Thanks! Designed & made to my specs. Can't wait to take a group shot with my Okins!@Snappo , Wow, nice pipes!!

-

SCAM WARNING! See how this scam works in Classifieds.

-

The Frolic by Limelight Giveaway has started!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Discontinued The Okin by D.M. Pipes

- Thread starter Stu

- Start date

-

- Tags

- charcoal powered okin portable

Okin testing has gone slowly for the other beta testers because Dan has been experimenting to find the best charcoal, and I'm the only one who has anything but the original bamboo charcoals. I'm using poplar, which turns out to burn a little too quickly. The good news is that the poplar charcoals are virtually tasteless and can produce thick vapour. The bad news is that you need two of them to finish a .07 g load (my normal size) and the vapour tends to be hot and harsh. I don't really want to comment much until we get the latest maple charcoals from Dan next week, but I will try to answer any questions.

The last charcoals that I posted, I said they were birch, actually, they were poplar.

As Pak says, the poplar is burning just a bit too quickly. I am averaging about 3 minutes, just a bit too short to fully vaporize a full load. I've tested the poplar more now, and agree that they are just too hot. But, still better than the bamboo IMO.

I've since been on the hunt for something better, the holy grail of charcoals! This time I tested a batch of poplar and maple dowels in the 5/8" and 3/4" diameter. I was using 1/2" diameter in the past.

My first batches in this new size pretty much ruled out poplar, they just burned too fast still, even when using larger charcoals. And they are very ashy.

So that's that. Poplar is out. But the maple looked promising...

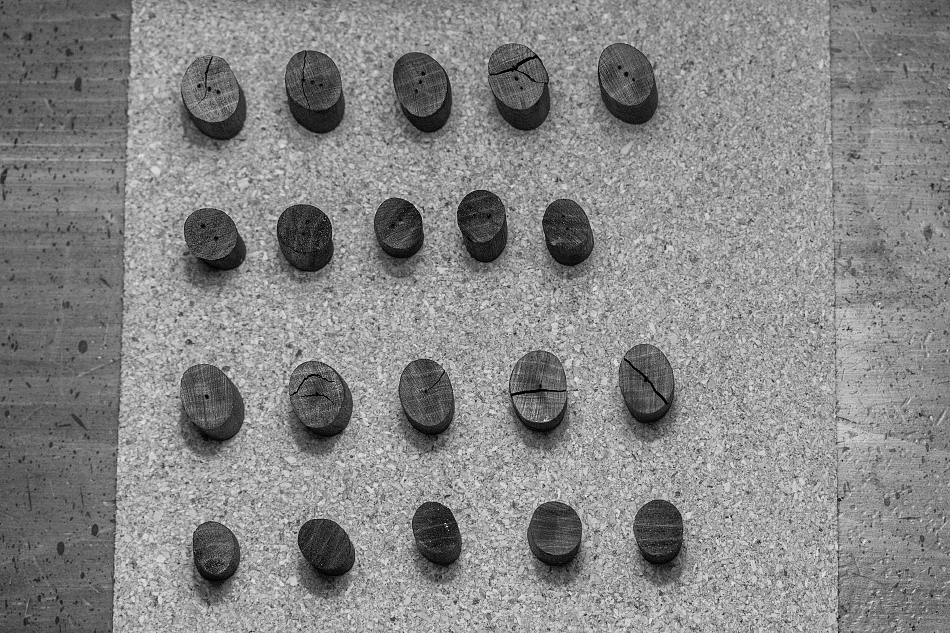

For my second batch, I used maple only, in 4 different sizes. These sizes were determined by narrowing down my best results from previous tests. Note that originally I was making charcoals 1" long.

From the top row down:

- 3/4" diameter, 3/4" length

- 5/8" diameter, 3/4" length

- 3/4" diameter, 5/8" length

- 5/8" diameter, 5/8" length

Results:

The 3/4" diameter dowels, regardless of length, had a major problem with cracking. 4 out of the 10 pieces in that diameter cracked completely in half (I put them back together for these photos). They were also too large to fit the tip of the Okin.

So, the 3/4" diameter is out, I sort of knew this going into it... but I wanted to know for sure.

The 5/8" diameter dowels had a 100% success rate. Non of them cracked, and they all fit perfectly, with a good seal without modification. They are all very consistent in shape. All of these charcoals could be used no problem.

I got non of the "noodle effect" that you get with charcoals that are smaller in diameter, but longer in length.

I think that when the chunk of wood is roughly the same in diameter and length, it tends to shrink more equally in all directions, reducing the tendency to warp.

Instead of drilling a single center hole, I drilled 4 small holes. The 4 holes diffuse the heat entering the chamber, and make for a much better taste all the way through a session. No more central hot spot. The 4 holes remain intact all the way through the burn.

Here was an earlier test with shorter charcoals, note the multiple holes. I have since found that 4 holes works really nicely, no need for more.

The heat generation is fairly constant from start to finish, and the duration of burn is a solid 5 minutes with the 5/8" length charcoal. You can push it beyond 5 minutes, but at this point a fully loaded chamber is spent, so I see no need to go beyond this. The 3/4" length charcoal will be tested further to see if there is any benefit to the longer burn time...

The only prep needed for these is to poke or drill 4 holes through the charcoal. Since you are drilling down into the flat face of the charcoal, it's actually much easier and much less messy than drilling the side wall holes into the bamboo. You can just set these charcoals onto a flat surface and poke the holes. It's very easy because of the way the wood fibers are orientated, vs. going through the side. You can do it without getting your fingers dirty at all. Overall MUCH better prep than the bamboo charcoals.

The maple burns cleaner than both poplar and bamboo.

And, it produces less ash than poplar.

So, this is basically IT. I'm settled. I've pretty much exhausted every economical option available to me, and this is the best.

I'll be making a batch of these maple charcoals for each of the testers and send them out next week.

In the mean time, I'll be doing more testing with these to make sure that they are going to be consistent. I will also compare the 3/4" length to the 5/8" length.

As Pak says, the poplar is burning just a bit too quickly. I am averaging about 3 minutes, just a bit too short to fully vaporize a full load. I've tested the poplar more now, and agree that they are just too hot. But, still better than the bamboo IMO.

I've since been on the hunt for something better, the holy grail of charcoals! This time I tested a batch of poplar and maple dowels in the 5/8" and 3/4" diameter. I was using 1/2" diameter in the past.

My first batches in this new size pretty much ruled out poplar, they just burned too fast still, even when using larger charcoals. And they are very ashy.

So that's that. Poplar is out. But the maple looked promising...

For my second batch, I used maple only, in 4 different sizes. These sizes were determined by narrowing down my best results from previous tests. Note that originally I was making charcoals 1" long.

From the top row down:

- 3/4" diameter, 3/4" length

- 5/8" diameter, 3/4" length

- 3/4" diameter, 5/8" length

- 5/8" diameter, 5/8" length

Results:

The 3/4" diameter dowels, regardless of length, had a major problem with cracking. 4 out of the 10 pieces in that diameter cracked completely in half (I put them back together for these photos). They were also too large to fit the tip of the Okin.

So, the 3/4" diameter is out, I sort of knew this going into it... but I wanted to know for sure.

The 5/8" diameter dowels had a 100% success rate. Non of them cracked, and they all fit perfectly, with a good seal without modification. They are all very consistent in shape. All of these charcoals could be used no problem.

I got non of the "noodle effect" that you get with charcoals that are smaller in diameter, but longer in length.

I think that when the chunk of wood is roughly the same in diameter and length, it tends to shrink more equally in all directions, reducing the tendency to warp.

Instead of drilling a single center hole, I drilled 4 small holes. The 4 holes diffuse the heat entering the chamber, and make for a much better taste all the way through a session. No more central hot spot. The 4 holes remain intact all the way through the burn.

Here was an earlier test with shorter charcoals, note the multiple holes. I have since found that 4 holes works really nicely, no need for more.

The heat generation is fairly constant from start to finish, and the duration of burn is a solid 5 minutes with the 5/8" length charcoal. You can push it beyond 5 minutes, but at this point a fully loaded chamber is spent, so I see no need to go beyond this. The 3/4" length charcoal will be tested further to see if there is any benefit to the longer burn time...

The only prep needed for these is to poke or drill 4 holes through the charcoal. Since you are drilling down into the flat face of the charcoal, it's actually much easier and much less messy than drilling the side wall holes into the bamboo. You can just set these charcoals onto a flat surface and poke the holes. It's very easy because of the way the wood fibers are orientated, vs. going through the side. You can do it without getting your fingers dirty at all. Overall MUCH better prep than the bamboo charcoals.

The maple burns cleaner than both poplar and bamboo.

And, it produces less ash than poplar.

So, this is basically IT. I'm settled. I've pretty much exhausted every economical option available to me, and this is the best.

I'll be making a batch of these maple charcoals for each of the testers and send them out next week.

In the mean time, I'll be doing more testing with these to make sure that they are going to be consistent. I will also compare the 3/4" length to the 5/8" length.

Jazzah

Well-Known Member

I have been thinking about a propper off-grid vape for quite some time. The sublimator UFO and the Lotus vaporizer use an open flame, so they came close, but since there is no way to effectively use them with a normal flame as opposed to a torch, they don't qualify as apocalypse vapes. Today I came across this thread. WOW. Aesthetically, this must be the most appealing vape i've ever seen. Also, this is the first thread I've come across were there seems to be a real interaction between creator and smokers that isn't just about creating hype and future income. As said many times, the picture quality is ridiculous and the updates are regular and numerous. In fact, you even upload an insight into the production process, further strengthening the impression of an honest craftsman. Whether spontaneous or premeditated, your approach and communications on this forum are flawless. I can't wait to get my hands on an Okin myself. Thanks to the beta testers in advance. Unlike what someone previously commented, I think we will all benefit from the fact the testers are veterans.

@Dan Morrison

Have you tried drilling the holes before the charring process? If it works I think that could be an even less messy way of making the embers. One more thing: Every picture you have shown, from the room to the tools (like the hammer), conveys this aura of pre- or early industrial times when people still lived closer to nature and craftmen were less estranged from the products they made. It creates this nostalgic feeling, a longing for a time I've never known. Mad respect. I hope you can make a descent living out of it. Wish you the best of luck and will most definately be ordering an Okin when possible.

@Dan Morrison

Have you tried drilling the holes before the charring process? If it works I think that could be an even less messy way of making the embers. One more thing: Every picture you have shown, from the room to the tools (like the hammer), conveys this aura of pre- or early industrial times when people still lived closer to nature and craftmen were less estranged from the products they made. It creates this nostalgic feeling, a longing for a time I've never known. Mad respect. I hope you can make a descent living out of it. Wish you the best of luck and will most definately be ordering an Okin when possible.

Last edited:

there is no way to effectively use them with a normal flame as opposed to a torch

You can definitely light an Okin charcoal (or at least the bamboo and poplar ones) with a regular lighter, but a torch sure helps. A candle would be better than a lighter, and would set the tone nicely for your apocalypse vaping experience.

@Dan Morrison

Have you tried drilling the holes before the charring process? If it works I think that could be an even less messy way of making the embers.

@Jazzah , Thanks!

I don't even know what to say to all that kindness!

I don't even know what to say to all that kindness! The problem with pre-drilling 4 holes in every single piece of wood is that it would just take a whole lot of time... And because the drill bit would be very small, you'd have to do it by hand.

I would drill them after the conversion process to make it easier for myself, the charcoal is easier to drill than the raw wood. But letting the end user prepare the charcoals has the added bonus of being able to customize your hole location and the amount... There could be a perfect "one fits all" hole pattern, but everyone has different tastes...

But, I'll see what the testers say, if it's too much prep, I'll just have to drill them here in the shop.

Jazzah

Well-Known Member

I already DIY my own charcloth for firestarting with firesteel and carbon knife, so I will definately be making my own. I took the time to browse through your blog and, once again, you make beautiful stuff. just one question. Have you got any idea how the holes in the charcoal could be made without dremel or other electrical tools? could it be done with a manual drill as long as the drillbit is fine enough, or in some other way? Don't bother spending any time figuring out an answer to this question if you don't have one alrdy though. Can wait to toke on your creation.

I already DIY my own charcloth for firestarting with firesteel and carbon knife, so I will definately be making my own. I took the time to browse through your blog and, once again, you make beautiful stuff. just one question. Have you got any idea how the holes in the charcoal could be made without dremel or other electrical tools? could it be done with a manual drill as long as the drillbit is fine enough, or in some other way? Don't bother spending any time figuring out an answer to this question if you don't have one alrdy though. Can wait to toke on your creation.

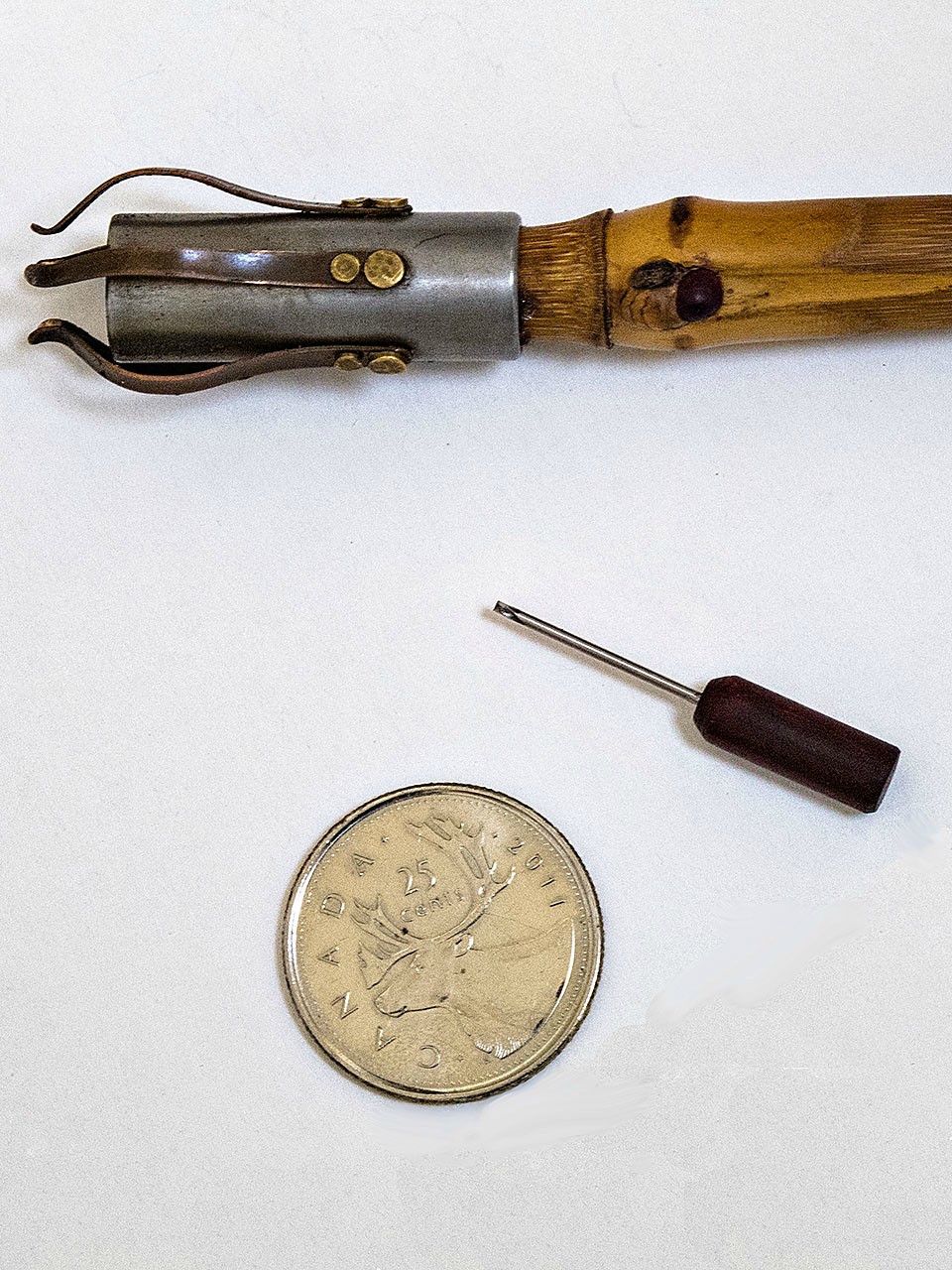

My Okin came with a little tool for making holes in the charcoal. Based on my experience with it, I think that it won't be a problem to make our own holes. That would be the best solution. You choose how many holes to make and what pattern they are in, and Dan has a lot less work and worry.

@Jazzah , Each Okin will come with a little hand drill. The charcoal is soft enough that the drill goes through it pretty easily, It's like drilling through a carrot, haha. It only takes a few seconds per hole.

@grokit , Not sure how that would work... depends how soft the wood is. Soft maple doweling is fairly accessible, I would say even more accessible than bamboo. Other hardwoods might work well too, like oak or birch.. Softwoods don't work very well because they burn too hot and fast.

@grokit , Not sure how that would work... depends how soft the wood is. Soft maple doweling is fairly accessible, I would say even more accessible than bamboo. Other hardwoods might work well too, like oak or birch.. Softwoods don't work very well because they burn too hot and fast.

Jazzah

Well-Known Member

Each Okin will come with a little hand drill.

Genius!

Or are you just kidding?

Madcap79

Jack of all trades, master of none.

No no. Genius.Genius!

Or are you just kidding?

Quetzalcoatl

DEADY GUERRERO/DIRT COBAIN/GEORGE KUSH

What is this, a drill for ants?!

Jazzah

Well-Known Member

@pakalolo

Thank you very much for the visualization. The Okin just keeps getting more brilliant.

@Dan & the testers

I know the current coal experiments are all about finding the most suited one, so this question won't be all that relevant for the end result, but have you guys noticed flavor differences when using different kinds of wood for coals ?

Thank you very much for the visualization. The Okin just keeps getting more brilliant.

@Dan & the testers

I know the current coal experiments are all about finding the most suited one, so this question won't be all that relevant for the end result, but have you guys noticed flavor differences when using different kinds of wood for coals ?

Quetzalcoatl

DEADY GUERRERO/DIRT COBAIN/GEORGE KUSH

I was wondering that too and even wrote it in my previous post but ya know, comedy and all...@pakalolo

Thank you very much for the visualization. The Okin just keeps getting more brilliant.

@Dan & the testers

I know the current coal experiments are all about finding the most suited one, so this question won't be all that relevant for the end result, but have you guys noticed flavor differences when using different kinds of wood for coals ?

Charcoal being charcoal I don't think there would be much if any distinct taste between different species... Cursory Google search tells me:

Charcoal is a light, black residue, consisting of carbon and any remaining ash, obtained by removing water and other volatile constituents from animal and vegetation substances. Charcoal is usually produced by slow pyrolysis, the heating of wood or other substances in the absence of oxygen (see char and biochar.)

I never seriously got into hookah but did enjoy it, never noticed any difference in taste with the same shisha and different coal types but it did also go through water...

Keep the pictures coming, I love a good tease

I know the current coal experiments are all about finding the most suited one, so this question won't be all that relevant for the end result, but have you guys noticed flavor differences when using different kinds of wood for coals ?

I've only tried bamboo and poplar, and Dan is the only one who has tried anything else.

One of my first tests with the Okin was to burn a charcoal with nothing in the tip to look for flavours and also to see what if any visible gases were produced. Bamboo charcoal does have a distinct taste. It's not unpleasant to me but of course, taste is subjective. Some might find it objectionable, either because they don't like the taste or they simply don't want any added flavours. Additionally, there is significant exhaust from burning bamboo charcoal. It's not a lot but it's there.

The poplar charcoal has no flavour that I can detect, and also produces only the tiniest of exhaust puffs. It is a big improvement in both these areas, but it burns too fast. Dan's experiments with maple are encouraging and I am eager to try maple charcoals sometime next week.

I know the exhaust comments will bother some. We speculate that some of it could be water vapour, but let's face it, we are burning something here. It would be naive to believe that you won't be inhaling some combustion by-products. Based on my charcoal-only tests, the amount of visible exhaust is a tiny portion of the visible vapour I get when the tip is loaded. Anyone who is absolute in avoiding combustion will not want to use the Okin, however. For me, the price is well worth the Okin experience.

The maple is just like the poplar as far as taste goes, i.e. there is non.

I will note that I have not been able to reproduce Pak's experiments in getting any visible vapor from just the charcoal itself. Technically speaking, the charcoal should not produce any visible vapor, but further investigation is needed here.

I'll try placing a wide glass tube in front of a black surface, and draw only hot air from a maple charcoal through the tube. I'll try a charcoal that has been sitting around, and one that has been freshly oven dried and handled with gloves to rule out the possibility of water vapor and oils from my hands.

I will note that I have not been able to reproduce Pak's experiments in getting any visible vapor from just the charcoal itself. Technically speaking, the charcoal should not produce any visible vapor, but further investigation is needed here.

I'll try placing a wide glass tube in front of a black surface, and draw only hot air from a maple charcoal through the tube. I'll try a charcoal that has been sitting around, and one that has been freshly oven dried and handled with gloves to rule out the possibility of water vapor and oils from my hands.

The maple is just like the poplar as far as taste goes, i.e. there is non.

I will note that I have not been able to reproduce Pak's experiments in getting any visible vapor from just the charcoal itself. Technically speaking, the charcoal should not produce any visible vapor, but further investigation is needed here.

I'll try placing a wide glass tube in front of a black surface, and draw only hot air from a maple charcoal through the tube. I'll try a charcoal that has been sitting around, and one that has been freshly oven dried and handled with gloves to rule out the possibility of water vapor and oils from my hands.

I look forward to your results as much as I do to the maple charcoals. Good news there.

For the record, I've already done your proposed test with the bamboo charcoal, including one that had been baked at 120°C/250°F for 45 minutes. I got quite visible amounts of something. I'll sacrifice a poplar to see what I get.

For the record, I've already done your proposed test with the bamboo charcoal, including one that had been baked at 120°C/250°F for 45 minutes. I got quite visible amounts of something. I'll sacrifice a poplar to see what I get.

Oh right! I forgot that you did that test with the oven baked one as well! There's so much testing going on I can't keep track of it all, haha. Thanks for that Pak! So it seems that the bamboo does produce some sort of vapor, hmm.

I noted that if I had a batch of bamboo charcoal that wasn't brought up to the right temperature (lower than 600c), there would be a strange smell or taste associated with it, the lower the temperature during the carbonization process, the more VOCs are still left in the final charcoal.

I found that when I took the bamboo up higher than that, to maybe 900-1000c, it didn't burn very and was too difficult to light. The hardwood doesn't seem to have that issue, so I've been taking it up to as high a temperature as I can. The higher temperature carbonization should help reduce VOCs even further than what I was able to achieve with bamboo.

I noted that if I had a batch of bamboo charcoal that wasn't brought up to the right temperature (lower than 600c), there would be a strange smell or taste associated with it, the lower the temperature during the carbonization process, the more VOCs are still left in the final charcoal.

This could explain my results.

Meanwhile, I tried the glass tube with poplar charcoal to see what happened. I did not get any visible exhaust but I did get an unexpected and interesting result.

Recall that one of the issues with poplar is that it produces a lot of light flaky white ash. I've mentioned in the beta thread that the poplar always left some white ash deposited on the screen, and that I've noticed some of it in my ABV. Well, I did my test in a semi-dark room. It was immediately obvious that inhaling produced a constant stream of sparks that got pulled back into my mouth. They didn't burn but they did make me cough. This material would never reach your mouth in a loaded stem, of course. Kind of an interesting light show, but definitely a confirmation that it's not the right charcoal.

Whoa, Pak, ha. I would definitely put a couple clean metal screens into that glass tube for any future tests!

The first metal screen in the Okin is meant to catch most of the ash that comes off the charcoal. Anything that gets through should be caught in the loaded chamber, or very rarely, I see a few specks of ash on the fabric stem filter if I load the chamber extremely loosely.

I wouldn't want to just inhale through a clear tube directly from the charcoal, because of the ash/sparks. You will 100% get ash in your mouth.

I am going to try adding additional steel filters to the end of the metal tip, ideally to catch 100% of the large ash particles/sparks before it reaches the load in the chamber. I also wonder if it would be possible to add grains of active carbon to the very end of the metal tip, right before the chamber load. This could be a good filter for not only the ash, but also ultra-fine particles, CO, and trace VOCs from the charcoals. Effectiveness would just be speculative at this point, however.

The first metal screen in the Okin is meant to catch most of the ash that comes off the charcoal. Anything that gets through should be caught in the loaded chamber, or very rarely, I see a few specks of ash on the fabric stem filter if I load the chamber extremely loosely.

I wouldn't want to just inhale through a clear tube directly from the charcoal, because of the ash/sparks. You will 100% get ash in your mouth.

I am going to try adding additional steel filters to the end of the metal tip, ideally to catch 100% of the large ash particles/sparks before it reaches the load in the chamber. I also wonder if it would be possible to add grains of active carbon to the very end of the metal tip, right before the chamber load. This could be a good filter for not only the ash, but also ultra-fine particles, CO, and trace VOCs from the charcoals. Effectiveness would just be speculative at this point, however.

For the record, I didn't see anything like this with the bamboo charcoal and I put it down to the extreme flakiness of the poplar charcoal. You've said the maple doesn't produce ash like that so I would expect that there isn't nearly as much to worry about.

Also for the record, I was using a screen in my test. I think hitting that without one would have been a most unpleasant experience.

Also for the record, I was using a screen in my test. I think hitting that without one would have been a most unpleasant experience.

Oh, well that's good! haha.

Poplar vs. maple of the same size, maple produces less ash, but still more ash than bamboo.

Poplar vs. maple of the same size, maple produces less ash, but still more ash than bamboo.

Jazzah

Well-Known Member

I also wonder if it would be possible to add grains of active carbon to the very end of the metal tip, right before the chamber load. This could be a good filter for not only the ash, but also ultra-fine particles, CO, and trace VOCs from the charcoals. Effectiveness would just be speculative at this point, however.

This sounds like a great idea, but you would need a screen in front of the active carbon fine enough to filter out all the tiny sparks and embers or you would risk lighting the active carbon as well. Although I have no clue as to how it is to smoke/vape on the Okin, I don't think this Carbon addition would be a necessity and would only further complicate the process of maintaining the vape and acquiring the needed materials. Nevertheless, maybe it's just me complicating it in my head and this addition could be added in a simple and straightforward way. Can't wait for the in depth reviews !!!!

as for the action itself, it could be called smaporizing charnabis. I leave it to you guys to decypher that word concoction

Last edited: