I'm sure someone has mentioned it to them.......

In companies as well run as Arizer seems to be they most definitely are watching field returns. A single return can wipe out the profit from dozens of sales. You go broke warrantying bad products.

My guess is they think they have a handle on it (they may well, our statistics are highly questionable at best), if they think it's getting out of hand all they really have to do is go back to the old, proven, software. The former model is still an option, there was noting compelling forcing the change.

Time will tell.

Sure. I charge when I'll be nearby when I can. The top LED lights at about the 80% charge point, sometimes a bit more, a bit over 8.0 Volts total. The charge LED stops flashing about .4 Volts later with both cells at 100% (due to the protection board preventing either battery from going over 4.3 or so (really hard on them).

Each time you take it that high does a bit more damage. Stopping short by 10% (less than one session per charge) doubles the lifespan of the battery. Twice. Drop it another 10% and it doubles again. The difference between say 300 cycles and 1200.....you do the math.

Never charge to the wall and store them that way, use it right away or don't do it. Store at about 2/3 charge. Lots of great reading on the topic here:

http://batteryuniversity.com/learn/article/how_to_prolong_lithium_based_batteries

Lots of other good resources out there, but Battery University reads easily and covers the topic well.

You might consider dumping the brass, many are concerned about it as a material. To make it '

free machine' so it's easy to cut into wool

they add lead to it. For most of us avoiding lead when possible is a no brainer. The lead content is the problem with brass plumbing fitting and fixtures (unless you pay extra for lead free), but there you quickly get protected by calcium and other deposits, not so in this vape use. Rather, I suggest you cut a piece of the SS concentrate pads made for this use in the Volcano. Two styles, either work fine for this. This is actually .003 diameter wire, carefully woven into a tube. Very effective for the job, designed for it by the Germans and all. Be careful with letting concentrate contact the bowl, it'll stain it.

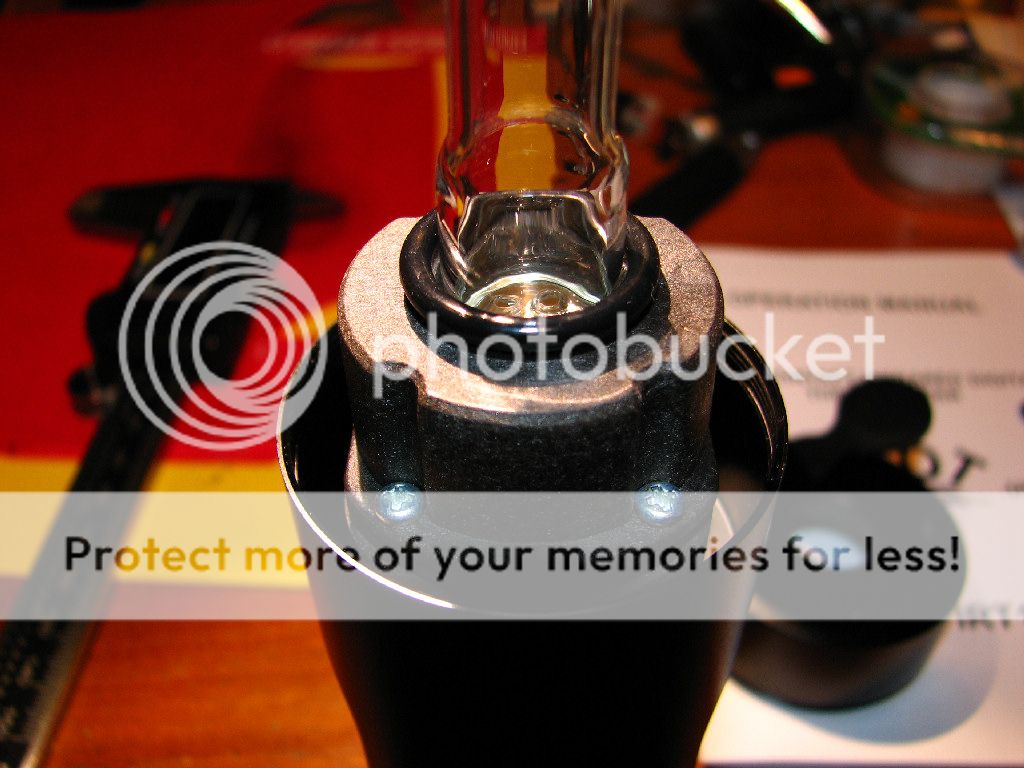

You might want to rethink the ring from a couple of angles. First off, that's the wrong material. It's soft neoprene since it's intended for household plumbing (usually Buna N). Typical maximum temperature ratings on hardware store ring is like -35° to +250° F.

I think the size may be off too, I couldn't get any metric sizes to work nearly as well as the SAE #113 size:

http://www.mcmaster.com/#9396k26/=r96e2v

Notice this material is rated for -65° to +425° F, much more suitable for us.

I'd also be very careful with the 'collet' idea, that's not what you want. The ring should grip the stem on it's own, the cap hold the ring tight enough so it doesn't rotate. Any more than that is very likely to break the thin plastic tabs where the screws are on the bottom. They were never designed to tighten a collet.

A little over a year back we collectively decided you want 1/4 to perhaps as much as 1/2 a turn after contact, no more. And 113 was the right ID, you should sand or otherwise thin the ring as needed. If not, try a thinner cord ring with that ID. Perhaps the 015 size?

Regards,

OF