pxl_jockey

Just a dude

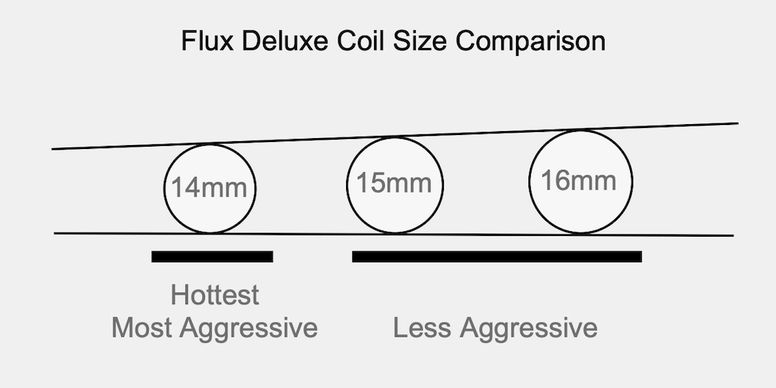

I had replaced my original coil with a more aggressive version and it’s ruined my enjoyment & experience with the FD. That’s why I’ve been so quiet here and haven’t had anything to add... because I’m not able to use the bloody thing at all anymore. I wish I hadn’t been curious about the different coil diameters because I was very happy with the performance before and used it all the time but after switching out the coil, my FD is running way too hot. It’s just roasting/burning my weed now and the VC’s cap gets stuck on the tip every time and cannot be removed until it cools down. I’ve tried many tip & cap combos, and the issues are consistent; it’s a tremendous pain in the ass that’s reduced my FD to simply collecting dust. Anyone here with any advice or experience with this please lmk, I DM’d with mr_c in August with no reply (guess he’s too busy rn) and just haven’t bothered to reach out again. Fortunately, like most here, I have other options so I’m not sweating it.

I’ve ordered some new batteries with a lower CDR than the Sony VTC-5As to see if that helps, although the Sony’s worked amazingly well before the coil switch. If the new batts don’t help, I’m sending the FD back and don’t really care how long it takes because I’m certainly not getting any use of it and just pisses me off every time I happen to look over and see it.

I’ve ordered some new batteries with a lower CDR than the Sony VTC-5As to see if that helps, although the Sony’s worked amazingly well before the coil switch. If the new batts don’t help, I’m sending the FD back and don’t really care how long it takes because I’m certainly not getting any use of it and just pisses me off every time I happen to look over and see it.

to do before i would change size

to do before i would change size I want people to enjoy using this, and the FD's coil size is equivalent to a shoe size - it needs to fit you to be comfortable.

I want people to enjoy using this, and the FD's coil size is equivalent to a shoe size - it needs to fit you to be comfortable.

I've choosen 15mm. I make this decision because of the description "how it works, how many hits/puffs" etc. On my DIY IH I have standard coil (probably 16mm) without glass and I got 3 sessions/puffs from one bowl, no combustion but abv is dark. I expect that 15mm will be similar. There is a new relay so it could works a little bit in different way that last versions with mosfets. I will see soon how it will work and give you a meritorical review.

I've choosen 15mm. I make this decision because of the description "how it works, how many hits/puffs" etc. On my DIY IH I have standard coil (probably 16mm) without glass and I got 3 sessions/puffs from one bowl, no combustion but abv is dark. I expect that 15mm will be similar. There is a new relay so it could works a little bit in different way that last versions with mosfets. I will see soon how it will work and give you a meritorical review.

So, I guess I offer it so that there's something for everyone. As an aside,

So, I guess I offer it so that there's something for everyone. As an aside,  The comments are somewhere back in the thread - December or January, most likely.As a result I now glue the button directly to the top of the switch. I still have a quantity of the caps, however. If someone reading this wants to try this as a means of reducing your heating profile a bit,

The comments are somewhere back in the thread - December or January, most likely.As a result I now glue the button directly to the top of the switch. I still have a quantity of the caps, however. If someone reading this wants to try this as a means of reducing your heating profile a bit,

That would be bad.

That would be bad.