Hey Guys! I'm back! Had to get account approval for even discussing the possibility of selling 3D printed accessories for vapes. Fortunately @vtac approved selling 3D printed accessories, and I'm back baby! (I'll be posting links in my signature once I have my threads and store built)

After a bunch of testing on this issue, I can say it doesn't seem like a temperature safety issue going on, nor does it sound like a 'feature'. My unit has the same issue whenever I set the temperature between 398F and 402F - anywhere between there causes issues. If I set the temperature up to 403 or higher, the problem is resolved.

It does not seem to be caused by an overheating issue either as I will run a low-temp session, wait a few hours, then finish my session by starting at 375. After two minutes at 375, I bump it up to 400F - but the temperature still reads 375F!! If i bump up again to 404F, the screen updates to reflect 404F. If I power cycle (leaving it set at 400F), the unit will read 398F! Other times it reads 397F, but never 399, 400, 401, or 402F.

Strange, I have the daisy flowers with the stem, and have had no problems with them. I have not broken a single glass flower in my 2 weeks of constant use (using the same ones every time). In fact, the only time I've really had to handle broken glass flowers was when I first recieved my package of 50 - about 15 to 20 of the flowers were stuck together as if they had been thrown in a pile while still soft and they stuck together.

Perks of having a 3D printer - I can make my own containers any shape and size I want

Don't know how well this would work - but take a paper towel or a few cotton balls- apply a bit of Iso (don't drench the paper towel, but get it 'moist') - stuff the chamber and let the iso soak in for 10-20 minutes - try cleaning with a cotton swab and some fresh iso (make sure you are using the 91% iso).

---------

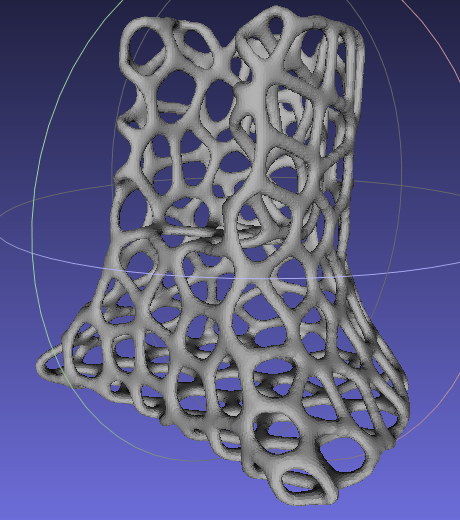

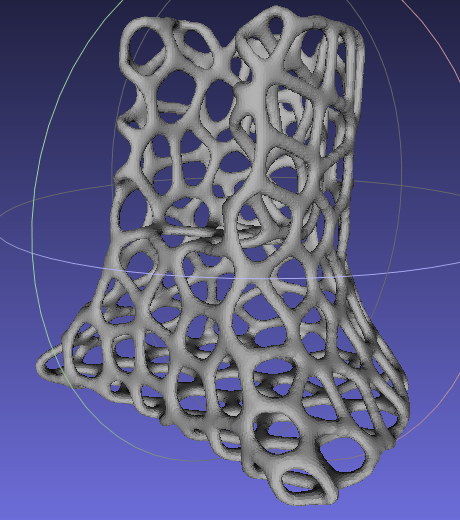

Just an update on the 3D printed loading stands. I have a model nearly ready for sale, but I want to 3d print one last test fit before I upload a link (should have that ready in a day or two). I'm also working on finalizing the dimensions for this kick@ss stand, once I get time to test-print and confirm it fits, I'll also upload this to my store for sale:

Seems to me a LOT of guys are reporting this exact thing? Always at the end of the session (hot unit) and hangs up at 398F?

I smell some sort of temperature safety going on, normal type failures usually don't repeat like that. I don't think it's an accident. I think the way it shows up when the unit is hot and not when cold is telling.

Has anyone got a resolution/explanation from the maker?

OF

After a bunch of testing on this issue, I can say it doesn't seem like a temperature safety issue going on, nor does it sound like a 'feature'. My unit has the same issue whenever I set the temperature between 398F and 402F - anywhere between there causes issues. If I set the temperature up to 403 or higher, the problem is resolved.

It does not seem to be caused by an overheating issue either as I will run a low-temp session, wait a few hours, then finish my session by starting at 375. After two minutes at 375, I bump it up to 400F - but the temperature still reads 375F!! If i bump up again to 404F, the screen updates to reflect 404F. If I power cycle (leaving it set at 400F), the unit will read 398F! Other times it reads 397F, but never 399, 400, 401, or 402F.

I noticed that I've been breaking glass pipe screen stems inside my Ascent due to the high temps (these new glass screens are more breakable) Some pieces are tiny. If you are saving your ABV be careful, you don't want to ingest shards of glass.

Strange, I have the daisy flowers with the stem, and have had no problems with them. I have not broken a single glass flower in my 2 weeks of constant use (using the same ones every time). In fact, the only time I've really had to handle broken glass flowers was when I first recieved my package of 50 - about 15 to 20 of the flowers were stuck together as if they had been thrown in a pile while still soft and they stuck together.

9. Primary Strain, pre-ground. That is the container that my 40+ Glass flowers came in. It is the *PERFECT* diameter for tap-loading the Ascent. And the lid is attached and opens with one hand... important if the other hand is full of Ascent. I would buy more of these for #8 and #6, but, unfortunately, "small container with lid" is too broad a search in Amazon, so I haven't been able to find more. Any help here?

Perks of having a 3D printer - I can make my own containers any shape and size I want

Does anyone have tips on how to get the oil jars out? Mine is stuck inside the chamber.

Also this thing is terrible for oils and any concentrates it seems. The lids come off too easy and the oil goes everywhere in the chamber too. Does anyone know of a good way to get the chamber white again? The oil stained in brown pretty badly and a few iso scrubbings haven't helped.

Don't know how well this would work - but take a paper towel or a few cotton balls- apply a bit of Iso (don't drench the paper towel, but get it 'moist') - stuff the chamber and let the iso soak in for 10-20 minutes - try cleaning with a cotton swab and some fresh iso (make sure you are using the 91% iso).

---------

Just an update on the 3D printed loading stands. I have a model nearly ready for sale, but I want to 3d print one last test fit before I upload a link (should have that ready in a day or two). I'm also working on finalizing the dimensions for this kick@ss stand, once I get time to test-print and confirm it fits, I'll also upload this to my store for sale: