-

SCAM WARNING! See how this scam works in Classifieds.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Winegums' Woodcraft

- Thread starter Winegums

- Start date

little maggie

Well-Known Member

Just curious about whether these stems are comparable to the dynavap ones in terms of cooling.

To be honest I haven't tried one of the steel core stems without a condenser in it yet to see if there's a difference. I don't imagine there being a noticeable difference between the steel cores and the regular wood if you use the condenser tube. The problem with making things to sell is I don't want to get them dirty or use them so I haven't tried one yet. I should probably make one for myself at some point. XDJust curious about whether these stems are comparable to the dynavap ones in terms of cooling.

little maggie

Well-Known Member

The length makes a difference. I have one from pp that is pretty long and so much cooler. I can't tell from the pictures how long yours are. I know you have the length for stems posted but I can't quite tell what that means.To be honest I haven't tried one of the steel core stems without a condenser in it yet to see if there's a difference. I don't imagine there being a noticeable difference between the steel cores and the regular wood if you use the condenser tube. The problem with making things to sell is I don't want to get them dirty or use them so I haven't tried one yet. I should probably make one for myself at some point. XD

Steel is a great improvement over glass. I've managed to break my wood/glass ones.

All my previous stems are the long length 62mm "stems" that DynaVap makes them at. This is so you can use the standard condenser, XL condensers with mouth pieces and XL Omni condensers inside them.The length makes a difference. I have one from pp that is pretty long and so much cooler. I can't tell from the pictures how long yours are. I know you have the length for stems posted but I can't quite tell what that means.

I've only made one short 45mm body designed for the Omni and standard condensers with mouth pieces and that was sold to @scalescliffs

Diffusion will help a lot with cooling as well as the vapour length. I could see a long condenserless stem really cooling the vapour.

scalescliffs

cashed

That's where I hit a snag unfortunately. My little lathe is about as little as they come, so I can only do about 4" of material at a time. That might be enough? if not I'll have to get creative and turn two halves separately then glue them up after.I will usually be chucking that body into a bubbler. I will report back about vapor temp. Maybe our next collaboration will be a condenserless, thinner and longer Omni body, perhaps cigar length, @Winegums?

Would that work? A VapBlunt could be cool.

scalescliffs

cashed

That's where I hit a snag unfortunately. My little lathe is about as little as they come, so I can only do about 4" of material at a time. That might be enough? if not I'll have to get creative and turn two halves separately then glue them up after.

The introduction of the tubing allowing condenser free use is interesting. Four inches of body is probably plenty, considering the tip and Omni MP add what, 47mm of length? Would the increased length negatively affect the function?

I don't think it would do too much to effect the function of the piece. The biggest trade off for diffusion and cooling is that you have more vapour condensating on the walls.The introduction of the tubing allowing condenser free use is interesting. Four inches of body is probably plenty, considering the tip and Omni MP add what, 47mm of length? Would the increased length negatively affect the function?

GreenHopper

20 going on 60

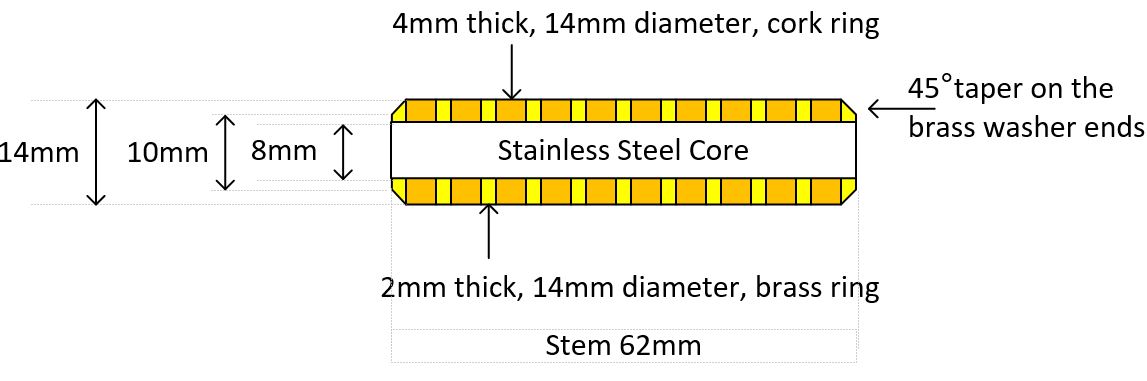

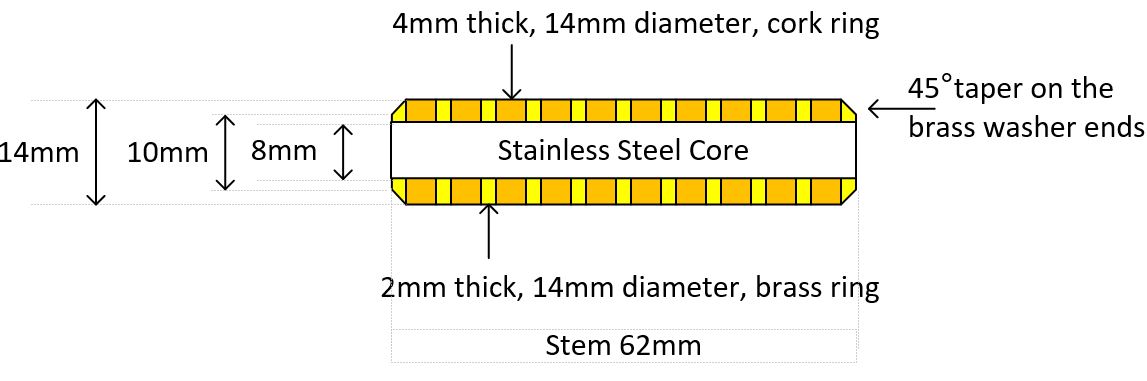

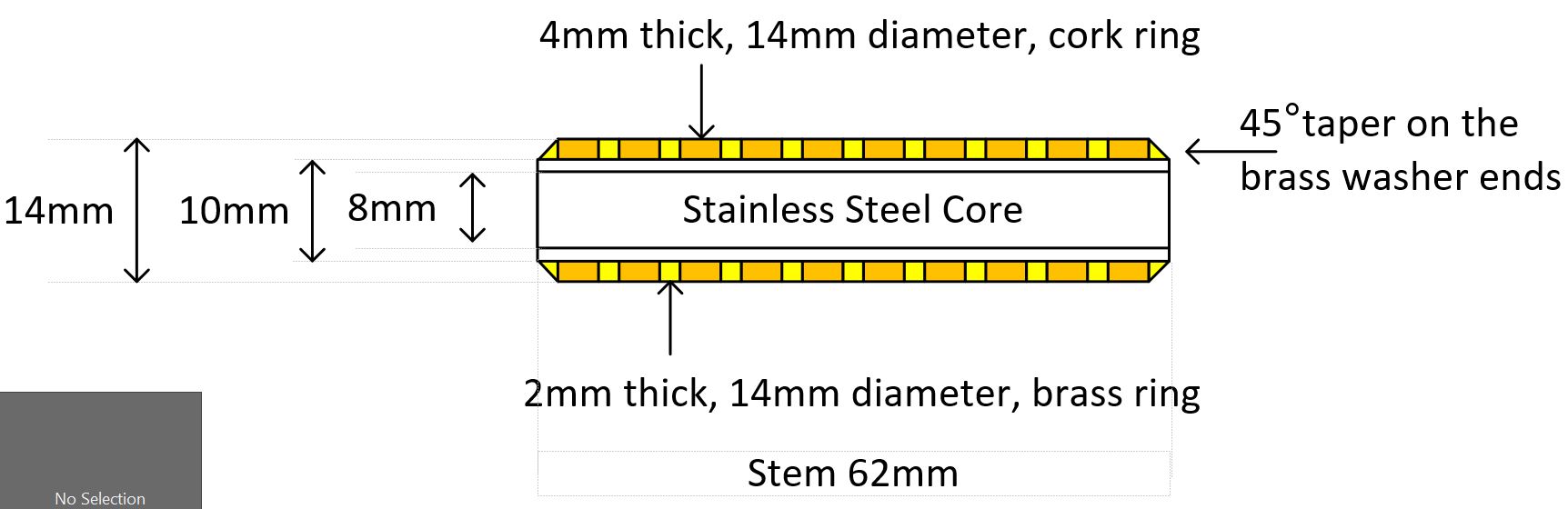

So here is my initial markup of the Brass ring & Cork ring stem.

I have no idea if it's feasible so this really is just the brainstorming stage.

Open to ideas, criticisms and concerns.

For example:

Just trying to draw this up gives me a lot of appreciation for what you (@Winegums) and @phattpiggie do in regards to these custom stems. I know there is also so much more to it when it actually comes down to having to create them.

I'm having fun though

I have no idea if it's feasible so this really is just the brainstorming stage.

Open to ideas, criticisms and concerns.

For example:

- I'm not sure the tapered ends would be doable?

- I'm not sure if one end of the entire stem should taper down an additional 1mm in order to fit a 14mm GonG better?

- Does one end of the cork needs to be lacquered (if thats the right term

) to stop the cork from affecting the vapour when in the GonG

) to stop the cork from affecting the vapour when in the GonG  ?

? - Should the brass rings be 1mm wide rather than 2mm?

- Are 4mm wide, 4mm thick cork rings going to just fall apart?

Just trying to draw this up gives me a lot of appreciation for what you (@Winegums) and @phattpiggie do in regards to these custom stems. I know there is also so much more to it when it actually comes down to having to create them.

I'm having fun though

This would be one tough piece to create. The cork would only be 2mm thick on the outside as well as the brass since the stainless steel I have is 10mm OD X 1mm wall. I'd also be afraid of the rings on the ends falling off since there's so little surface area to glue to and brass is notoriously resistant to adhesives.So here is my initial markup of the Brass ring & Cork ring stem.

I have no idea if it's feasible so this really is just the brainstorming stage.

Open to ideas, criticisms and concerns.

For example:

So I'm completely figuring this out as I go and I need you guys to let me know what you think.

- I'm not sure the tapered ends would be doable?

- I'm not sure if one end of the entire stem should taper down an additional 1mm in order to fit a 14mm GonG better?

- Does one end of the cork needs to be lacquered (if thats the right term

) to stop the cork from affecting the vapour when in the GonG

?

- Should the brass rings be 1mm wide rather than 2mm?

- Are 4mm wide, 4mm thick cork rings going to just fall apart?

Just trying to draw this up gives me a lot of appreciation for what you (@Winegums) and @phattpiggie do in regards to these custom stems. I know there is also so much more to it when it actually comes down to having to create them.

I'm having fun though

GreenHopper

20 going on 60

This would be one tough piece to create. The cork would only be 2mm thick on the outside as well as the brass since the stainless steel I have is 10mm OD X 1mm wall. I'd also be afraid of the rings on the ends falling off since there's so little surface area to glue to and brass is notoriously resistant to adhesives.

Damn it, you know what I've gone and done, I've failed to represent the OD of the stem.

OD added:

Having said that, doesn't make a difference to the cork or brass thickness so I think you are correct sir!

It's gonna need some tweaking.

Less brass, more cork?

Give up on the cork all together?

Just give up?

This is why I like drawing stuff up, saves a lot of wasted time, materials and frustration

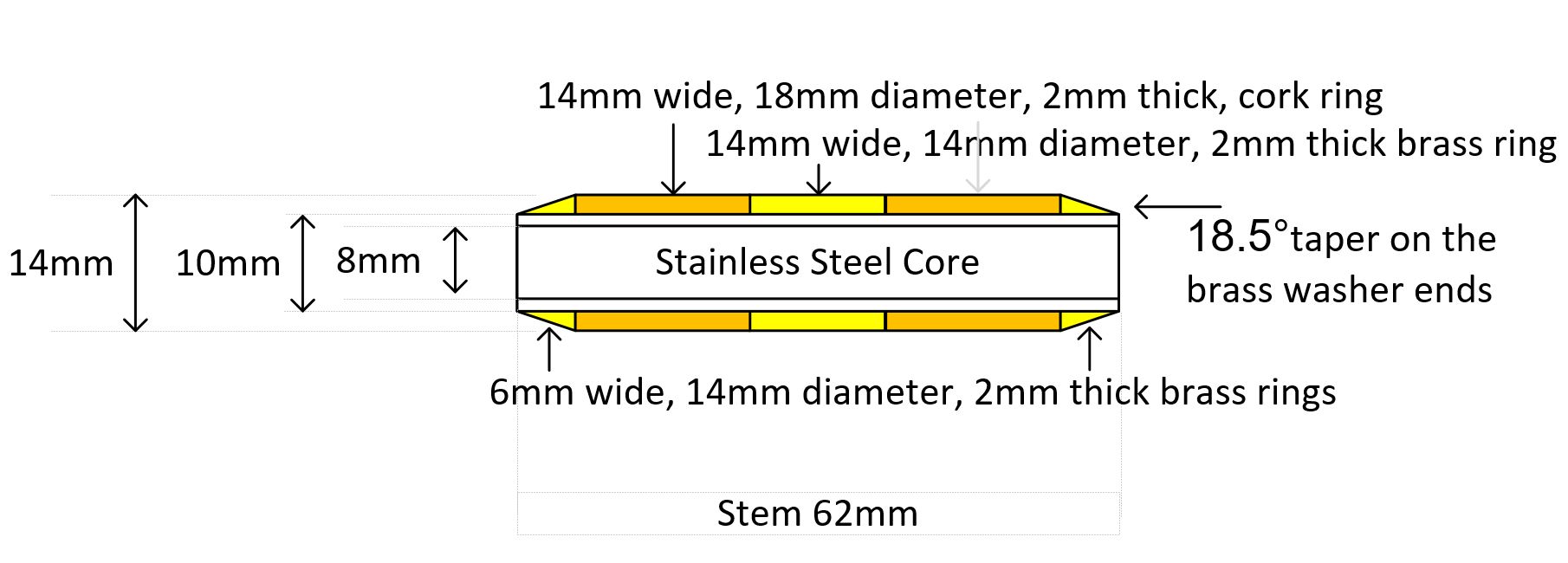

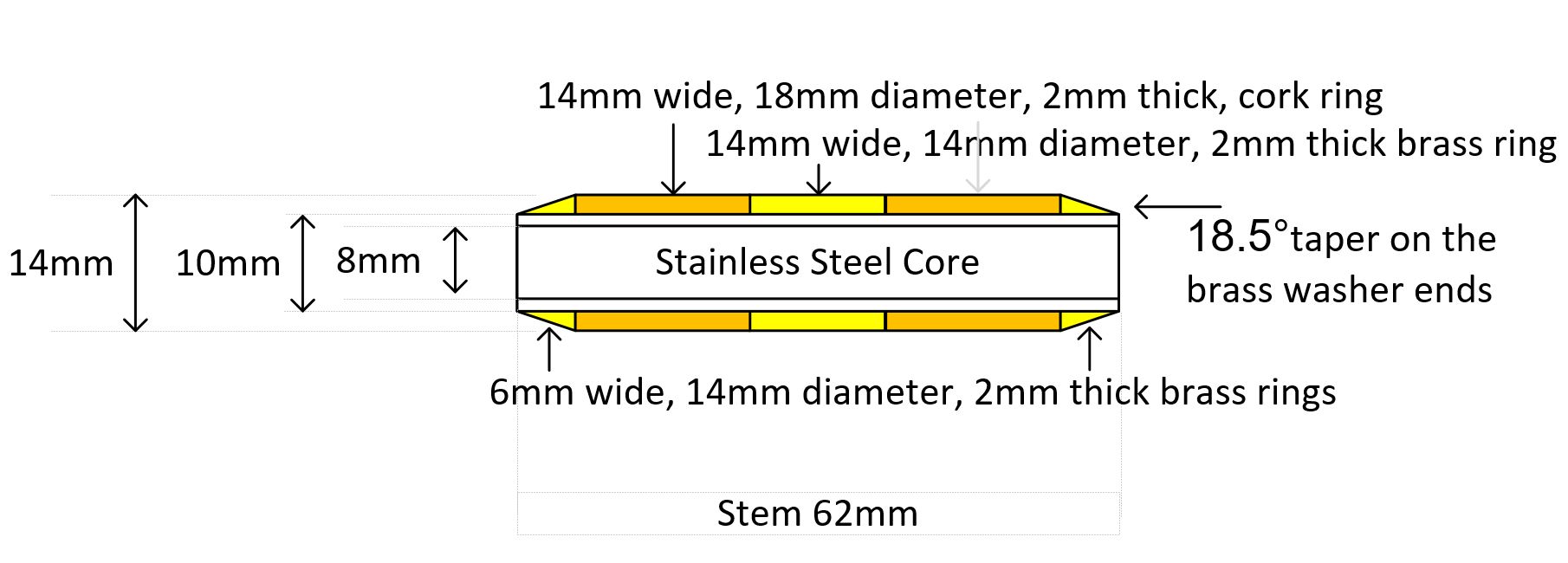

I think that cork and brass could work but in larger sections of each material, especially the cork. Thicker 3mm brass on the ends and more cork in the middle would go a long way to making it "buildable" and last longer. If the cork were to be a bit wider than the brass tip it would seal pretty nicely in a water piece I'm thinking.Damn it, you know what I've gone and done, I've failed to represent the OD of the stem.

OD added:

Having said that, doesn't make a difference to the cork or brass thickness so I think you are correct sir!

It's gonna need some tweaking.

Less brass, more cork?

Give up on the cork all together?

Just give up?

This is why I like drawing stuff up, saves a lot of wasted time, materials and frustration

A lot of the time I don't really need a physical drawing but there's always a mental image of what I'm working towards. When things get more complicated I'll start to write things down. I really appreciate drawings most for communication with others. People work faster and have less confusion when it's all visible on a piece of paper.

EDIT: Just a suggestion but I could also make a brass and leather piece which would be cool all on its own.

Last edited:

GreenHopper

20 going on 60

I think that cork and brass could work but in larger sections of each material, especially the cork. Thicker 3mm brass on the ends and more cork in the middle would go a long way to making it "buildable" and last longer. If the cork were to be a bit wider than the brass tip it would seal pretty nicely in a water piece I'm thinking.

A lot of the time I don't really need a physical drawing but there's always a mental image of what I'm working towards. When things get more complicated I'll start to write things down.

EDIT: Just a suggestion but I could also make a brass and leather piece which would be cool all on its own.

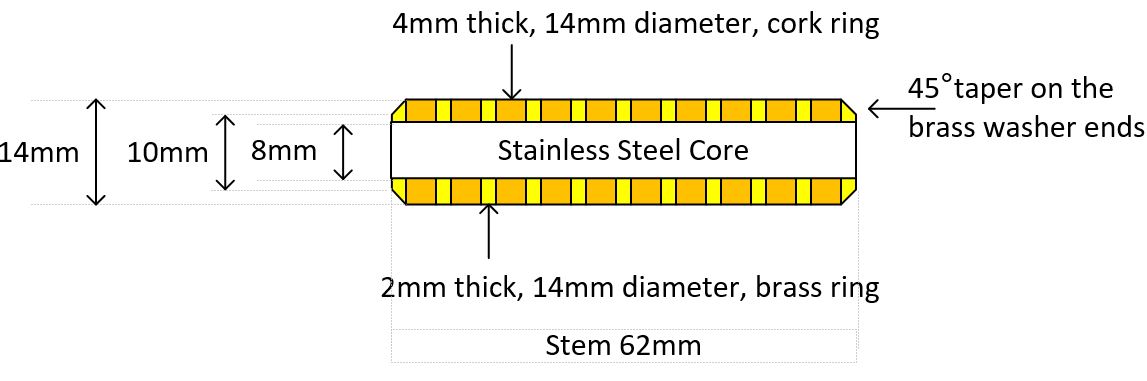

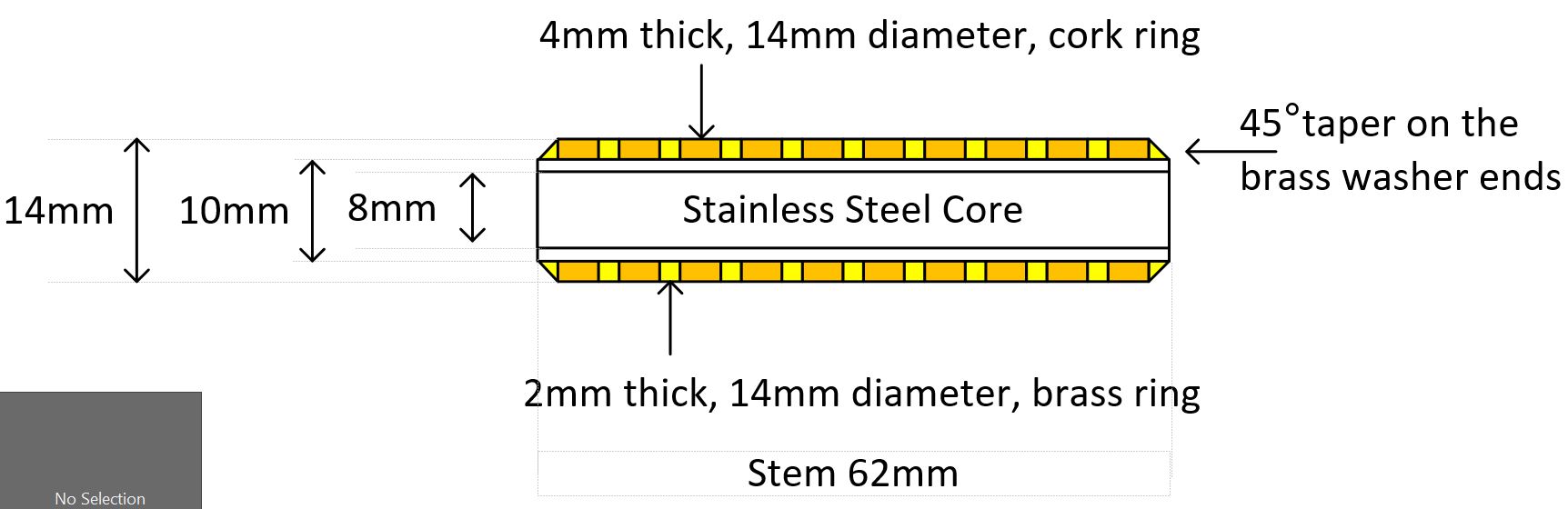

Cool, I've made a few amendments:

I think this is a little more inline with what you suggested.

Again, feel free to let me know what will work and what will not and thank you for your time and patience bud.

@GreenHopper It's doable but as @Winegums says it would need a bit of working out.

The only thing I'd worry about would be how long the cork would last before it started get grubby or losing bits.

If you did it like the pen makers then it would be soaked in CSA, super glue, this would give much more strength to the cork.

Or have the whole thing 'stabilised'. I've never worked with cork so this is all just guess work.

Like Winegums I don't work to a diagram for anything I'm making. I can usually see the end product, but not always.

If someone else has an idea then it's always best to get a drawing or pictures of what they want, I'm sure Winegums will agree, for us to know what you want then the more info the better.

I say this because I have an order for a very involved piece which I would never have understood from a typed conversation.

I really appreciated the time and effort put in and the sketch I was given has helped me understand what the customer has in their minds eye.

Greenhopper I'll make a copy of the drawing you've done and show you how I would go about it. I don't have a metal lathe but perhaps Winegums could do it. Or a nice man with his CNC machine??

The only thing I'd worry about would be how long the cork would last before it started get grubby or losing bits.

If you did it like the pen makers then it would be soaked in CSA, super glue, this would give much more strength to the cork.

Or have the whole thing 'stabilised'. I've never worked with cork so this is all just guess work.

Like Winegums I don't work to a diagram for anything I'm making. I can usually see the end product, but not always.

If someone else has an idea then it's always best to get a drawing or pictures of what they want, I'm sure Winegums will agree, for us to know what you want then the more info the better.

I say this because I have an order for a very involved piece which I would never have understood from a typed conversation.

I really appreciated the time and effort put in and the sketch I was given has helped me understand what the customer has in their minds eye.

Greenhopper I'll make a copy of the drawing you've done and show you how I would go about it. I don't have a metal lathe but perhaps Winegums could do it. Or a nice man with his CNC machine??

GreenHopper

20 going on 60

@GreenHopper It's doable but as @Winegums says it would need a bit of working out.

The only thing I'd worry about would be how long the cork would last before it started get grubby or losing bits.

If you did it like the pen makers then it would be soaked in CSA, super glue, this would give much more strength to the cork.

Or have the whole thing 'stabilised'. I've never worked with cork so this is all just guess work.

Like Winegums I don't work to a diagram for anything I'm making. I can usually see the end product, but not always.

If someone else has an idea then it's always best to get a drawing or pictures of what they want, I'm sure Winegums will agree, for us to know what you want then the more info the better.

I say this because I have an order for a very involved piece which I would never have understood from a typed conversation.

I really appreciated the time and effort put in and the sketch I was given has helped me understand what the customer has in their minds eye.

Greenhopper I'll make a copy of the drawing you've done and show you how I would go about it. I don't have a metal lathe but perhaps Winegums could do it. Or a nice man with his CNC machine??

Hello buddy,

I was thinking the cork may need to be lacquered, I was thinking more to stop the cork from absorbing the vape smell and affecting future hits as I read that somewhere on this forum in relation to cork reducers in GonG's. Either way I think you guys are right and the cork will need to be treated somehow.

I'm warming up to the idea of more cork and less brass.

I'm glad the drawings help out, I figured it was the best way to describe what I have in my head.

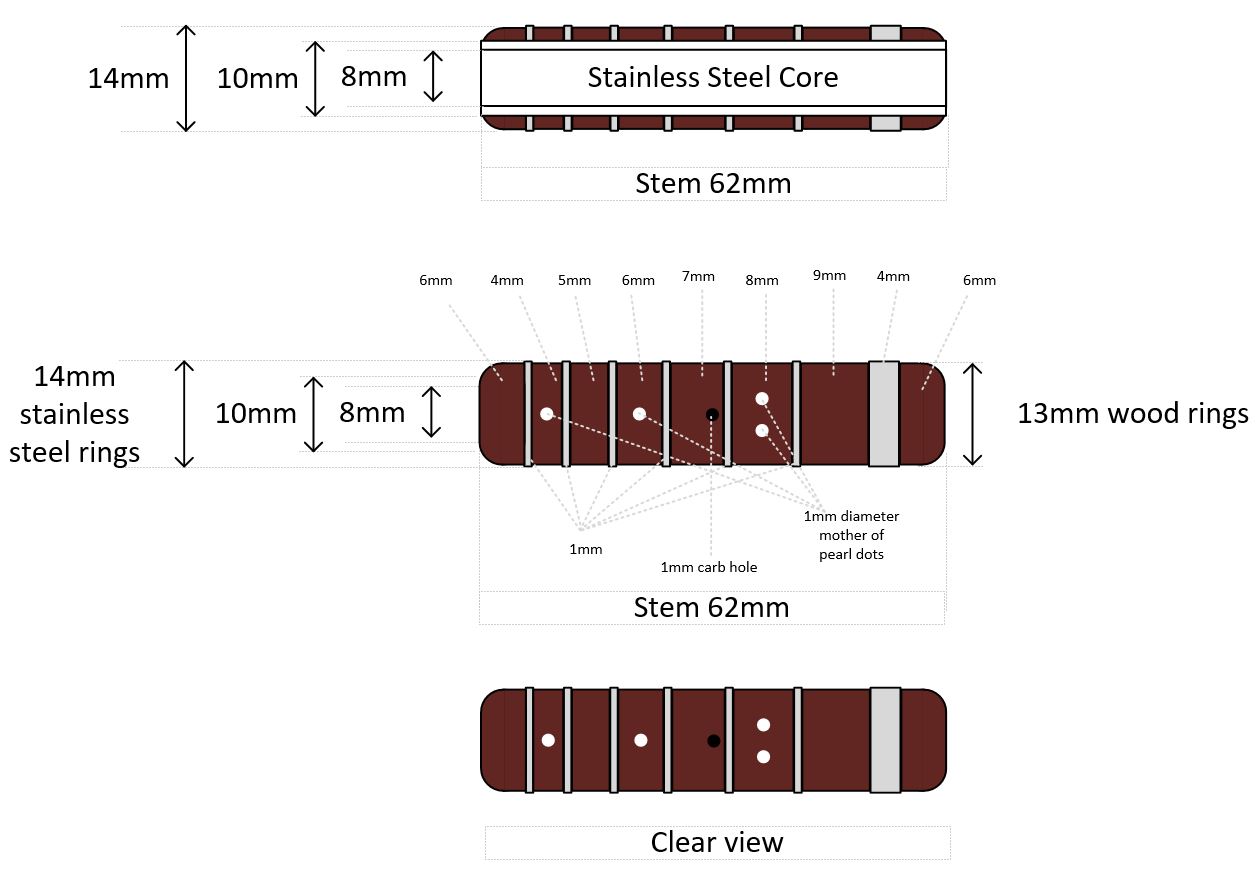

I had a batshit crazy idea for you to do @phattpiggie for when my turn comes around

but having gone through this process with @Winegums I think I'm going to have to scale back my ambitions/madness a little.

but having gone through this process with @Winegums I think I'm going to have to scale back my ambitions/madness a little.

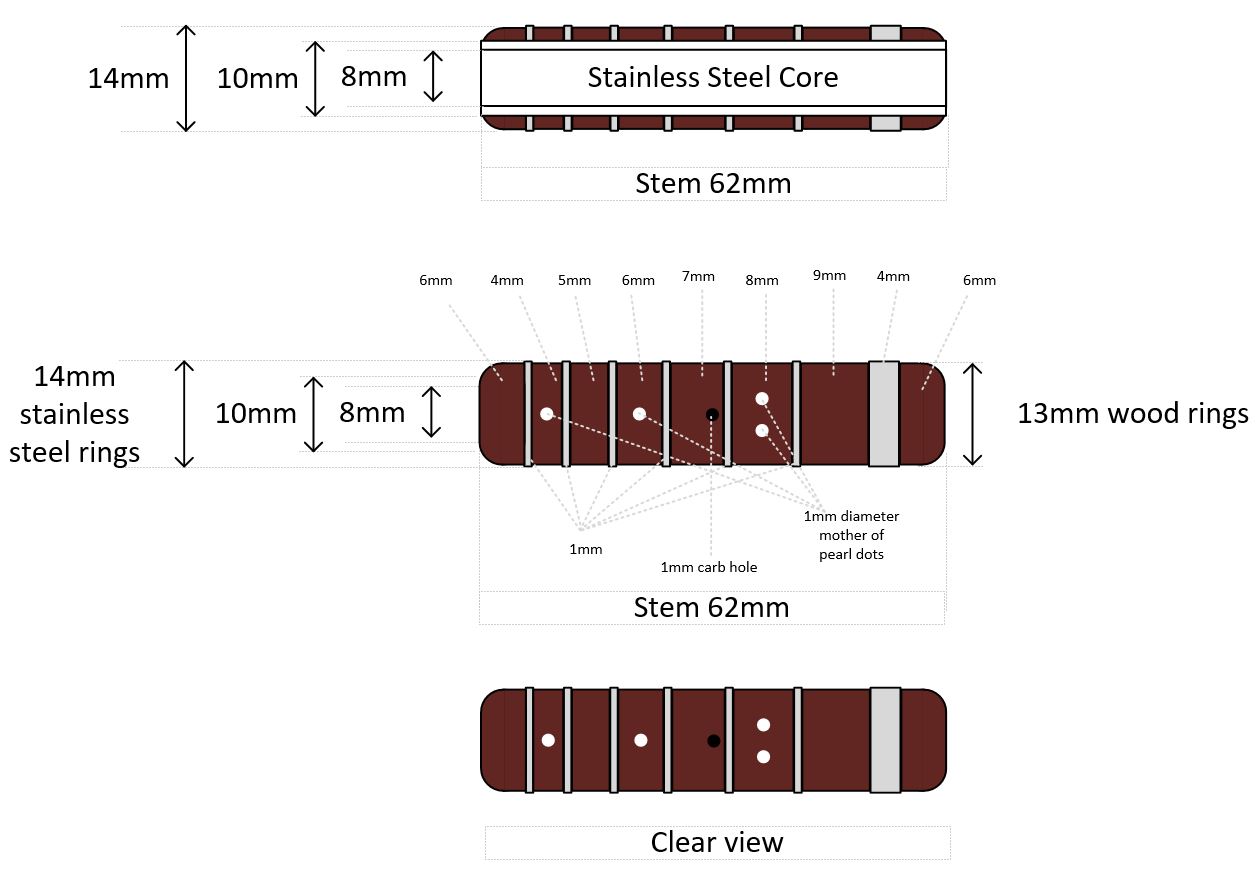

It's based on the fretboard of a guitar.

Again I can see it's totally OTT but hey gotta dream, then bend back towards reality

Greenhopper I'll make a copy of the drawing you've done and show you how I would go about it. I don't have a metal lathe but perhaps Winegums could do it. Or a nice man with his CNC machine??

If you, or anyone else wants the original VSDX (visio) diagrams I'm more than happy to share them. They are vector based diags so can be fairly easily manipulated if you have a copy of MS Visio.

Now who do I know with a CNC machine? Cough...@VapCap...cough

Once again, thank you to you both for your time and interest.

Cool, I've made a few amendments:

I think this is a little more inline with what you suggested.

Again, feel free to let me know what will work and what will not and thank you for your time and patience bud.

Like Piggie said in his post I feel that the cork would not last long given the thickness. I spent nearly 7 summers in a row on the Fraser River fishing for sockeye and the cork just doesn't seem to last or look too great after a year or two. As a maker I really don't want to produce something that I know won't stand the test of time well. I can do the brass pieces with no problem, it's the thin cork that bothers me.

Stabilizing the cork could be an option but it would ruin the feeling of it, basically reducing it to plastic.

On most items that use cork it's at least 1/4" thick or greater with rounded edges that are wider than the other materials on the handle. This is because they expect the cork to wear down and for it to shrink and expand with varying moisture levels.

Hello buddy,

I was thinking the cork may need to be lacquered, I was thinking more to stop the cork from absorbing the vape smell and affecting future hits as I read that somewhere on this forum in relation to cork reducers in GonG's. Either way I think you guys are right and the cork will need to be treated somehow.

I'm warming up to the idea of more cork and less brass.

I'm glad the drawings help out, I figured it was the best way to describe what I have in my head.

I had a batshit crazy idea for you to do @phattpiggie for when my turn comes aroundbut having gone through this process with @Winegums I think I'm going to have to scale back my ambitions/madness a little.

It's based on the fretboard of a guitar.

Again I can see it's totally OTT but hey gotta dream, then bend back towards reality

If you, or anyone else wants the original VSDX (visio) diagrams I'm more than happy to share them. They are vector based diags so can be fairly easily manipulated if you have a copy of MS Visio.

Now who do I know with a CNC machine? Cough...@VapCap...cough

Once again, thank you to you both for your time and interest.

That's something I could do! I've built my own custom electric guitar and that would be such a cool piece!

What about a section of Deer antler instead of the thicker metal? This would represent the nut of the guitar.

GreenHopper

20 going on 60

Like Piggie said in his post I feel that the cork would not last long given the thickness. I spent nearly 7 summers in a row on the Fraser River fishing for sockeye and the cork just doesn't seem to last or look too great after a year or two. As a maker I really don't want to produce something that I know won't stand the test of time well. I can do the brass pieces with no problem, it's the thin cork that bothers me.

Stabilizing the cork could be an option but it would ruin the feeling of it, basically reducing it to plastic.

On most items that use cork it's at least 1/4" thick or greater with rounded edges that are wider than the other materials on the handle. This is because they expect the cork to wear down and for it to shrink and expand with varying moisture levels.

That's something I could do! I've built my own custom electric guitar and that would be such a cool piece!

What about a section of Deer antler instead of the thicker metal? This would represent the nut of the guitar.

Right got ya, thicker cork, I'm going to have a play with the dimension of the cork. Think outside the GonG so to speak. Might have to come back to this idea at a later date though as I'd much rather the fretboard.

I'm more than happy for you to take on the fretboard design, it was going to be something I was going to ask @phattpiggie to do for me after one of those indian summer jobbies as I find the swirls mesmerizing.

But I've got plans on owning many custom stems as the VapCap has captured my imagination so there will be plenty to go around

, plus the HGL I'm praying I can get one day

, plus the HGL I'm praying I can get one day

Deer antler is a fantastic idea, I watched Rey Mears create a knife handle in his 'Ray Mears' Bushcraft S02E04 - Sweden' episode using deer antler and I love the concept. If it's possible to use it for the fret markers as well that would work really nicely, I wouldn't even mind if they were a little bigger (the fret markers).

The diagrams are just rough guides and I completely trust you to work with the materials as you see fit. The dimensions are also just a guide to describe an idea, I'm not even tied to any particular wood or metal. I'll happily let you work with whatever your instinct tells you as I have never built my own guitar

I know you are just dieing to know so I'll tell ya, I play a DeArmond

Not the greatest guitar in the world, not even close but I really like the goltone pick-ups and I think it looks great. Plus my dad bought it for me many years ago so I'm keeping it forever.

Not the greatest guitar in the world, not even close but I really like the goltone pick-ups and I think it looks great. Plus my dad bought it for me many years ago so I'm keeping it forever.

Also there is no rush on this project, I waited a year for the GrassHopper, I'm still waiting for a flying DeLorean powered by a MrFusion.

This is my custom Cherry body guitar that me and my dad built together.Right got ya, thicker cork, I'm going to have a play with the dimension of the cork. Think outside the GonG so to speak. Might have to come back to this idea at a later date though as I'd much rather the fretboard.

I'm more than happy for you to take on the fretboard design, it was going to be something I was going to ask @phattpiggie to do for me after one of those indian summer jobbies as I find the swirls mesmerizing.

But I've got plans on owning many custom stems as the VapCap has captured my imagination so there will be plenty to go around, plus the HGL I'm praying I can get one day

Deer antler is a fantastic idea, I watched Rey Mears create a knife handle in his 'Ray Mears' Bushcraft S02E04 - Sweden' episode using deer antler and I love the concept. If it's possible to use it for the fret markers as well that would work really nicely, I wouldn't even mind if they were a little bigger (the fret markers).

The diagrams are just rough guides and I completely trust you to work with the materials as you see fit. The dimensions are also just a guide to describe an idea, I'm not even tied to any particular wood or metal. I'll happily let you work with whatever your instinct tells you as I have never built my own guitar

I know you are just dieing to know so I'll tell ya, I play a DeArmondNot the greatest guitar in the world, not even close but I really like the goltone pick-ups and I think it looks great. Plus my dad bought it for me many years ago so I'm keeping it forever.

Also there is no rush on this project, I waited a year for the GrassHopper, I'm still waiting for a flying DeLorean powered by a MrFusion.

https://www.instagram.com/p/tKNfJRkfYx/

I'll work on experimenting with metal rings and machining this week. I have to develop a process before I can do any repeatable work. I really want to make a piece with some metal rings for my own personal collection as well so I better get on it!

GreenHopper

20 going on 60

This is my custom Cherry body guitar that me and my dad built together.

https://www.instagram.com/p/tKNfJRkfYx/

I'll work on experimenting with metal rings and machining this week. I have to develop a process before I can do any repeatable work. I really want to make a piece with some metal rings for my own personal collection as well so I better get on it!

Oh bud, that is a beautiful axe, you should post a pic in the 'Come Now (To Celebrate Your Wood)' thread.

Love it

little maggie

Well-Known Member

Beautiful. Do most of the vapcap stems on your website have steel cores or only the one above?

Just the one at the moment. Anything new I'm producing will have the stainless steel core. If you like the looks of one in the shop but want a steel core let me know and I can do my best to reproduce or even modify the design to your liking.Beautiful. Do most of the vapcap stems on your website have steel cores or only the one above?