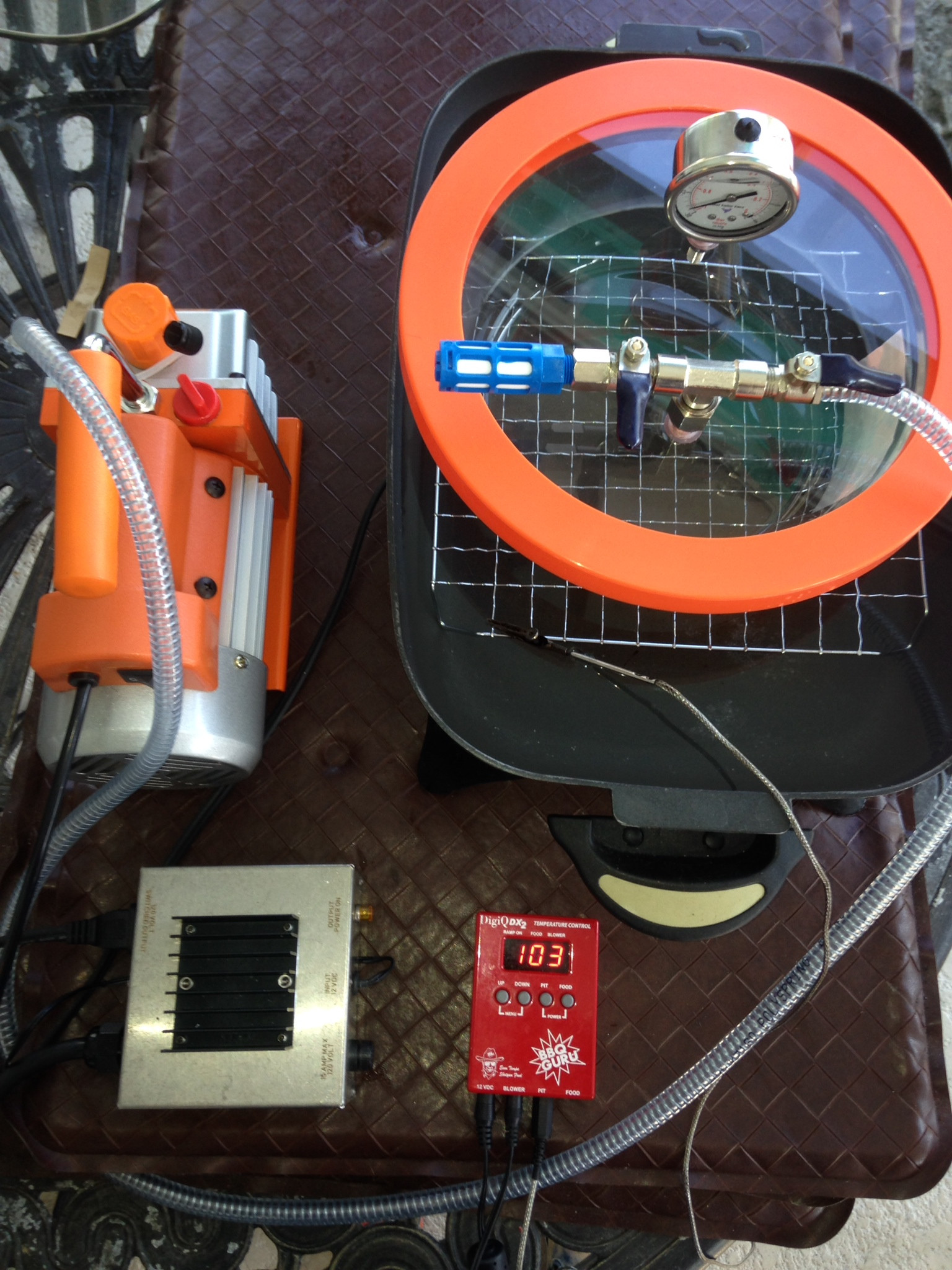

Very nice setup

@DieHard you went all out with the PID, I would recommend replacing the water in your larger pot with sand you can pickup at the local hardware for $5. It holds and distributes the heat perfectly and never evaporates or causes moisture around your product. Also it looks like you are assuming the temperature of the water bath/pot of sand is equal to the temperature of your oil inside the chamber, that's not the case though.

Calibrating the internal temp is important, for example on my aluminum chamber external PID temp reading of 137f = 117f in the chamber. Omega makes these adhesive temperature strips from 90-f - 120f and are perfect to have inside the chamber for real time accurate internal temps (you can find them listed as part no. 'RLC-60-90/120-10' on '

http://www.omega.ca/shop/pptsc.asp?ref=rlc-60). Butane is heavier than air and proper purges take either high temps, a long time, or some assistance by way of things like light usage of a heat gun to make it perfectly flat and thin as possible or flipping the patty. If you thought you were done purging and you do this it will keep purging usually.

Of course the ingestion of butane at these levels is hardly a health concern and it comes down to personal preference how 'clean' you want the end product to be. The real issue is that ALL canned solvents contain isopentane and neopentane, if you've ever heard of mystery oil a grease like substance left behind after blasting several cans of butane and letting it evaporate, this is it. It seems as any internal temp below 90f is insufficient to attempt to purge these after blasting, ideally you would remove them through distillation in your closed loop setup. The closed loop you use because safety is cool and open blasting is not ideal from a safety or environmental and possibly financial standpoint. terppextractors dot com have a legit business based around gray wolf from skunkpharms terpenator mk3 design that you can build yourself if you wanted.

Worth noting also is the analog vacuum gauges aren't accurate as their readings don't properly reflect its relation to the current altitude, but your true vacuum level will. A digital vacuum gauge hooked up to the air intake side of your valve on your chamber would allow you to accurately read 10,000micron (-29.5inHg) of vacuum regardless of your altitude, which is the ideal purge presure for shatter with temps anywhere between 95f-117f. One way to 'calibrate' your analog vacuum gauge is to remember water boils at 100c (212f) and under vacuum this lowers, water that has an exact temperature of 53f will boil at exactly -29.5inHg. You can use this method to see exactly where on your gauge this happens, but don't leave the pump running too long while doing that as pulling water into your pump isn't the best.

As for the desired end product it comes down to several variables (some which you may not be able to control unless your grow it yourself) like starting material,age of material,temperature of solvent/material during extraction,solvent type/mixture,purge temp/time/pressure, all leading to a different end result.

I figured the chamber temp would be lower so I set my temp to 120f to try to achieve +\- 100f. I like the idea of a temp strip inside the chamber but what about off gassing from the temp strip.

I figured the chamber temp would be lower so I set my temp to 120f to try to achieve +\- 100f. I like the idea of a temp strip inside the chamber but what about off gassing from the temp strip.  , maybe...never even considered that.

, maybe...never even considered that.