nachooo

Well-Known Member

Thanks, as english is not my native language it cost me a little to understand..but finally I think I get it..also I dont know nothing about electronics, in fact is the first time I have been soldering something to a circuit board…You have me stumped as should work the same.

However, there is a plan "B".

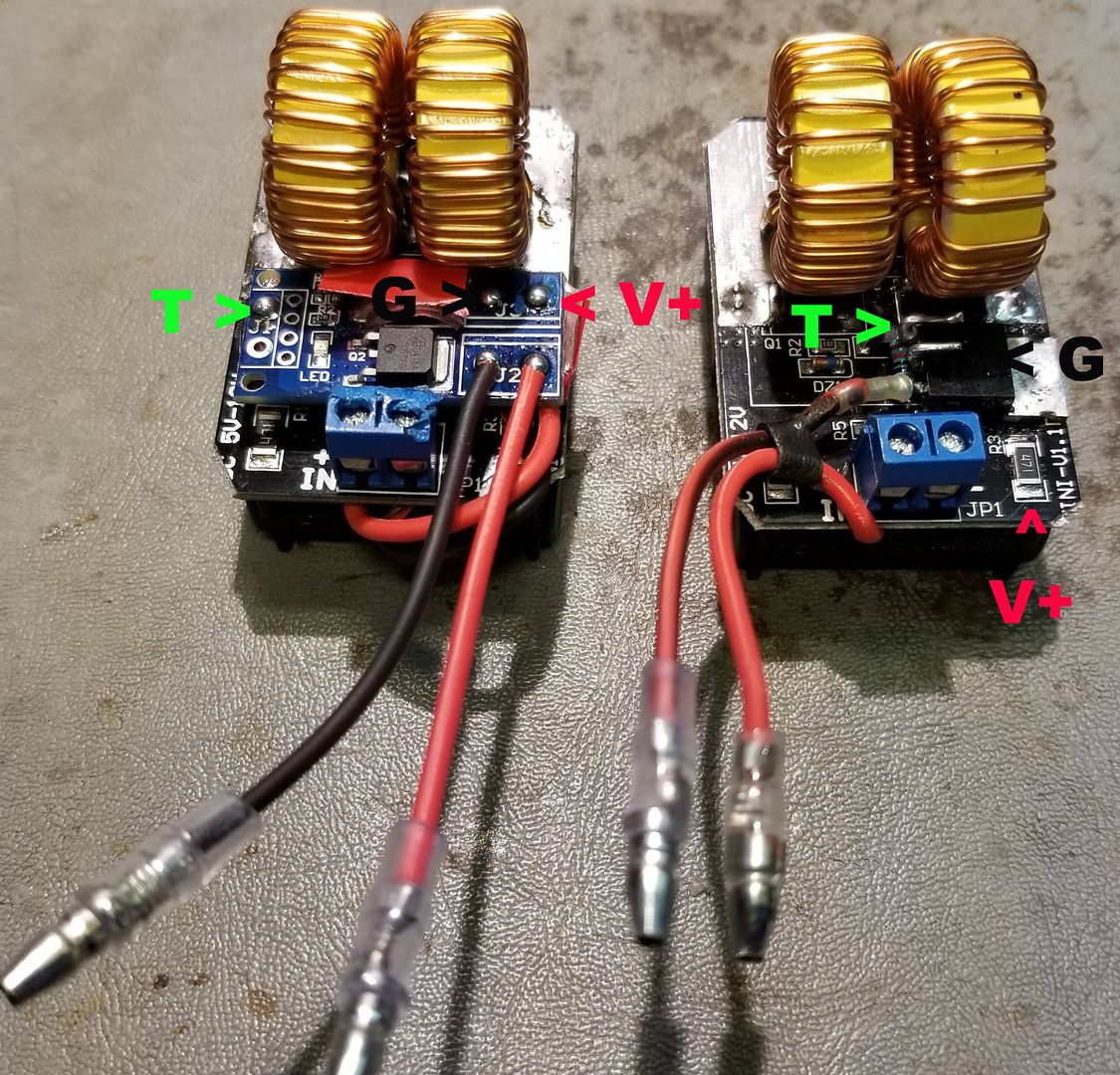

I stopped using those FET boards and have been using a single IRF540N FET and a 10 K resistor instead. Takes less room and more secure. The 10 K resistor goes between the gate and drain. Zoom in on the picture and you'll see it at the bottom of the FET. I cleared a spot on the board which is all ground and soldered the FET through the hole directly to the board. This is the new main ground for the circuit. The input ground is the source of the FET and the gate is the new "trigger" input. I've marked the connection points of the two circuits below. They have identical function. The Ground connection is for the power indicator LED inside the tube.

Enjoy and good luck!

So for me to understand, I pick the new mosfet, remove the black paint of the board until metal appears in the correct place, sold the metal base of the mosfet as in the pic, put a 10 K resistor between the gate and the (drain or source???)

The ground (negative) of the battery should be solder to the source in the mosfet...and the positive from battery connected to the (in + ) in the Little blue conector...

I Will not use any led light inside the tube..

I undertand that one of the wires from the momentay switch must go to the trigger wich is the gate in the mosfet… But where should the other wire from the switch must be attached?

Is this all I have to do? Do I need to do more connections?

Sorry and thanks for your patience….I am very noob at this..I had to look at the wiki what is a mosfet and its parts etc...I have started to like electronics since this little project