hardboiledfrog

tinkerer

First off thanks to all for your amazing contributions to the cannabis community, I have learned a lot from all of your forum posts.

I love dabbing concentrates but I wasn't thrilled with using a blazing torch in my livingroom or tripping over e-nail wires as I am often clumsy.

Plus e-nail setups are kind of a kludge and you have to plug them in.

I'm a tekkie and I have some experience with pcb design so I designed a small Zero Voltage Switching driver based on an open source circuit I found here:

https://markobakula.wordpress.com/power-electronics/500w-royer-induction-heater

Thanks Marko!

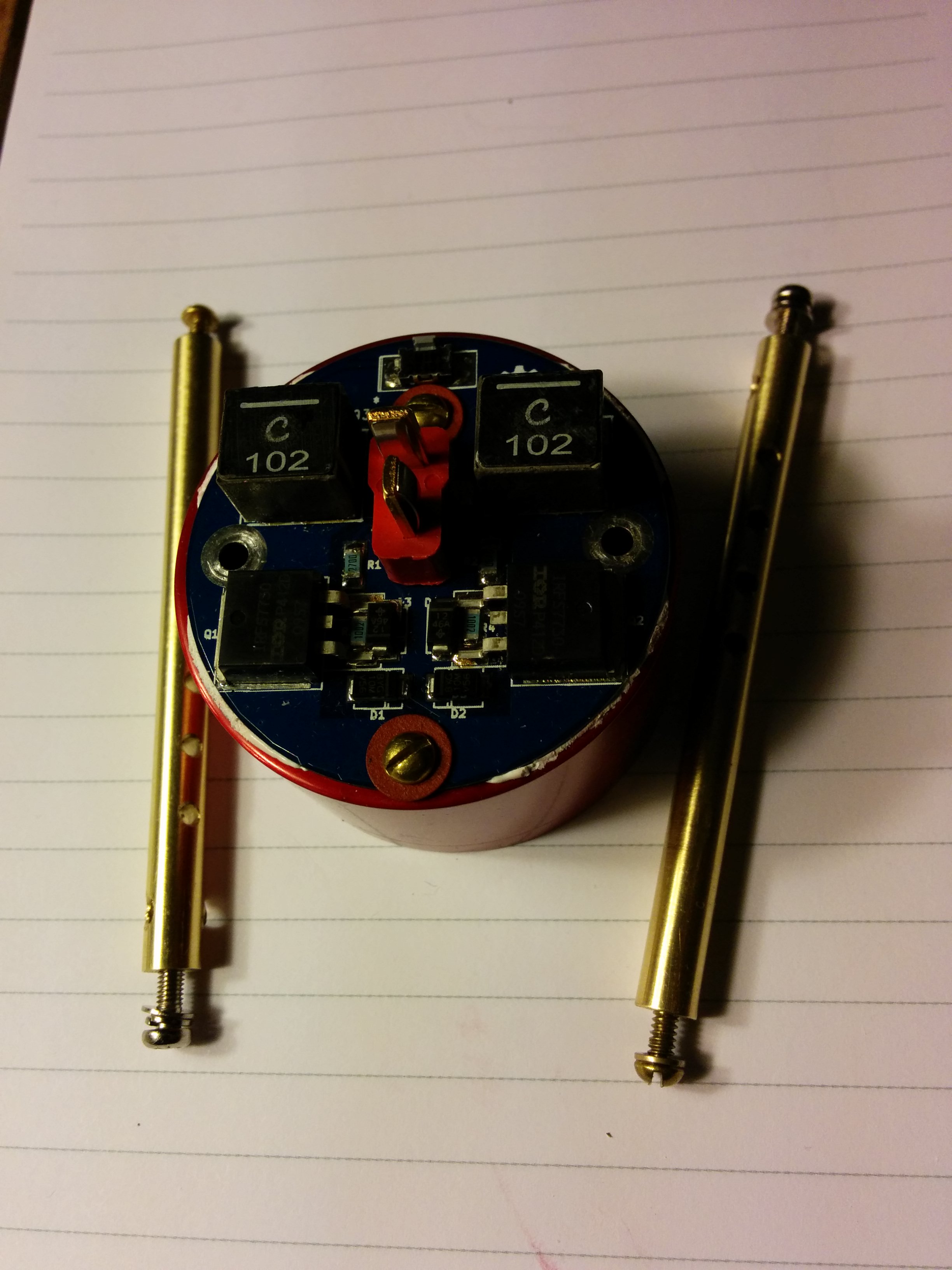

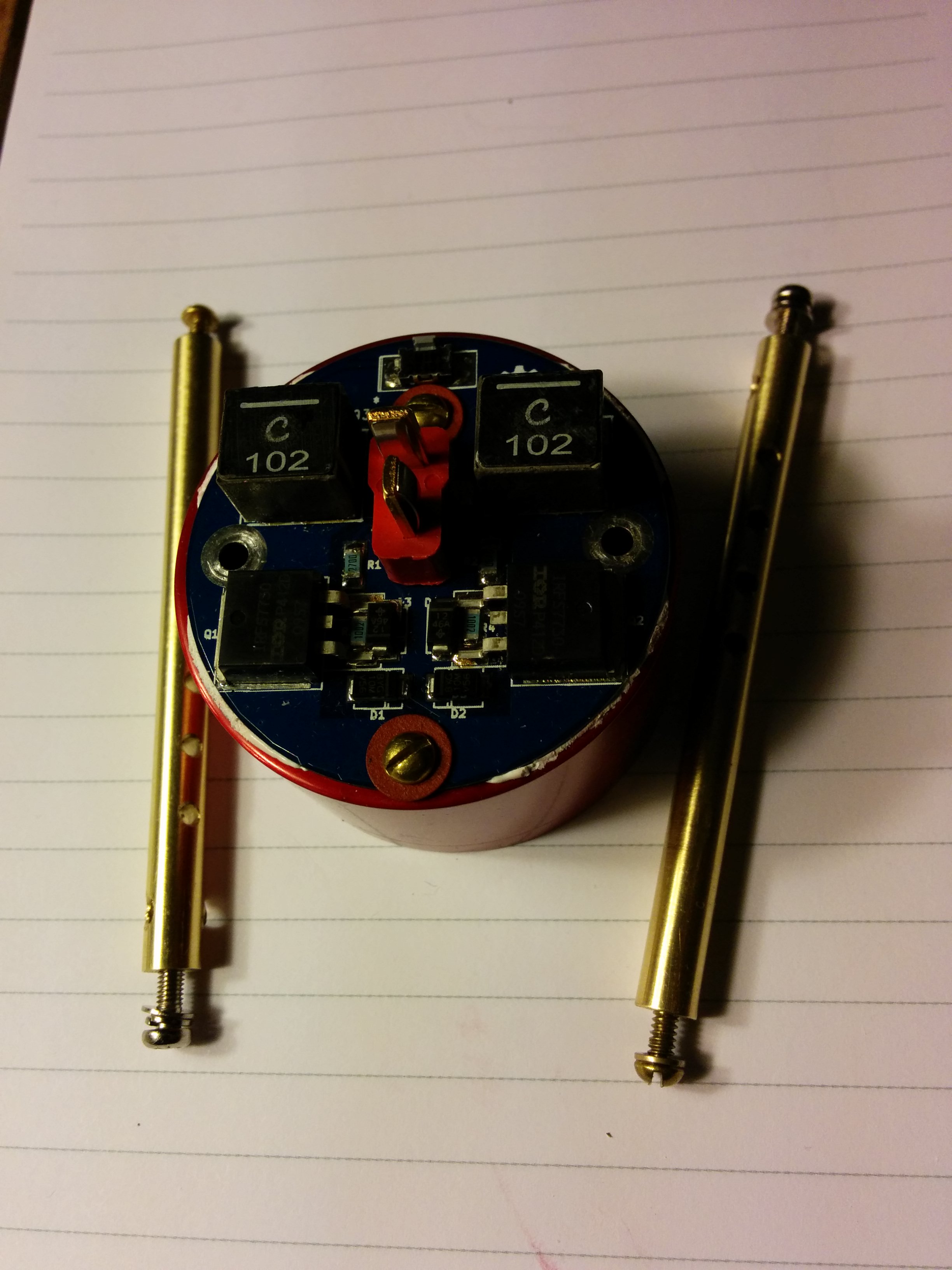

The board is glued to a 2" x 1" aluminum disc heatsink with thermal epoxy and bolted to a tank circuit of multiple 1uF caps and a work coil which makes up an induction heating module.

The module and a lithium battery pack can fit in a flashlight form factor. With 4 26650 size cells it can do over 700 watts, with the smaller 18650 cells about 300 watts.

The caveat is a short duty cycle since there is no water cooling for the work coil and mosfets plus it's a very high current drain on the battery pack. And of course it only works with metallic nails.

This works out pretty good though for soldering, brazing, and heat treating small parts and tool bits.

And my favorite application, dabbing. I've been dabbing with these and various prototypes daily (when I'm not out of dabs ) for over 3 1/2 years and loving it.

) for over 3 1/2 years and loving it.

No flames, no leaky torches, much less of a fire hazard, no running out of butane in the wee hours of the morning and it's portable.

Here's my youtube channel showing a modifed Sky Ray King flashlight and flashlight host body I machined from common aluminum pipe. https://www.youtube.com/channel/UCmXQuHq1qPXiN0dIDZ4BBZw

This is open source, the pcb design files (in Kicad format) and BOM with part sources are hosted on github here:

https://github.com/hardboiledfrog/smt-zvs-driver

imgur album:

https://imgur.com/a/7MlHF

I hope that other tekkies and diyers will give this a try and find it as useful as I have.

And be sure to exercise all the applicable safety precautions that apply to induction heating and lithium batteries.

Regards,

hbf

I love dabbing concentrates but I wasn't thrilled with using a blazing torch in my livingroom or tripping over e-nail wires as I am often clumsy.

Plus e-nail setups are kind of a kludge and you have to plug them in.

I'm a tekkie and I have some experience with pcb design so I designed a small Zero Voltage Switching driver based on an open source circuit I found here:

https://markobakula.wordpress.com/power-electronics/500w-royer-induction-heater

Thanks Marko!

The board is glued to a 2" x 1" aluminum disc heatsink with thermal epoxy and bolted to a tank circuit of multiple 1uF caps and a work coil which makes up an induction heating module.

The module and a lithium battery pack can fit in a flashlight form factor. With 4 26650 size cells it can do over 700 watts, with the smaller 18650 cells about 300 watts.

The caveat is a short duty cycle since there is no water cooling for the work coil and mosfets plus it's a very high current drain on the battery pack. And of course it only works with metallic nails.

This works out pretty good though for soldering, brazing, and heat treating small parts and tool bits.

And my favorite application, dabbing. I've been dabbing with these and various prototypes daily (when I'm not out of dabs

) for over 3 1/2 years and loving it.

) for over 3 1/2 years and loving it.

No flames, no leaky torches, much less of a fire hazard, no running out of butane in the wee hours of the morning and it's portable.

Here's my youtube channel showing a modifed Sky Ray King flashlight and flashlight host body I machined from common aluminum pipe. https://www.youtube.com/channel/UCmXQuHq1qPXiN0dIDZ4BBZw

This is open source, the pcb design files (in Kicad format) and BOM with part sources are hosted on github here:

https://github.com/hardboiledfrog/smt-zvs-driver

imgur album:

https://imgur.com/a/7MlHF

I hope that other tekkies and diyers will give this a try and find it as useful as I have.

And be sure to exercise all the applicable safety precautions that apply to induction heating and lithium batteries.

Regards,

hbf

Last edited: