TPV

Vape enthusiast.

Hello.

Since I started using mj almost daily I have developed a throat sore that lasted for a good while, like months. That made me think about my health and I started looking up vaporization technologies and started to experiment. Since I am not wealthy to buy vaporizers (volcano, etc) and I do enjoy the process of designing things for myself I have started to tinker and experiment. Found out about these nifty ceramic PTC heating elements that only reach a specific temperature and do not go higher due to the ceramic material properties of increasing resistance and shutting the electric current down thus only achieving the design target temperatures.

After experimenting with arduino and lcd panel for the vaporizer interface I settled on a regular industry standard PID termperature controller which is way more convenient.

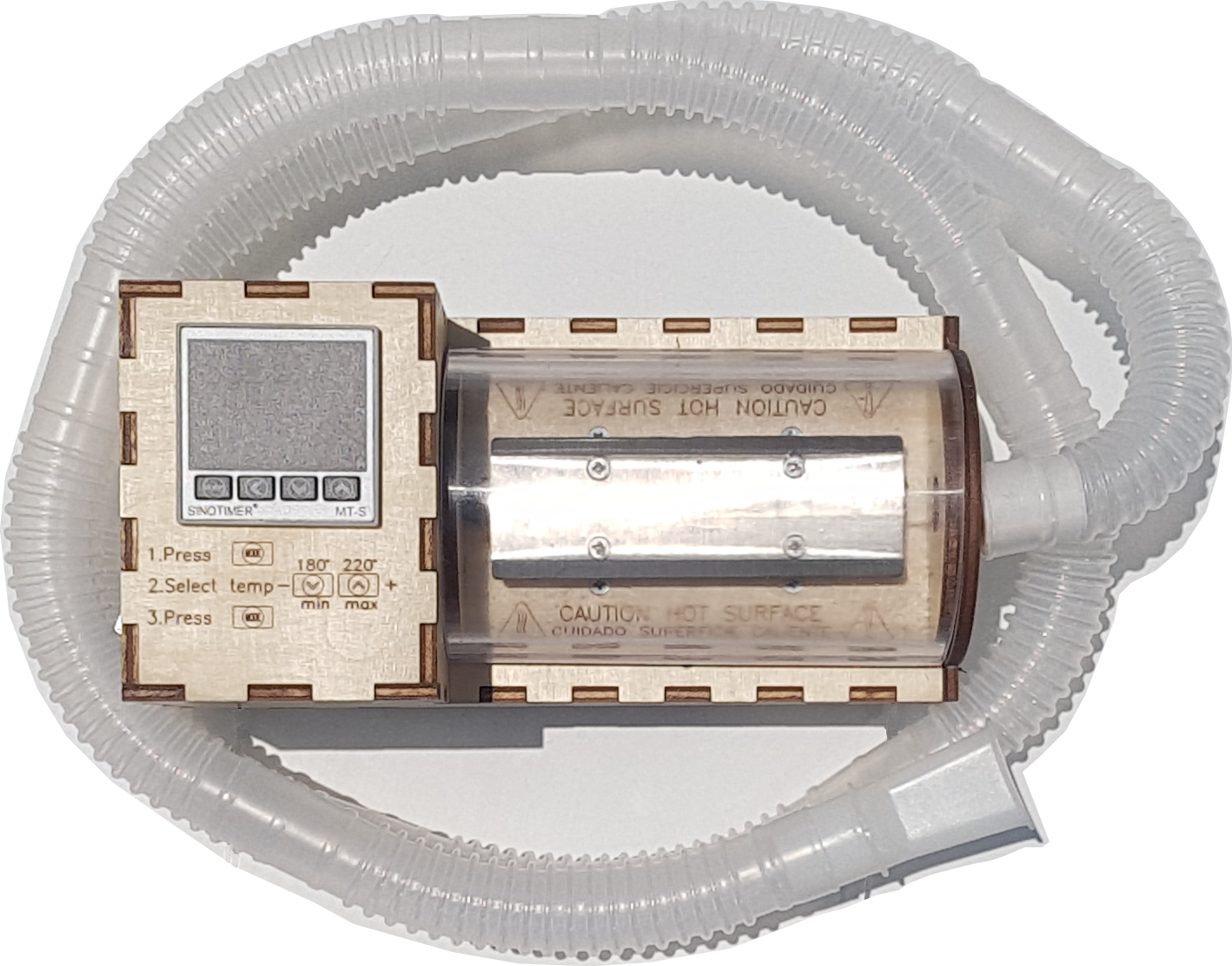

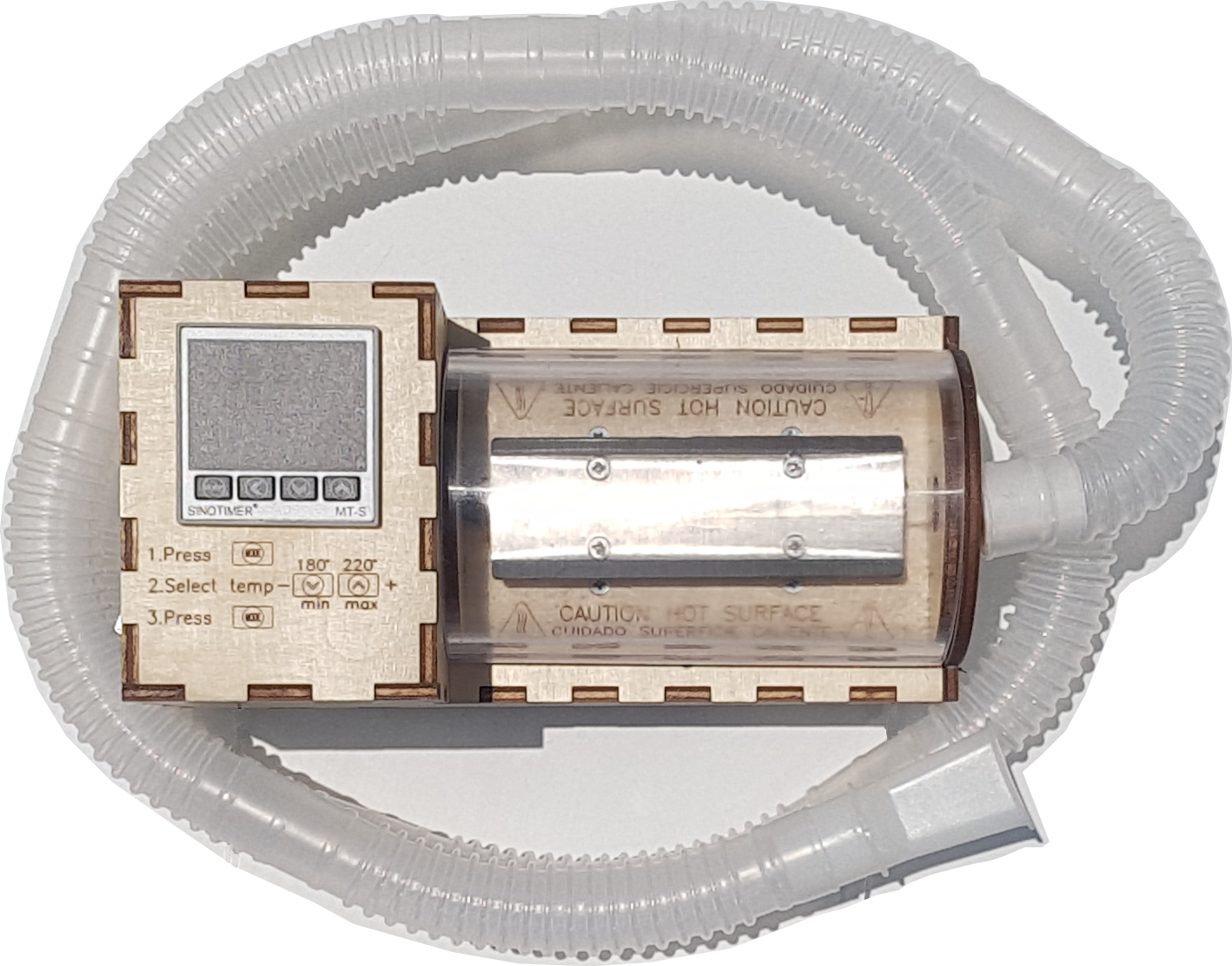

Long story short, after maybe a year my design converged into what I call "The people's vape", with a housing made of lasercut Baltic birch plywood, a temperature controller that powers a ptc resistance through a solid state relay. Very simple components, not much to break here. Polycarbonate (lexan) transparent cover (heat formed) to watch the material. Solid polycarbonate sheet is very tough and resistant, does not get hot enough to become soft unlike acrylic sheets, thermoforming polycarbonate is an art in itself.

The vaporizer reaches into operational temperature in 1 min 20 seconds. Can be used individually or by a party.

Here is the website The people's vape. Currently I have no shop but I do intend to sell it on person to person basis.

I ask $100 usd plus shipping, mind you I live in Mexico.

Comment, critique and suggest.

Some pictures:

Since I started using mj almost daily I have developed a throat sore that lasted for a good while, like months. That made me think about my health and I started looking up vaporization technologies and started to experiment. Since I am not wealthy to buy vaporizers (volcano, etc) and I do enjoy the process of designing things for myself I have started to tinker and experiment. Found out about these nifty ceramic PTC heating elements that only reach a specific temperature and do not go higher due to the ceramic material properties of increasing resistance and shutting the electric current down thus only achieving the design target temperatures.

After experimenting with arduino and lcd panel for the vaporizer interface I settled on a regular industry standard PID termperature controller which is way more convenient.

Long story short, after maybe a year my design converged into what I call "The people's vape", with a housing made of lasercut Baltic birch plywood, a temperature controller that powers a ptc resistance through a solid state relay. Very simple components, not much to break here. Polycarbonate (lexan) transparent cover (heat formed) to watch the material. Solid polycarbonate sheet is very tough and resistant, does not get hot enough to become soft unlike acrylic sheets, thermoforming polycarbonate is an art in itself.

The vaporizer reaches into operational temperature in 1 min 20 seconds. Can be used individually or by a party.

Here is the website The people's vape. Currently I have no shop but I do intend to sell it on person to person basis.

I ask $100 usd plus shipping, mind you I live in Mexico.

Comment, critique and suggest.

Some pictures: