Have you ever taken TC measurments of the dab surface vice set point. Do you have another set of data for comparison?

As we spoke, I did the hand tightening for the reasons you mentioned and got what I got. I did just tighten it up more than that and no cracking of the SiC and I did cut 45 degrees off of the delta but its still 194 degrees at 800 set point.

I do not think its my controller which works perfectly. If anything, perhaps I have a bad TC in the coil that reports a higher temp (K-type TC temps are measured by voltage output....yes??). But please remember, I was not the only one in this thread complaining about having pooling of my concentrates at temps where I would expect them to boil off sharply.

As far as PID not being set for flat coil....as far as I can tell, a flat and a barrel coil are pretty much identical except in the way that they are wound....but electrically the same coil.

Dunno.

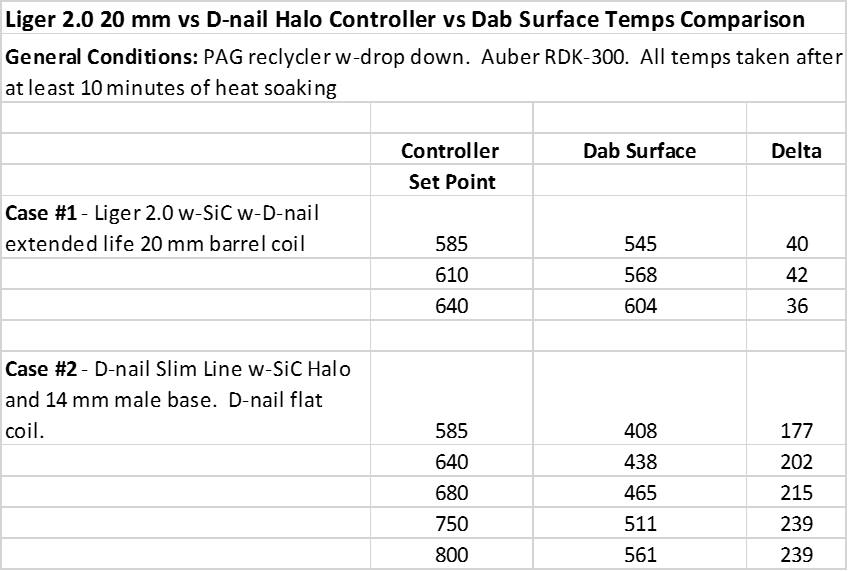

More data after flattening and tightening:

Run #2 after flattening and tightening, again, set point, measured dab surface, and resulting delta. I was able to cut it down a bit by flattening and tightening but that's rather the end of that road and my measurements are consistent...well, at least they in the same universe.

Again: set point, dab surface measured temp, the resulting delta.

750 572 178

800 606 194

I have not actually done the thermocouple testing (the thermocouples that I have are for lab application, are incredibly expensive and are not rated for dabbing temps, but rather temps used in processing - much lower temps lol).

However, I also do not experience pooling/vapor trails from my SiC halo when assembled identically to yours, using the same kind of 120v d-nail extended life flat coil and a d-nail 1.2 controller at much lower temps than those that you have used (my usual temp would be 520-580f, hard maximum for the SiC halo would be 620f or so). If I raise the temp on the dial to 750f in my configuration, it vapes in an instant flash, and the taste is reliably so bad that I would never dab again if that was my only choice of how to administer it. Remember, I'm dabbing full melt here brother. Full melt tolerates more heat before tasting bad than rosin/solvent extracts. If 6 star full melt tastes bad on a SiC nail, it is WAYYYYY too hot.

Please also remember that my coil is much older than yours, has been heated up for years on end and should be expected to require more juice to get the same heat due to oxidation changing the thermal properties of the metal heater coil over time.

I should clarify that for your situation, if anything needs replacing, it is probably the coil IMO. It is more likely to my mind that the behavior that you are observing is related to a problem with the thermocouple measurement being problematic.

Do you have a buddy with another controller and flat coil heater? I do think it would be very helpful to try the same coil and nail with another controller, and then the same controller and nail with another coil

I'm gonna talk with my design/engineering friends from d-nail when I get a moment and mention the deltas you're observing, since they really do seem strange to me! I hope that we can get to the bottom of this sooner than later!

I definitely think that the most crucial step in troubleshooting is going to be accessing another controller and coil to isolate the problem

BTW having your coil as flat as possible should minimize chances of breakage from over-tightening - so it couldn't have hurt that you've done this now

Please understand that I've been told about SiC halos that have broken from over-tightening on more than one occasion now (although it is not at all common, the overtightening seemed to be significant to achieve this kind of failure!). If that titanium expands too much against the SiC due to assembly which is too tight, it'll eventually break.

@ensabbahnur one thing that we need to recognize is that the d-nail graph does not identify any universally 'optimal temp'. In fact, from their explainer of the dish temp charts:

"Ideal temperature will vary based on the chemical composition of the essential oil you are vaporizing, amount of material being vaporized, and of course your personal tastes"

They go on to explain that:

"For typical use, we suggest using a dish temperature at or below 600°F, so our temperature charts are marked with a horizontal line at that mark. This traces over to the line representing the coolest point on the dish, if you follow this line down, it shows the heater temperature to set on your unit. For example, with the D-NAiL® SiC HALO™, a heater temperature of 695°F will make the coolest part of the dish about 600°F. Depending on your concentrate and preferences, after trying this temperature you may wish to adjust it up or down. For maximum flavor, we suggest using the lowest heater temperature that still provides full vaporization in a reasonable time. Running your unit hotter will vaporize faster, however you will experience a smaller flavor profile due to the destruction of sensitive volatile components."

Source:

http://www.d-nail.com/info/science/ (see heater and dish temp analysis section)

Please understand that I've been told about SiC halos that have broken from over-tightening on more than one occasion now (although it is not at all common, the overtightening seemed to be significant to achieve this kind of failure!). If that titanium expands too much against the SiC due to assembly which is too tight, it'll eventually break.

Please understand that I've been told about SiC halos that have broken from over-tightening on more than one occasion now (although it is not at all common, the overtightening seemed to be significant to achieve this kind of failure!). If that titanium expands too much against the SiC due to assembly which is too tight, it'll eventually break.