Looking for a solution to cleaning roasting tubes that is also affordable and easy?

Paper roasting tubes may be the answer. They have the following benefits.

Affordable

Disposable

Renewable

Unbreakable

Light weight

Easy to make

Adds no taste

Provides a good air seal

Screen stays cleaner longer

Can be made almost any size or length

Doesn’t rob heat away from roast

No chance of burning your skin from a hot tube

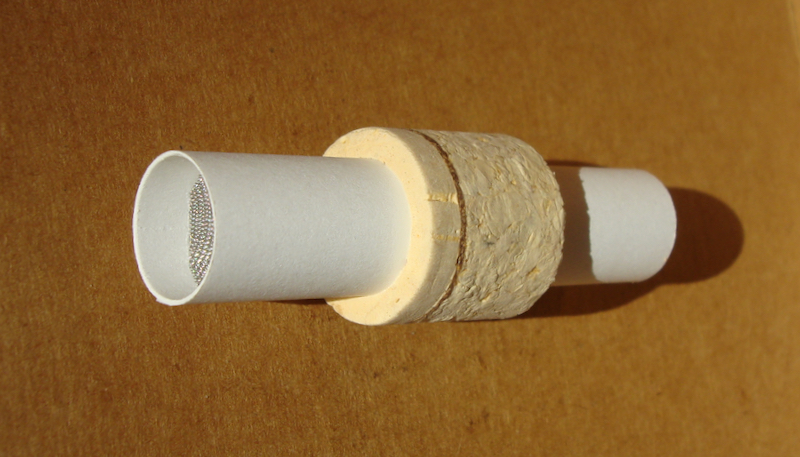

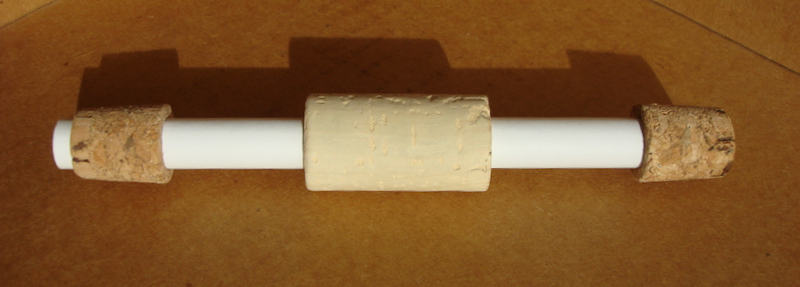

I am using tapered cork tube connectors to secure plain white paper wrapped around an appropriately sized dowel or rod, which is then removed to create the paper tube.

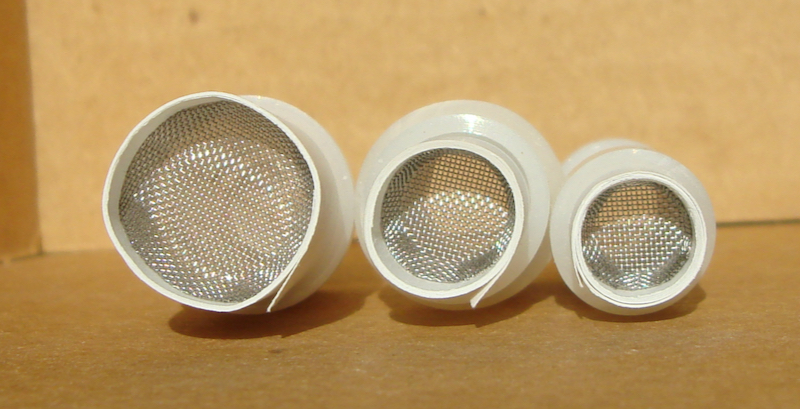

A basket screen fits into the end of the tube and holds firmly onto the paper within the cork connector. The tapered cork connector allows the paper roasting tube to fit into any 18mm female connection units like 7th floor, Lamart, iHeat and GTVF.

This paper roasting tube fits my 7/16” ss heater cover. Will have to see how long it lasts. So far the screen is staying very clean.

Paper roasting tubes will work for any herbal roasting system that uses a separate tube to hold the herbal material. Let’s see how creative everyone can be.

Happy Roasting

Paper roasting tubes may be the answer. They have the following benefits.

Affordable

Disposable

Renewable

Unbreakable

Light weight

Easy to make

Adds no taste

Provides a good air seal

Screen stays cleaner longer

Can be made almost any size or length

Doesn’t rob heat away from roast

No chance of burning your skin from a hot tube

I am using tapered cork tube connectors to secure plain white paper wrapped around an appropriately sized dowel or rod, which is then removed to create the paper tube.

A basket screen fits into the end of the tube and holds firmly onto the paper within the cork connector. The tapered cork connector allows the paper roasting tube to fit into any 18mm female connection units like 7th floor, Lamart, iHeat and GTVF.

This paper roasting tube fits my 7/16” ss heater cover. Will have to see how long it lasts. So far the screen is staying very clean.

Paper roasting tubes will work for any herbal roasting system that uses a separate tube to hold the herbal material. Let’s see how creative everyone can be.

Happy Roasting