@OF

"

Know anything about the TCR of whatever Chinese alloy they use in garden variety 510 atomizers?"

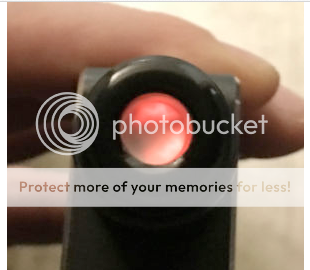

@OF So you know that the resistive material is deposited as a film in Matt's donuts? I was amazed to see that the black one I got on e-bay reveals a wound coil or a zigzag inside (can't tell if it's in 2 or 3 dimensions) when heated enough to glow!

Understood. I've told you 'all I know' on that topic, really: 'there are a lot of alloys in use, mostly Nichrome A and C'. But, since often it's physical properties (like strength at temperature) or electrical ('right' changes with temperature to help regulate), lots of what might make one alloy an advantage over another might not count.

In the 5 Watt or so e-cig based heaters I'm not even sure they're all Nichrome. In fact I know they're not. For sure I have some specifically advertised as such (that is 'non Nichrome').

If you want to experiment, I suggest you fish it out. Check the resistance change (cold to hot) and see what sort of percent change you get. If you get little/none (very possible, for example Kanthal A) you're SOL I think. If it's a couple dozen percent (it's like 40% with the DC doughnut) you're Jake. A few percent and you're on real thin ice?

As far as the 'Chinese alloy' it, of course, has nothing to do with origin, metals are metals. I didn't responding on your prior asking: "

@OF do you have a TCR for Chinese Peoples' Nichrome?". I gave a pass to it then, perhaps an error?

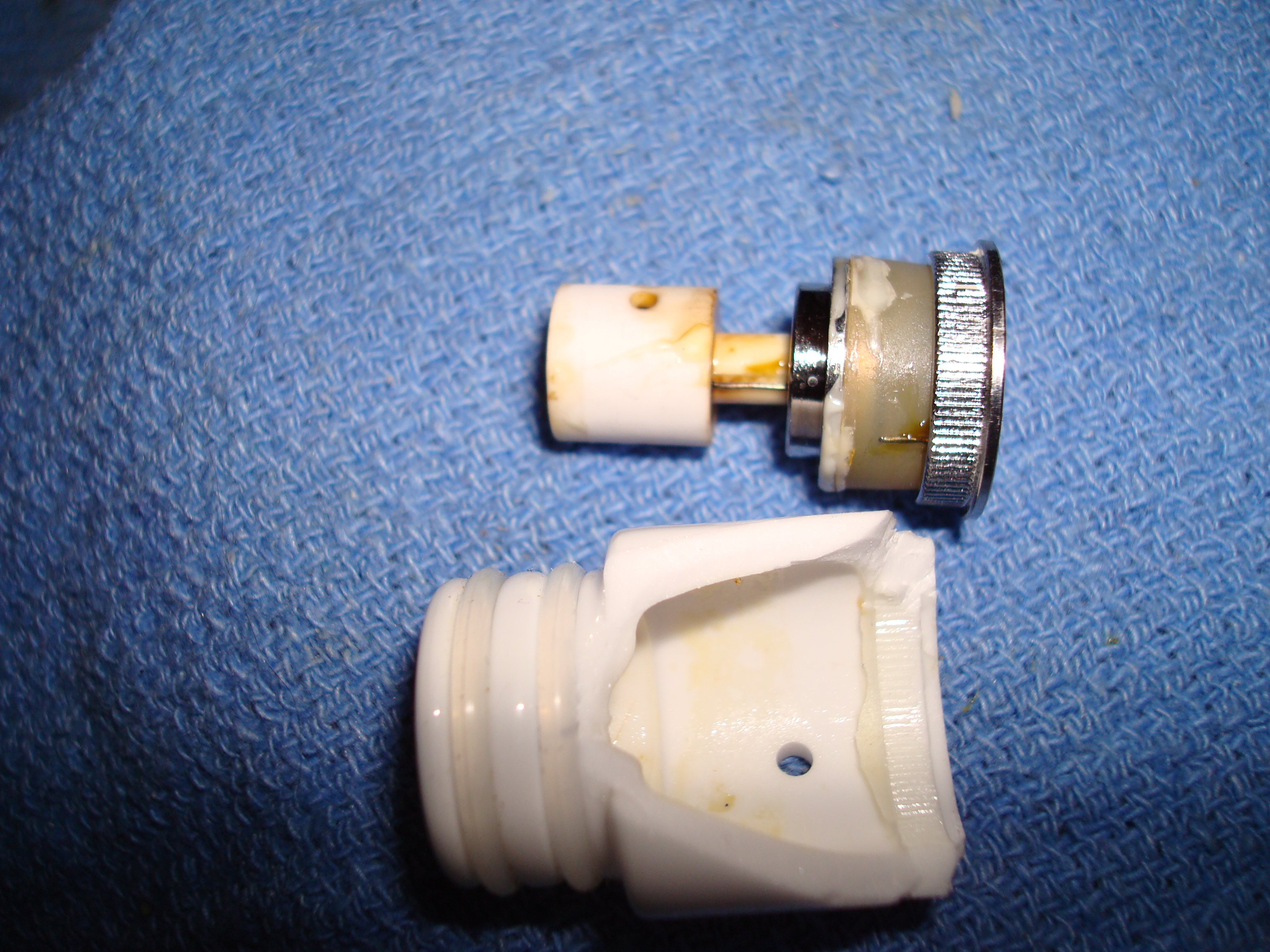

The loose doughnut I bought from Matt sure is, as the ones in DT bases seem to be, . And good thing, pretty hard to put a coil in a package that thin. How thick is the 'pancake' (can't call it a doughnut, there's no hole...... OK, maybe a Danish?). in that guy? I was thinking of ordering one or two to play with sometime, off hand it seems like a bad idea not having the vent hole in the middle, kind of asking for lots of splatter?

It could be a coil of course, depositing films is 'less cost effective' in many environments but making them thin would be a problem. Sometimes the film is masked as it's deposited to give a longer path, sort of like the element in a toaster might (if you allow the versions that use ribbon are basically flat).

I think there's a serious advantage to the DT approach of a deposited film on top of a 'green' (low fired) substrate (that won't change shape much in final firing/glazing). As well as the shape. If you 'cast' ceramic around a metal coil stresses can cause degrading the ceramic (which is why so many have SS jackets welded on, the ceramic 'falls apart' with use). The same problems come up making high power resistors with ceramic jackets, at lower temperatures.

Interesting information, even if it isn't making sense yet, thanks. Maybe I should have ordered one...... Please let us know how it performs (all that really matters in the end?). TIA

OF

(never thought I'd be giving YOU one of these)

(never thought I'd be giving YOU one of these)