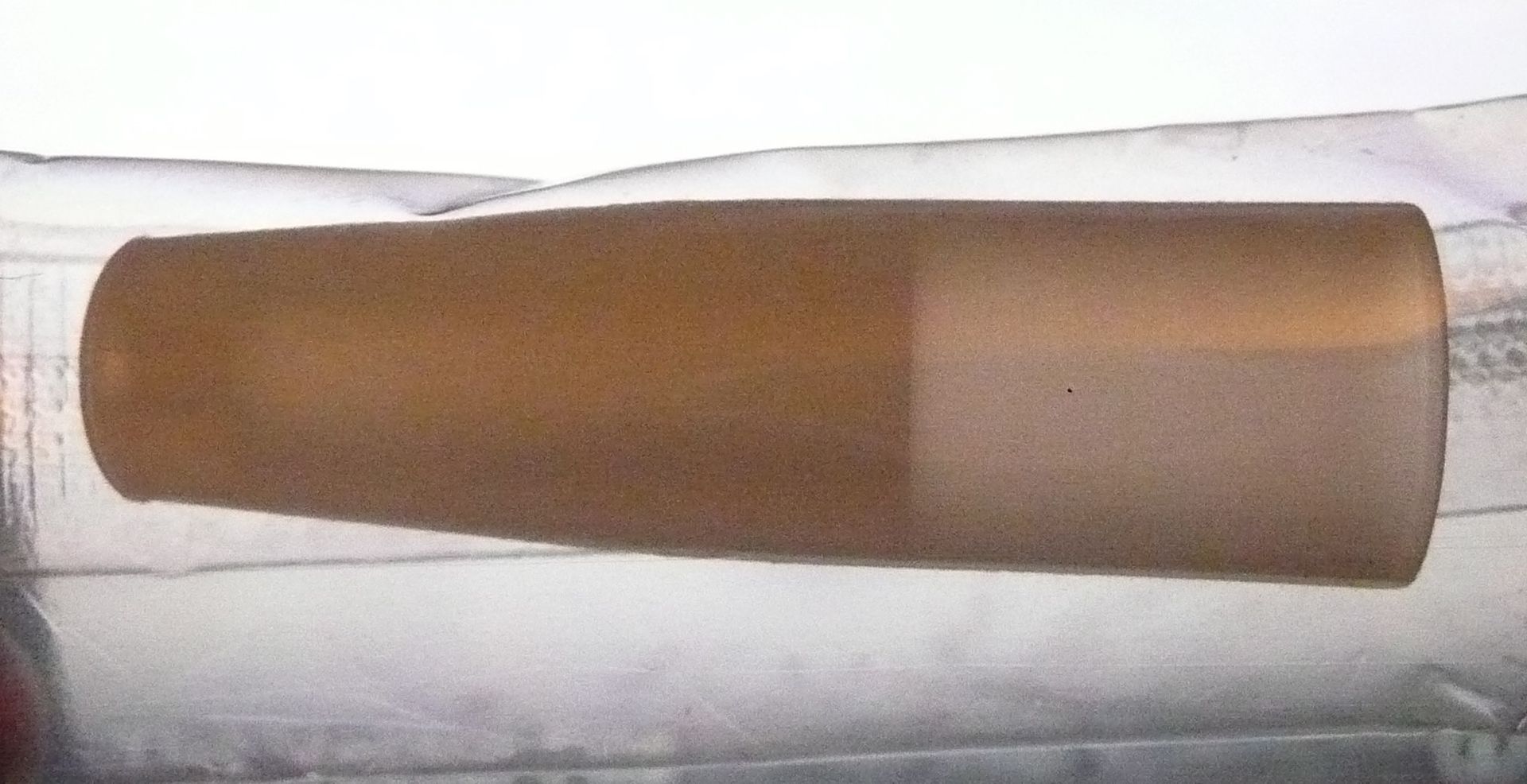

It's the "fat lip" that was out of round and too fat. I don't believe they can make them all that uniform.

What I found is that after going red-hot over 1000 deg, it drops down and maintains around 550 for a good while, and that's the apparent average vaping temp, which seems very tame, but sure does the job. Any conflicting data?

I agree with both those observations (that is they make sense to me). I think the stems are 'fire polished' on the end (just the rim heated to melting/fusing temperature and allowed to cool). This, combined with the variation in OD from the 'blow out', means they will have some (hopefully controlled) variances. To be more precise would call for expensive grinding and etching I think? I also think the system was designed to have the stems work OK when quite loose, looser than many of us like.

I also note some variations in the lip at the top, I suspect it's fire polished as well. Also, in addition to a couple of the stems being out of round I found a couple of mine had a fair bit of reverse taper (the mouth was bigger than the OD back near the partition). This was a big setback in the quest for a scheme to tighten up stems and what led me back to the ring idea and convinced me the key was the ID and material (ability to stretch and spring back the right amount) without any clamping forces.

The Ti temperature makes sense as well. Although I bet the glowing metal is more than 1000F. This is an evaporation exercise (phase change). Changing phase (from liquid to vapor in this case) takes a huge amount of energy compared to what it takes to heat the same amount liquid (or vapor) even a single degree. Like boiling a pan of water, as long as there's liquid left it never gets hotter than 212F (100C) on the inside of the pan. There may be 1000 degrees on the outside surface of the pan (against the glowing burner or directly in the gas flame) but 1/16 inch or so away through metal that conducts heat very well the temperature is nearly 1000 degrees less. There is a very large temperature drop, driven by Thermodynamics, across that thin pan metal. Same on the nail, the inside of the nail is still much hotter, but the heat from the surface has all been taken up making vapor until it drops down to the boiling point of the the liquid.

It's called 'latent heat' in some technologies. It's what makes steam burns so dangerous. The steam is not all that hot (you can eassily wave your hand through a 1000F (or hotter) torch, right?) but the heat energy (in calories or BTUs) available as the water vapor at 212F turns into water condensation (also at 212F) is HUGE compared to the energy available in the warm vapor from incidental contact since again Thermodynamics limits that in the same way the drop in temperature across the pan cross section happens, the rate heat can transfer (move) to your skin is much lower there. This heat energy is what seemed to disappear in the pan of boiling water where lots of energy went in but nothing got hotter (water, pan and vapor all stayed at 212F give or take, only the ratio of liquid to vapor shifted).

This drop (say in degrees per inch) in the pan material is a function of material and the delta (difference) in temperatures. In electricity we'd have similar rules (Ohms law in fact) with the factors being voltage for temperature, current for heat flow and resistance for the thermal conductivity of the metal. There are similar rules for magnetism involving MMF (Magna Motive Force), permeability and the flux we generally measure (as in Gauss or Teslas).

Complex stuff for sure, only fun to a twisted few of us, but that's how I understand it to work.

OF

...need to know if your ash catcher fits the D020 directly so that it clears the sides, or is the stem bridge too short? Thanks!!!

...need to know if your ash catcher fits the D020 directly so that it clears the sides, or is the stem bridge too short? Thanks!!!

...need to know if your ash catcher fits the D020 directly so that it clears the sides, or is the stem bridge too short? Thanks!!!

...need to know if your ash catcher fits the D020 directly so that it clears the sides, or is the stem bridge too short? Thanks!!!

...need to know if your ash catcher fits the D020 directly so that it clears the sides, or is the stem bridge too short? Thanks!!!