-

SCAM WARNING! See how this scam works in Classifieds.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ed's TnT Wooden Vapor Tubes & Vapor Stems

- Thread starter Ed's TnT

- Start date

Watch out, sure like to see all the positive interest already from my earlier post yall @Aezhenn @NickDlow @SSVUN~YAH @HellsWindStaff @TeeJay1952 @TheDudeNextDoor @Philreal187 @starvingmusician24 @yogoshio I guess its fair to say that you all are as excited as I am lol!

Good morning all, @hd_rider Ahh that is a good question, lets not worry about that until I get the betas done and out so the testers can report on their findings. I do want to get a seat at the grown folks table though.

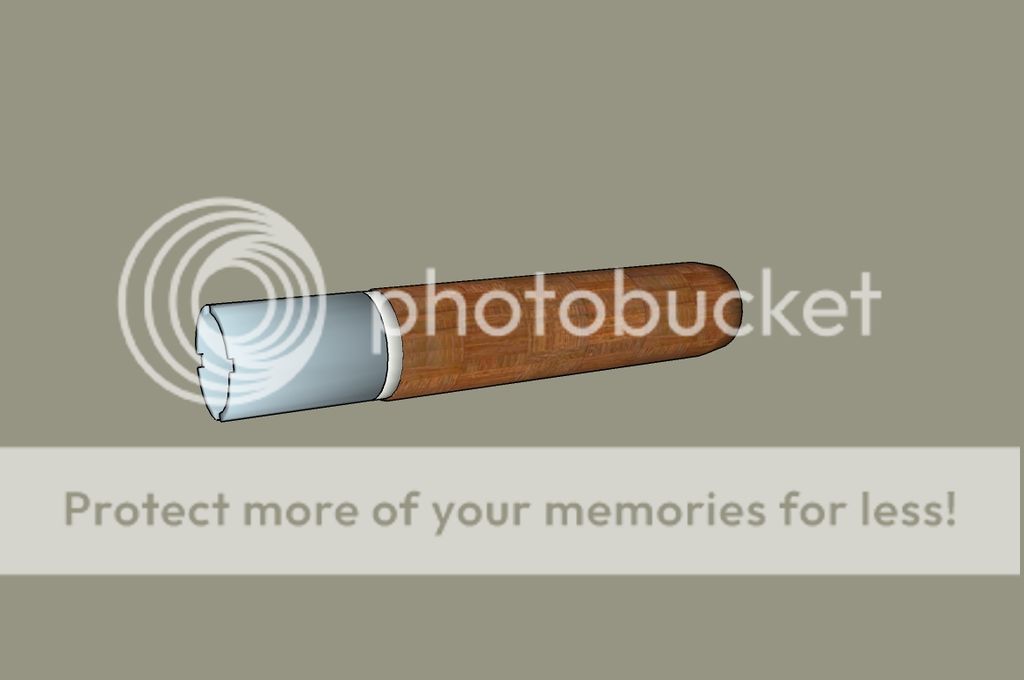

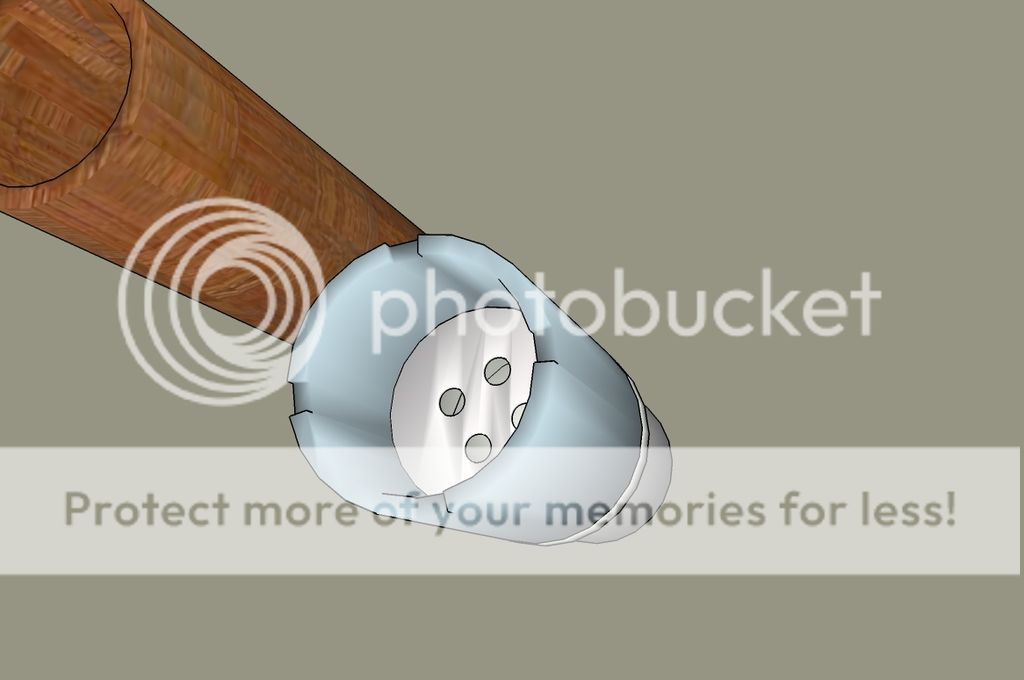

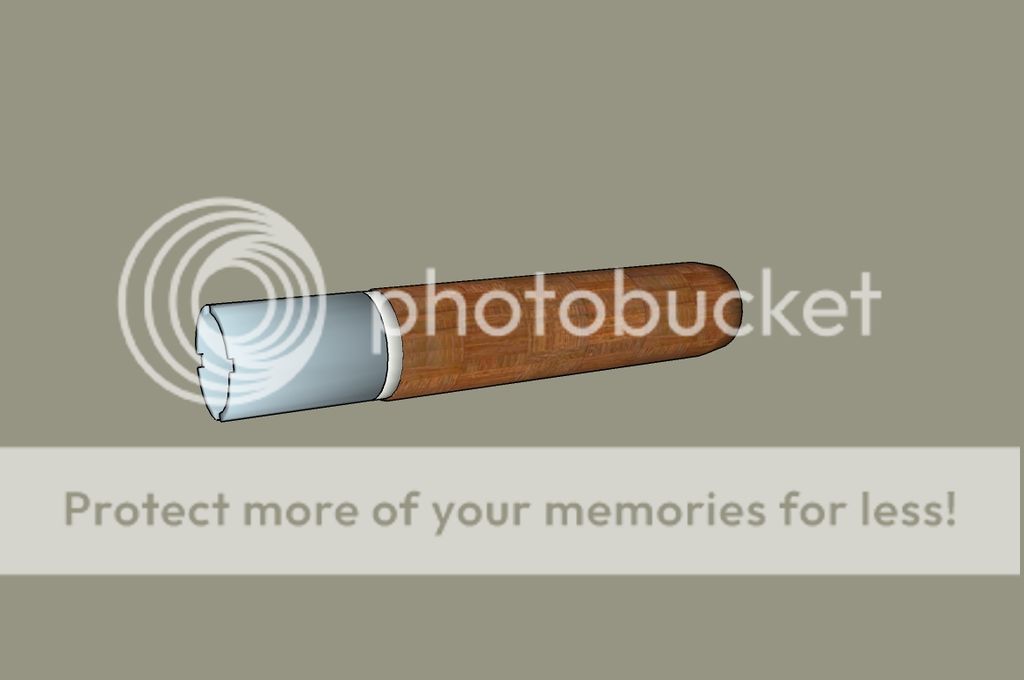

Ok so for a quick round of Show & Tell, keep in mind this is a simpleton piece, its more about function at this point rather than beauty, this is the Mahoe piece I told ya about above. It doesnt have a heater installed yet nor a screen in the air path. The stem will work just like my Nano stems I make which allow you to load a larger capacity rather than going inside with a smaller load.

Like I said keep in mind this is just a simpleton, yall know what I am capable of, there will be many variations in looks in the future. Hope you all like where I am starting!

Ok so for a quick round of Show & Tell, keep in mind this is a simpleton piece, its more about function at this point rather than beauty, this is the Mahoe piece I told ya about above. It doesnt have a heater installed yet nor a screen in the air path. The stem will work just like my Nano stems I make which allow you to load a larger capacity rather than going inside with a smaller load.

Like I said keep in mind this is just a simpleton, yall know what I am capable of, there will be many variations in looks in the future. Hope you all like where I am starting!

Reflections

Well-Known Member

It is Beautiful Ed!! Congrats on finally moving forward to the next step!

virtualpurple

Well-Known Member

Good morning all, has been a really great past few days, got alot done, still got a ton to do that never changes. So excited yall, we leave for our trip in 2 weeks, still doing research and such, cant wait to see the scenery out there, have never been farther than east texas really. The inspection went well at the new house, there are a few minor things that need to be fixed and I kinda know my way around a house from top to bottom I have been there with a hammer or screw. Had a few jobs years and years back, started out painting, took to it rather quick, ohhh was so much fun when I took up a roller and brush, I could transform a place in no time. I got my hands on a great cut brush and could trim out a room so quick, roll over the walls, bam done! Went to doing this and that before I knew I could hang sheet rock, lay floor covering, carpet, tear out walls, rebuild walls, cabinets hey even spent quiet a bit of time on a roof and ladder, ohhh that sucked, seems like the only times we did roofs it was blazing freaking hot, believe me toting bundles up a ladder all day is no day at the park! I hated that and hated painting cabinets, I never for the life of me understand why anyone would want to paint their cabinets, yeah me being a wood guy would never do that and after you have painted a bunch of em its the last thing you wanna do, but at the end of the day I was good at it and it payed well, gotta eat right. I gotta get everything lined out and will begin that before we leave for the trip, should be final a couple weeks after we get back. I felt like the other day I hadnt bought myself a new pair of shades, my sunglasses are a must, gotta have em thats all it is to it! Oakley has brought back their half jacket model updated and looking sweet, got em polarized also. Oh wouldnt ya know it they had a sale on Oakley gear, my laptop bag has gotten old and worn, they had a sale on Oakley back packs, just had to have one of them too, it was a sale, a sale on great gear, a sale on something I needed  so there you have and so will I tomorrow! My girl and I went out for dinner to a local mex joint, was a fun time, where ever we go we talk to people, the waiter, the owner, folks at the joint, no matter what we meet people then make friends. Was really cool seeing our guy, hes young but always does us right, keeps em coming and checks back, we have gotten to know him well. He has MS, just found out a few weeks back, tough for him at such a young age but he does his best to keep putting one foot in front of the other. We were about done for the evening and he says of course you both know its happy hour, yeah we are all over it, says how bout a couple shots, I was like hey surprise us, says he brought us a couple of Don Julio's finest on him, what a night! We got home before dark in bed just after, slept well and now have the whole day ahead of us. Did get in some beautiful B&W Ebony for VapCap stuff, gotta a ton of VC stuff to turn before I leave, these will be very nice. Ewwww just remembered my BF just scored us up tickets for Widespread Panic one mo gin in Alabama in September, woot woot, so so cant wait to see them one last time for a while.

so there you have and so will I tomorrow! My girl and I went out for dinner to a local mex joint, was a fun time, where ever we go we talk to people, the waiter, the owner, folks at the joint, no matter what we meet people then make friends. Was really cool seeing our guy, hes young but always does us right, keeps em coming and checks back, we have gotten to know him well. He has MS, just found out a few weeks back, tough for him at such a young age but he does his best to keep putting one foot in front of the other. We were about done for the evening and he says of course you both know its happy hour, yeah we are all over it, says how bout a couple shots, I was like hey surprise us, says he brought us a couple of Don Julio's finest on him, what a night! We got home before dark in bed just after, slept well and now have the whole day ahead of us. Did get in some beautiful B&W Ebony for VapCap stuff, gotta a ton of VC stuff to turn before I leave, these will be very nice. Ewwww just remembered my BF just scored us up tickets for Widespread Panic one mo gin in Alabama in September, woot woot, so so cant wait to see them one last time for a while.

For an update on the Vapor Bomb, I have gotten the air paths done for the betas, gotta get the bodies turned and heaters installed, then assemble the wiring and control, all is coming together, just had a thought earlier bought another aspect of it that I am excited to work up and trick it out, going to be alot of fun to come! Got a bunch of wood yall know put back, my boys arent that tall yet, in fact they stand on a huge block of Cali Redwood Burl I bought a few years back, guess I am going to have to get them something else to stand on lol.

@Stevenski Good morning sir, am glad you like what you see, keep an eye out for much to come!

@Aezhenn You gotta love Mahoe, its a vibrant wood with much to tell, glad you like bro!

@Reflections I appreciate you stopping by and thank you for your kind words! I hope all is well for you and yours!

@virtualpurple Hello, so glad I can finally make this happen, you are so right was quiet a while back when you and I spoke of this, guess its about time right! I am glad I can count on you, hope I can get ya soon!

Wish you all the best!

so there you have and so will I tomorrow! My girl and I went out for dinner to a local mex joint, was a fun time, where ever we go we talk to people, the waiter, the owner, folks at the joint, no matter what we meet people then make friends. Was really cool seeing our guy, hes young but always does us right, keeps em coming and checks back, we have gotten to know him well. He has MS, just found out a few weeks back, tough for him at such a young age but he does his best to keep putting one foot in front of the other. We were about done for the evening and he says of course you both know its happy hour, yeah we are all over it, says how bout a couple shots, I was like hey surprise us, says he brought us a couple of Don Julio's finest on him, what a night! We got home before dark in bed just after, slept well and now have the whole day ahead of us. Did get in some beautiful B&W Ebony for VapCap stuff, gotta a ton of VC stuff to turn before I leave, these will be very nice. Ewwww just remembered my BF just scored us up tickets for Widespread Panic one mo gin in Alabama in September, woot woot, so so cant wait to see them one last time for a while.

so there you have and so will I tomorrow! My girl and I went out for dinner to a local mex joint, was a fun time, where ever we go we talk to people, the waiter, the owner, folks at the joint, no matter what we meet people then make friends. Was really cool seeing our guy, hes young but always does us right, keeps em coming and checks back, we have gotten to know him well. He has MS, just found out a few weeks back, tough for him at such a young age but he does his best to keep putting one foot in front of the other. We were about done for the evening and he says of course you both know its happy hour, yeah we are all over it, says how bout a couple shots, I was like hey surprise us, says he brought us a couple of Don Julio's finest on him, what a night! We got home before dark in bed just after, slept well and now have the whole day ahead of us. Did get in some beautiful B&W Ebony for VapCap stuff, gotta a ton of VC stuff to turn before I leave, these will be very nice. Ewwww just remembered my BF just scored us up tickets for Widespread Panic one mo gin in Alabama in September, woot woot, so so cant wait to see them one last time for a while.For an update on the Vapor Bomb, I have gotten the air paths done for the betas, gotta get the bodies turned and heaters installed, then assemble the wiring and control, all is coming together, just had a thought earlier bought another aspect of it that I am excited to work up and trick it out, going to be alot of fun to come! Got a bunch of wood yall know put back, my boys arent that tall yet, in fact they stand on a huge block of Cali Redwood Burl I bought a few years back, guess I am going to have to get them something else to stand on lol.

@Stevenski Good morning sir, am glad you like what you see, keep an eye out for much to come!

@Aezhenn You gotta love Mahoe, its a vibrant wood with much to tell, glad you like bro!

@Reflections I appreciate you stopping by and thank you for your kind words! I hope all is well for you and yours!

@virtualpurple Hello, so glad I can finally make this happen, you are so right was quiet a while back when you and I spoke of this, guess its about time right! I am glad I can count on you, hope I can get ya soon!

Wish you all the best!

little maggie

Well-Known Member

I'm in. Where do I sign up for the Ed bomb? I love the color of the one you made.

One question- will I be able to micro dose with the new stems? I imagine the answer is yes since I can do that with either the ud or enano. Can't wait!

One question- will I be able to micro dose with the new stems? I imagine the answer is yes since I can do that with either the ud or enano. Can't wait!

Oogendoogan

Well-Known Member

I am 100 percent interested in one of these. And the blue mahoe looks super beautiful Ed. Can't wait to hopefully be one of your first customers with this thing. I've been wanting another log vape for a while now.. Eyeing woods and different threads. Your the man Ed, I want yours. I love wooden vaporizers more than anything and not having a log had made me sad and this post just made me very happy  I cant wait to see Ed's Vapor Bomb on the desktop page

I cant wait to see Ed's Vapor Bomb on the desktop page

I cant wait to see Ed's Vapor Bomb on the desktop page

I cant wait to see Ed's Vapor Bomb on the desktop page

Good morning everyone, wow have been busy turning new B&W Ebony for the VC, these pieces are absolutely stunning, this species is so much fun! Cant wait for S&T, will be exciting! Am still gearing up for the road trip, been buying smalls here and there, gathering tools and all. I have so much to do, so much preparation to be done, gotta check my spare, pack some tools, got a first aid kit and meds for us all, gotta find my jumper cables, so much to do. I am giving it hell though and the boys and I will work really hard the next few days going over it all inspecting. Just put in an order for big blue point oysters this morning, going to get my girl to pick em up next weekend, the boys will be at their moms for that weekend since they will be gone with me for so long, my girl gets the oysters, ill get the steaks, got a thought for a twist on JapWraps. What ya think, shuck a few oysters, get the big jalapenos, dig out the seeds, stuff it with an oyster then pack it full of pepper jack cheese then wrap it in pepper crusted bacon, RRRRRRRRRRRRRRRRRRRRRRRRR thats got to be good right?????? Yeah thinking we get a nice bottle of red wine to go along with it, I am not much of a wine guy, guess I got to much redneck in me, seems Budwieser goes with anything lol! I have had a few glasses of red wine along the years and favor it but unsure of any brands or such I should look for in a good bottle, any help would be greatly appreciated by myself and my girl am sure! Got some rat killing to do this morning, bills to get ready before I leave, gotta get my butt back out in the shop soon. Hope all is well out there!

@yogoshio You know thats gotta be a good feeling to know that you were all good, glass sucks, wood rules! Thanks for stopping by bro and for spreading the news, wish you the best!

@little maggie Good morning sunshine, I got an email into you waiting to hear back, pls holla at me when you can! Thanks for your interest in the VB, hope to have the beta bombs out by middle to end of July ( thanks @Vape Dr. ) hang in there with me. Not sure about microdosing, I dont get out much, if you say you can do it with the other stems I make then yes you will be able to with the VB as well. Keep an eye out for updates to come!

@Oogendoogan Woot woot, glad to see your enthusiasm bro, wont be too awful long and you will have a VB of your own! Wish you the best and pls take care!

@yogoshio You know thats gotta be a good feeling to know that you were all good, glass sucks, wood rules! Thanks for stopping by bro and for spreading the news, wish you the best!

@little maggie Good morning sunshine, I got an email into you waiting to hear back, pls holla at me when you can! Thanks for your interest in the VB, hope to have the beta bombs out by middle to end of July ( thanks @Vape Dr. ) hang in there with me. Not sure about microdosing, I dont get out much, if you say you can do it with the other stems I make then yes you will be able to with the VB as well. Keep an eye out for updates to come!

@Oogendoogan Woot woot, glad to see your enthusiasm bro, wont be too awful long and you will have a VB of your own! Wish you the best and pls take care!

Oogendoogan

Well-Known Member

Will do, you take care and have fun on your vacation Ed! If anyone deserves some time off it is you, go enjoy yourself with the kids and have a blast!!@Oogendoogan Woot woot, glad to see your enthusiasm bro, wont be too awful long and you will have a VB of your own! Wish you the best and please take care!

I am honestly so exited about the VB. I am positive that this is one of my next vapes. you couldn't have announced this at a more perfect time for me. I started vaping with a log and now i am getting into wood vapes, so i guess i need another log right? I mean I do not think i need to say it in this thread but there is just something about wood that makes a vape more than just a machine it makes it a piece of art and a piece of my house and life that i love and cherish.

Your the man Ed. i want your log. I love your wood work and i love the way you do things. I wish you nothing but luck with the beta bombs and i really hope everything works out perfectly so i can hold one of your beautiful logs in my own hands ASAP. I will be following this thread closely and also any new thread that comes up for the VB

little maggie

Well-Known Member

Just thinking about the change in Ed's direction. Ed has already contributed so much to my vaping experience. Almost all of my vapes from the Lily to the Haze have stems that Ed has made and that improve my use of them. And that's not including all the dynavap wood pieces that are on their way to me.

It's going to be exciting to see what he comes up with next.

It's going to be exciting to see what he comes up with next.

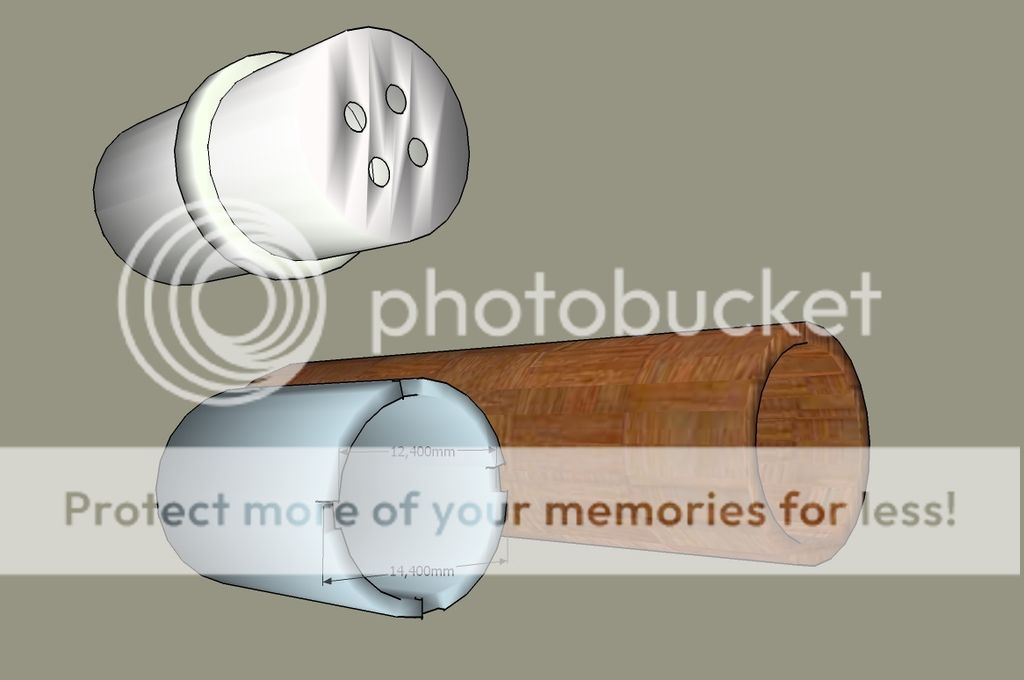

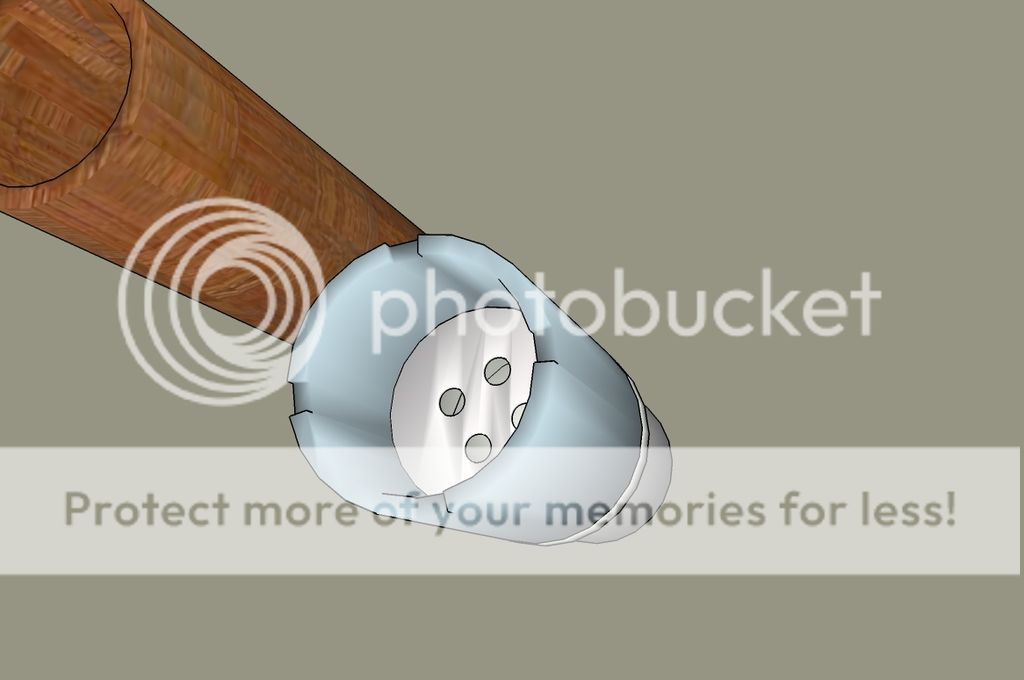

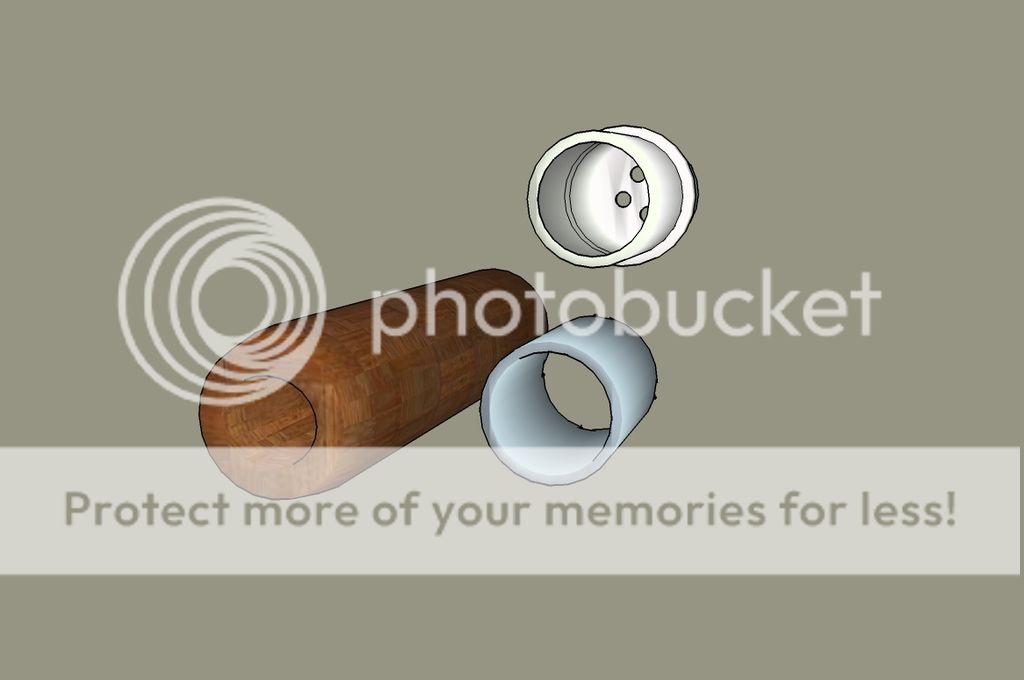

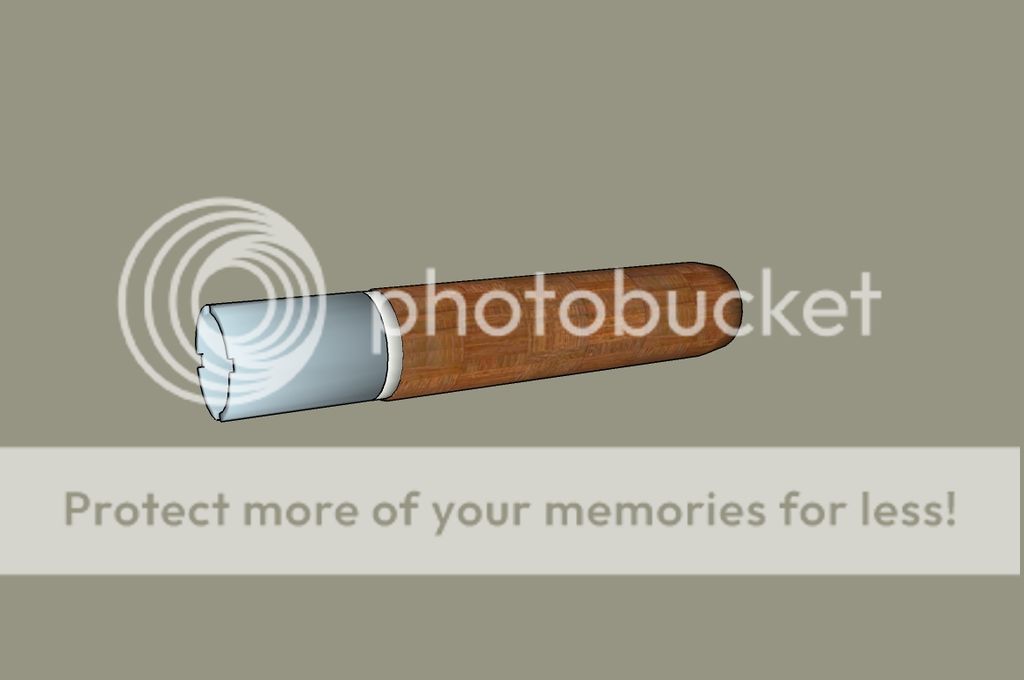

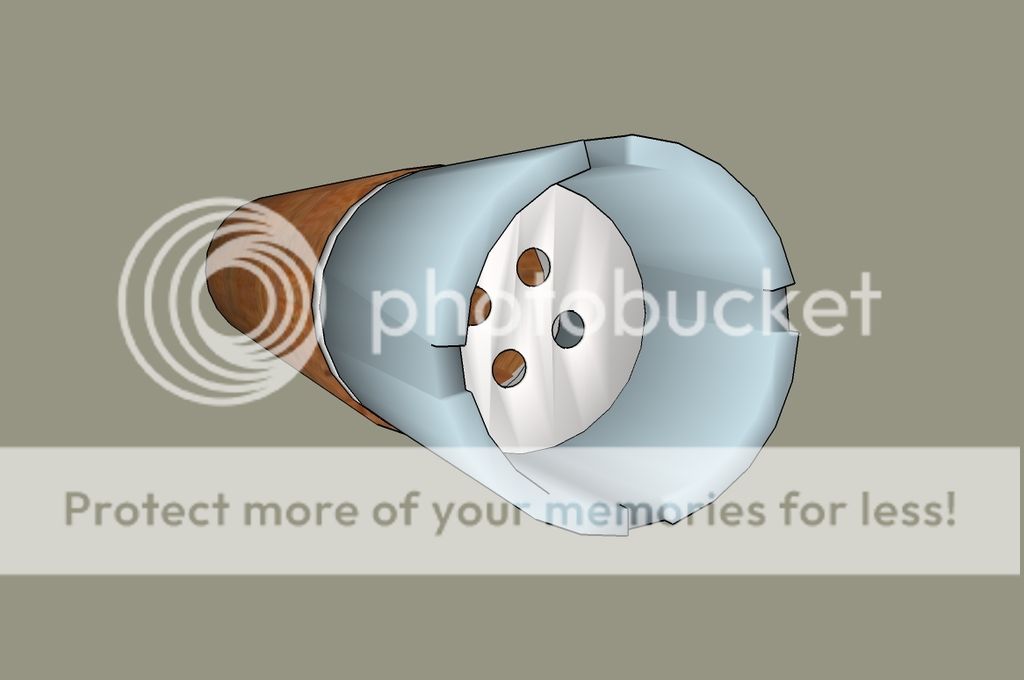

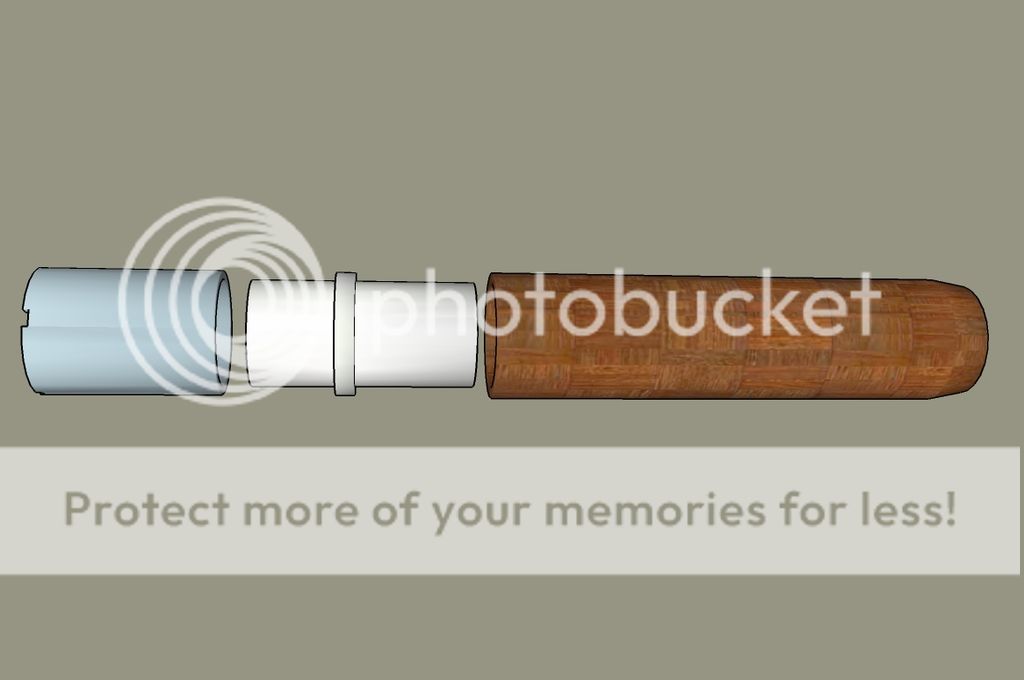

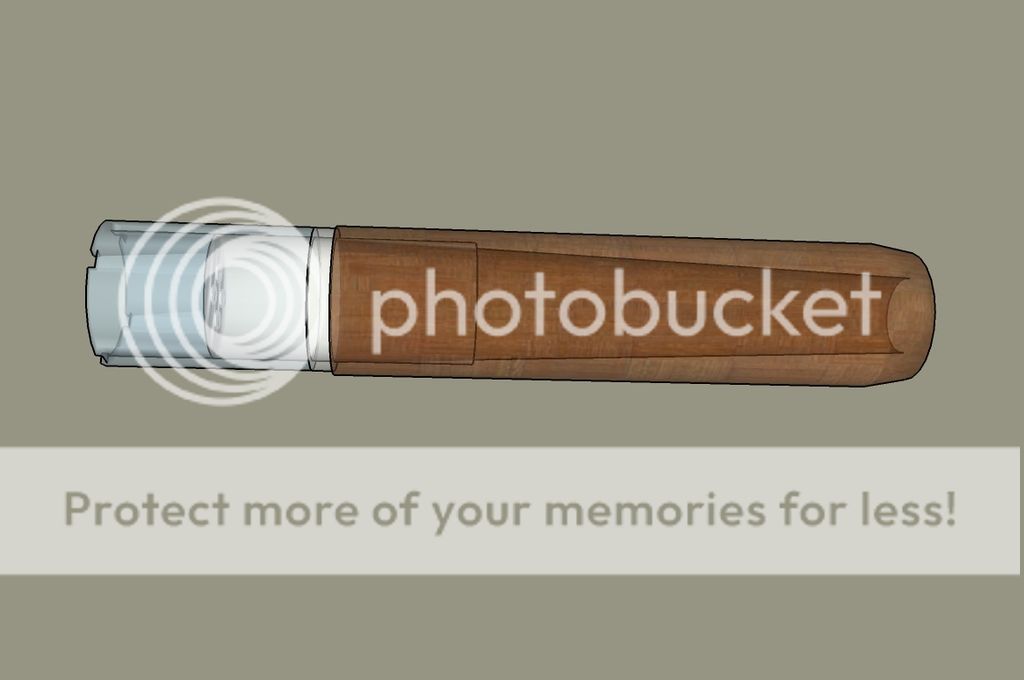

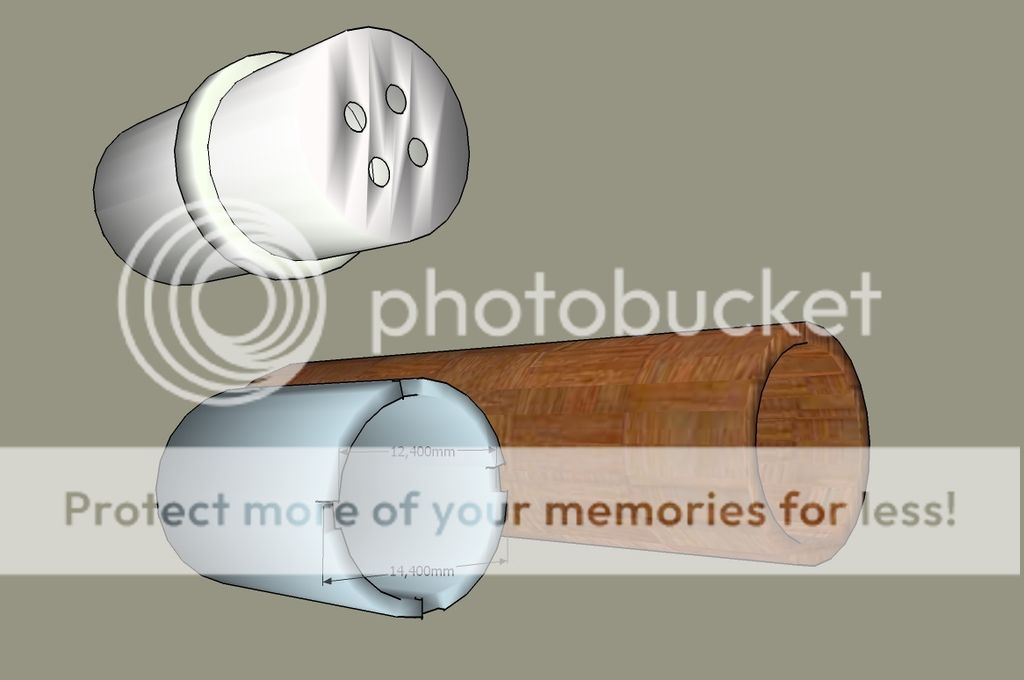

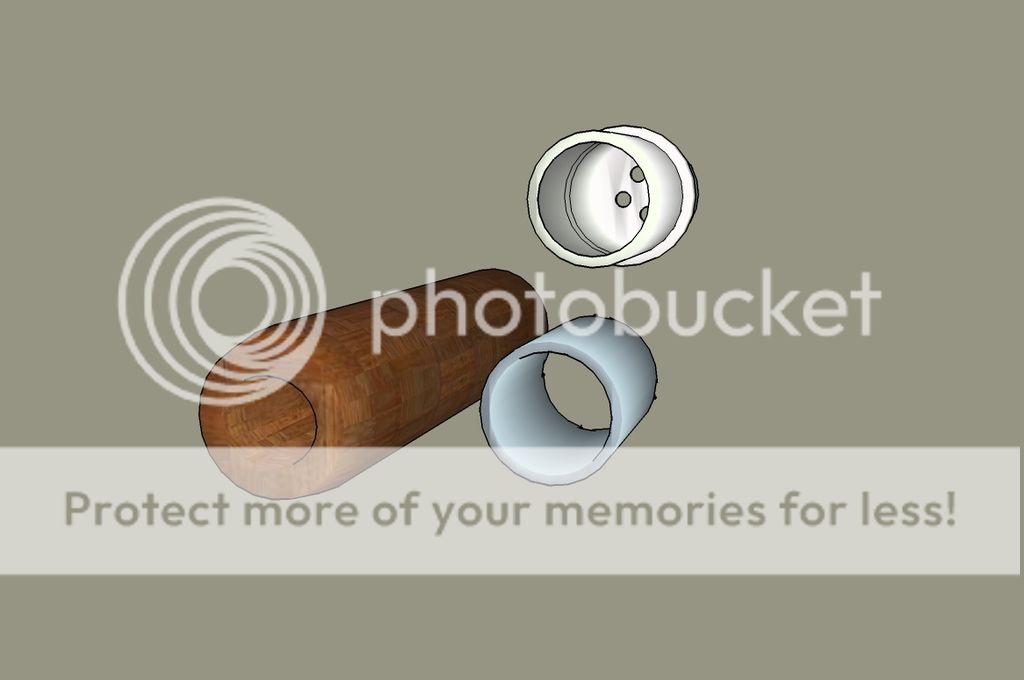

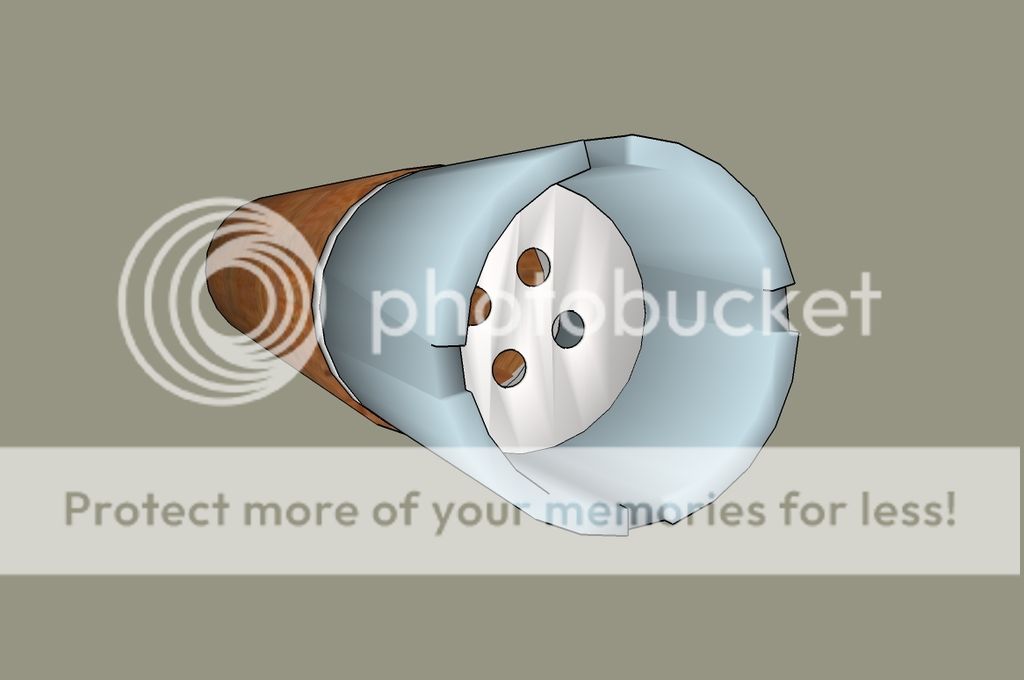

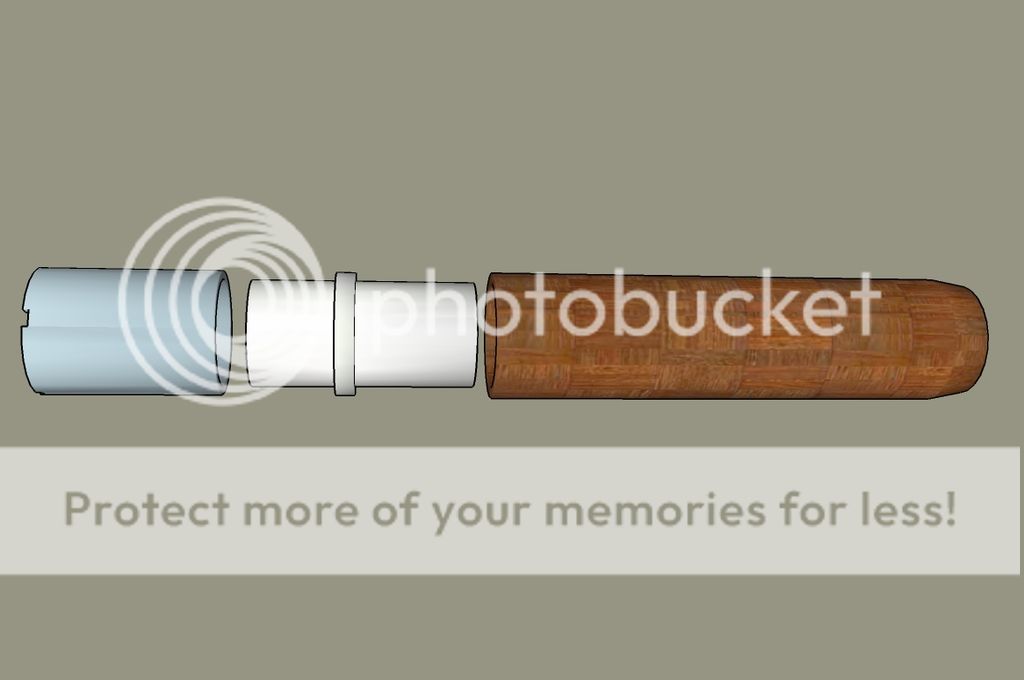

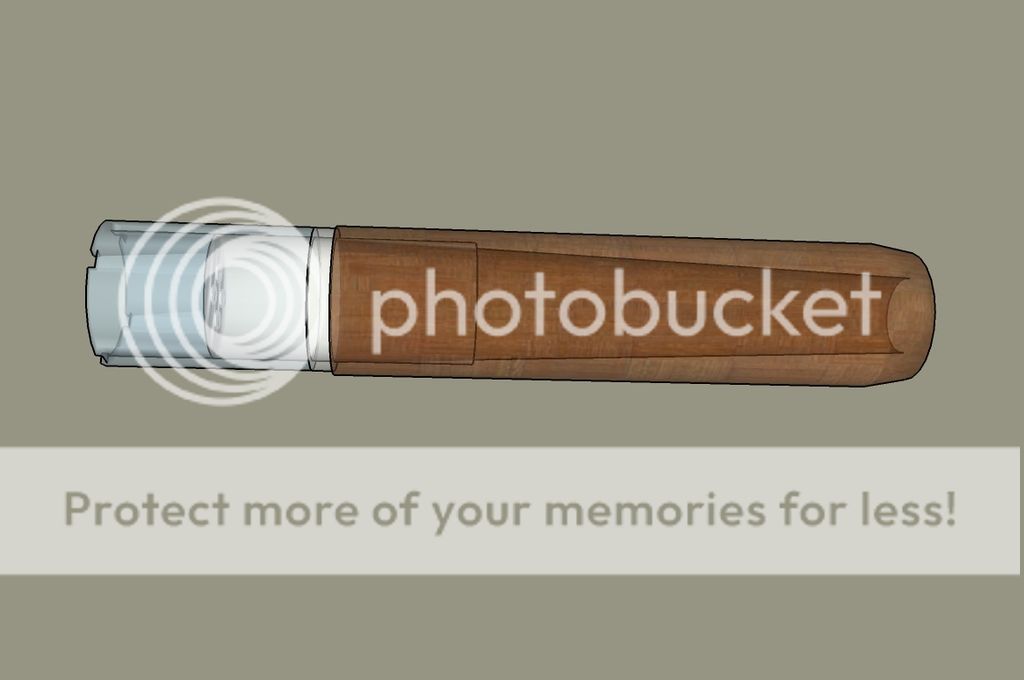

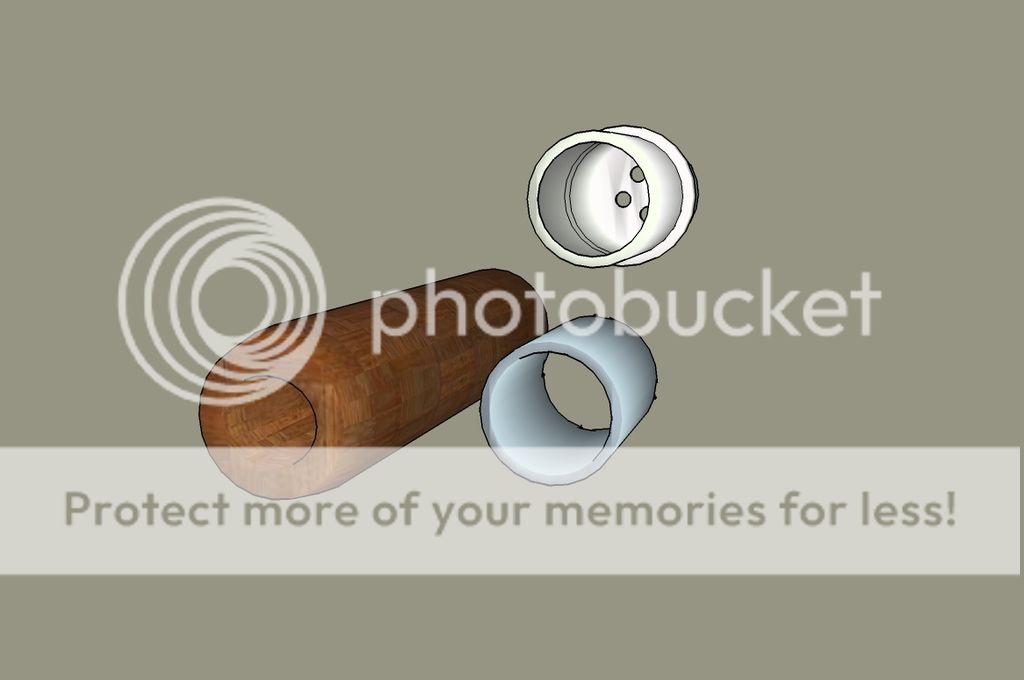

Some food for thought ...

Or at least what I would like to get for my Air ,made from Ed's hands .

.

.

But a different ( design) approach ...

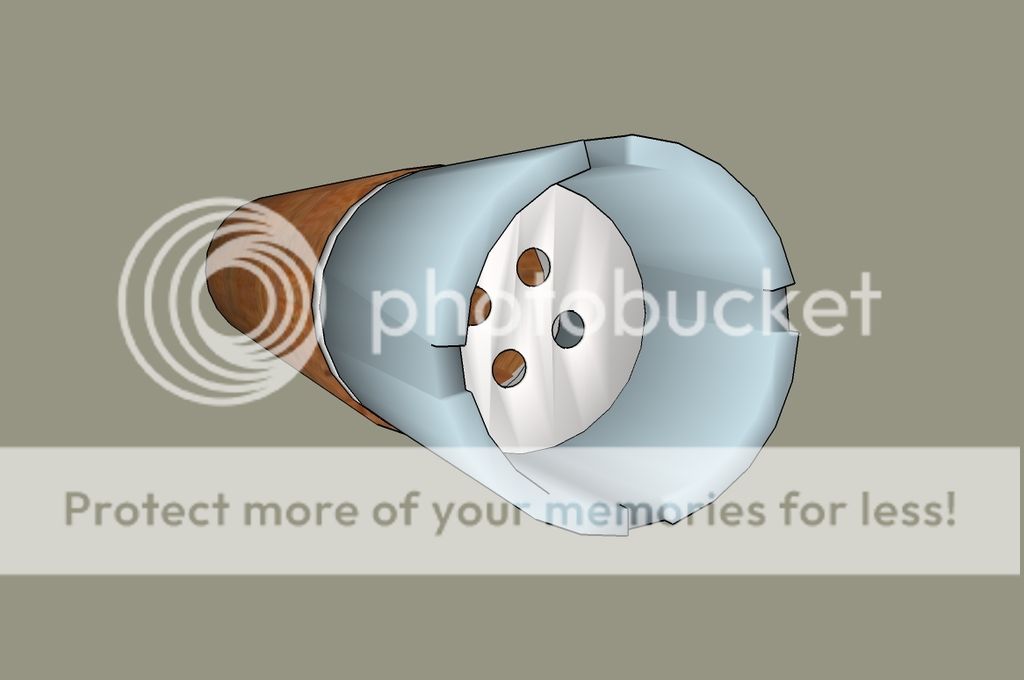

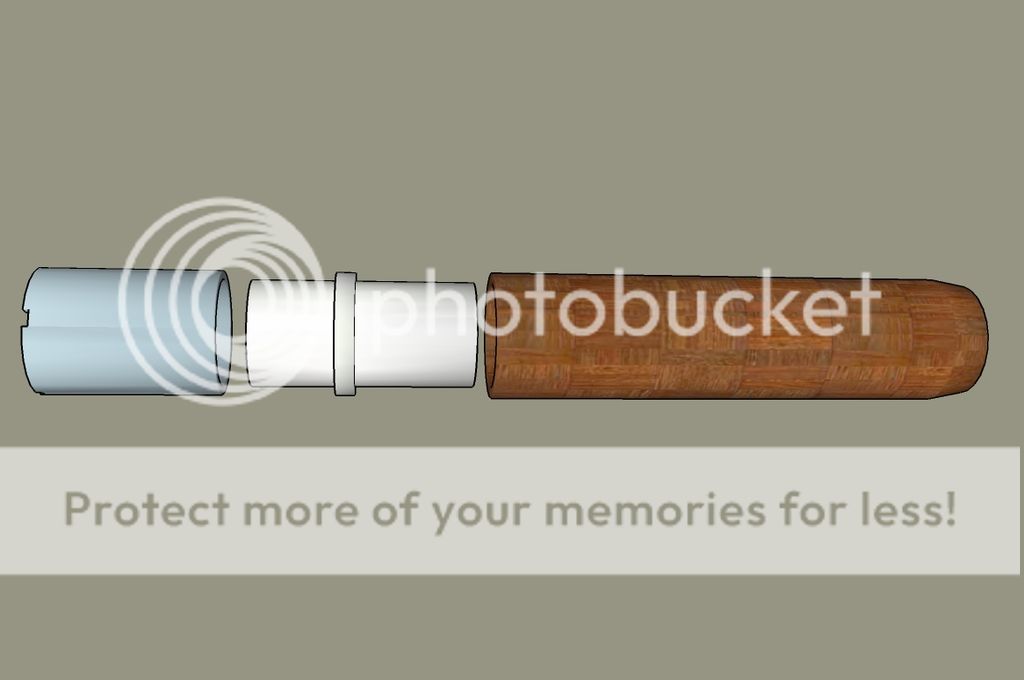

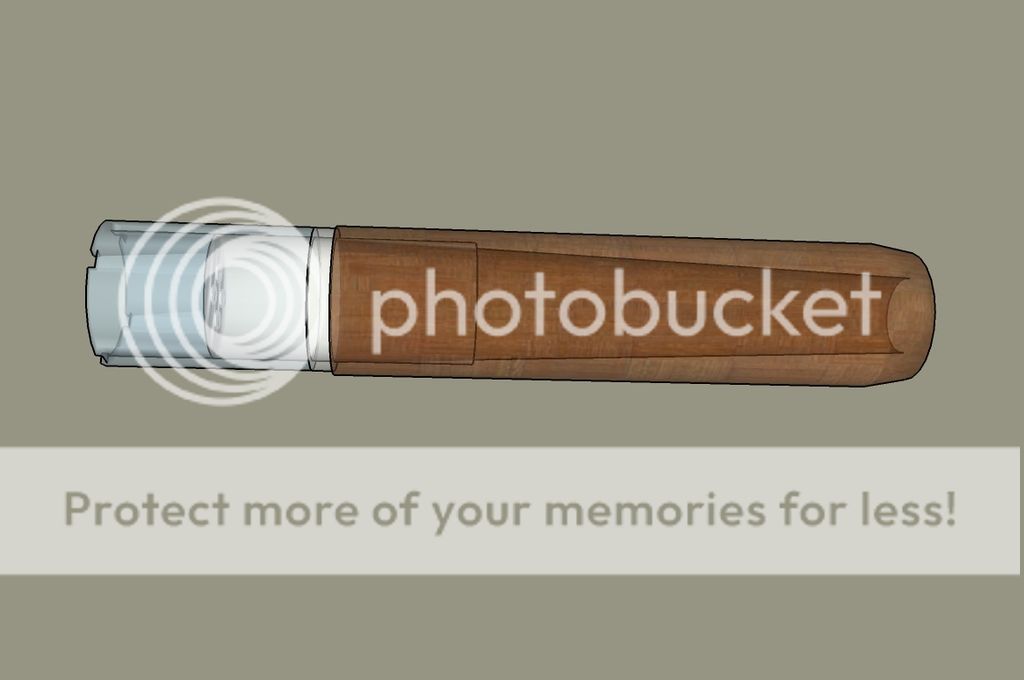

From left to right : The light blue tinted part is the bowl ( ~20 mm in length ).

Could be made out of 316L stainless steel or out of Titanium

(grade 2 is relatively easy to find ).

The white part is the "joint/screen" part .It has threadings at the bowl side and it's plain on the

wooden mouthpiece side .Could be made also from stainless steel or titanium if the mouthpiece

is made from wood.If the mouthpiece is going to be made of metal then it's better the joint part to be made out a heat-resistant and inert/non-toxic polymer,like pure teflon(PTFE) or Zytel FG.

That ,in order not to conduct heat .And also being lighter .

This joint part can be made at the lathe from s.steel / titanium/ PTFE rod .

The next is the mouthpiece made out of some exotic wood

(BTW,being greek ,my favourite is the olive tree wood ).

The wooden mp is connected to the joint just by sliding in .

Like the old-style tobacco pipes ,with the ebonite mouthpieces ,

pushed tightly into the pipe's main body ..

(could it be threaded ? )

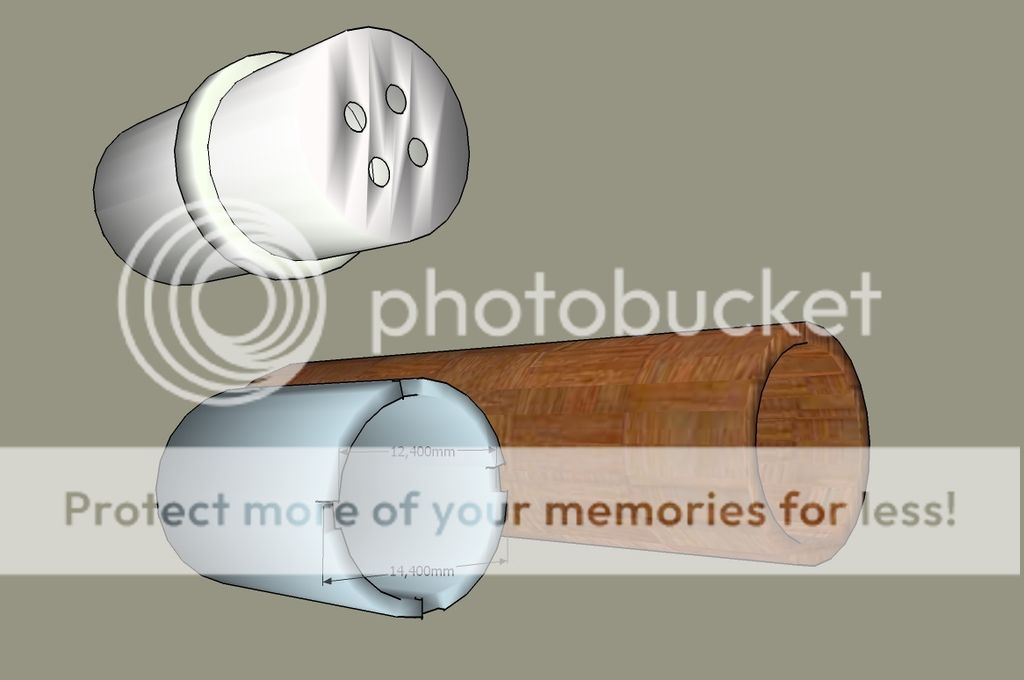

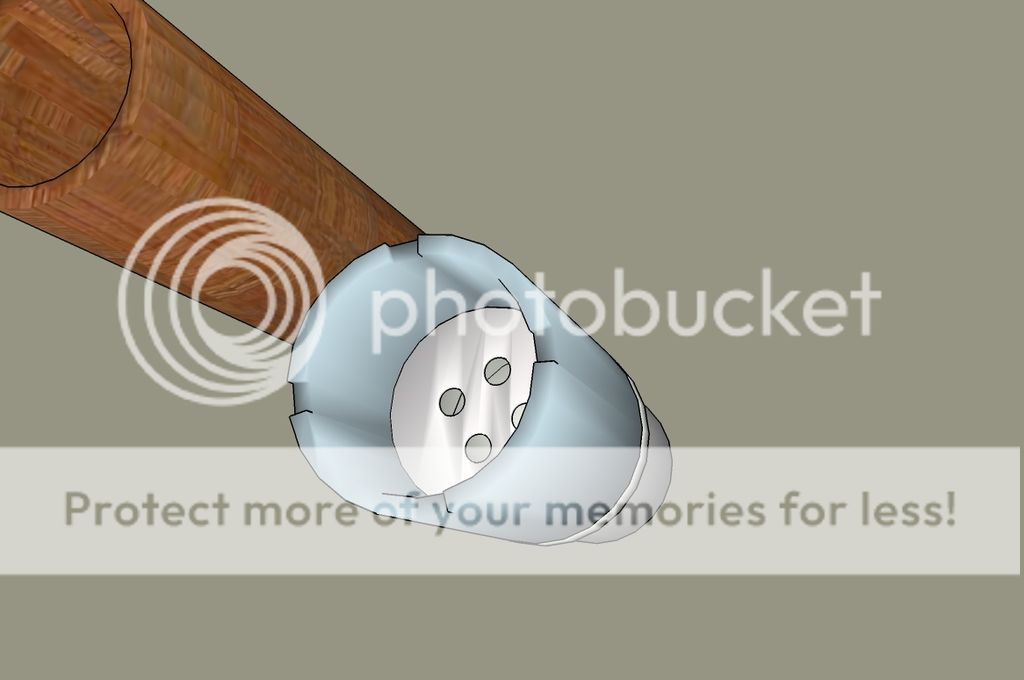

Also ,by using -of different thicknesses -threaded washer rings as spacers ,

screwed on at the joint part-before the bowl ,the volume of the bowl is increased .

"Adjust-A-Bowl " concept !

I hope that Ed will appreciate the whole idea ...

-Not any small parts ,like o-rings,screens,retaining rings,pins,etc are utilised ...

-Easy to clean (seems so ) ...

-"Adjust-A-Bowl "

"

And I'm pretty sure that it's a piece of cake for him ,to make some test-stems ...

I'm willin' to buy these "test-stems" ,anyways ...

Or at least what I would like to get for my Air ,made from Ed's hands .

.

.But a different ( design) approach ...

From left to right : The light blue tinted part is the bowl ( ~20 mm in length ).

Could be made out of 316L stainless steel or out of Titanium

(grade 2 is relatively easy to find ).

The white part is the "joint/screen" part .It has threadings at the bowl side and it's plain on the

wooden mouthpiece side .Could be made also from stainless steel or titanium if the mouthpiece

is made from wood.If the mouthpiece is going to be made of metal then it's better the joint part to be made out a heat-resistant and inert/non-toxic polymer,like pure teflon(PTFE) or Zytel FG.

That ,in order not to conduct heat .And also being lighter .

This joint part can be made at the lathe from s.steel / titanium/ PTFE rod .

The next is the mouthpiece made out of some exotic wood

(BTW,being greek ,my favourite is the olive tree wood ).

The wooden mp is connected to the joint just by sliding in .

Like the old-style tobacco pipes ,with the ebonite mouthpieces ,

pushed tightly into the pipe's main body ..

(could it be threaded ? )

Also ,by using -of different thicknesses -threaded washer rings as spacers ,

screwed on at the joint part-before the bowl ,the volume of the bowl is increased .

"Adjust-A-Bowl " concept !

I hope that Ed will appreciate the whole idea ...

-Not any small parts ,like o-rings,screens,retaining rings,pins,etc are utilised ...

-Easy to clean (seems so ) ...

-"Adjust-A-Bowl "

"

And I'm pretty sure that it's a piece of cake for him ,to make some test-stems ...

I'm willin' to buy these "test-stems" ,anyways ...

Last edited:

stickstones

Vapor concierge

Some food for thought ...

Or at least what I would like to get for my Air ,made from Ed's hands .

.

But a different ( design) approach ...

From left to right : The light blue tinted part is the bowl ( ~20 mm in length ).

Could be made out of 316L stainless steel or out of Titanium

(grade 2 is relatively easy to find ).

The white part is the "joint/screen" part .It has threadings at the bowl side and it's plain on the

wooden mouthpiece side .Could be made also from stainless steel or titanium if the mouthpiece

is made from wood.If the mouthpiece is going to be made of metal then it's better the joint part to be made out a heat-resistant and inert/non-toxic polymer,like pure teflon(PTFE) or Zytel FG.

That ,in order not to conduct heat .And also being lighter .

This joint part can be made at the lathe from s.steel / titanium/ PTFE rod .

The next is the mouthpiece made out of some exotic wood

(BTW,being greek ,my favourite is the olive tree wood ).

The wooden mp is connected to the joint just by sliding in .

Like the old-style tobacco pipes ,with the ebonite mouthpieces ,

pushed tightly into the pipe's main body ..

(could it be threaded ? )

Also ,by using -of different thicknesses -threaded washer rings as spacers ,

screwed on at the joint part-before the bowl ,the volume of the bowl is increased .

"Adjust-A-Bowl " concept !

I hope that Ed will appreciate the whole idea ...

-Not any small parts ,like o-rings,screens,retaining rings,pins,etc are utilised ...

-Easy to clean (seems so ) ...

-"Adjust-A-Bowl "

"

And I'm pretty sure that it's a piece of cake for him ,to make some test-stems ...

I'm willin' to buy these "test-stems" ,anyways ...

Dude...that's a serious 'young member' post...thanks for the contribution! I like your style!

Dude...that's a serious 'young member' post...thanks for the contribution! I like your style!

Thank you !

The initial idea can be found here :

http://fuckcombustion.com/threads/the-arizer-air.16415/page-368#post-985658

Good morning everyone, hope all is well and you all are doing your best to stay cool, its freaking miserably hot down in my neck of the woods, omgosh its ridiculously hot, hell has to be a terrible place! Still buying gear for the trip, went this morning getting the last smalls and other stuff on the list, walmart hit me for $200, asked the cashier was there anything she could roll back, she smiled and said nah! Feel like I have covered pretty much all our needs and then some, rather have more than we need than need and not have right, will probably still need and not have something but rest assured we got TP & water, got something to wipe with and something to drink if nothing else, lol! Still working on the VC order, am more than half way done, will finish it up the next few days and there will be so many more woodies out there for others to enjoy. I must tell you all the boys and myself are so excited about this trip, its finally almost here, we are all electric about it, I have noticed that the closer we get to leaving the more the boys talk about it and keep saying dad I cant wait for next sunday to get here, not long now!!!

@Oogendoogan Will for sure do bro, going to be tough letting all that work pile up but will all be worth it to see all the sites the smiles and relive the memories made the rest of our lives! My man I am so excited bout the Vapor Bomb also and I so agree there is so much life and character in wood that you cant get in any other medium out there. I am almost certain I wont have time to make any VB bodies before we leave unless the stars align or a clone knocks on my door but who knows, when I get back will fill orders and work up the beta bombs for sure! Wish you the best bro!

@little maggie Good morning, got your email and sent ya one back havent heard from ya though, your order will ship in the morning and you will receive tracking this evening or early tomorrow morning. Wow I hadnt thought about it but I guess I have been a part of many of your vapes, I am very grateful! Thanks for being a part of all I have been able to offer so far and for your support in the future!

@stardustsailor Good morning and wow what an idea and drawings foremost! I like what you have come up with but just dont feel it would be any less work involved, in fact I feel it would be quiet a bit more if ya think about the manufacturing process and all the added steps. First off I would have to get the PTFE rod, by your design I would have to chop it to length, turn down both ends, then bore the 4 holes. I began making the stems with the one large draw hole because users felt the 4 were somewhat restrictive. Threads are one thing I have thought of but quickly forgot about due to the thickness of the SS bushing and the wood itself just not a good idea so orings would have to be used anyway. Using the orings has greatly increased the amount of time that I spent making the stems, before I changed the design just cutting the pins, installing them, grinding and polishing was taking a lot of time. I do like the space idea as far as being able to adjust depth, that is a great thought and may be applied at some point. Right now, I chop the wood, bore the wood once, turn it, put the oring on, push it in the bushing, drop in a screen, push in a clip, done. Your design I chop the wood, bore the wood, turn the wood, chop the PTFE rod, turn the rod, bore 4 holes, put 2 orings on/one for the wood/one for the bushing, then assemble. I just counted to steps, suppose its bout the same when ya list em out but the amount of time spent your way is more at various steps, time is money, something I never have much of each and then Id have to raise the price per stem considerably and who wants to spend quiet a bit more on a piece of wood anyway or at least thats what I hear often. Dont get me wrong I like a challenge and could probable make this happen had I have the time. I am not sure if you have seen my latest project, as @little maggie mentioned above I am headed in another direction and to be honest custom work and some stem work is going to slow down, custom has stopped for now due to all the wholesale and retail I have to keep up with there is only so much time in the day and only so much one man can do. Some people may think thats Ed's TnT is a company of size, not saying you do, but it is a company of one, one man giving it hell is all I can do, never standing still nor letting the grass grow between my toes, it all started with one/me and may end with one/me, if thats how it supposed to be then thats good enough for me! Thanks again for the idea and the drawing figure you spent more time on the images and design than I did with this post, well done!

@stickstones & @Shrike Aint it though, I gota feeling we going to be hearing alot of good stuff outa this guy!

@Oogendoogan Will for sure do bro, going to be tough letting all that work pile up but will all be worth it to see all the sites the smiles and relive the memories made the rest of our lives! My man I am so excited bout the Vapor Bomb also and I so agree there is so much life and character in wood that you cant get in any other medium out there. I am almost certain I wont have time to make any VB bodies before we leave unless the stars align or a clone knocks on my door but who knows, when I get back will fill orders and work up the beta bombs for sure! Wish you the best bro!

@little maggie Good morning, got your email and sent ya one back havent heard from ya though, your order will ship in the morning and you will receive tracking this evening or early tomorrow morning. Wow I hadnt thought about it but I guess I have been a part of many of your vapes, I am very grateful! Thanks for being a part of all I have been able to offer so far and for your support in the future!

@stardustsailor Good morning and wow what an idea and drawings foremost! I like what you have come up with but just dont feel it would be any less work involved, in fact I feel it would be quiet a bit more if ya think about the manufacturing process and all the added steps. First off I would have to get the PTFE rod, by your design I would have to chop it to length, turn down both ends, then bore the 4 holes. I began making the stems with the one large draw hole because users felt the 4 were somewhat restrictive. Threads are one thing I have thought of but quickly forgot about due to the thickness of the SS bushing and the wood itself just not a good idea so orings would have to be used anyway. Using the orings has greatly increased the amount of time that I spent making the stems, before I changed the design just cutting the pins, installing them, grinding and polishing was taking a lot of time. I do like the space idea as far as being able to adjust depth, that is a great thought and may be applied at some point. Right now, I chop the wood, bore the wood once, turn it, put the oring on, push it in the bushing, drop in a screen, push in a clip, done. Your design I chop the wood, bore the wood, turn the wood, chop the PTFE rod, turn the rod, bore 4 holes, put 2 orings on/one for the wood/one for the bushing, then assemble. I just counted to steps, suppose its bout the same when ya list em out but the amount of time spent your way is more at various steps, time is money, something I never have much of each and then Id have to raise the price per stem considerably and who wants to spend quiet a bit more on a piece of wood anyway or at least thats what I hear often. Dont get me wrong I like a challenge and could probable make this happen had I have the time. I am not sure if you have seen my latest project, as @little maggie mentioned above I am headed in another direction and to be honest custom work and some stem work is going to slow down, custom has stopped for now due to all the wholesale and retail I have to keep up with there is only so much time in the day and only so much one man can do. Some people may think thats Ed's TnT is a company of size, not saying you do, but it is a company of one, one man giving it hell is all I can do, never standing still nor letting the grass grow between my toes, it all started with one/me and may end with one/me, if thats how it supposed to be then thats good enough for me! Thanks again for the idea and the drawing figure you spent more time on the images and design than I did with this post, well done!

@stickstones & @Shrike Aint it though, I gota feeling we going to be hearing alot of good stuff outa this guy!

Oogendoogan

Well-Known Member

Thanks Ed! i hope you had a great fathers day today. its a little late and i was out with my dad all day but i came back and this post made me happy. A clone would be fucking great!@Oogendoogan Will for sure do bro, going to be tough letting all that work pile up but will all be worth it to see all the sites the smiles and relive the memories made the rest of our lives! My man I am so excited bout the Vapor Bomb also and I so agree there is so much life and character in wood that you cant get in any other medium out there. I am almost certain I wont have time to make any VB bodies before we leave unless the stars align or a clone knocks on my door but who knows, when I get back will fill orders and work up the beta bombs for sure! Wish you the best bro!

I really woudnt be against the idea of an Ed clone to tell you the truth, he seems a like a nice guy and twice the wood work? now that just seems like good math and it seems like a good deal for everyone

I really woudnt be against the idea of an Ed clone to tell you the truth, he seems a like a nice guy and twice the wood work? now that just seems like good math and it seems like a good deal for everyone  I am very high so i will just leave you with that. take it easy man.

I am very high so i will just leave you with that. take it easy man.

Good morning, got a feeling today is going to be a good day, hoping it turns out great, time will tell!

@Oogendoogan Thanks my man, better late than never homie! You bet, an Ed Clone would sure speed up production and he's gotta be a nice guy or else he's toast, aint about to deal with another me being a jerk, that aint cool! If it works and #2 does a good job will see about getting a #3 made from #1, all will be good just so long as they dont try to rock the boat or try to take the wheel, I am the captain of this ship buddy!

Now for a quick Show & Tell, I have just finished up that slab of natural edge Amboyna Burl I got a while back for my good guy @NickDlow this piece is set for a 2 1/8"OD log, 2 1/4"OD log, 2 1/2"OD log, with 6 stem holes, 3 w/my UD bushing & 3 w/UD OEM SS tip. There was a few voids in it you may remember, filled those with epoxy, sanded em and slicked it out. This is a beautiful piece and cant wait to see how it looks loaded Nick, I know you will be dying to post up then as I am dying to see it! Hope you like, should be there tomorrow! Wish you well and hope you are back to yourself!

@Oogendoogan Thanks my man, better late than never homie! You bet, an Ed Clone would sure speed up production and he's gotta be a nice guy or else he's toast, aint about to deal with another me being a jerk, that aint cool! If it works and #2 does a good job will see about getting a #3 made from #1, all will be good just so long as they dont try to rock the boat or try to take the wheel, I am the captain of this ship buddy!

Now for a quick Show & Tell, I have just finished up that slab of natural edge Amboyna Burl I got a while back for my good guy @NickDlow this piece is set for a 2 1/8"OD log, 2 1/4"OD log, 2 1/2"OD log, with 6 stem holes, 3 w/my UD bushing & 3 w/UD OEM SS tip. There was a few voids in it you may remember, filled those with epoxy, sanded em and slicked it out. This is a beautiful piece and cant wait to see how it looks loaded Nick, I know you will be dying to post up then as I am dying to see it! Hope you like, should be there tomorrow! Wish you well and hope you are back to yourself!

In French, we could say "un appel au voyage!"

In French, we could say "un appel au voyage!"