I've seen your picture and its incorrect. The holes are just for cooling. Air doesn't travel through it. While there are also holes in the bottom part under the chamber, there are no holes on the otherside. But since those holes under the chamber are so small most air will get sucked from the slit between bottom and top part

First of all it's not my picture, it was sent to me by my Smiss contact. In fact I had the same reaction as you did at first, wondering where fresh air was drawn in, then they sent me the picture to explain me and I never questioned it.

It turns out we are both right, and thanks to you I was able to open both of my FM8's to have a detailed look and found some interesting things. Here is a picture of the bottom lid with the internal screen removed:

The first red arrow shows the cuts inside the bottom part where the air can flow, the second arrow shows that there's a gap all around anyways to draw air from, and the yellow arrow shows the bottom hole (more on that later)

Here we can see a better view of the bottom part of the lid, naked this time, with the knife pointing at the cuts where they meant air to be drawn from. This air is supposed to be sucked from the exterior holes on the side of the device body and flow through the hinge, which indeed is hollow (red arrow):

This is where it becomes a bit weird: on the other side of the hinge there is only a very small gap between the metal hinge tip and the metal support rod, and this gap leads to the empty space where indeed some air can be drawn from the body side holes...

But this empty space unfortunately is not completely isolated from the electronics section: a part of it is opened to let the bowl wires pass, and it leads to the PCB's and batteries area... so do we really want to draw air from this area? Seeing how convoluted this air path is, I think the "convection effect" from pre-heated air flowing around the heater is super limited anyways.

So we are both right in the sense that in theory air can be drawn from the body side holes, but in practice, it's likely to come as you said more from the gap between the lid and bowl (with the silicone seal)

But here's what I found and it's a very easy fix. In the next picture you can see the bottom lid with the sticker removed seen from below and the knife is pointing at the "bottom hole" that is directly facing the bowl (sorry for the crappy focus):

With a marker pen mark the hole on the sticker. It's exactly center width and 2.6cm from the side (bevel included):

I used a lighter to make the tip of my screwdriver hot enough to melt the sticker plastic, and using a twisting movement was able to drill a clean hole in the sticker, opening the "bottom hole" and allowing a direct bypass of the convoluted air path by letting fresh air come directly from the exterior:

As I said previously, having the lid closed or opened doesn't really change the air flow in practice, so don't expect a big change with this fix but at least it creates a less complicated air path with less risk to suck air from the electronics section.

The first device I opened was the pre-production sample so next picture shows the glue they used (white silicone bonding adhesive) to seal the black silicone piece at the bottom of the bowl and create a tight seal around the no longer existing internal glass straw, with its top protruding:

In my second device this part is not glued anymore meaning there is a potential for air leaks here, even if in practice this silicone part is pressed against the plastic and held in place by another plastic piece not shown above (this piece clips on the 4 pins you can see on the right of the picture, and there are 4 other pins on the back side)

Here is for reference a picture of the internal glass straw. As you can see again it's a bit convoluted, and they reported having tolerance issues with this part, so they replaced it with the "stainless steel tube", more on that afterwards:

In the next picture you can see the silicone part seen from below, on the pre-production sample, with the internal glass straw removed. As you can see the glass straw top goes directly into the slot facing the bottom of the ceramic bowl, where only 5 small holes are drilled:

Now on the production sample you got this stainless steel tube and as you can see there are two problems: first it should have a cut on its side to let vapor flow to the "elbow" corner of the silicone but it only has 4 tiny slits and is otherwise flush with the silicone bottom. The second problem is that it only has 7 tiny holes, many of which were already clogged in my device. This is I think a big problem for airflow and can only get worse over time:

Here you can see the stainless steel tube better, once removed:

So my advice for a second fix would be to remove this piece altogether, to improve air flow and ease maintainance. I know it won't be a solution for you guys but I was able to swap mine with the internal glass straw of the pre-production device, getting something closer to the intended design.

I did a short test (with this fix plus the intake hole fix) and it was clearly better, even if not perfect.

By the way to open the device you need to use an exacto knife and you can raise the top sticker cover at the location pointed by the red arrow in next picture. If you are careful you won't damage it but even if you do, here's what the top looks like with no sticker (it's not that ugly so you could live without):

This means it should be relatively straight forward to open your device for maintainance and cleaning!

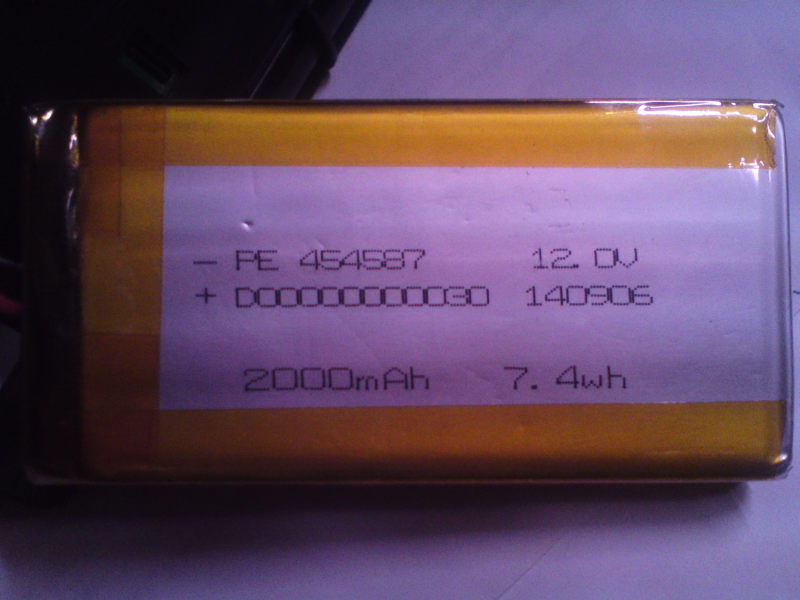

Last but not least, here's a picture of the exact battery specs and model number. It should be servicable with two wires to solder, provided they come with the small PCB built-in (to be confirmed):

You can check this by letting it heat up to a set temp and then immediately hold power for 2sec and then revive the unit fast then the actual temp should be a little bit higher then the set temp. Not a big problem since he heating of the inside is not that responsive but I felt like mentioning it.

Yes I told them there was some overshoot and the PID parameters could be better tuned. Maybe it will be for the next revision.

It's food grade silicone but the vapor will touch the plastic of the housing before getting inhaled.

My bad I was a bit quick when poking around the "air tunnel" inside the device, and indeed this part is made of hard plastic, exactly like in the Ascent. So yes technically the vapor travels through some plastic (and even more now that the internal glass straw has been removed)

There is enough space to build a straight airpath and then use 2xremoveable glasses like in the Ascent. And the air intake would be easy to fix.

There is enough space to build a straight airpath and then use 2xremoveable glasses like in the Ascent. And the air intake would be easy to fix.