Conduction: Friend or Foe for Flavor? [Part 2 of 3]

This post is intended to explain my thought process and why I made various decisions designing the Screwball (aka my dream daily driver).DHV Categories

Based off of my research, this is how I would categorize DHVs:| DHV Type | Heater(s) | Heating Method | Notes: |

| Convection DHV | Convection only | Hybrid (Convection + Conduction) | Convection is said to have better flavor, due to slower heatup times which activate more low temp terps. |

| Hybrid DHV | Convection + Conduction | Hybrid (Convection + Conduction) | Hybrid/Conduction is said to give more 'stoney' effects, due to more efficient heat transfer which activates more sedative cannabinoids at higher temps. |

| Conduction DHV | Conduction only | Conduction | Bad for flavor due to uneven and inefficient heating. Leads to overheating on the outside perimeter of the bowl |

IMO, I think most/all vapes offered today are Convection or Hybrid focused. It seems like pure conduction vapes are outdated, and not recommended by users.

The 'Ideal Vaporization System'

IMO, vaping cannabis is more than using a vaporizer/banger/e-rig/etc. It's a complete system / equation / mini science project to reach our desired end result.Each variable of the equation (heater, flower, glass rig, etc) makes a difference when altered, and can change the overall consumption experience.

Because users have different preferences (joint size, inhale speed/duration, product type, etc) it adds context to the equation, and you can adjust certain variables to help reach your desired outcome.

"How Would You Like Your Steak Cooked?"

(I apologize in advance to any vegetarians/vegans for using this reference)IMO, the analogy of how people like their steak prepared is a good example for vaping cannabis too.

Dry Herb Vaping 'Doneness' Chart

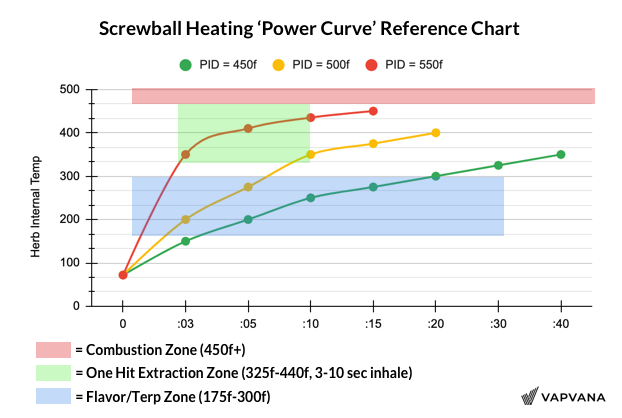

IMO, a 'herb doneness' chart would like something like this:| Doneness | Herb Temp (F) | Herb Temp (C) | AVB Color (Not Reliable) |

| Extra Low Temp | 300f - 350f | 149c - 176c | Very Lightly Browned |

| Low Temp | 350f - 375f | 176c - 190c | Lightly Browned |

| Medium | 375f - 400f | 190c - 204c | Brown |

| Dark | 400f - 425f | 204c - 218c | Dark Brown |

| Extra Dark | 425f - 445f | 218c - 229c | Darker Brown |

| Combustion | 450f+ | ~232c+ | Black/Charcoal |

Temperature Control = Experience Control

Because different cannabinoids are activated at different temperatures, you can control your experience based off of your desired herb end temp.

The Thermodynamic Equation

Based off of the variables in our control, there are different ways to reach our desired outcome.In other words - the users consumption preference will provide the context needed to adjust the equation in their favor, aka "how we roast our herb for our desired outcome?"

The process can be thought of as a thermodynamic equation. The controllable factors in the equation for convective heating are temperature, pressure, surface area, mass, and flow rate.

The mass, shape, and density of the ground material is important to the equation. A puck shape, similar to that used when making espresso seems to work the best. If we want even extraction, the entire puck must be heated to the level needed to volatilize the desired plant oils.

Complete extraction also seems to be a tough point to define. The plant material contains a wide spectrum of oil densities. There are some heavy oils and tars within the plant material that we really don’t want to volatilize. Some are only released with the heat of combustion. The most flavorful oils are released at lower temperatures. It all depends upon how dense of oils you want to volatilize to determine your fully extracted point.

Designing The Screwball for Low Temp Vaping

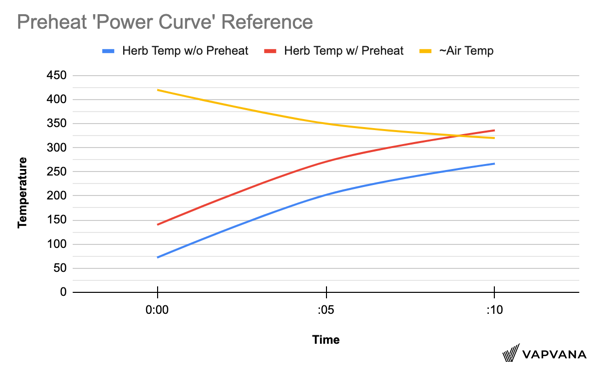

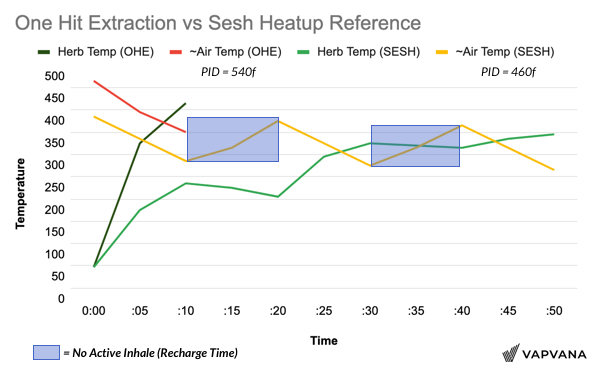

With the goal to operate at the lowest convection air temps possible, while still reaching our desired end herb temp, this is how I designed the SB around each variable in our control.Temperature

With a goal to lower convection air temps, my idea was to maximize heat transfer in all ways possible:- Using 750 2.5mm ruby gems operated at lower temps better than ~230 3mm pearls

- The gems also retain heat better, allowing for a more consistent air temp

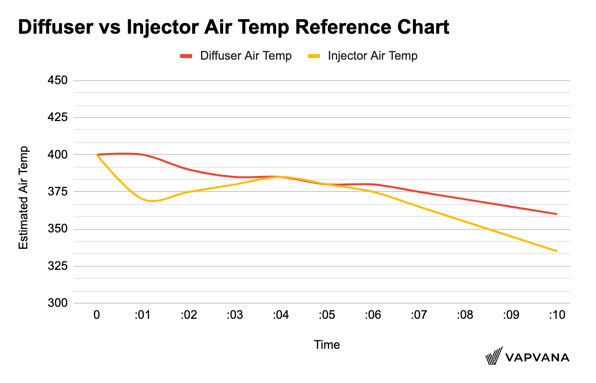

- Using a diffuser style (vs injector) housing removes unnecessary air-path length

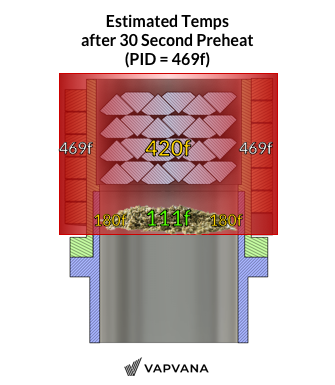

- Allow the housing & coil to go over the bowl walls, adding conduction heating when necessary

- Using Titanium which allows for fast and efficient heat transfer

Pressure

Because all parts of the system are custom made to work together, it allows for a more refined/airtight seal. By lowering the atmospheric pressure, it allows for cannabinoids to vaporize at lower temperatures.(This can also be controlled by your inhale speed.)

Surface Area

The Screwball bowl ratio was designed to maximize airflow and surface area.- The full size bowl has a 2:1 ratio (20mm ID, 10mm height)

- The half size bowl has a 4:1 ratio (20mm ID, 5mm height)

Mass

After testing both Titanium and SS versions, it seems like Titanium performs better due to there being less metal mass in the 'system'

Flow Rate

The Screwball has a balanced airflow due to adjusting different variables in the system.- Using a 25mm coil provides more airflow than the common 20mm sized coil

-

- By maximizing airflow in different areas, it creates a balanced draw with using more restrictive media in the housing

Last edited:

Enjoy and stay safe!

Enjoy and stay safe!