TommyDee

Vaporitor

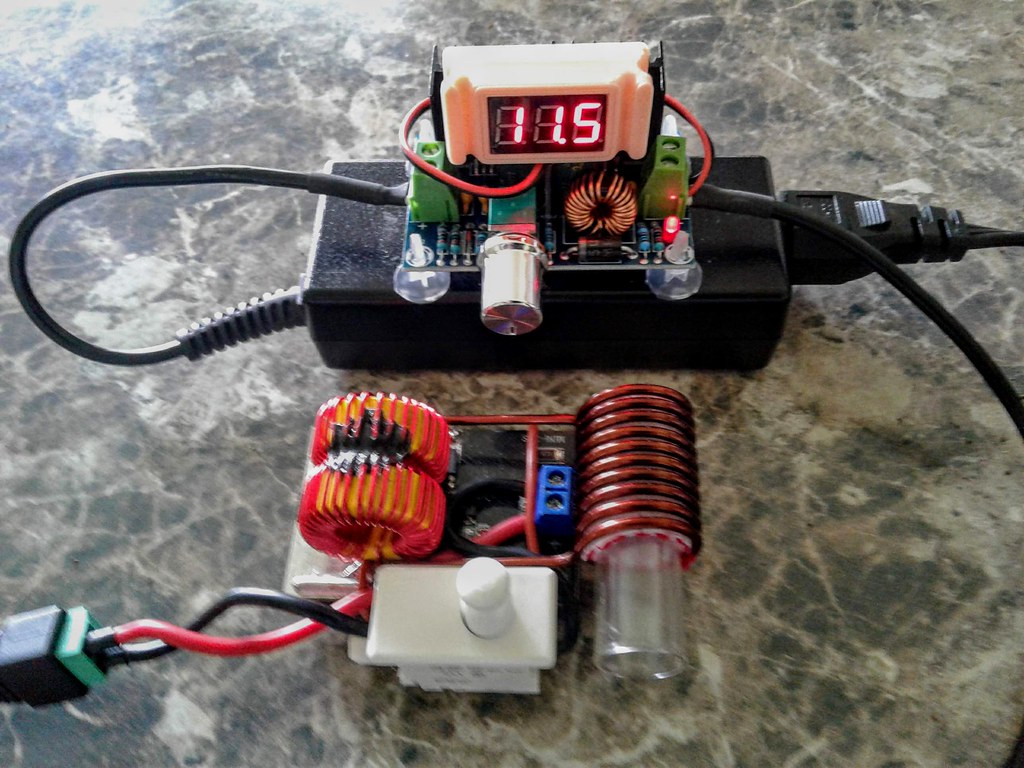

Turning down the voltage at the same ingress will bake it exactly the same, just slower. Make the flat of the cap flush with the bottom of the coil. It won't take you quite as far to the edge. Maybe a 1/16" past the coil will give you a good hard hit. Remember to gauge the second bake, not the first.Update! So I got home from work I used some of the copper wire that I had from the power supply wiring. I tighten the coils, fired her up had 10.5 volts which was about 62-65 watts on my other meter.

Put the induction heater so it was easy to see the tip of the cap coming through stuck it out about a an eighth of an inch and, And did definitely hit hard I thought maybe I combusted so I checked ABV perfectly golden green, went for round two still taking a decent amount of time got a little distracted It clicked I pulled out got another huge hit check the ABV definitely riding that line of combustion like a dark roast coffee color no ash (honestly I don't even know if that's combustion or not in vape terms) but I definitely learned to respect the click and squeezing the coils together definitely made a big difference I think I might turn down the voltage a little bit if my next run is that dark.

I could definitely see why people actually build diy it's so customizable especially with the variable voltage

Also, that copper banding should be something like twine, cotton, or anything non-conductive. Although that epoxy is tough - it ain't that tough ;] Not to mention that the IH is probably heating the copper wire as well, and that is what will soften the insulation.

I don't know much about induction heaters but I'm curious if anyone here has ever tried to use one with a titanium nectar collector? I'm thinking a 10mm titanium nectar collector might be able to get hot enough?

Titanium won't heat much at our expected pace. The cap is what makes VCs heat - the heat is transferred to the tip - and while drawing, the tip heats the cap. You need something that reacts to the induction field.