TommyDee

Vaporitor

Thanks for reporting back on that test @Edgedamage - I know the specs on the cutoff voltage is very cavalier.

The 14500 were weak enough that even as a matched pack, they'd have trouble without a balancing circuit between the cells. They were rated for for it but failed under scrutiny.

If you do cells, you can do protected cells. I have 10A (8.5 amps) 18650. That way you know each cell is protected, although still considered second level protection. Nothing beats a good old fuse soldered in the line in my book.

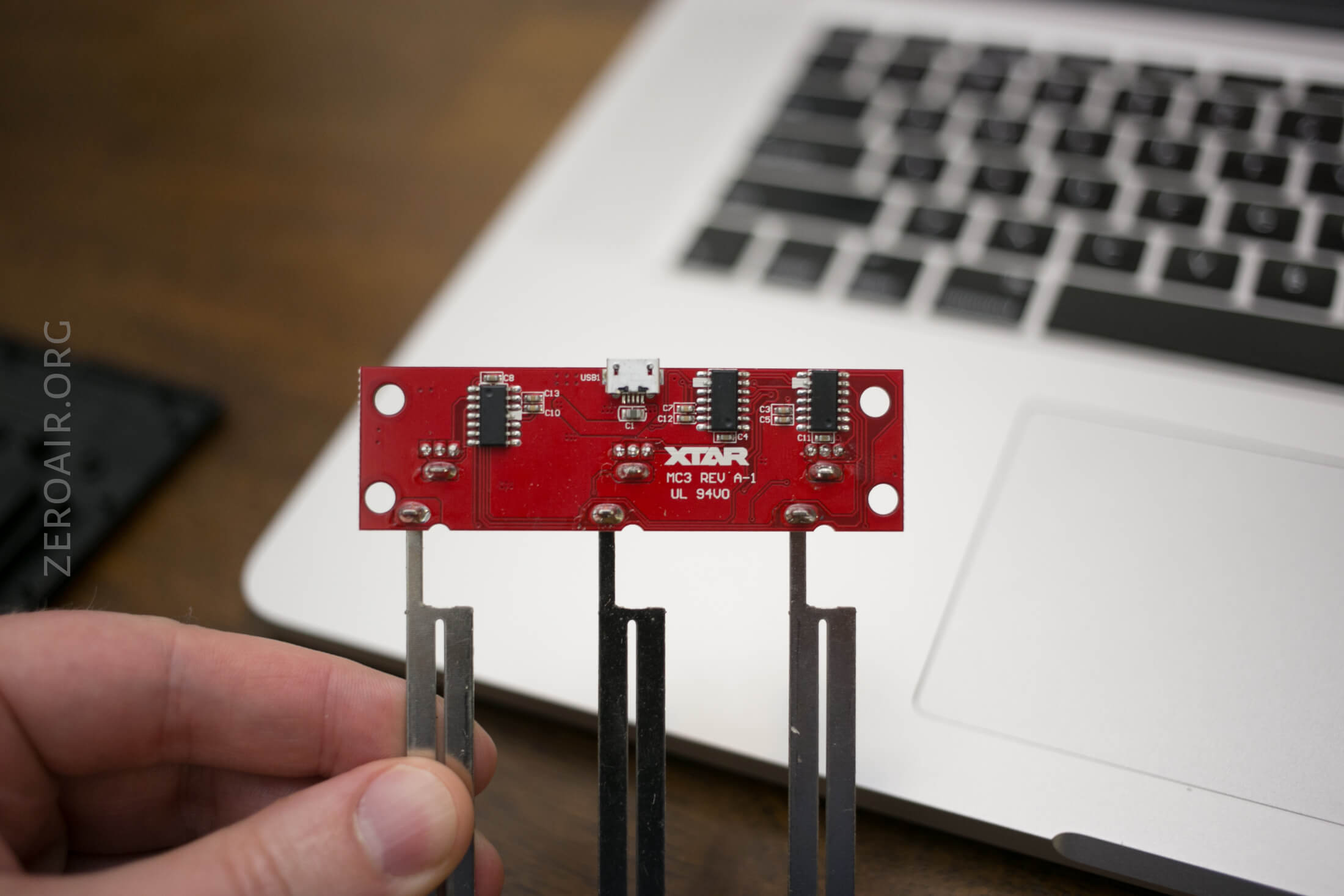

What do you think of the 2S/3S chargers?

The 14500 were weak enough that even as a matched pack, they'd have trouble without a balancing circuit between the cells. They were rated for for it but failed under scrutiny.

If you do cells, you can do protected cells. I have 10A (8.5 amps) 18650. That way you know each cell is protected, although still considered second level protection. Nothing beats a good old fuse soldered in the line in my book.

What do you think of the 2S/3S chargers?