I have not done it but this method should explain my concept for 2-cell IH's:

The coil wire length, not the number of turns, is what what determines the power draw when a vapcap is inserted. Original wire length of the coil is ~33" for a 3S solution. This normally operates at around 10.5V (to the module) at maybe 6 amps to come up with about 63 watts of power to the cap. To reduce the voltage down to 6-8.4V, you need to remove some coil wire length - 33" for 3S does calculate to 22" of coil wire length for 2S.

Do know that to reach that 60 watts, you will be putting more current through the circuit, maybe even 10A at 6V LBV or 7.2V @ 8.33A at nominal.

Hi folks,

Hi TommyDee,

Can you explain me what i can do with the heater work coil and how it changes the performance?

So adding length reduces my power draw while taking same time to click?

So reducing length increases my power draw while taking same time to click?

more turns = faster heating and this does what to the circuit?

Lesser turn?

What do the double or triple coil windings? can I count them as normal or does the further distance to the dyna change anything?

the turns better centered on the heating spot allows to better adjust the aggression of the heater?

what can I change by adding or removing coil diameter?

what does a change of the wire diameter?

what is not "good" to modify or change? Something to keep in mind?

What is your most favourable workcoil and why?

then to your halfpint:

what does the reducing of the capacitor and the smaller coil core do to the circuit?

what happens if I reduce the capacitor and keep the coils like before... How does this change the circuit and the performance?

what other capacitor options are there?(looking into further miniaturization...)

And finally what is the best way to get a own insertion sensing?

what sensors can I use near the work coil with out damaging them?

oha that where quite a lot of questions

thank you very much for all your efforts amazing thread!

greetings

Gr1nse

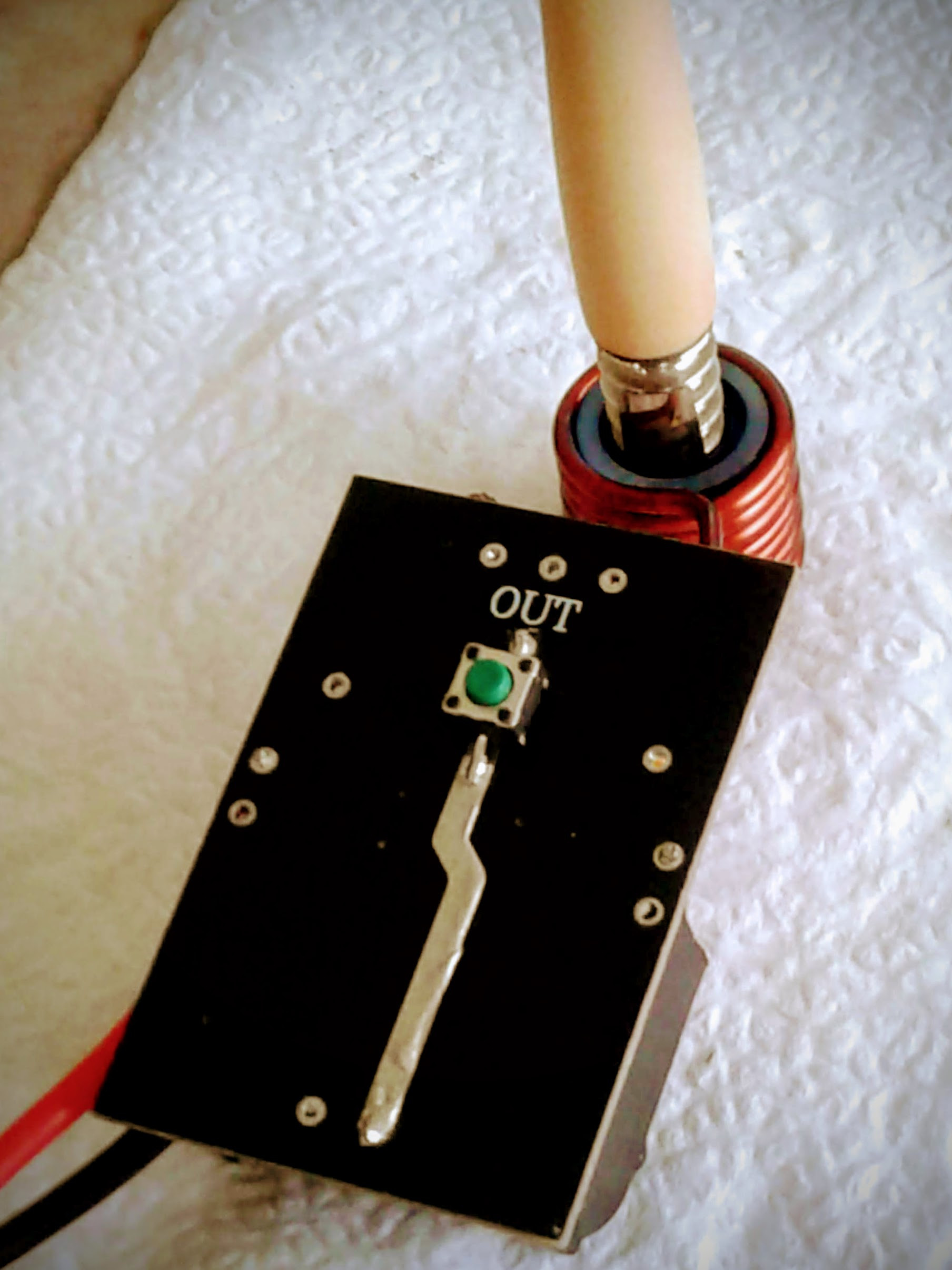

Right button charges the capacitor and left button discharges (so I can stop heating manually if the Dynavap clicks before it finishes discharging). Using a 100μF cap in parallel with 200kΩ to keep it high for ~20 seconds. Also have two 1k resistors (in parallel) between the discharge button and ground to prevent a short (not sure what these resistors are rated for so I made sure to keep the max power dissipation under 125 mW just in case).

Right button charges the capacitor and left button discharges (so I can stop heating manually if the Dynavap clicks before it finishes discharging). Using a 100μF cap in parallel with 200kΩ to keep it high for ~20 seconds. Also have two 1k resistors (in parallel) between the discharge button and ground to prevent a short (not sure what these resistors are rated for so I made sure to keep the max power dissipation under 125 mW just in case).