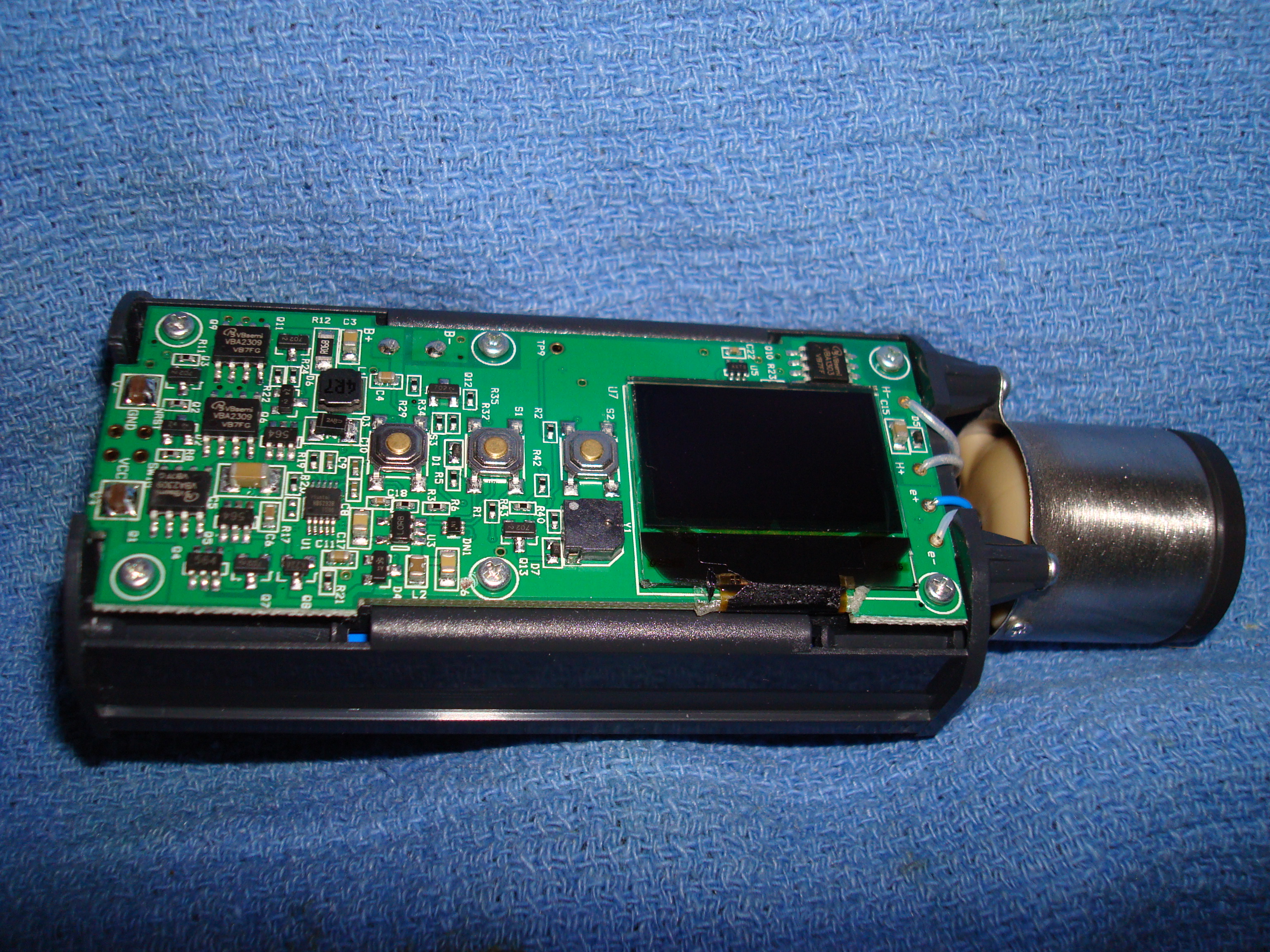

I don't think it's really all that tight a fit, here's the photo I posted the other day from the inside. Blow it up and check out the slot for the wires, IMO it's quite big, bigger than needed and it could have easily been sealed with tape? IMO there's less restriction there than in the stem, vents in the oven or I bet the star shaped air vent in the back?

Nowhere near 99.9% IMO. This is easy to test, tape up the stem opening (around the stem) and star shaped vent in the back and see if it still draws OK. Don't forget the hole in the top the cover goes through. I just repeated this test. Flow is more restricted, but it still draws OK proving that

at least some of the air goes over the PCB which is all the purists need to scream 'Witch!'.

In that test you can also discover that the star shaped vent is not as important as the gap around the stem in terms of flow. You can tape up that vent and hardly know. Remember that the fit between chassis and inner tube wall is not gas tight either, that too would need to be sealed during assembly?

Your added photo shows the gap but the perspective is such that you can't see how deep it really is. The wires fill a small percentage of the opening? Less than 'half the bottom half' of the slot? Plenty of opening left for airflow.

I just think Arizer doesn't recognize this as a design goal. They could have done a much better job of sealing it off easily enough, but just don't see any advantage avoiding a risk they don't consider legitimate?

OF

.

.

I'm sure arizer isn't worried about a few kids talking shit in America when their market is worldly.

I'm sure arizer isn't worried about a few kids talking shit in America when their market is worldly. The solo2 is incredible!

The solo2 is incredible!