seriousTone

Well-Known Member

So I've been fiddling around with the idea of having some custom stems printed out for myself, for my vapcap, and finally found a company that I like the aesthetic of their ceramics. I don't really like the glazed look and a lot of the glazed 3d printed ceramic items I've seen look sort of sloppy and thick.

This companies ceramics have more of a sandstone look and slight texture to them. Just so happens the company is in the middle of expanding for a month or two so I can't get any test prints made yet. But in the meantime I've been having a blast not only coming up with different ideas for stems and trying to produce them in my software but setting them up and rendering out a nice "photo" of them.

I've spent so much time just messing around with the renderings that I figured I might as well share them with you guys here as I know a lot of you would appreciate them. Not only that but I'm sure you guys all have some sweet ideas that would be fun to try and create.

I've only done a handful of vapcap stems so far but the designs could be converted to stems for Nomads, e-nanos, etc. pretty easily. Some of these might not be do-able, in the end, either and will probably be tweaked and/or changed before I get them test printed but the renders still look pretty sweet and I can't wait to actually try them out. And believe me, I have a ton more ideas for designs that I just haven't had the time to get to yet, including a/some tobacco pipe shaped ones that I've always wondered if the form factor would be cool.

This companies ceramics have more of a sandstone look and slight texture to them. Just so happens the company is in the middle of expanding for a month or two so I can't get any test prints made yet. But in the meantime I've been having a blast not only coming up with different ideas for stems and trying to produce them in my software but setting them up and rendering out a nice "photo" of them.

I've spent so much time just messing around with the renderings that I figured I might as well share them with you guys here as I know a lot of you would appreciate them. Not only that but I'm sure you guys all have some sweet ideas that would be fun to try and create.

I've only done a handful of vapcap stems so far but the designs could be converted to stems for Nomads, e-nanos, etc. pretty easily. Some of these might not be do-able, in the end, either and will probably be tweaked and/or changed before I get them test printed but the renders still look pretty sweet and I can't wait to actually try them out. And believe me, I have a ton more ideas for designs that I just haven't had the time to get to yet, including a/some tobacco pipe shaped ones that I've always wondered if the form factor would be cool.

It all started with just a standard stem shape

I personally like a flat "black and mild" style mouthpiece

Round mouthpiece version

Square Pattern...eh kinda cool but will probably tweak

This one has potential but I'll definitely make changes as it is probably too brittle

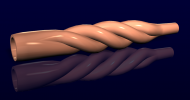

And finally, my absolute favorite and an example of the possibilities that 3d printing gives you over standard wooden stems. (I love wood)

Let me know what you guys think, and would love critiques/suggestions as some motivation to start designing again!