@VapCap : Any thought of, say, an anodized aluminum sleeve? I'm wondering if heat fins (like on this "bone" pipe) would be enough to keep it reasonably cool.

I don't know I completely understand what you are asking. Other than the very end of the VapCap, where the cap is and the heat is applied, the unit doesn't get hot. The glass the original is constructed from is essentially an insulator compared to metal and the heat even after many cycles doesn't make the unit uncomfortably hot. In addition to this, the way the inverse induction airflow is designed, cooling air washes the inside surface of the unit like a counter flow heat-exchanger absorbing the heat from where it doesn't belong (in the body or stem as well as cooling the condenser tube) and dissipates it into the vapor stream.

I have fins incorporated into the Ti tips, but there is much more to it than just the fins when it comes to effective thermal management. At the interface between the tip and the body or stem, there are several high temperature orings. These orings not only allow for easy assembly/disassembly, but also create an effective thermal break to dramatically reduce the thermal progression of heat from the Ti ti into the rest of the unit. This is in addition to the inverse induction airflow described above.

So even though this unit is very small, and it can be heated with a torch, it doesn't get hot like the old style "one hitters do"

I welcome comments and feedback for others who have been using a VapCap for a while.

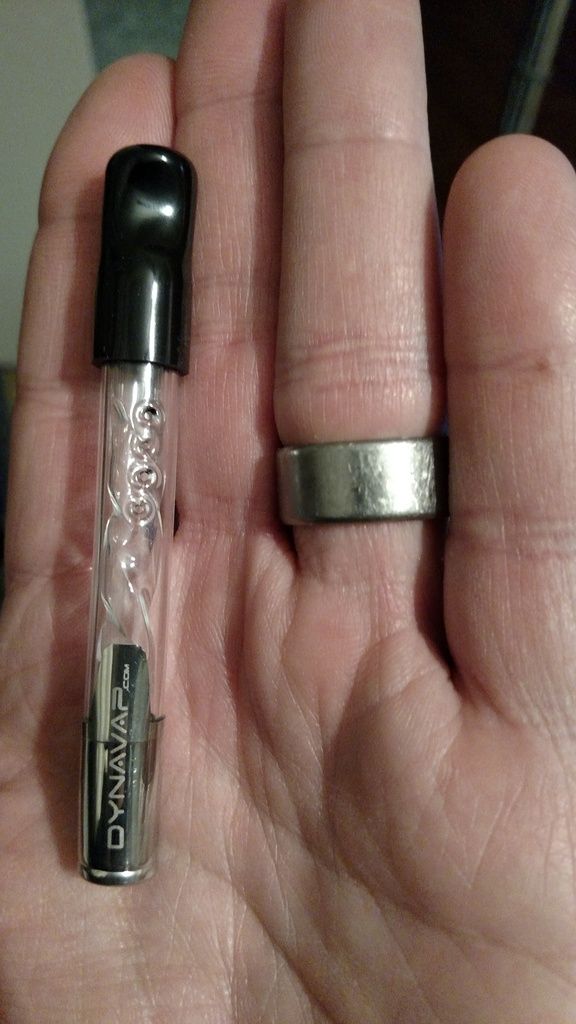

Also here are a few pictures of some of the next generation parts and upgrades I hope to have available soon.

The Two Barrel

And the Four Barrel with a high performance turbulator throttle body/condenser.

Also, I am working on a production run of the crowns for the Ti Woody. Hopefully those will be ready soon. When they are, they will be available at no cost to anyone who currently has a Ti Woody and then they will be incorporated into all Ti Woodys moving forward.

Thank you everyone for the support!

Cheers,

George