Sorry, moderators, to spam everyone up with back-to-backs, these are some long posts

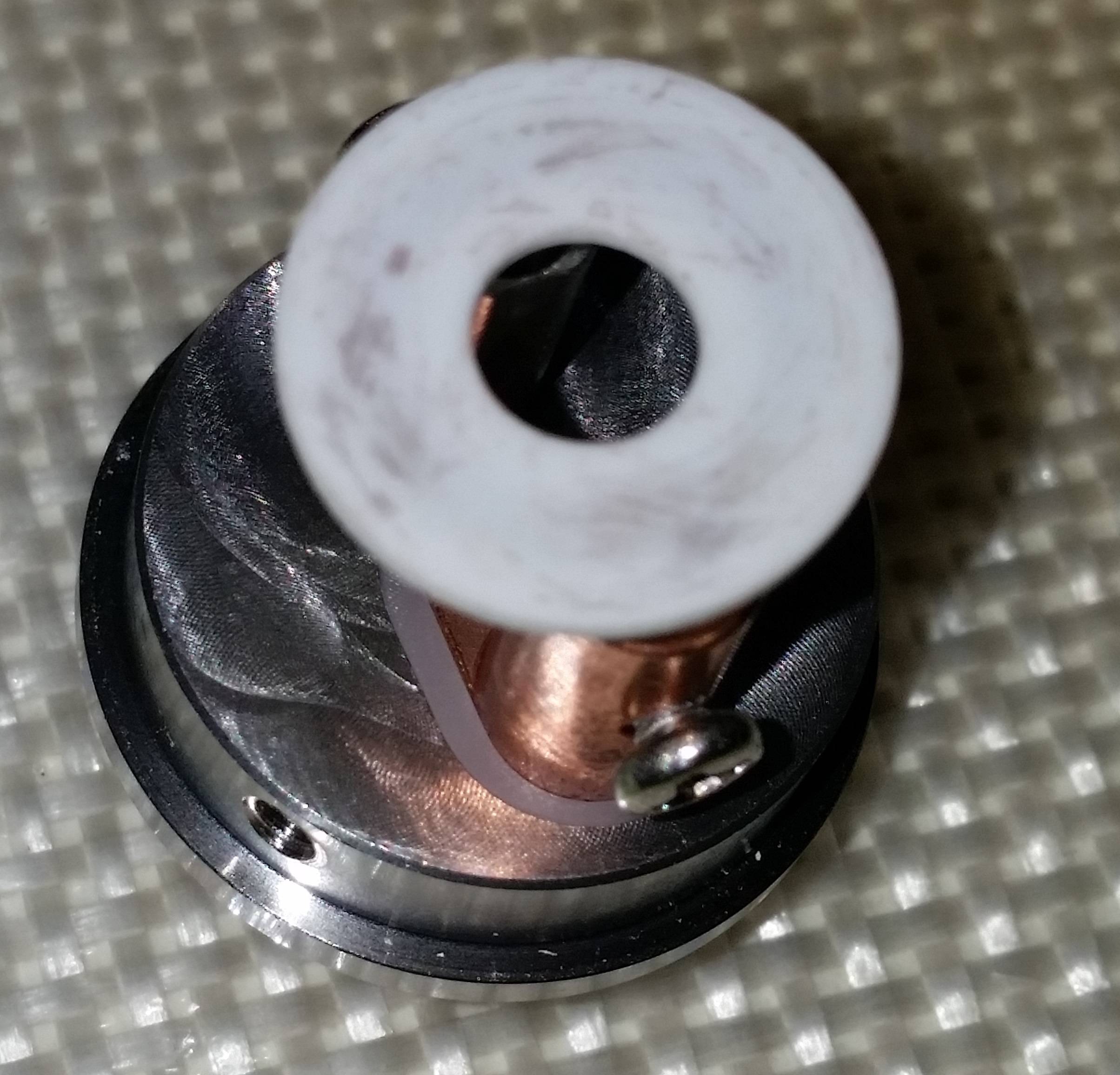

Are we even certain the donuts have a linear TCR? Theoretically one may imagine that the functional TCR of a ceramic donut heater may be complicated by the fact that the heater is not a homogeneous material. It is instead a complex of conductive metal and insulating ceramic, so you end up with two different functions combined. First, the shapes of these two functions may be different, along with their placement on the graph. Second, the way the two functions combine may be complicated.

Careful here, TCR is based on the temperature of the heater, not the doughnut. It senses the metal, not the ceramic (which is sure to be cooler by Thermodynamics). That loss (heat wise) is going to change with temperature, no doubt being more at first (until the rest of the atty warms up, conduction will be greater) and radiation plays a bigger role as temperatures rise.

It's important, I think, to not keep thinking in terms of XX Ohms rise when trying to understand how TCR is used. It's not the absolute change in Ohms, but the relative change in percent.

Yes, I think I follow you there: the TCR we put into our mods is intended to control only coil wire temps, and I think I follow you on the relativeness of the rise determining our TCR #, but as far as absolute rises in resistance, that is all I can observe on my joyetech's so that's what I'm working with.

Edit: TCR can also be expressed as 1760 PPM for alumina -- anyone tried 175?

I'm also sure that alumina has nothing to do with the TCR technique here. Alumina is an excellent insulator, it just doesn't conduct a significant current under any conditions we're dealing with. The exact same things happen with bare wire (no ceramics at all), right?

And yes, it's true that alumina doesn't conduct, nor is it the conducting mass in our donut. However, it is transferring the heat to our materials after receiving the heat from the wire embedded inside. It is relatively accurate to approximate the "coil" then as being made of alumina, since the resistance (of the actual coil) rises with temperature. The TCR value for the actual coil is likely in the low 200s, which may explain why I saw earlier that TCR 190 seemed to work well (in the middle of the two, since the "coil" would have an ideal TCR of 176). I think we will find that everything we can try is an "approximation at best," but it is extremely helpful to compare our estimates and measured outcomes. That is how we improve our technique!

It may not be "conventional" to model a change in resistance of an insulator, but it has proven to be a useful approximation, at least to me, given my circumstances (no TC mods).

So the wire (which is the only thing we can really (kinda) control with TC mods) is 240-ish, the alumina / ceramic donut is 175, even though it's a resistor and not really subject to the TCR formula as it applies to metal conductors? Or does it still?

Unless your donut is entirely different from mine, I respectfully doubt it's 370 degrees. To each his own, but I don't see the point of using a TCR value that makes the display have no relation to actual temperature.

Agreed, since the donut is doing all/most of the heating, that is what I want the number on the screen to reflect, not the temperature of the wire.

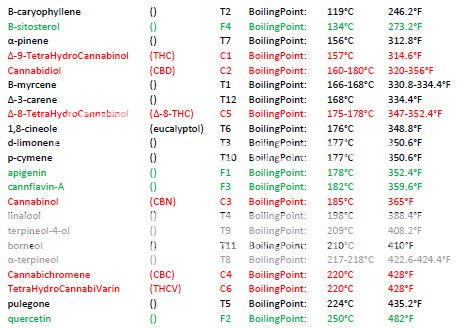

On issue #2, can we agree that what we want to control is the temperature that the oil is bubbling at? Temp will never be identical across the donut, and the donut-oil interface isn't ideal either. But let's pretend it is for now.

I disagree....or do I?

Not sure if I follow you here, fern.

For sure, the ultimate goal here is to only boil/vape the oil, not to burn it, combust it, or degrade it through pyrolysis. I want this because it provides the best flavor and most efficient use of materials. For me, I even want to avoid degrading THC into CBN and catalyzing the creation of benzene (both above 390F) but I compromise those ideals to some degree because they interfere with big vape production.

I could be mis-interpreting you here, but if you want the #s on your screen to match the actual temperature your oil is being heated to, then no, that's not my goal with the whole TCR thing. Adding another layer of heat transfer can make this already imprecise quest more difficult. I just want my TC mod screen to reflect the donut temps; I know the temp of my donut resistor still must be alot higher than the necessary minimum temps for vaping due to the less-than-complete energy transfer between wire, to donut, to oil.

PS: For me at least, the exercise in Physics IS the part to enjoy!

I'm enjoying the challenge of dialing this thing in on a VW mod, one that's small and convenient to carry with my V3, and since it's working well enough, no need to be hasteful in replacing with a TC mod!

Me too

(but not the VW part) The ultimate enjoyment is still the smooth big satisfying clouds that result

But from a guy that has no background in math, physics, engineering, etc, I'm having alot of fun conducting this "research" and learning alot from u guys.

It's too bad I can only conduct so many "experiments" with real actual loaded up donuts.

haha

I'm a low-moderate level guy...after 2 good donut loads vaped to completion...I need to take a rest and enjoy myself after a successful test

As far as scaling goes... it's much more effective and much easier to spend the few extra bucks on an IR thermometer with a variable setting, but if you (or

@Vape Donkey 650) want to know how to scale it, PM me and I'll see how well I can explain it (depends on how medicated I am...)

I definitely think airflow is a primo factor here, since the TCR settings everyone is using are an educated guess, with tweaking at best. Because, at least on my two v3's, airflow is crazy compared to the v2.7's I've used. The v2.7's are much more restricted, so they will stay closer to target temp. Overshooting (setting a higher target temp) may help with v3's, since the cooling is so extreme. TCR is important, but what the mod is really regulating here is the resistance, aiming for a target resistance based on what TCR setting you tell it. The TCR is just a scaling factor, and I think you hit the nail on the head - the best way to figure it out is to keep testing!

I think I'm with you there, the mod can only (and wants to) measure coil resistance changes with the TCR, not secondary resistors. We're throwing a wrench into the whole TC-mod idea with our ceramic heaters and we may have to cheat and fudge the TCR #'s to get what we want, but if we can tolerate a little imprecision and experimenting, we can get great results. I think that's what we're doing now?

It will be cool if future TC mods (joyetech firmwares?) incorporate new "ceramic" TC modes that might try to account for these issues with some re-worked mathematical modeling?

Oh yea, if you want to try and show me how to scale the readings of my basic, presumably 0.95 emissive IR gun, please do. But I probably could get some better instruments

WOWW~!

thanks matt

@divinetribe . and thanks

@Vape Donkey 650 ,

@fernand ,

@OF .. unbelieveable vape I just had on this V3 DT !

..using the VTCmini w/ TCR 190, 21W, 380ºF.... thanks. right out of the gate, you guys cracked the code lol. reminds me of the documentary i just watched about compaq trying to crack IBMs code. ha

vape on my friends

and may we continue this open source investigation

ha thanks

Not quite there yet but we're working on it.

FWIW, @ TCR 190, I've settled on higher temps than I would use with the v2.5 @ TCR 245, as some have noted. 380, on most materials, feels a little light and wispy for my tastes, and I'm finding 390-400 to be a better starting temp for a good balance of flavor and cloud. Totally subjective, and variable, with other people's mods and oil types as well.

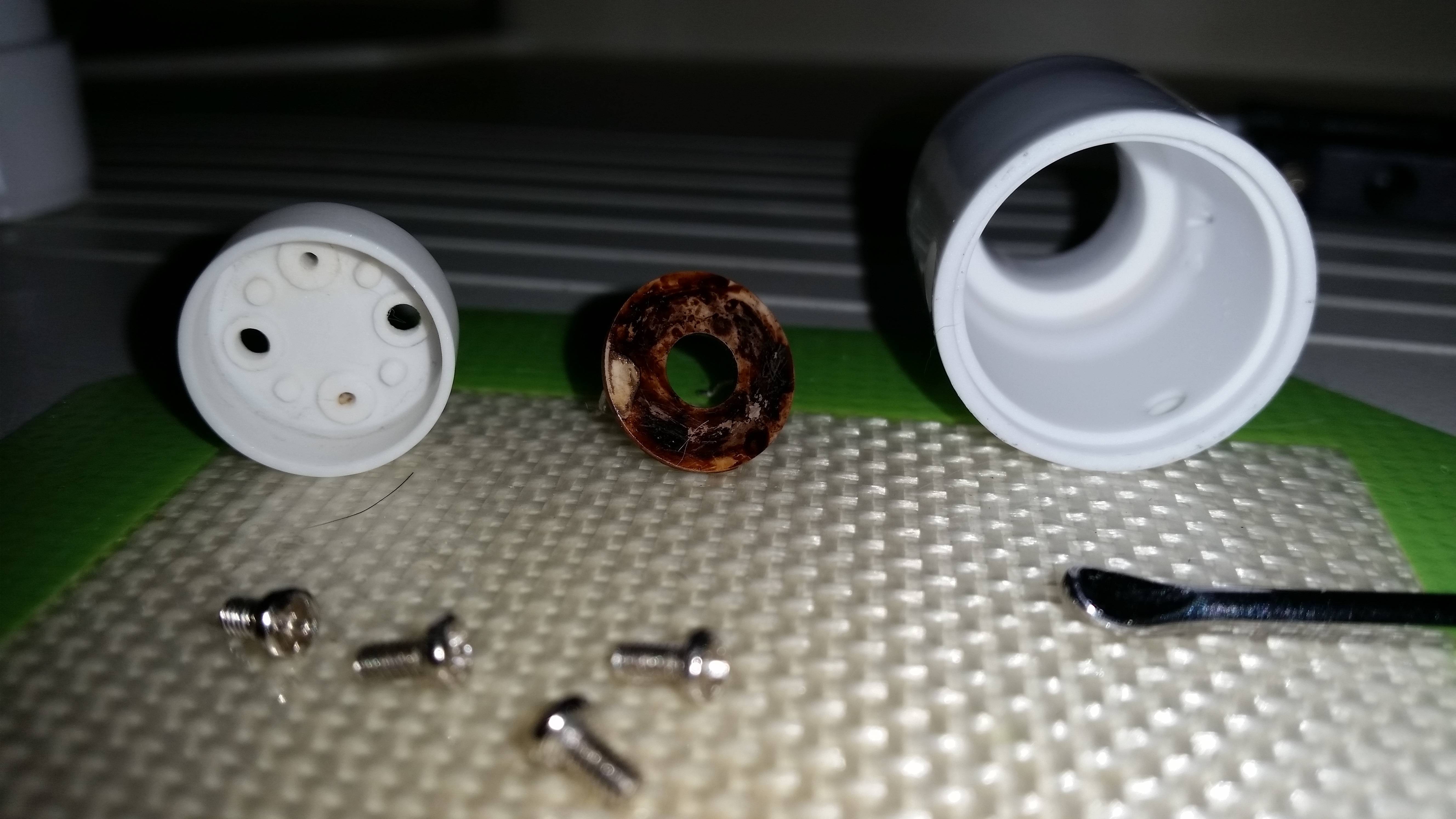

I finally got around to vaping some co2 oils on the new large donuts too, and I was disappointed with 380 and 390F

Nice flavor but hardly any cloud. I need to do 420F with co2's to get a nice cloud now, and noticing most co2s give a little less cloud production and hits per load compared with shatters, just like with the 2.5, but is smoother and often tastier. Also super clean, I've had like 10 co2 loads on a large donut and it has no residue at all....but......

i had been hoping v3 worked like v2. Too bad, v3 has drain holes in the bottom of the cup under the donut, so if the temp doesn't climb fast enough, the entire load melts and drains down under the cup.

Yes this

That's why the instructions say to inhale as soon as you start pressing the button. Start your inhale slow to give it time to heat up, and speed up once the screen says temp protection.

Yes this too. With co2 oil, I was noticing much more fresh looking reclaim underneath the donut in the cup. Its low viscosity must be making it fall down under during the lengthy 4-sec warmup @ 32w. I've gone over to 40w for a quicker warming, and trying to start my draw earlier, getting better results, but still a work in progress....

wow....so nice. Gives a very nice, substantial cloud. I wanna say in between small and large sized donut clouds, for the load (uh-duh, thnx capt. obvious

wow....so nice. Gives a very nice, substantial cloud. I wanna say in between small and large sized donut clouds, for the load (uh-duh, thnx capt. obvious  ) but these are just my first impressions. Flavor very good too, and the TC performance seems pretty steady on an Evic (very little protection), moreso than the large

) but these are just my first impressions. Flavor very good too, and the TC performance seems pretty steady on an Evic (very little protection), moreso than the large

Not sure if I follow you here, fern.

Not sure if I follow you here, fern. (but not the VW part) The ultimate enjoyment is still the smooth big satisfying clouds that result

(but not the VW part) The ultimate enjoyment is still the smooth big satisfying clouds that result

haha

haha

I forget, maybe 6-8 big

I forget, maybe 6-8 big

With this type of usage, leakage will most likely be an issue without a redesigned cup

With this type of usage, leakage will most likely be an issue without a redesigned cup

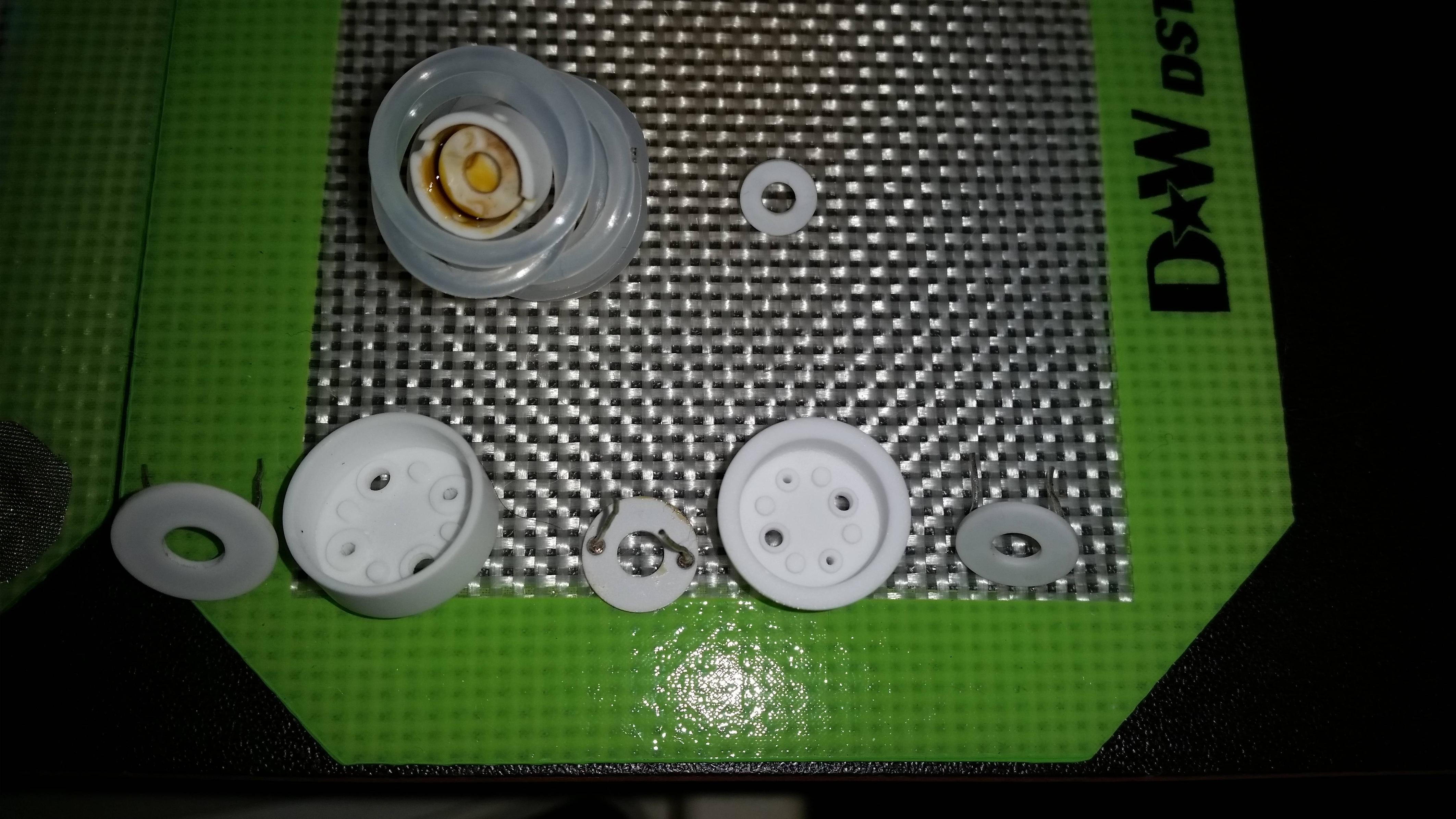

I also have some of the small black ceramic donut wicks from W9, I may try and see if one of those helps prevent oil from going where it isn't wanted when I do round 2 of testing tonight.

I also have some of the small black ceramic donut wicks from W9, I may try and see if one of those helps prevent oil from going where it isn't wanted when I do round 2 of testing tonight.