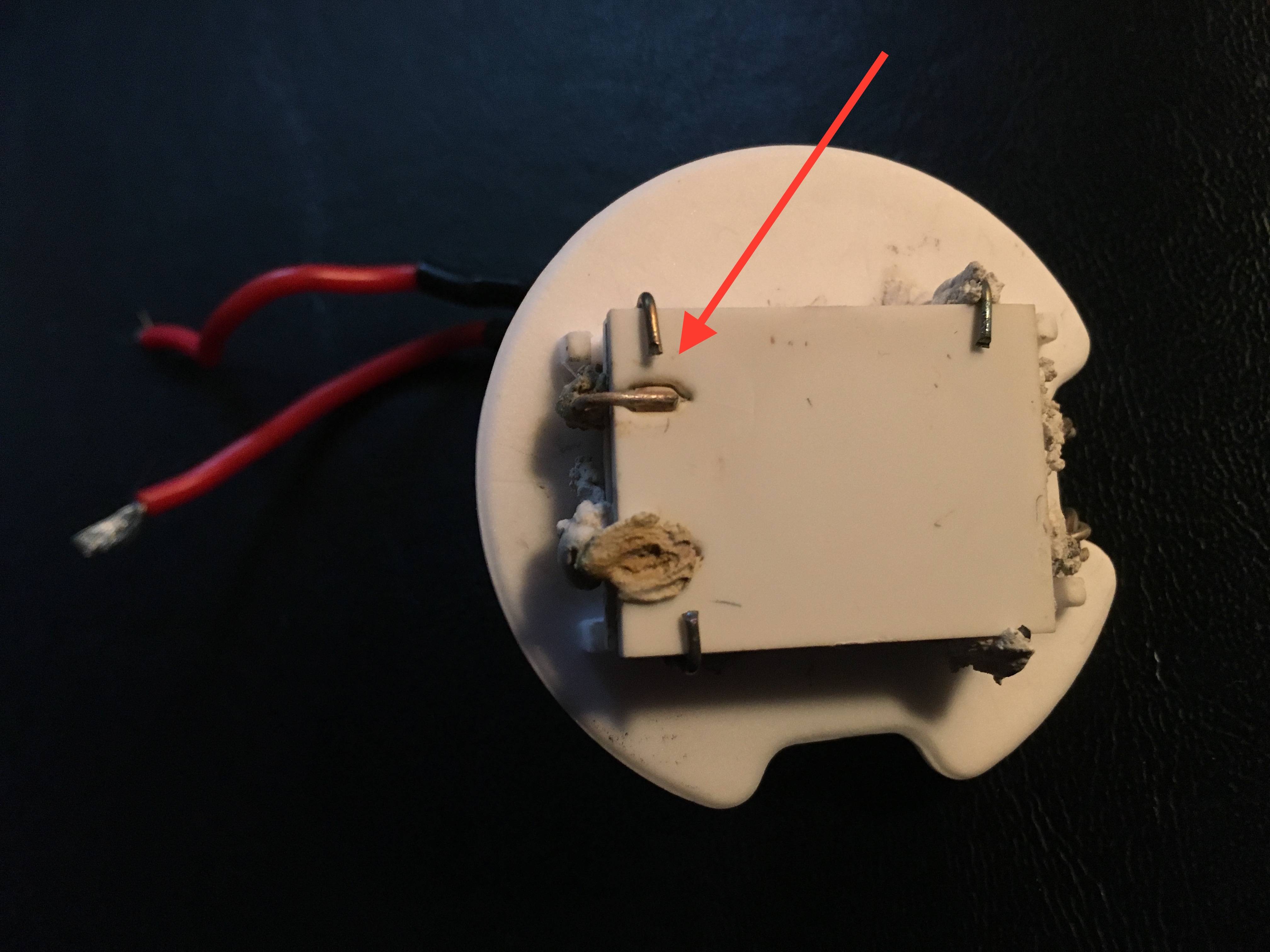

When my bases burned out, I first saw occasional bright flashes of light coming from under the ceramic disc. After the unit failed, the circuit board visible through the bottom of the unit was somewhat blackened.

My theory is that the ceramic coating covering the heater contact wears away enough to allow the current to bridge the gap to the retaining wire on the top of the heater. That creates a short in the circuit which fries the base.

Now whenever I notice a bright flash of light coming from under the ceramic disc on my VB2, I open it up and look at the heater contacts. If I notice that the ceramic coating has burned off one of the heater contacts, I replace the heater. I'd rather get a few hours less out of a heater than have it short out and burn up another base.

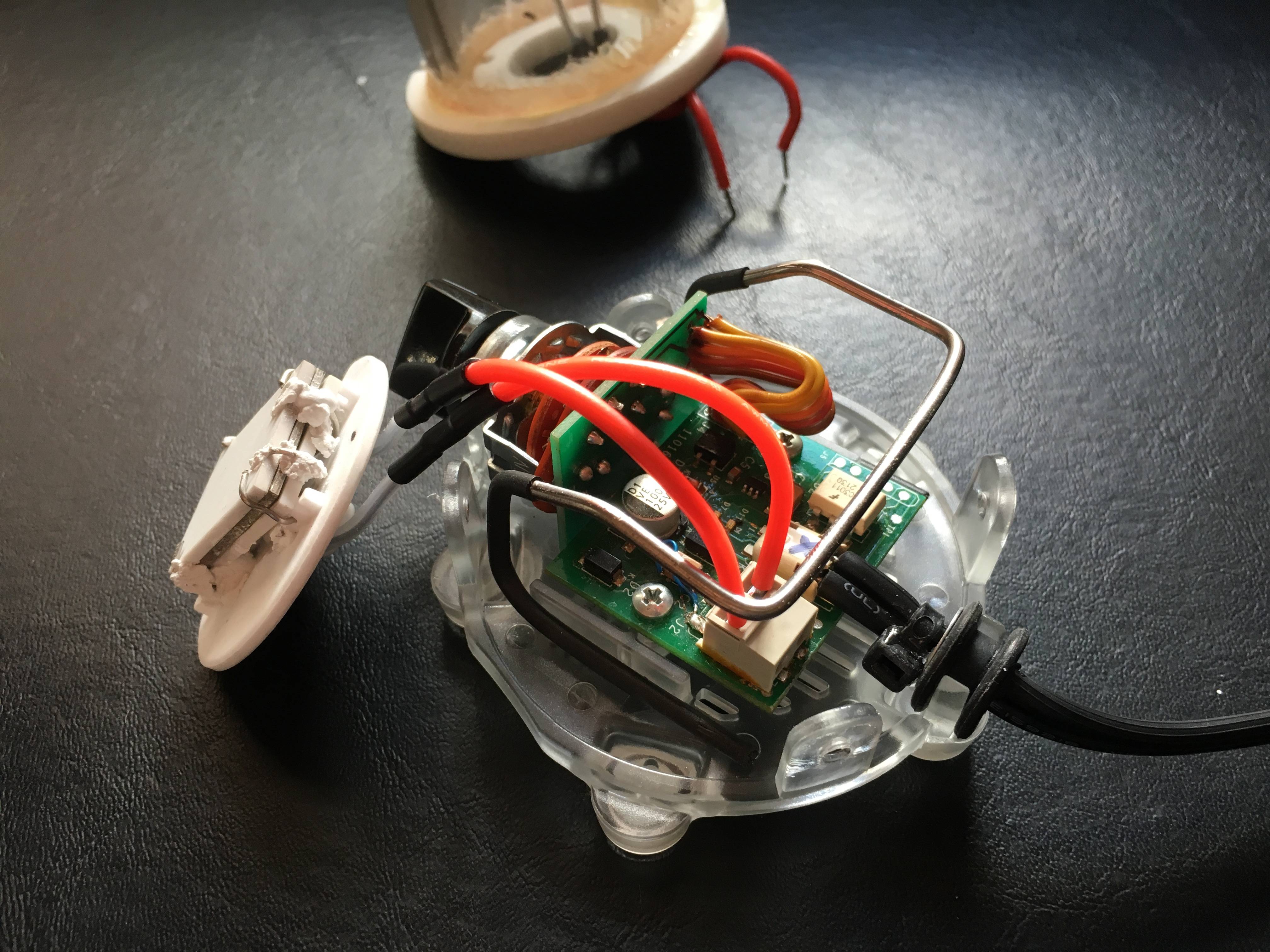

Hello, this can help explain what you've seen. First about the electronics in the base.

The base: VB2.0's startup cycle flashes the green lights for 10 seconds, then they tick on and off for 3 minutes. Once the lights shine continuously the unit is ready to dab off of. If your VB2.0 does not flash, tell us.

The heaters half burning out: VB2.0 should burn the ceramic disc back to pure white after about 10-20 minutes at high setting. If your dabs spread out and turn black, then don't clean back to white, one of the two ceramic heaters has broken and you need to replace the heater assembly.

Why heaters crack: To reach the temperatures we need for the Leidenfrost effect the heater's ceramic material is under internal stress. It's very similar to ceramic nails.. A crack in the wrong spot causes air to reach the heating track inside and it burns up, creating the little lightening effect. This happens in all ceramic heaters built this way, from vape pen donuts or enails that use these thin flat heaters.

We've studied this cause of failure for 10 years, since the time we adapted them for VB1. We pushed the expected lifetime of VB1 over 10 years and hope to do the same with VB2. VB2's are lasting some users well over 2 years, and others sometimes a month, which has us very busy looking for answers.

The internal stress I mention is a strong push & pull set up by difference in temperature between the hot central regions and the edges. The material is the most strong and dense we know, so we can't increase its strength. We have all sorts of ways to decrease the stress, and have figured out all sorts of ways over the last 10 years. For VB2.0, we created a sandwich of 2 ceramic heaters with a solid slab of nickel metal between. The nickel helps spread out the heat (and does not break down over time like Ti). Both heaters work at half power, which helps them last a lot longer.

So... if you see the lightening effect- it's probably a micro crack in the heater. Any time you get a new heater or send your unit for the free service we give you our latest embodiment.

If your base (the electronics) fail again we're going to try to send you a new one as we did the heaters. Progress...

Fyi, the ceramic potting (the part that fell off your contacts) is an improvement intended to decrease corrosion of the nickel brought on by oxygen & heat. Losing those won't cause a problem like shorting or arcing.

Linus

I actually prayed for this! Proof prayer works!

I actually prayed for this! Proof prayer works!