We know from experimentation that moisture does affect yield, so work is definitely being done by water vapor, and the pressure and flow it creates.

Water does not have to be boiling to create vapor pressure. Water will evaporate at room temperature, and although boiling water vaporizes faster, it's still far from an instantaneous process.

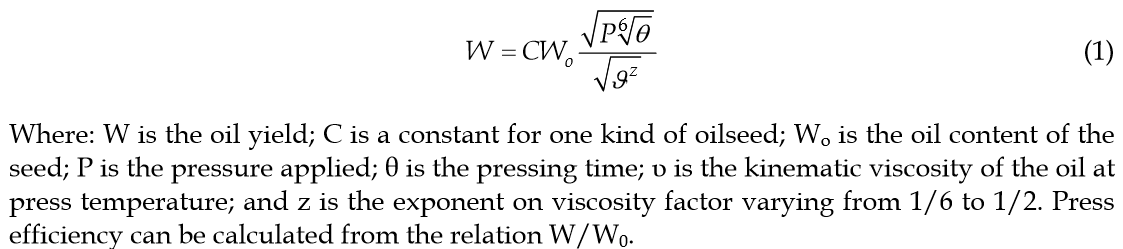

The chart below shows how vapor pressure ramps up with temperature. It shows that 80c water produces about half as much vapor pressure as boiling water, and should vaporize roughly half as quickly.

80c is 176f, and when we press at that temperature, the moisture content will work just the same as it does at higher temperatures, just half as quickly. This is why press times must be increased when using lower temperatures.

Edit:

I've come up with a way to press using a vacuum, and achieve a completely raw extraction!

According to skunkpharm, thc boils at 62.6f / 17c in a 100 Micron vacuum. Terpenes are more volatile and will boil sooner.

This means a 100 Micron vacuum will allow us to collect rosin at room temperature. This is achieved by using the pressure of the press to break open trichomes, vaporizing their contents using vacuum, then recondensing and collecting the vaporized fraction.

Here are the mechanics of it:

A vacuum pump is attached to the outlet of a cold trap like this:

The cold trap is packed in dry ice, and the inlet of the trap is connected to a flexible silicone tube stuffed full of flowers, maybe even to the point it is stretched out. This stuffed tube is what will be pressed.

The other end of the silicone tube is connected to a digital vacuum regulator like this:

The regulator is set to about 100micron. As the pump pulls a vacuum, the regulator will maintain the vacuum level. The air the regulator allows in will create flow inside the apparatus, from the regulator, through the material, and to the cold trap. This flow should provide the same utility that water vapor does in an open system, facilitating the transportation of the rosin.

The silicone tube would collapse under vacuum, so it must be adequately filled to facilitate flow. With this setup it may be possible to progressively "mash" the material in the tube while turning it, to break open as many trichomes as possible while inhibiting flow as little as possible.

To operate, the cold trap would be chilled, and the silicone tube would be filled then closed/sealed. Next, a vacuum is pulled, and once established the material is pressed. When condensate collection tapers off, the vacuum is let off and the silicone tube is refilled. The cold trap could be used for multiple pressings, and will only need to be emptied when full/desired.

ha.

ha.

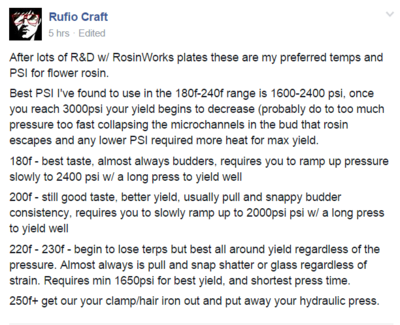

well at least it's not after 2,500 psi

well at least it's not after 2,500 psi