I say they are proof that pretty sells. That is a 5 ton press. How can it possibly compare to an Elysian, Daxtractor or really any well built 20 ton press for that kind of money?

well, from their site:

8 tons of pressure (15,300 lbf @ 140 psi compressed air) output from our custom fabricated, oil-less, maintenance-free pneumatic cylinder

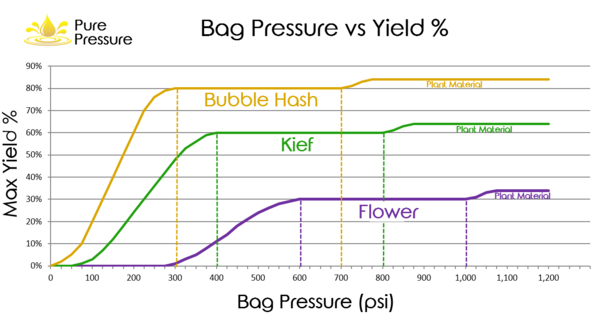

But also, wrt to max pressure, how much do you need and how much can be effectively applied.

Then there is the issue that none of these press companies do much to define wtf they mean when they say, for example, 20 tons of pressure. Is that 20 tons/psi at the head end of the pump? what the heck does it really mean

It ain't 20 tons/psi all over the surface of the plate, right. If we distribute the pressure across a large plate the lbs/psi of course will be lower, correct?

Then, we insert our load with has some surface area so now is the head pressure only being applied to to that smaller surface and has lbs(or tons)/psi gone back up.

I know some folks who think most people put way too much pressure on their loads and I'm pretty certain that nobody with a HF 20 ton press is really putting 20 tons on the payload.

Please don't get me wrong, I have no dog in the Pure Pressure fight....don't own one, don't plan to buy one for home use (LOL), and have had no interactions with them. Just thought I would throw their name into the hat on commercial presses.

But I still think there is little to no clarity (or at least no clarity between my two ears) about what these pressure specs really mean.

Cheers

P.S. - oh, ok...I see the other version is 5 ton. Thought this from their FAQ might be interesting:

Q- Do your rosin presses provide enough pressure?

A - Yes, because we believe making the highest quality rosin has more to do with finesse than brute force.

Our custom USA fabricated oil-less, maintenance-free pneumatic cylinders offer the perfect amount of force for pressing rosin. Not only that but when used with clean, dry compressed air their lifespans are measured in the

millions of presses.

Efficiently utilizing either 8 tons (16,000 lb / f) of force with the

Longs Peak or 5 tons (10,000 lb / f) of force with

Pikes Peak V2, both of our premium rosin presses offer incredible reliability AND even pressure distribution. Even better, with our Pressware technology, it automatically calculates the pressure at the bag for you!

Through extensive testing we have discovered that

extremely high pressure pressure does not equate to significantly higher yields, and furthermore, excess pressure only serves to push undesirable material (such as lipids and inert organic particles) into your rosin, thus reducing its quality.