KeroZen

Chronic vapaholic

WARNING / DISCLAIMER:

1) When dealing with electrical devices connected to the mains, there is a serious risk of death or injury. Please be careful and use your common sense. Always work with the power cord unplugged.

2) To reduce the risk of fire in case of unexpected failure, always unplug the PSU when you are not using it and when you are leaving home.

3) Having your Zion tethered will increase the risk of damaging it if someone trips on the cable. If you are lucky the adapter should unplug, but otherwise it can make your Zion fly in the room and you will likely break the internal glass parts if it happens.

4) Even if the output voltage is quite low, the amps are relatively high and could cause some shock or injury. So be careful when touching the exposed contacts on the adapter side too.

5) In short: use your brain and don't hold me responsible if you screw up!

Introduction

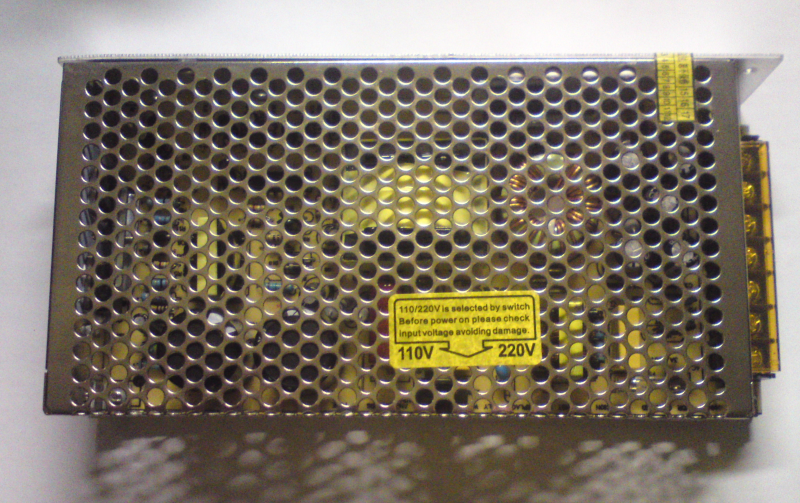

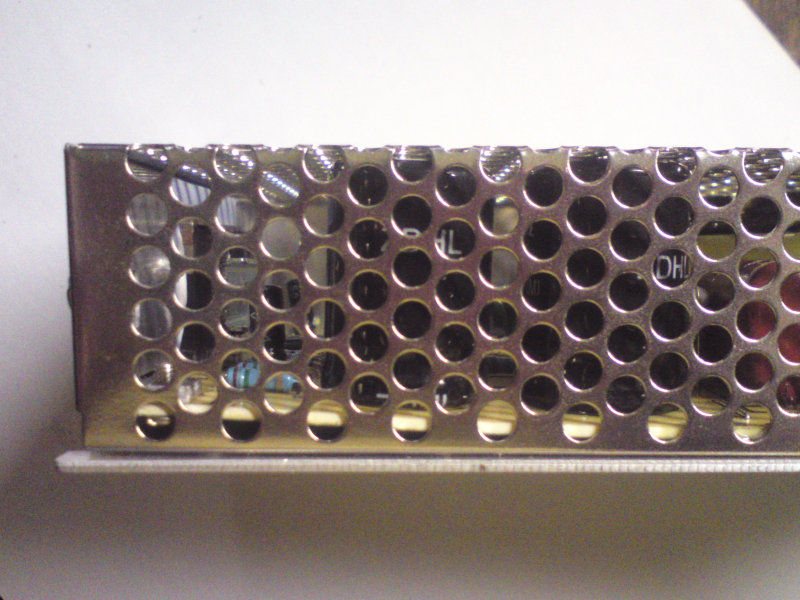

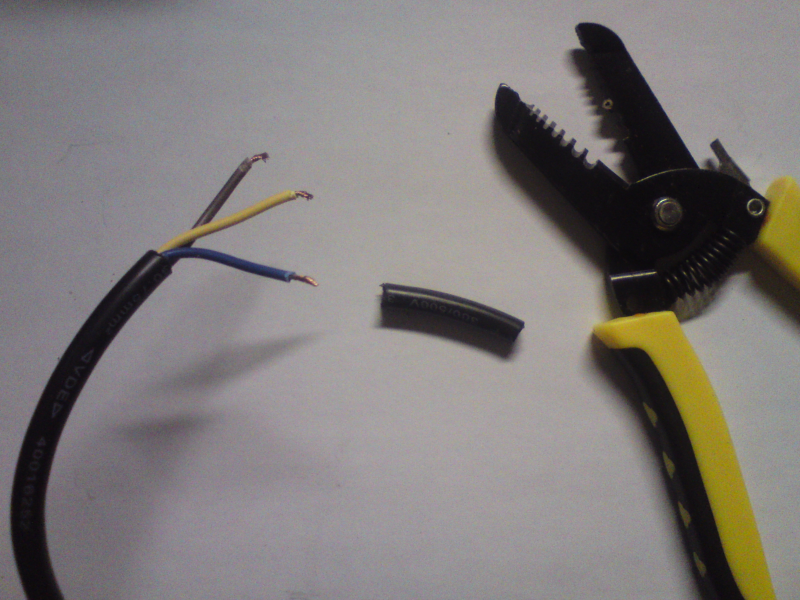

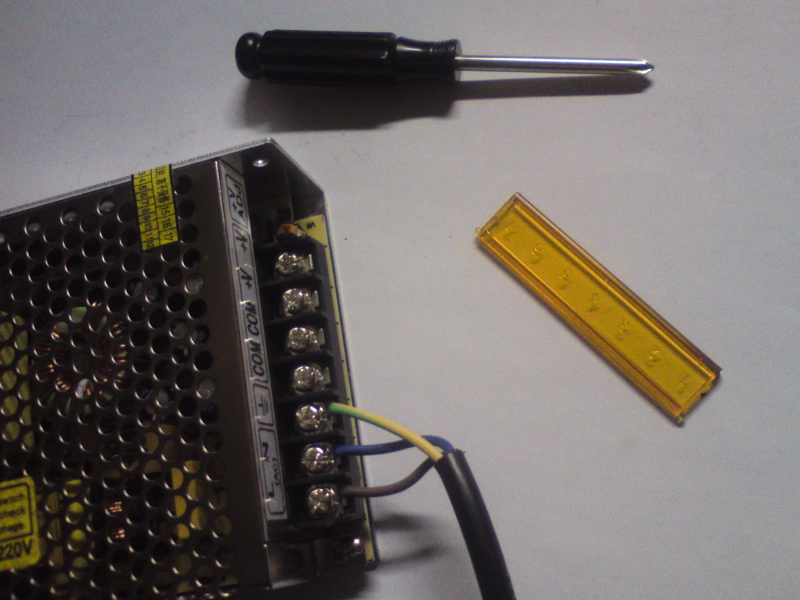

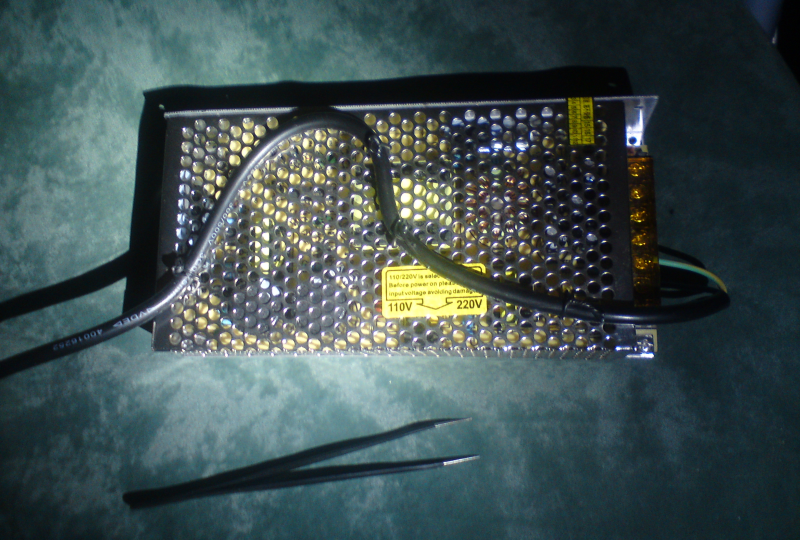

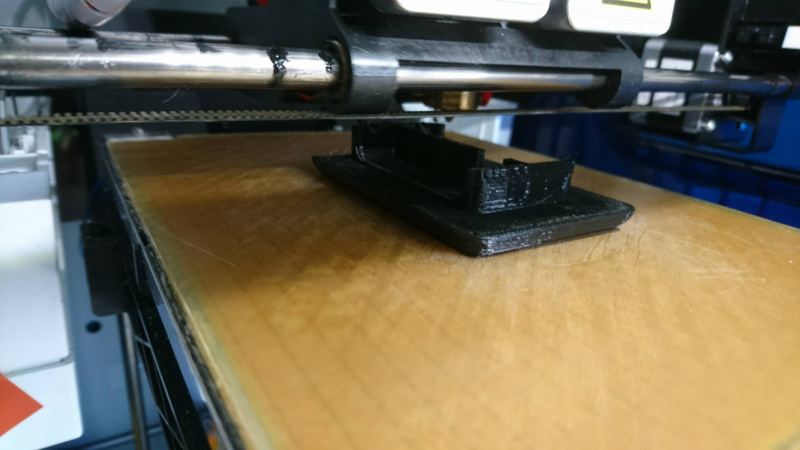

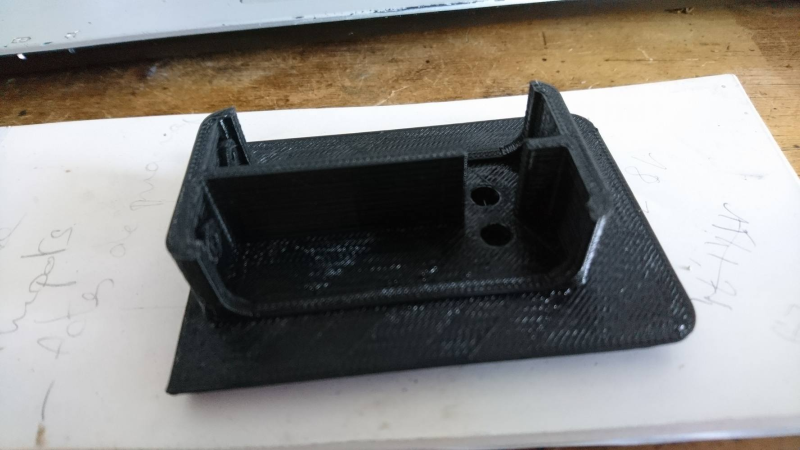

I will try to produce a step by step guide to create a Zion Power Adapter (ZPA) from scratch using cheap parts easily available. I currently have a fully working prototype that I've been enjoying at home, but it's not ready for prime time yet (mind you, the kid is a bit ugly...)

I could wait for its completion and show you only the end result but then this guide would be very short and not super instructive. I think it's best to show you the progression and the various iterations. Plus if I don't post it now, there's a risk I will forget the details... so let's get to it while it's still hot!

This will by no means be complicated and apart from basic soldering (unless you use an alternative for that specific part, more on that later) you won't need any skill at all. If you want to use wood for the door on the other hand, then it will be more involved (unless you manage to hobo Ryan to make him sell you a pre-made door... or if you sacrifice your existing door but I don't recommend that)

Pros

- Turns your Zion into a desktop, in a non permanent fashion (can always revert to batteries)

- No battery voltage to monitor anymore, no cells to swap and charge

- Unlimited autonomy

- Zion will be lighter to hold, adapter weights less than two cells

Cons

- Tether limits your motion range, can be annoying when passing around in group settings

- Serious risk of tripping on the wire and damaging your Zion in the process

1) When dealing with electrical devices connected to the mains, there is a serious risk of death or injury. Please be careful and use your common sense. Always work with the power cord unplugged.

2) To reduce the risk of fire in case of unexpected failure, always unplug the PSU when you are not using it and when you are leaving home.

3) Having your Zion tethered will increase the risk of damaging it if someone trips on the cable. If you are lucky the adapter should unplug, but otherwise it can make your Zion fly in the room and you will likely break the internal glass parts if it happens.

4) Even if the output voltage is quite low, the amps are relatively high and could cause some shock or injury. So be careful when touching the exposed contacts on the adapter side too.

5) In short: use your brain and don't hold me responsible if you screw up!

Introduction

I will try to produce a step by step guide to create a Zion Power Adapter (ZPA) from scratch using cheap parts easily available. I currently have a fully working prototype that I've been enjoying at home, but it's not ready for prime time yet (mind you, the kid is a bit ugly...)

I could wait for its completion and show you only the end result but then this guide would be very short and not super instructive. I think it's best to show you the progression and the various iterations. Plus if I don't post it now, there's a risk I will forget the details... so let's get to it while it's still hot!

This will by no means be complicated and apart from basic soldering (unless you use an alternative for that specific part, more on that later) you won't need any skill at all. If you want to use wood for the door on the other hand, then it will be more involved (unless you manage to hobo Ryan to make him sell you a pre-made door... or if you sacrifice your existing door but I don't recommend that)

Pros

- Turns your Zion into a desktop, in a non permanent fashion (can always revert to batteries)

- No battery voltage to monitor anymore, no cells to swap and charge

- Unlimited autonomy

- Zion will be lighter to hold, adapter weights less than two cells

Cons

- Tether limits your motion range, can be annoying when passing around in group settings

- Serious risk of tripping on the wire and damaging your Zion in the process

Last edited:

), but I find it interesting and I think it could give a lot of people ideas!

), but I find it interesting and I think it could give a lot of people ideas!