a great way to use this is to buy two #8 alumina ceramic tig parts. Use a silicone o ring over the bottom part of #1 alumina ceramic tig part connecting to an 18mm joint of bubble/waterpipe. This creates a full seal. Then use a dremel with part 9901HP to hollow out the larger part of #1 piece. This will allow the #2 alumina ceramic (with rubies, saphire balls etc),to sit flush with the #1piece and allow for almost full airflow, pics coming soon. Hits great thank yall for all the input

-

SCAM WARNING! See how this scam works in Classifieds.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Pinky: an open-source DIY injector style thermal extraction device

- Thread starter 4everpushingaboulder

- Start date

Flow

Well-Known Member

Hi @DRAG-0n,a great way to use this is to buy two #8 alumina ceramic tig parts. Use a silicone o ring over the bottom part of #1 alumina ceramic tig part connecting to an 18mm joint of bubble/waterpipe. This creates a full seal. Then use a dremel with part 9901HP to hollow out the larger part of #1 piece. This will allow the #2 alumina ceramic (with rubies, saphire balls etc),to sit flush with the #1piece and allow for almost full airflow, pics coming soon. Hits great thank yall for all the input

Any pics please ?

shopdognyc

Well-Known Member

VapePerson

Searching for Tremendous

i think this will work too

manakata

Active Member

if anyone is looking for PID and coils i bought 2 sets of PID and Coil. High Five Enails has a promo right now if you buy a PID and Coil kit you get another for free. so i ended up with 2 PIDs and 2 20mm coils for $211.. maybe you can go halfers with someone but the promo ends in 18 hours from this message and the code is on their website.....they work great with my FP i tested one and i actually like it better than the auber i got of CH also the coils are not compatible with CH PID or Auber. just thought i let you guys know FYI since im working on a DYI ball vape myself. just experimenting.

Guava Dog Diesel

Member

I’ve used it with my flip brick, but it started burning the wood so I stoppedHas anyone tried to use one of these with a sticky brick? I would love something like this for my Maxx to make it more user friendly for friends.

takes mine a little under 3 minutes to get to 570. But stays at that temp consistently, maybe a couple 15second heat ups but thats it * forgot to quoteHow is the heat up time on this? Looks fun.

shopdognyc

Well-Known Member

I like using wood bowls, flip brick, hot rod injector, noisy cricket, etc. Burn isn't so bad. What temp are you going at? I keep at 550.I’ve used it with my flip brick, but it started burning the wood so I stopped

SavageCore

Well-Known Member

Here's a build list for the UK.

For the Pinky:

Extras/Safety:

Also will add to this thread AWistfulNihilist's video building theirs:

(starts at 3:50)

For the Pinky:

- #8 53N61S TIG Nozzle (eBay)

- 1/2" Stainless Steel Pipe Screen (Amazon)

- 3mm Ruby balls (Recommended Vape Supplies)

Extras/Safety:

- QaromaShop Stand (Recommended Vape Supplies)

- Coil/Enail

- Wood Handle (Recommended Vape Supplies) or Flowerpot Handle (Vapefiend)

Also will add to this thread AWistfulNihilist's video building theirs:

(starts at 3:50)

VincentTheHealer

Well-Known Member

I love how he insisted multiple times on how hard alumina is and how every mark is from softer materials.Also will add to this thread AWistfulNihilist's video building theirs:

vaporoufixtras

sigma vape enjoyer

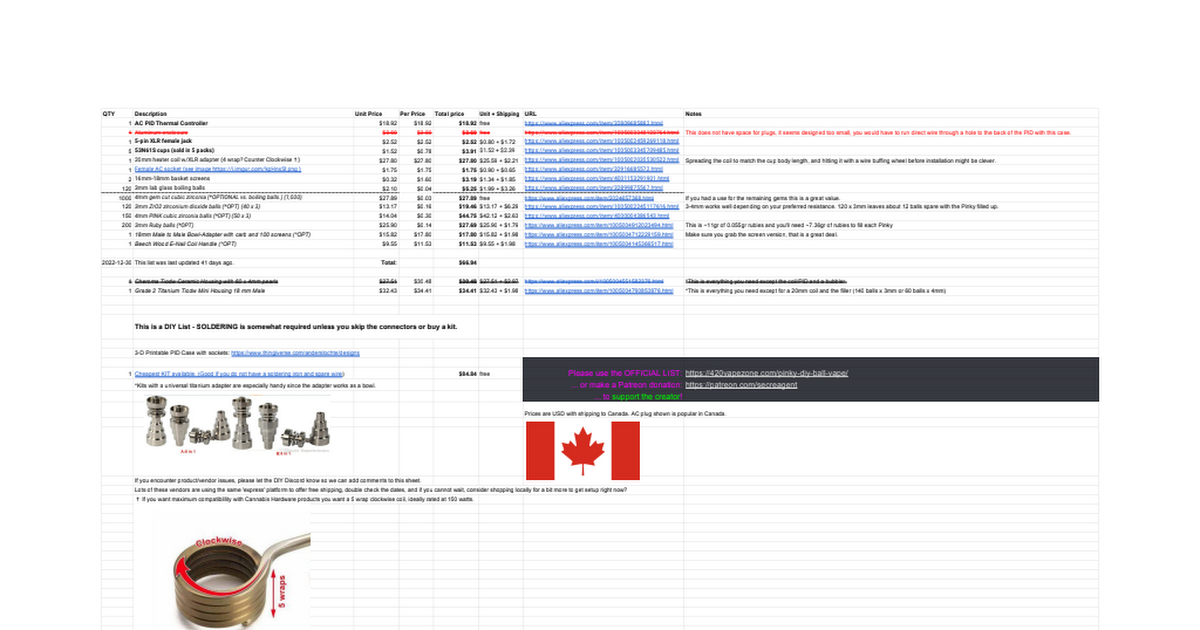

Pinky international parts list

Taken from 420Vapezone discord (credit to HarryWC, minor edits by me)

docs.google.com

docs.google.com

Pinky injector & PID:

If you want to avoid doing any wiring yourself you can get this kit and skip the first five items from the PID list. It also includes a carrying case and some other stuff but it's 30€ more expensive: https://www.aliexpress.com/item/1005002267928962.html

You can don't have to get an enail handle as the Pinky is very light. Regarding the stand there isn't any particularly good budget option out there (that includes a heatshield) but you can simply use a ceramic coffee mug.

Taken from 420Vapezone discord (credit to HarryWC, minor edits by me)

Pinky International Parts

Pinky injector & PID:

- This $19 PID seems to be the cheapest: https://www.aliexpress.com/item/32809685882.html

- Aliexpress also sells an aluminum enclosure for $4: https://www.aliexpress.com/item/1005003348123764.html

- A 5-pin XLR female jack for under $1: https://www.aliexpress.com/item/1005002459269118.html

- Female power sockets $0.90 each: https://www.aliexpress.com/item/32916685572.html

- 20mm coil w/XLR adapter is $35 here: https://www.aliexpress.com/item/1005002035530522.html

- 5-packs of 53N61S cups are $1.22 ($0.25 each) here: https://www.aliexpress.com/item/1005003345709485.html

- Basket screens are $0.32 each (2 per unit = $0.64) or 10 for $3.19 ($1.34+shipping): https://www.aliexpress.com/item/4001153291901.html

- 3mm lab glass boiling balls $5.25 ($1.99 + $3.26 ship): https://www.aliexpress.com/item/32899875567.html

ALT: 3mm Cubic Zirconia at $12 for 500 3mm balls (~250-300 x 3mm balls needed per vape) : https://www.aliexpress.com/item/2037972452.html

ALT: 3mm zirconium dioxide balls 60 at $10.09 ($5.30 + $4.79 ship): https://www.aliexpress.com/item/1005002245117616.html

ALT: 6mm PINK cubic zirconia balls are cute 50 for $20.64 ($15.12 + $5.52 ship): https://www.aliexpress.com/item/4000004386543.html https://cdn.discordapp.com/attachme...at-Back-Loose-CZ-Stone-Synthetic-Gems-For.png

- @Secreagent recommends the Ispire Wand banger, you can use @SavageCore's links above or check out VgooziEZ here (he ships internationally and for me it's cheaper than buying from UK): https://vgoodiez.com/products/borosilicate-straight-banger-for-the-wand-by-ispire

- You can use 3/4" (=19mm) screens in that bowl, see how to fit them in the bowl in the image below.

You can buy them here $2 for 100: https://www.aliexpress.com/item/1005003416225078.html - For a microdose bowl setup you can use this bong bowl: https://www.heisenberg.shop/heisenberg-standard-kopf-14-5.html

Credit @Spleeeno, see his video below on how it works. He's got a screen jammed up from below to hold the herb.

If you want to avoid doing any wiring yourself you can get this kit and skip the first five items from the PID list. It also includes a carrying case and some other stuff but it's 30€ more expensive: https://www.aliexpress.com/item/1005002267928962.html

You can don't have to get an enail handle as the Pinky is very light. Regarding the stand there isn't any particularly good budget option out there (that includes a heatshield) but you can simply use a ceramic coffee mug.

Last edited by a moderator:

vaporoufixtras

sigma vape enjoyer

concerned about the pinky material for daily or long term use

I was looking into this right now as I'm deciding on the material of the body of the injector (alumina for pinky, boro for brain, titanium for titi).

From what I found the cup used in the pinky is made from pink alumina oxide which is itself made from aluminum oxide and chromium oxide. Safety Data Sheets for both materials (1,2) show that while unhealthy to inhale (as is any kind of mineral dust) they don't cause any big problems. There are always impurities of course.

The material is extremely tough and heat resistant however so I guess there's no need to worry.

Last edited:

I was looking into this right now as I'm deciding on the material of the body of the injector (alumina for pinky, boro for brain, titanium for titi).

From what I found the cup used in the pinky is made from pink alumina oxide which is itself made from aluminum oxide and chromium oxide. Safety Data Sheets for both materials (1,2) show that while unhealthy to inhale (as is any kind of mineral dust) they don't cause any big problems. There are always impurities of course.

The material is extremely tough and heat resistant however so I guess there's no need to worry.

Spleeeno

Horsin around

now we all know that inhaling glass dust is fucking horrible while inhaling from a glass airpath is fine. this is the same thing as far as I can tell: as long as there's no powder involved, you're good. also I havent seen anyone get green powder from his pinky yet, so...

Last edited:

I sure hope so. It says exposure through mouth and skin which is exactly how we use it. That got me worried cos welding don't involve mouths but vaping does. I think the green is raw material. Says colorant for ceramics. I've got my Pinky parts on the way so am looking for some assurance myself. Thankfully switching to brain isn't much of a hassle. DIY rocksnow we all know that inhaling glass dust is fucking horrible while inhaling from a glass airpath is fine. this is the same thing as far as I can tell: as long as there's no power involved, you're good. also I havent seen anyone get green powder from his pinky yet, so...

Spleeeno

Horsin around

yeah obviously me saying it's safe is just broscience until someone does some tests on offgasing.

I just dont see anyone doing those pricey tests until the material is co-opted by bigger volume manufacturers, and maybe not even in that case...

cause when I look at all those "fda approved material!" stickers on vapes, even though the fda only tests if its foodsafe, not wtf happens with it at vaporization temps... I have some serious doubts

also quite ironic that the only company that provided those (again, very pricey) results for their vapes was S&B, with their mostly plastic and aluminium vapes, both materials with a rich history of alzheimers, infertility and cancer vapor seems to be clean though. atleast on the brand new devices used in those tests, now if you'd do the same test with a mighty that had 2 years of constant use...

vapor seems to be clean though. atleast on the brand new devices used in those tests, now if you'd do the same test with a mighty that had 2 years of constant use...

I just dont see anyone doing those pricey tests until the material is co-opted by bigger volume manufacturers, and maybe not even in that case...

cause when I look at all those "fda approved material!" stickers on vapes, even though the fda only tests if its foodsafe, not wtf happens with it at vaporization temps... I have some serious doubts

also quite ironic that the only company that provided those (again, very pricey) results for their vapes was S&B, with their mostly plastic and aluminium vapes, both materials with a rich history of alzheimers, infertility and cancer

vapor seems to be clean though. atleast on the brand new devices used in those tests, now if you'd do the same test with a mighty that had 2 years of constant use...

vapor seems to be clean though. atleast on the brand new devices used in those tests, now if you'd do the same test with a mighty that had 2 years of constant use...

Glorg

Well-Known Member

I use a blend of that green stuff as a honing compound for knife sharpening and stropping, it’s amazingly effective for that and I’ve had no issue with it. Definitely no skin reaction I’m assuming you’d need a decent amount of powder to cause issues. Kind of reminds me of when a specific company was trying to say terp pearls in a quartz banger could cause silicosis but that was a more cartoonish take.

also there is the pyrex glass option if those are afraid of the alumina ceramic, just in casenow we all know that inhaling glass dust is fucking horrible while inhaling from a glass airpath is fine. this is the same thing as far as I can tell: as long as there's no powder involved, you're good. also I havent seen anyone get green powder from his pinky yet, so...

vaporoufixtras

sigma vape enjoyer

and the titanium option (TiTi)also there is the pyrex glass option if those are afraid of the alumina ceramic, just in case

Hippie

Well-Known Member

Is there a standard pyrex nozzle that we can use in the same way?

Or an Alumina nozzle we can use with a 25 or 30mm coil?

I ordered a pyrex #8 nozzle to try but the outside diameter is about 25.9mm so that's no good for a 20mm coil but you may be able to stretch 25mm coil to fit (I don't have one of those to test).

The #8 pyrex nozzle is a pretty good fit on an 18mm female joint so it should work well, if the coil fits.

Or an Alumina nozzle we can use with a 25 or 30mm coil?

I ordered a pyrex #8 nozzle to try but the outside diameter is about 25.9mm so that's no good for a 20mm coil but you may be able to stretch 25mm coil to fit (I don't have one of those to test).

The #8 pyrex nozzle is a pretty good fit on an 18mm female joint so it should work well, if the coil fits.

Spleeeno

Horsin around

well yeah you have to use the pyrex nozzle with 20mm OD for the brain (cause its pinky and the brain...): https://aliexpress.com/item/1005001571424091.html

cause just like with the alumina ones, there are multiple "#8 nozzles" and the more important bit is the part number

edit: oh yeah and keep in mind: installing the screens is a hassle in the pinky, its on a whole nother level in the brain cause its just glass. so unless you plan on sanding some parts to make the screens stick this is the inferior version of the vape in any regard besides taste.

cause just like with the alumina ones, there are multiple "#8 nozzles" and the more important bit is the part number

edit: oh yeah and keep in mind: installing the screens is a hassle in the pinky, its on a whole nother level in the brain cause its just glass. so unless you plan on sanding some parts to make the screens stick this is the inferior version of the vape in any regard besides taste.