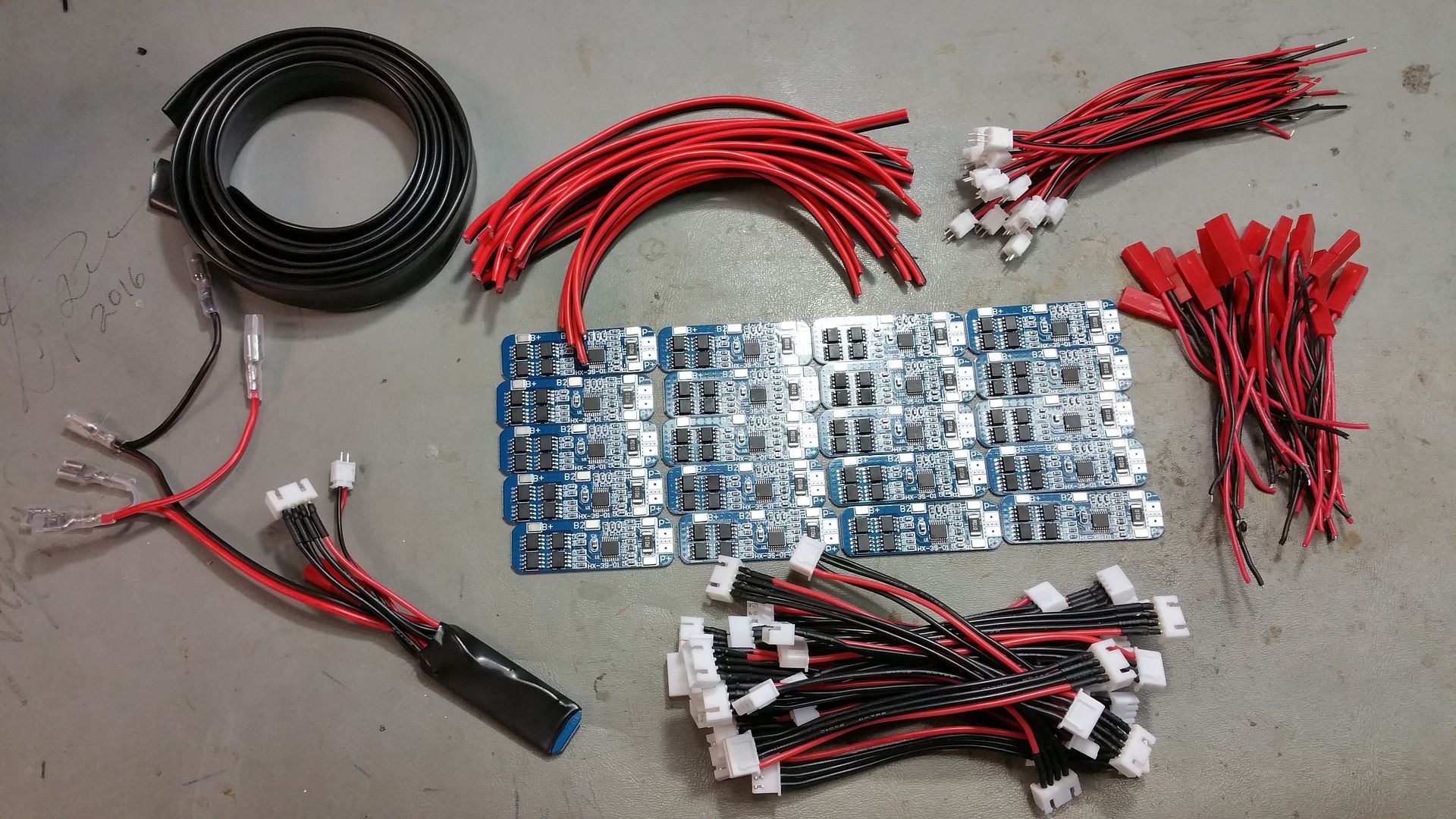

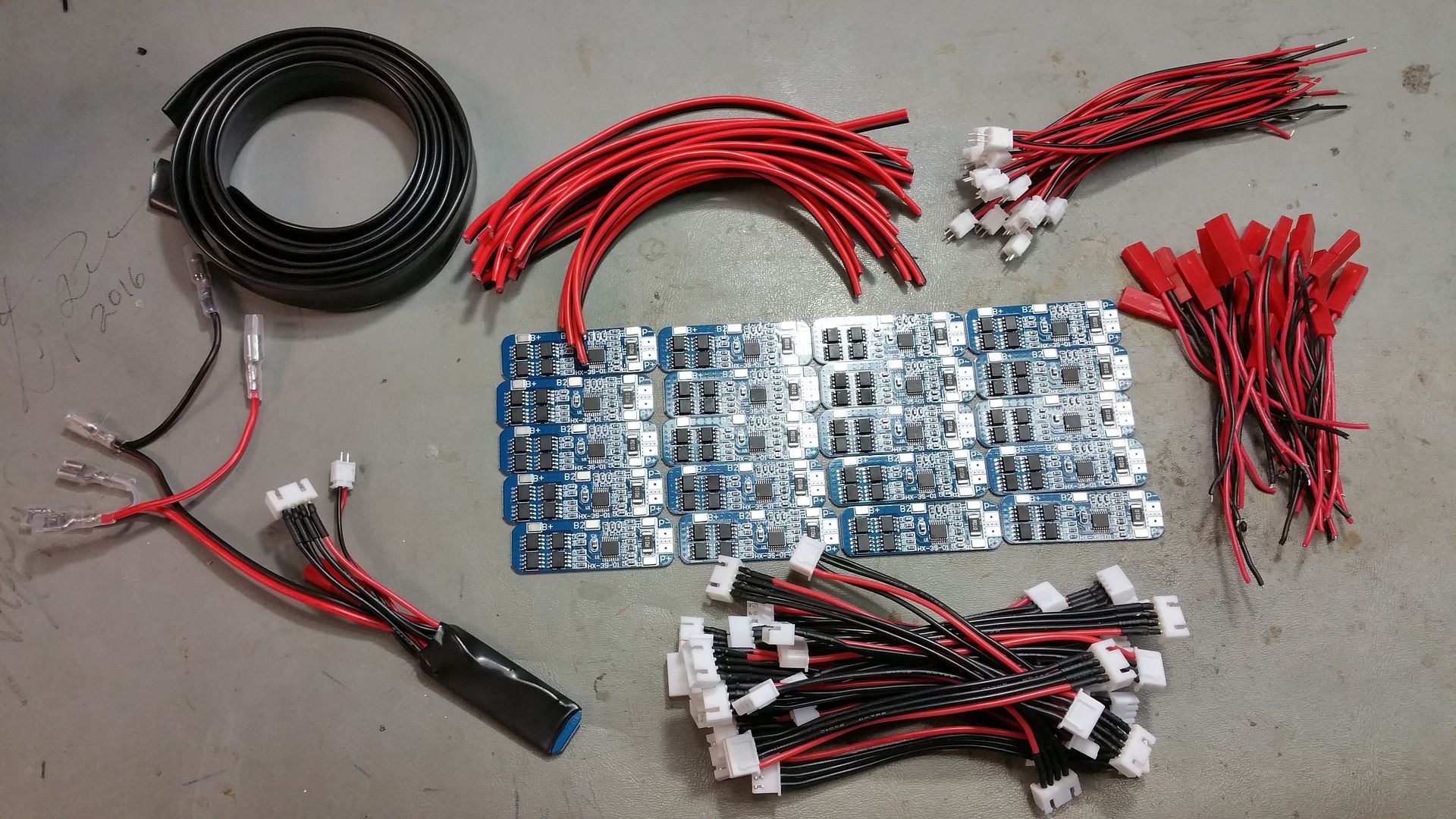

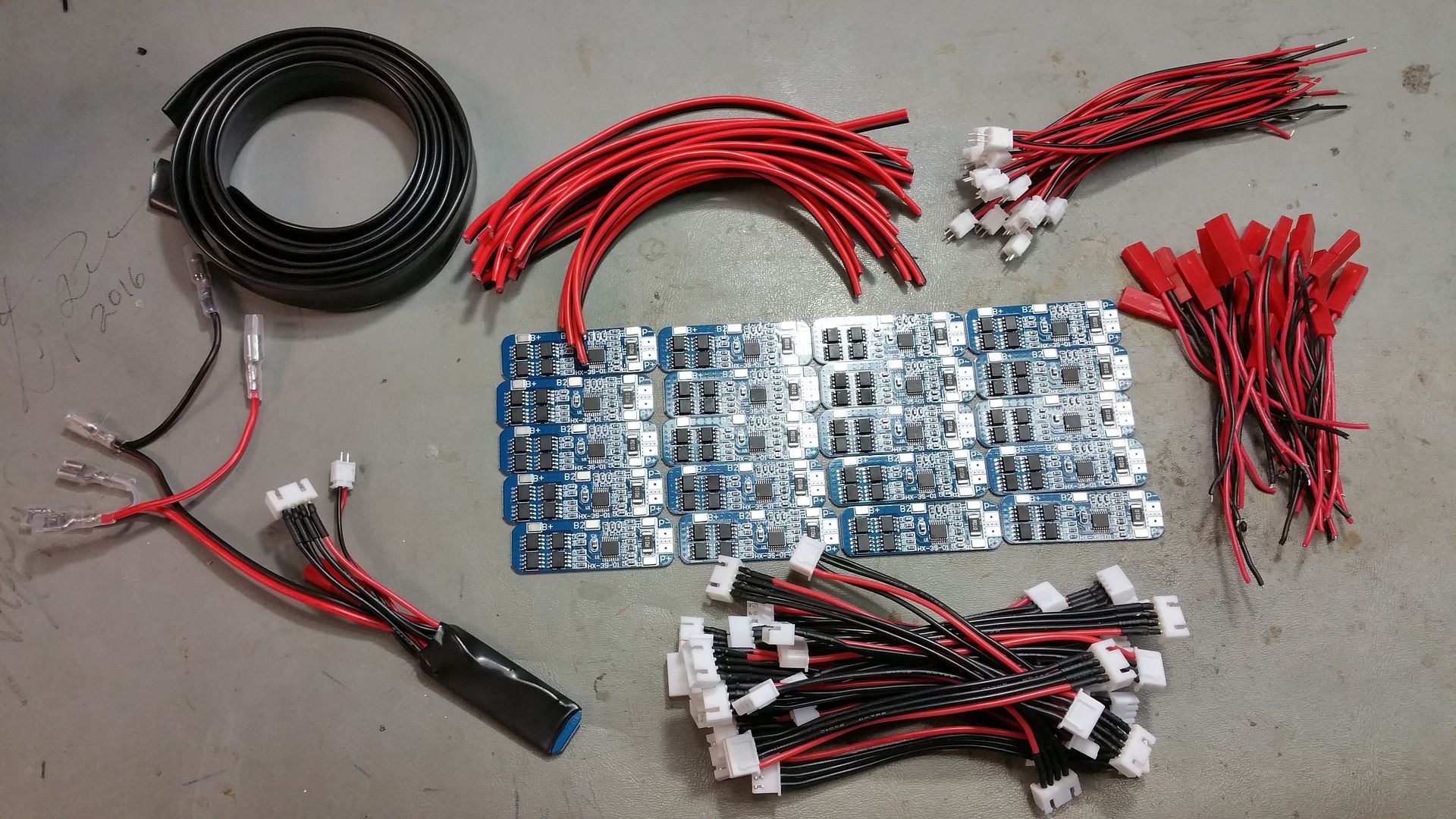

OK guys, I'm now starting to take names for the PSMini, just making a list but will give me an idea of how many supplies to get on the go. I have the design all figured out and know what is needed.

Couple changes in the circuitry.

Changing the BMS unit to a much smaller physical unit. The new BMS is rated for cut off at 8-10 amps which is a better match for the 100 Watt IH heater. I ordered both a 8 amp and a 10 amp version to find they are actually the same item but depending on the seller, is advertised at 8 or 10 amp. Thinking I will also start using these for the Skeletors as well.

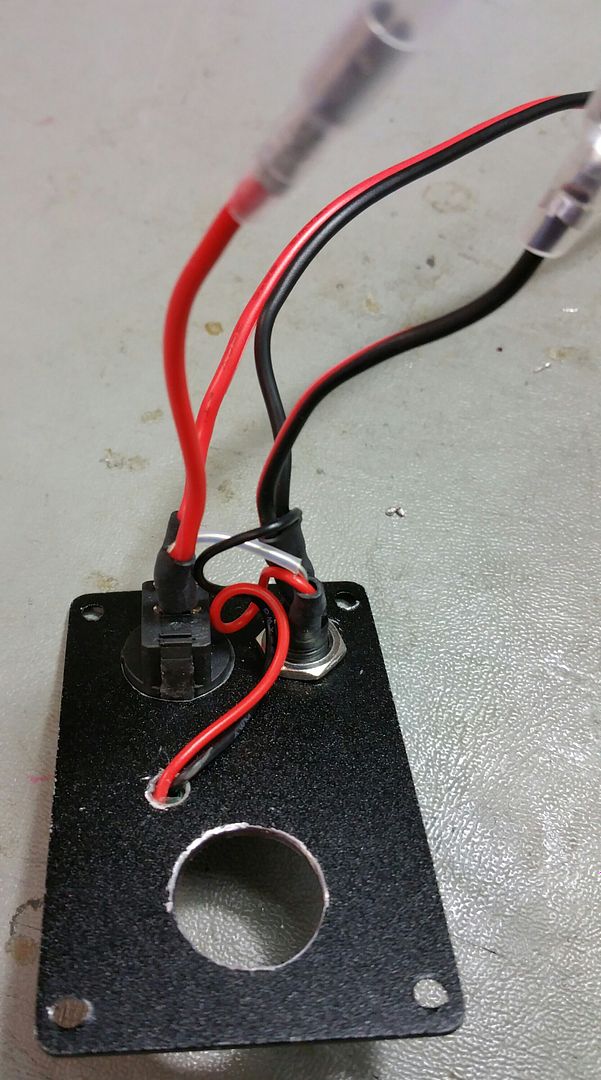

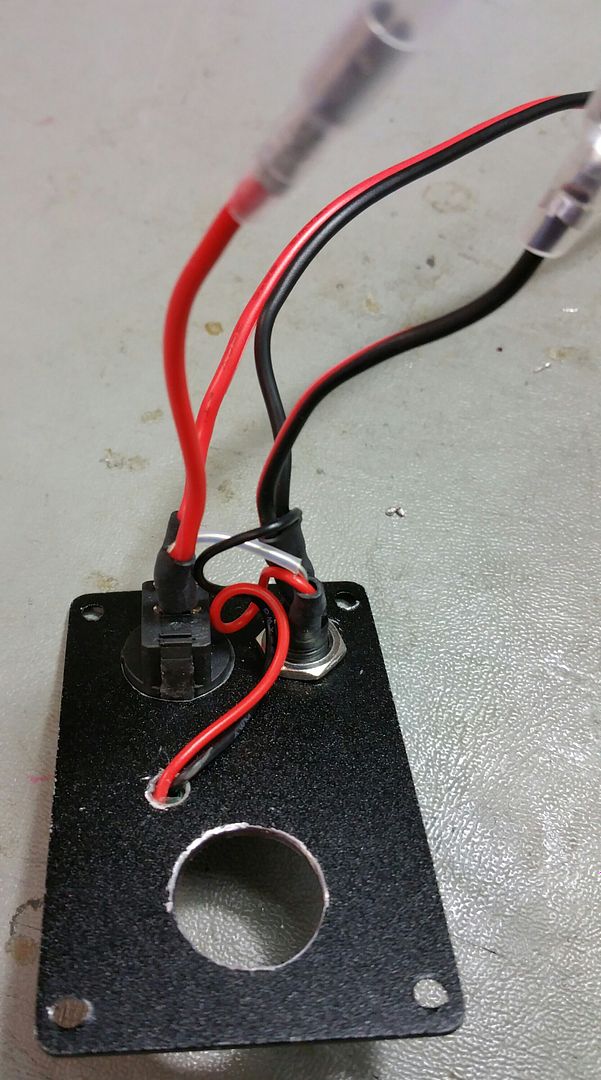

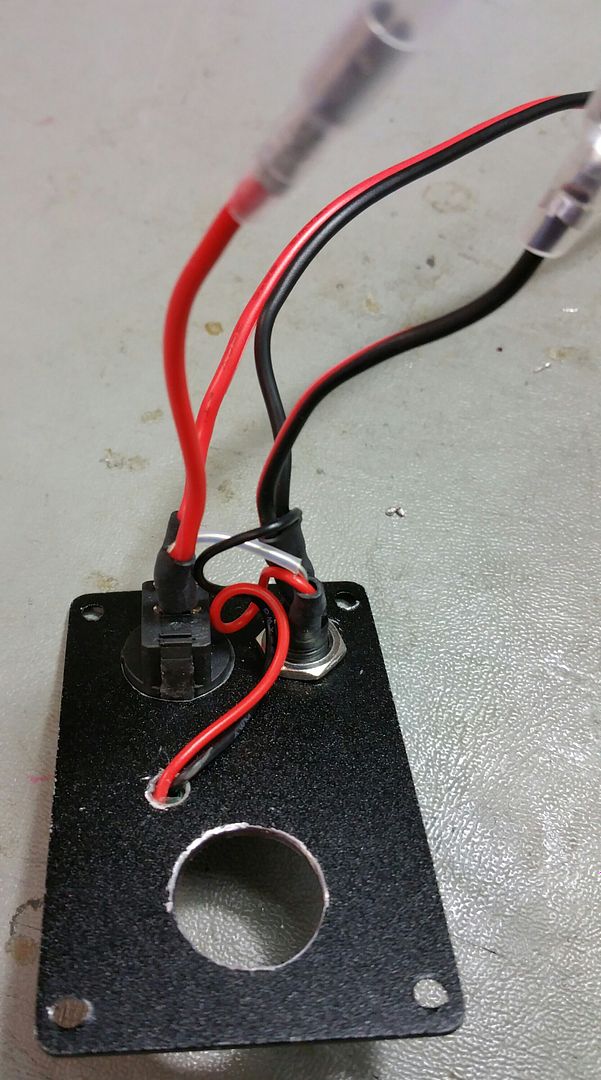

The charging port is now on the switched side of power. This means the switch needs to be in the "on" position for the battery to charge. Reason is because the charge port is accessible for something accidentally shorting if in one's pocket. Don't want that kind of pocket warmer.

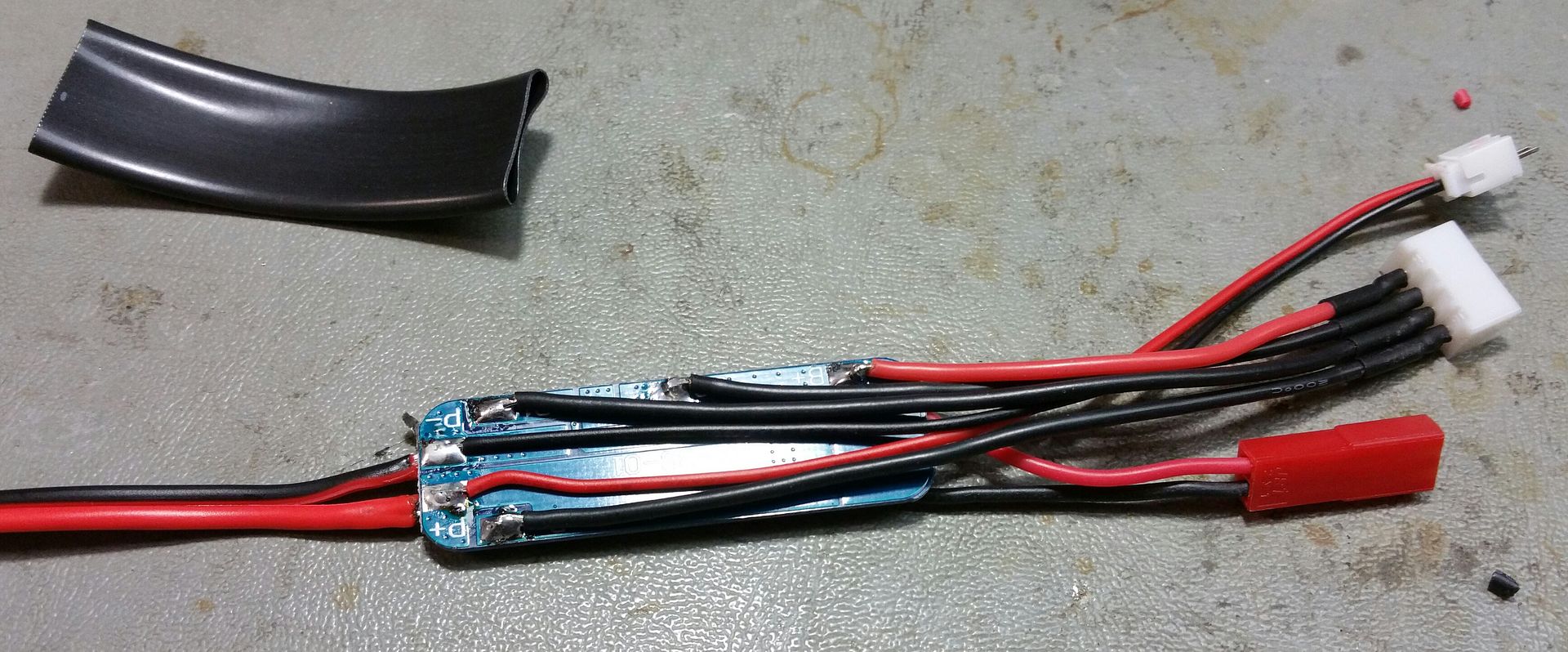

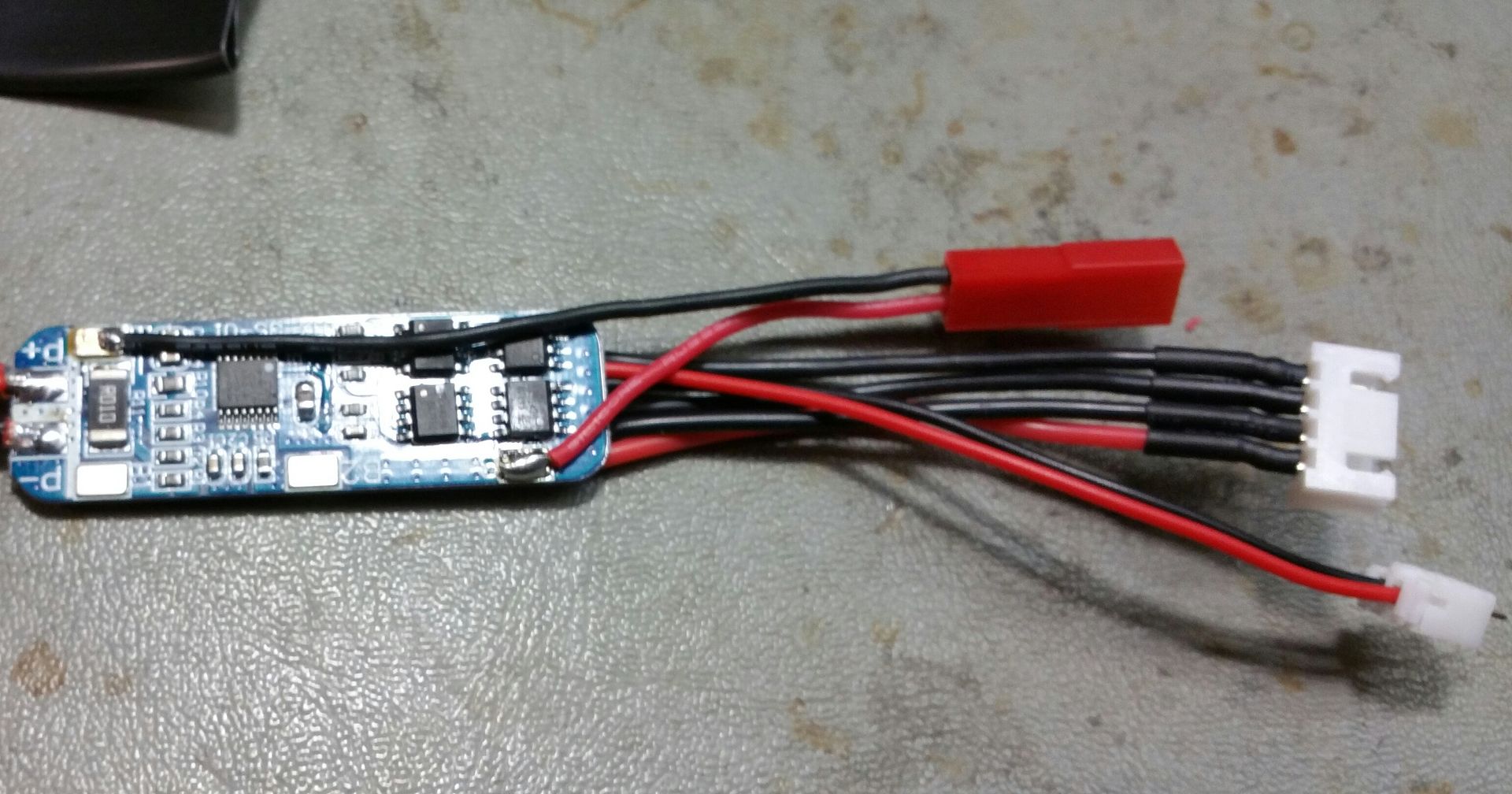

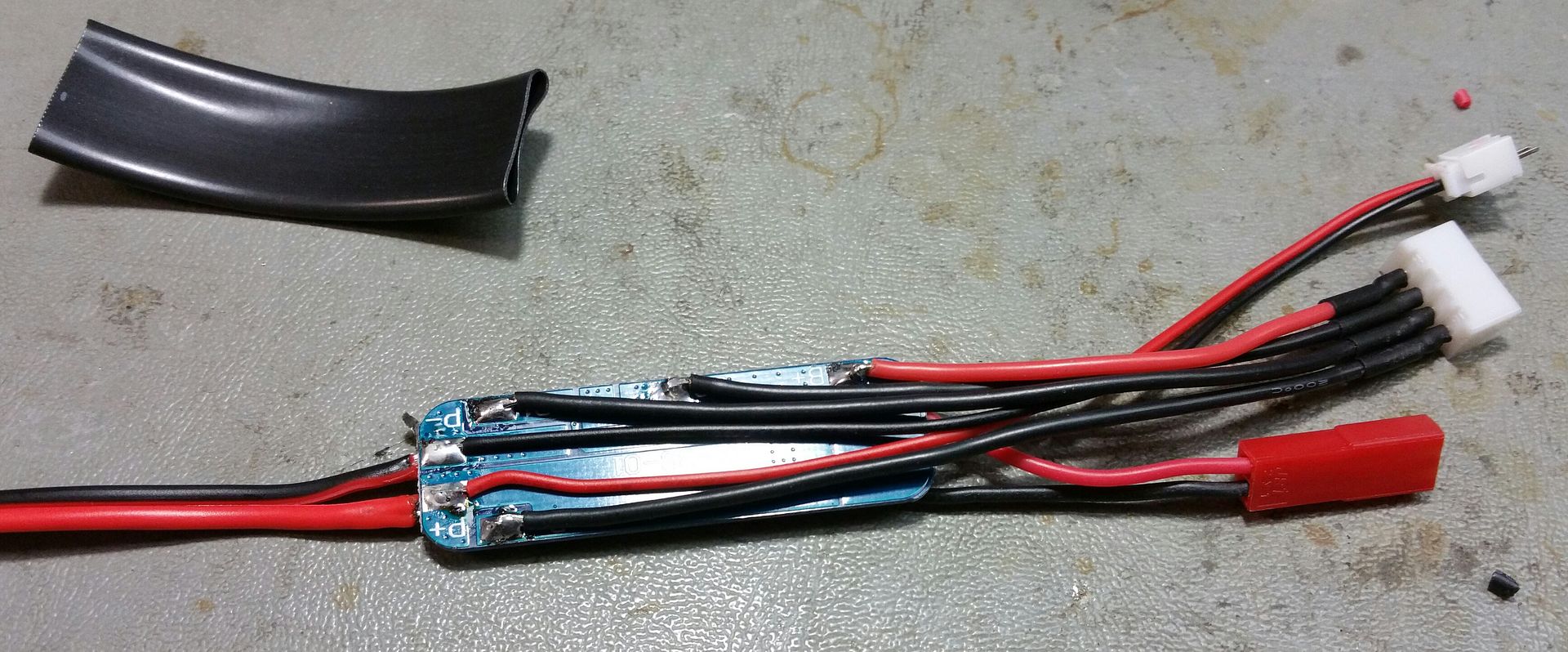

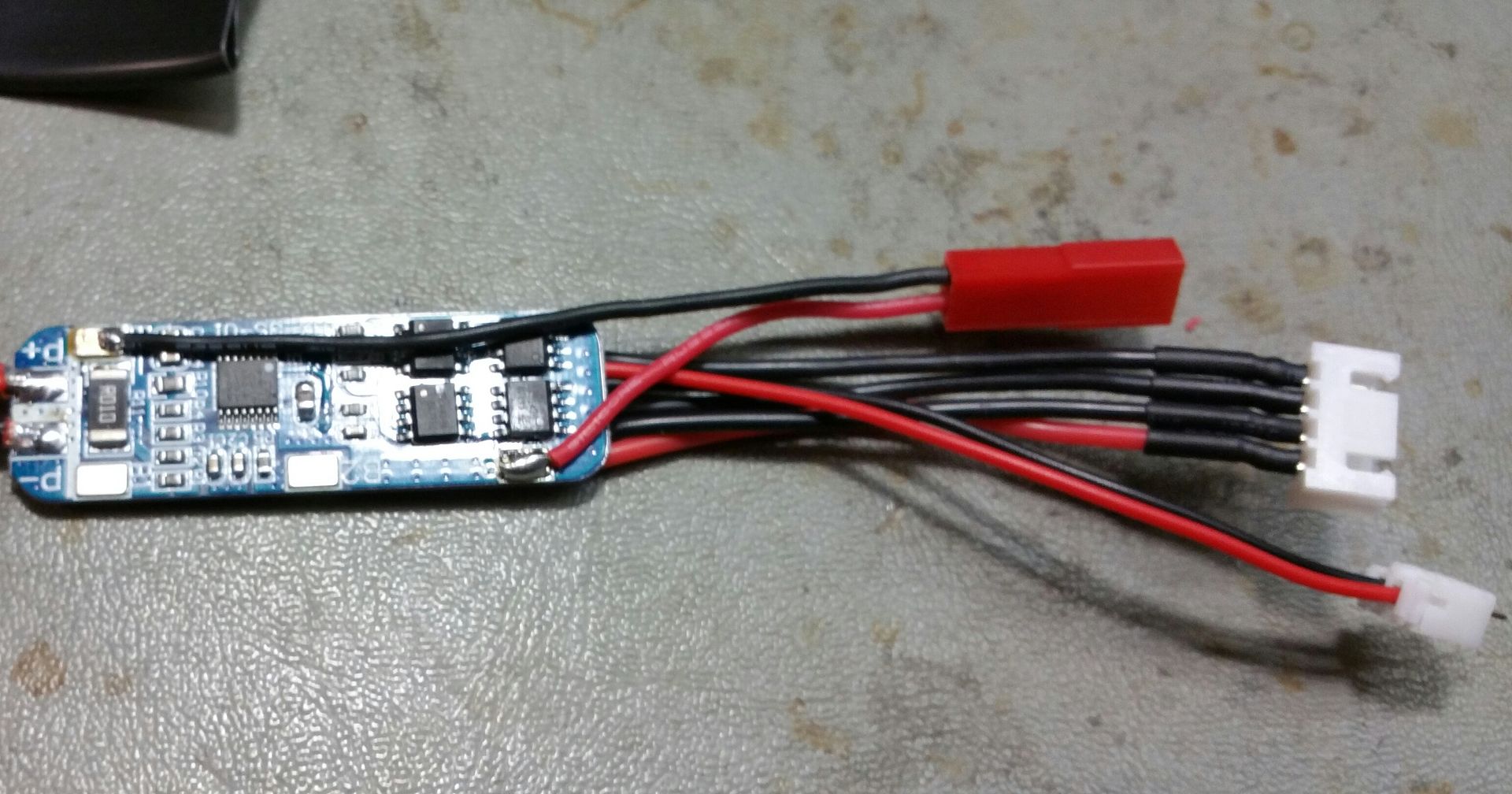

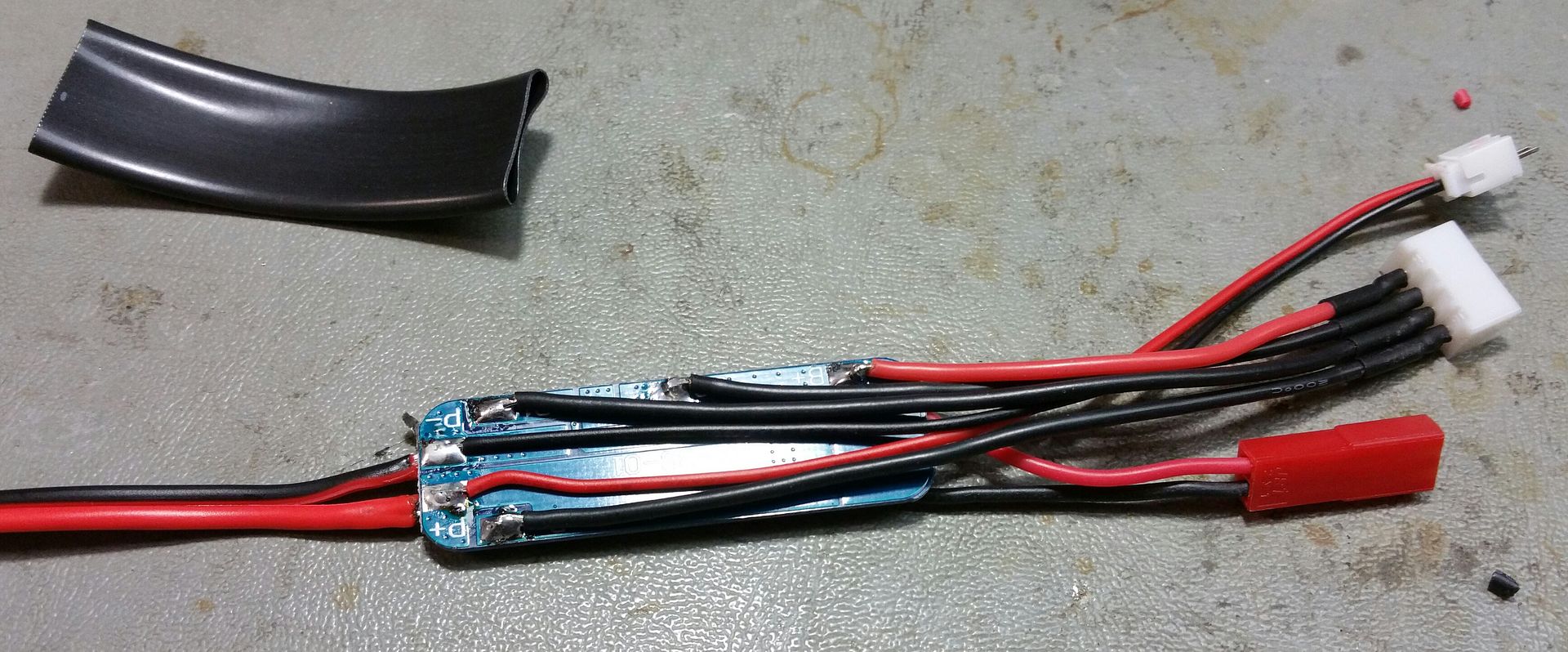

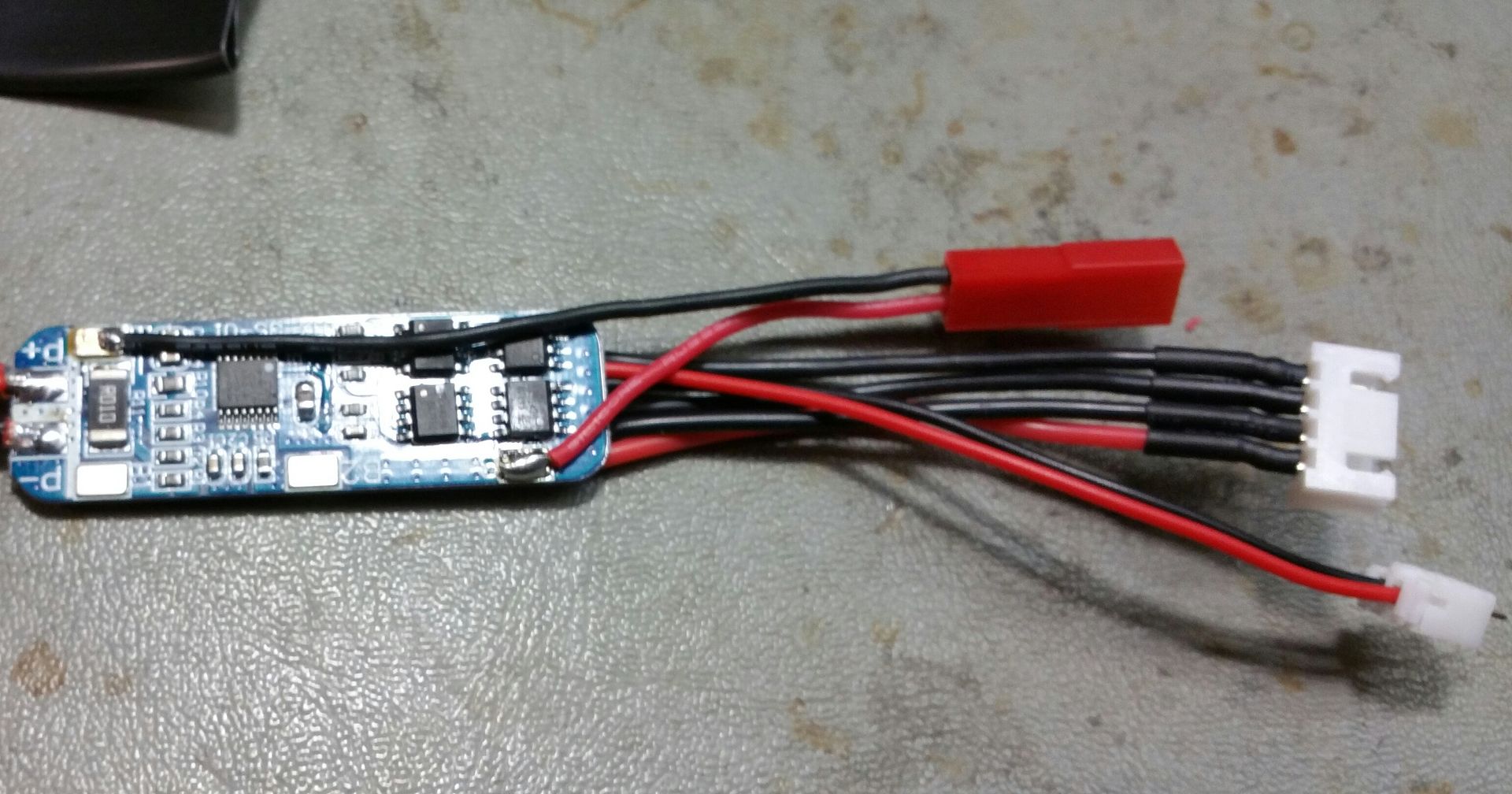

Here's a couple pictures of how the cable harness is assembled.

It is much more user friendly for replacing any parts that fail. The heater driver can be removed and replaced easily which means if needs repair, we only need to ship parts rather than the complete unit for service. All electronics and wiring is only attached to the top lid and can be separated from the rest of the unit as well.

All in all, I'm quite happy with this design and the simplicity of it. Generally, simple works best.

OK guys, I'm now starting to take names for the PSMini, just making a list but will give me an idea of how many supplies to get on the go. I have the design all figured out and know what is needed.

Couple changes in the circuitry.

Changing the BMS unit to a much smaller physical unit. The new BMS is rated for cut off at 8-10 amps which is a better match for the 100 Watt IH heater. I ordered both a 8 amp and a 10 amp version to find they are actually the same item but depending on the seller, is advertised at 8 or 10 amp. Thinking I will also start using these for the Skeletors as well.

The charging port is now on the switched side of power. This means the switch needs to be in the "on" position for the battery to charge. Reason is because the charge port is accessible for something accidentally shorting if in one's pocket. Don't want that kind of pocket warmer.

Here's a couple pictures of how the cable harness is assembled.

It is much more user friendly for replacing any parts that fail. The heater driver can be removed and replaced easily which means if needs repair, we only need to ship parts rather than the complete unit for service. All electronics and wiring is only attached to the top lid and can be separated from the rest of the unit as well.

All in all, I'm quite happy with this design and the simplicity of it. Generally, simple works best.

Has anyone found out the ideal amount of coil wraps and diameter to efficiently channel the heat into the base/mid tip and not cook the body or the very tip? Could we use a very small amount of windings and control the input voltage with a pot and transistor? I am completely naive to the physics of induction .

Thank you good sir. How to you ensure even heating of the load without heating the body as 10 turns is quite alot longer than the whole tip? On the Woody it won't be an issue but the M soaks heat down to the mouthpiece pretty well. Without any understanding of induction circuits this may be a silly question , but can we reduce the number of wraps and reduce the input voltage to suit, to get more concentrated heat more specifically where we want it?

Thanks for all the hard yards you've put into this project!

Thanks for all the hard yards you've put into this project!

Vap O matic

Well-Known Member

You should have gotten a tracking number with the shipping notification. If you can't find it, shoot me a PM and I'll dig it up. Use USPS for their tracking information now as has likely left Canada.

OK guys, I'm now starting to take names for the PSMini, just making a list but will give me an idea of how many supplies to get on the go. I have the design all figured out and know what is needed.

Couple changes in the circuitry.

Changing the BMS unit to a much smaller physical unit. The new BMS is rated for cut off at 8-10 amps which is a better match for the 100 Watt IH heater. I ordered both a 8 amp and a 10 amp version to find they are actually the same item but depending on the seller, is advertised at 8 or 10 amp. Thinking I will also start using these for the Skeletors as well.

The charging port is now on the switched side of power. This means the switch needs to be in the "on" position for the battery to charge. Reason is because the charge port is accessible for something accidentally shorting if in one's pocket. Don't want that kind of pocket warmer.

Here's a couple pictures of how the cable harness is assembled.

It is much more user friendly for replacing any parts that fail. The heater driver can be removed and replaced easily which means if needs repair, we only need to ship parts rather than the complete unit for service. All electronics and wiring is only attached to the top lid and can be separated from the rest of the unit as well.

All in all, I'm quite happy with this design and the simplicity of it. Generally, simple works best.

Howdy! If that thing works... and i know it works!!!

Fasten your seat belt! This thing hits like a bomb!

you should look for extra people who can solder too!

you should look for extra people who can solder too!

We're talking frequency when playing with coil or capacitor values. The voltage value hasn't much to do with it. At least not for what you're trying to achieve. Insertion depth is the only thing which is easily changed and staying within designed ranges. Do not insert past the heat sink fins. If you do, it will likely over drive the circuit and blow the FETs. This is one of the reasons I'm switching to the 8-10 amp BMS to help avoid over driving it. Taking 1 or 2 wraps off should still be OK but would have to see what results you get. I played for quite a while but decided to stick as close as possible to manufactures values. Altered the diameter some which will make some difference but not like dropping loops.Thank you good sir. How to you ensure even heating of the load without heating the body as 10 turns is quite alot longer than the whole tip? On the Woody it won't be an issue but the M soaks heat down to the mouthpiece pretty well. Without any understanding of induction circuits this may be a silly question , but can we reduce the number of wraps and reduce the input voltage to suit, to get more concentrated heat more specifically where we want it?

Thanks for all the hard yards you've put into this project!

@Pipes PSmini is looking good. You've kept it simple and functional. Kind of like a reliable manual car, with no computers to wonk out on you. Good move with the charge port wiring adjustment. It's not pretty when things go wrong with these batteries.

About the BMS cutoff - In most of the monitoring circuitry that I've seen, the ICs monitor a voltage drop over the charge+discharge transistor sets (depending on architecture of the BMS). When the voltage crosses a certain threshold (thee are usually a few thresholds, for instance - 10A for 100ms, or 30A for 100uS ) , the BMS will cutoff the appropriate mosfet. I've seen in a few BMS's that they add a resistor in series to the mosfets so that the voltage drop increases, this will lower the cutoff currents at the expense of that extra voltage drop. You may notice (or maybe not, its china afterall), that there's a different series R between the 8A and 10A models. If you find yourself sitting on the threshold for some reason, you could parallel that R with something to slightly increase cutoff thresholds, as long as the rest of the circuitry can handle it. It's difficult to find a BMS chip with the perfect thresholds without buying in bulk, so theres at least a way to tweak a little.

@rabidnz feel free to read back on some of my posts, I've written a bit about lower voltage IH. The main problem is driving the gates hard enough to keep them cool. I've found the IH will oscillate pretty well down to about 4~5V, but the gates need AT LEAST 8~10 to stay cool at working current. I plopped in a boost circuit to drive the gates at ~20v with 12v zenners, and they saturate pretty well. Of course, lower V will reduce output, so I bumped up capacitance to 1uF for about 10A*7V with 7 windings. Dropping below 4~5V will end up stalling oscillation and poof. A decent BMS is set to cut off at 2.5V CELL voltage, minus the drop and it gets awfully close to 4V, so software should intervene by then. We shouldn't push our batteries that low anyway if we want them to last much.

About the BMS cutoff - In most of the monitoring circuitry that I've seen, the ICs monitor a voltage drop over the charge+discharge transistor sets (depending on architecture of the BMS). When the voltage crosses a certain threshold (thee are usually a few thresholds, for instance - 10A for 100ms, or 30A for 100uS ) , the BMS will cutoff the appropriate mosfet. I've seen in a few BMS's that they add a resistor in series to the mosfets so that the voltage drop increases, this will lower the cutoff currents at the expense of that extra voltage drop. You may notice (or maybe not, its china afterall), that there's a different series R between the 8A and 10A models. If you find yourself sitting on the threshold for some reason, you could parallel that R with something to slightly increase cutoff thresholds, as long as the rest of the circuitry can handle it. It's difficult to find a BMS chip with the perfect thresholds without buying in bulk, so theres at least a way to tweak a little.

@rabidnz feel free to read back on some of my posts, I've written a bit about lower voltage IH. The main problem is driving the gates hard enough to keep them cool. I've found the IH will oscillate pretty well down to about 4~5V, but the gates need AT LEAST 8~10 to stay cool at working current. I plopped in a boost circuit to drive the gates at ~20v with 12v zenners, and they saturate pretty well. Of course, lower V will reduce output, so I bumped up capacitance to 1uF for about 10A*7V with 7 windings. Dropping below 4~5V will end up stalling oscillation and poof. A decent BMS is set to cut off at 2.5V CELL voltage, minus the drop and it gets awfully close to 4V, so software should intervene by then. We shouldn't push our batteries that low anyway if we want them to last much.

SloJimFizz

Unknown Member

Love my Skelator, awesome tool for the vapcap.

A trip to Hobby Lobby turned not so sucky by finding a better box with a flip top lid to complete my "Bedside".

$4.50 after 50% off. Yes please.

A trip to Hobby Lobby turned not so sucky by finding a better box with a flip top lid to complete my "Bedside".

$4.50 after 50% off. Yes please.

jerseydvd

Well-Known Member

@Pipes

How long should it take the cap to click on the Portside? Something must be wrong as I’ve held the vapcap in there for 30 seconds and no click. The tip of the VC is warm, but that’s it.

Batteries are fully charged yet the test button on the PS only has the first red led lit.

Yes, tried both switch positions.

Any ideas?

Thanks

How long should it take the cap to click on the Portside? Something must be wrong as I’ve held the vapcap in there for 30 seconds and no click. The tip of the VC is warm, but that’s it.

Batteries are fully charged yet the test button on the PS only has the first red led lit.

Yes, tried both switch positions.

Any ideas?

Thanks

stickstones

Vapor concierge

I tested 5 different caps and they all clicked in the 8 to 10 second range.

jerseydvd

Well-Known Member

Thanks, definitely something going on here then. Appreciate you testing!I tested 5 different caps and they all clicked in the 8 to 10 second range.

jerseydvd

Well-Known Member

@Pipes

How long should it take the cap to click on the Portside? Something must be wrong as I’ve held the vapcap in there for 30 seconds and no click. The tip of the VC is warm, but that’s it.

Batteries are fully charged yet the test button on the PS only has the first red led lit.

Yes, tried both switch positions.

Any ideas?

Thanks

Was a very simple fix. Thanks to @Pipes for the quick help!

Buy with confidence and enjoy!

Summer

Long Island, NY

what secures the battery holder in the Portside. mine is lose and rattles around. is there anything I can do to secure it permantly?

Mine rattles around, too. @Pipes said it's secured with double sided taped. You can reinforce it with additional double sided tape. I haven't as yet. Guess the rattling hasn't gotten to me yet.

@stickstones is that with a Skelly and if so which batteries?

My VTC4's, 15C rated, run about the same 8-10 seconds to the click.

Their 2100mah's give me 4-5 days run time doing 'dip 'til done' bowls.

Just wondering if people with different C rated batteries have noticed any difference in this initial heat time.

My VTC4's, 15C rated, run about the same 8-10 seconds to the click.

Their 2100mah's give me 4-5 days run time doing 'dip 'til done' bowls.

Just wondering if people with different C rated batteries have noticed any difference in this initial heat time.

jerseydvd

Well-Known Member

The VTC5As I use, are faster. Probably 5 sec tops.@stickstones is that with a Skelly and if so which batteries?

My VTC4's, 15C rated, run about the same 8-10 seconds to the click.

Their 2100mah's give me 4-5 days run time doing 'dip 'til done' bowls.

Just wondering if people with different C rated batteries have noticed any difference in this initial heat time.