AWistfulNihilist

Well-Known Member

This is my current path of research, I want to move the coils away from the inductor. I have several units I'm testing with, I'll take a unit and remove the capacitors from the bottom of the unit, solder them to the work coil and wire then to the inductors as you suggested (I think I have that right). I only have 16g at largest, I'll give it a shot with those while I get some 12.You could make the head quite a bit smaller if you wanted.

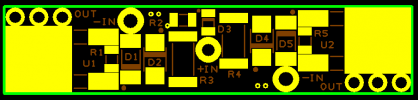

I love the concepts but the size is problematic. There is an opportunity to put only the coil and the black capacitor near the bowl. The connecting leads need to be sizable, and they need to run nearly parallel and close together, but they can be be conventional 12 gauge wire pair. The circuit board and inductors can remain remote. Limit the lead-length, of course. The lead-wires are still part of the active inductive circuit. That is why the lead-wire pair needs to run close together. Look at silicone hobby wire for flexibility.

Theory behind this - the work of the IH is done with a signal bouncing back and forth between the capacitor and the work coil. That is where all the high current happens. The feed-circuit, the energy stored in the inductors, is buffered by the inductors themselves stretching out the time domain. The capacitor's discharge is nearly instantaneous and is the reason for the high current pulse directly into a 1uh inductor, a virtual short circuit. Pay attention and you can fashion a nice little heater-head with a remote circuit box.

I think to make it really versatile I need 1' of cable between the heater and base (lift onto high bowls). I'll test with a couple lead lengths. 3"-12" and see when I start heating the coils more than the work.

You are appreciated as always Tommy!