-

SCAM WARNING! See how this scam works in Classifieds.

-

The Frolic by Limelight Giveaway has started!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Discontinued The Okin by D.M. Pipes

- Thread starter Stu

- Start date

-

- Tags

- charcoal powered okin portable

FlyingLow

Team NO SLEEP!

looks really cool, and would make a killer camping vape.

my only concern is the fucking mess and black shit that is inevitably going to get on everything from handling the coals. i have been full vape for nearly 2 years now, and the last thing I want to deal with at the house is ash trays and coal dust.

my only concern is the fucking mess and black shit that is inevitably going to get on everything from handling the coals. i have been full vape for nearly 2 years now, and the last thing I want to deal with at the house is ash trays and coal dust.

my only concern is the fucking mess and black shit that is inevitably going to get on everything from handling the coals. i have been full vape for nearly 2 years now, and the last thing I want to deal with at the house is ash trays and coal dust.

Interestingly, the bamboo charcoal doesn't act like hardwood charcoal, it doesn't mark your hands at all with black carbon. It's more of a hard charcoal that crumbles into large chucks if you crush it, rather than a powdery soft charcoal like those used for artists charcoals.

Obviously it is still a bit more messy than battery operated devices, because you have to dispose of the final little unburnt "butt" end of the charcoals.

Yes, I think so. It would be fairly straight forward to make a hinged bowl lid that holds the charcoals.

The only complication would be the size of the bowl. Imagine the burning tube of charcoal, with the inner walls glowing. The air is heated by being drawn through this tube, as the diameter of the charcoal gets larger, the hole size increases. So with a larger piece of charcoal, the heat is concentrated in the outer ring of the bowl. So you get uneven vaporization, with a slightly cooler spot in the middle. Conversely, with a smaller charcoal, the airway is too small, making a very hot concentrated point of heat in the center of the bowl.

That is why, for this portable vaporizer design, I have chosen the diameter of charcoal and herb chamber that best suits this method of vaporization.

So, the bowl, on a vaporizer pipe, would have to be roughly the same size as the chamber diameter (maybe a tad larger) that is being used in my portable vaporizer design. Not exactly a problem, but just a point worth sharing I think.

But, for right now, I am looking for something that I can produce in batches, at a high level of craftsmanship, at a lower price point than my current work.

With pipe making, each individual piece requires a lot of time and attention, the crafting process can't be streamlined too much.

That is why I am focusing on the portable vaporizer for the moment, but in the future I would definitely be interested in using the charcoal vaporization method in my pipe designs as well!

The only complication would be the size of the bowl. Imagine the burning tube of charcoal, with the inner walls glowing. The air is heated by being drawn through this tube, as the diameter of the charcoal gets larger, the hole size increases. So with a larger piece of charcoal, the heat is concentrated in the outer ring of the bowl. So you get uneven vaporization, with a slightly cooler spot in the middle. Conversely, with a smaller charcoal, the airway is too small, making a very hot concentrated point of heat in the center of the bowl.

That is why, for this portable vaporizer design, I have chosen the diameter of charcoal and herb chamber that best suits this method of vaporization.

So, the bowl, on a vaporizer pipe, would have to be roughly the same size as the chamber diameter (maybe a tad larger) that is being used in my portable vaporizer design. Not exactly a problem, but just a point worth sharing I think.

But, for right now, I am looking for something that I can produce in batches, at a high level of craftsmanship, at a lower price point than my current work.

With pipe making, each individual piece requires a lot of time and attention, the crafting process can't be streamlined too much.

That is why I am focusing on the portable vaporizer for the moment, but in the future I would definitely be interested in using the charcoal vaporization method in my pipe designs as well!

The following quote is a post by @Dan Morrison, taken from a deleted post that he made before his account was approved. I'm resurrecting it because it contains a lot of interesting information and discusses the carbon monoxide issue.

This is Dan from D.M. Pipes.

I'm just taking a break from working on a new and improved prototype...

A note about the carbon monoxide. I've been trying to gather all the info I can about this, but the studies that have been done have no correlation to this design. It's well documented that hookahs produce carbon monoxide, and if used in an enclosed space, can be quite harmful. Hookah users have all sorts of rules about how to avoid carbon monoxide poisoning. Many of them involve not using "quick light" charcoal, and having adequate ventilation.

The chemical reaction here is Carbon + Oxygen = Carbon Dioxide. When not enough oxygen is present for complete combustion, Carbon Monoxide is formed instead. So, from what I understand, the available oxygen plays a very important role here.

Hookahs are usually using a coal that is at least half smothered, and have an ember that is far larger than the ones I am using. They also stay lit for hours at a time.

The charcoals in my design burns on the inside diameter of the bamboo tube, as fresh air is being pulled directly through the hole, the resulting ember is very bright and burns hot, suggesting a mostly complete burn. Also, these embers burn for no more than 5-10 minutes at a time at the length I intend to supply. So the accumulated carbon monoxide in the room will not be substantial, no more than a candle I am guessing.

So, while I am interested in further information about this, I am fairly confident that this design produces only small amounts of carbon monoxide. While this may be a health concern to some, and I cannot say if it is as healthful than a battery operated device, I believe it's still a healthier alternative to smoking.

For the last while I have been researching the materials that I would like to use. It seems likely that I will be using stainless steel for the herb chambers. The herb chambers will have a groove machined on the ID of one end, into which a stainless steel screen will be fitted. This screen will be replaceable. No screen lasts indefinitely, and being able to replace it is a good idea, especially since I will be using a fine-medium mesh screen. Solid perforated discs don't have enough airflow in my opinion, same for ceramic. When the chamber is in the case, the open end will be covered, so no herbs will fall out. When the chamber is loaded into the device, the open end is sealed by a screen inside the device. This makes it so you never have to tediously remove a tiny little screen while re-loading the chambers. The screens, both in the device, and in the chambers, are only removed for replacement. They can be replaced with fine-medium mesh screens supplied by me, OR, replaced with generic stainless pipe screens that can be cut to size with scissors.

The outside diameter of the herb chambers will be polished for increased corrosion resistance, and because it looks nice. I may also experiment with heat treating the steel to produce various shades of gold, brown, blue, and dark purple, which I think would look awesome. Though, this surface finish is less durable, so I may recommend a coating of beeswax or petroleum wax on the outside of these chambers every once in a while.

The tip of the device, that will hold the charcoal, and the herb chamber, will be of medium carbon steel, most likely 1144 Stressproof for its moderate hardness, high tensile strength, and excellent maintainability. I would like to polish the inside diameter, for a nice mating surface with the herb chamber inside. The outside, however, will be intentionally rusted with traditional Japanese techniques, to produce a surface finish much like very old brown/black iron. This surface finish is used extensively in the making of traditional iron/steel samurai sword hardware. The richness and organic feel to this surface is amazing.

The prongs I have yet to figure out, they may be inlaid into the steel, and made from brass or copper, to produce a beautiful contrast between the two materials. This sort of inlay is very time consuming however, and I may have to save it for more expensive custom models. For the basic model, I will most likely attach the prongs with tiny brass screws, or brazing/hard solder.

I may or may not do the whole "bolt action" loading system. I will most likely save that for more expensive pieces, and just have the device come apart in the middle for loading the chambers.

At first, I wanted to make the distance from the charcoal to the chamber adjustable, for fine heat control, but the mechanism to make that work are iffy, as far as long term functionality goes. The only reliable way to make this work is with threading, and I would like to avoid threads if I can, they limit the wall thickness of the pieces, and I don't think they match the aesthetic I am going for. Mortise and tenon fits are only good between dissimilar materials, which is why I will be using it only for the union between the wooden half of the device, and the steel tip.

So, I think I will not make the chamber adjustable, but rather, the charcoal itself. Heat will be controlled by how far you push the charcoal down into the prongs. Or, even pull the charcoal out far enough to create a gap between the butt end of the charcoal and the steel tip, allowing cooler air to rush in. It does seem as though there is an ideal distance however, with very tight tolerance, a few millimeters change in distance seems to make a large difference. I think that the only time adjustments will have to be made, is possibly when it's winter time, and the ambient air is much colder, maybe. The majority of temperature control is with your breath.

As for the case, it will hold 4-6 herb chambers, and about 8-10 charcoals. This design I have not quite figured out yet. I am torn between a simple wooden box, much like a chopstick box, and done in the very minimalistic japanese style, a tube case..that will hold the chambers just like that shaving cream can from jurassic park (SO COOL!), or a hard leather sheath for the vaporizer, with a matching hard leather disc shaped case for the chambers and charcoals.

So, Any thoughts on all this? I've been obsessed with designing this thing. The first time I used the rough prototype, I knew it was something special. I've been a pipe maker for more than 10 years... but I haven't touched my pipe since...

Loving all the discussion so far!

Breathemetal

Well-Known Member

Oooooooooo i do want one

The following quote is a post by @Dan Morrison, taken from a deleted post that he made before his account was approved. I'm resurrecting it because it contains a lot of interesting information and discusses the carbon monoxide issue.

Thank you!

I think I'm about to fall in love with this thread the same way I've fallen in love with your blog Mr. Morrison.

Vapetologist

HamsterDAMAGED

No butane, no batteries; how do you get the charcoal lit? Snarf Snarf Snark.

With a match.

marduk

daydreamer

No butane, no batteries; how do you get the charcoal lit? Snarf Snarf Snark.

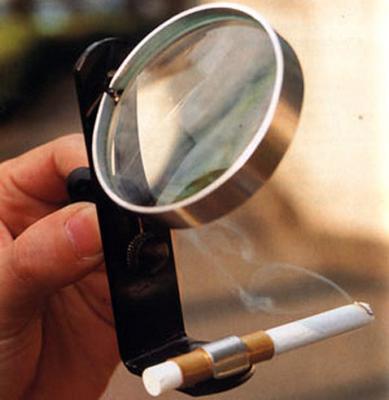

Also...

Use the flames from your campfire by night.

Or you can do something like this by day:

Question.

I have been on the fence about the loading system...

Those of you with portable vaporizers, how would you like to load your device?

Pre-loaded cartridges would be really nice, but, that also makes the case larger... makes the price a bit more, and there will be an issue with the cartridges making a perfect seal with the device. Slip fits between two metals will eventually lead to wear, since metal does not allow for much deflection of the material...like with a slip fit between two plastics, or metal and rubber..etc.. So, a steel cartridge slid into a metal barrel will eventually wear...and may be too loose in a few years time... Also, if the joint is too tight, it will be hard to remove the cartridges...

A screw threaded cartridge would be the solution... but even then, you have to wait for the cartridge to cool down for a minute or two before unscrewing the cartridge by hand to replace it... it would actually be faster to dump an integral cartridge while it is hot, load it, and then put the device back together to continue using it... BUT...loading a little cartridge like that if you're on the go can also be a hassle...

In short, A non removable chamber would give you:

-less moving parts, less cleaning, less to fail

-no need to wait for the cartridge to cool down before reloading

-easier to produce = lower price

-less convenient on the go, not as cool

Removable cartridges:

-cooler, more convenient on the go

-possible to preload with different herbs

-possible dedicated cartridges for concentrates

-different screen positions for cartridges that hold different amounts of material

-higher price

-larger case to hold the extra cartridges

-you'll have to wait a bit to remove the burning hot cartridges by hand

-extra bits to clean, more screw threads that will need cleaning

I have found that packing the device very loose works best, for even airflow and uniform vaporization. So, loading a cartridge like you would load a "one hitter" by sticking it into a dugout is not an option, this packs the material too tight. It needs to be sprinkled into the cartridge loosely.

Possible solutions for the problems presented above...

A leather holster, loops, or strip, built into the case, that you can use to hold the hot cartridge between you fingers, like a little oven mitt, so you can reload carts. when they are hot.

A case with a built in rotating dispenser... so you can put the herb chamber up to the dispenser hole, rotate the case, and drop the perfect amount of herb into the chamber...and away you go...

So... would you rather load herbs into a single chamber, every time, or, load pre-loaded cartridges into the device... hmmm..

I have been on the fence about the loading system...

Those of you with portable vaporizers, how would you like to load your device?

Pre-loaded cartridges would be really nice, but, that also makes the case larger... makes the price a bit more, and there will be an issue with the cartridges making a perfect seal with the device. Slip fits between two metals will eventually lead to wear, since metal does not allow for much deflection of the material...like with a slip fit between two plastics, or metal and rubber..etc.. So, a steel cartridge slid into a metal barrel will eventually wear...and may be too loose in a few years time... Also, if the joint is too tight, it will be hard to remove the cartridges...

A screw threaded cartridge would be the solution... but even then, you have to wait for the cartridge to cool down for a minute or two before unscrewing the cartridge by hand to replace it... it would actually be faster to dump an integral cartridge while it is hot, load it, and then put the device back together to continue using it... BUT...loading a little cartridge like that if you're on the go can also be a hassle...

In short, A non removable chamber would give you:

-less moving parts, less cleaning, less to fail

-no need to wait for the cartridge to cool down before reloading

-easier to produce = lower price

-less convenient on the go, not as cool

Removable cartridges:

-cooler, more convenient on the go

-possible to preload with different herbs

-possible dedicated cartridges for concentrates

-different screen positions for cartridges that hold different amounts of material

-higher price

-larger case to hold the extra cartridges

-you'll have to wait a bit to remove the burning hot cartridges by hand

-extra bits to clean, more screw threads that will need cleaning

I have found that packing the device very loose works best, for even airflow and uniform vaporization. So, loading a cartridge like you would load a "one hitter" by sticking it into a dugout is not an option, this packs the material too tight. It needs to be sprinkled into the cartridge loosely.

Possible solutions for the problems presented above...

A leather holster, loops, or strip, built into the case, that you can use to hold the hot cartridge between you fingers, like a little oven mitt, so you can reload carts. when they are hot.

A case with a built in rotating dispenser... so you can put the herb chamber up to the dispenser hole, rotate the case, and drop the perfect amount of herb into the chamber...and away you go...

So... would you rather load herbs into a single chamber, every time, or, load pre-loaded cartridges into the device... hmmm..

marduk

daydreamer

Question.

I have been on the fence about the loading system...

Those of you with portable vaporizers, how would you like to load your device?

I vote for preloaded cartridges. The loading convenience for an on-the-go vaporizer with a small chamber can't be overstated, IMO.

I have a Firewood 1.0 and a 2.1, which have chambers slightly larger than your vaporizer and I can tell you that loading the FW 1.0 is a hassle without a clean flat surface at hand. The 2.1 has glass capsules that you preload, and the ease of switching them out makes the whole experience that much better.

I'd be fine with the screw-in system for carts, but if you wanted to keep a slip fit design, would using two high-temp silicone O-rings in interior grooves work? It would be kind of like the opposite of the Lotus WPA system, where the two O-rings barely stick up above the metal surface. So sliding the cartridge into the unit would not invove any metal contact and there would be no metal wear.

Regarding the case having to be larger to accommodate extra cartridges, how about making a standard case that only holds 2 extra carts in addition to the installed one? Then for longer excursions you could have an optional case that holds up to 10 cartridges or so lined up in a row along with a space for the charcoal. The cases would still be slim and pocketable, and both cases could be externally identical with different inserts for each purpose.

BTW, are you thinking of a unique name for your vaporizer or will you simply be calling it Bamboo Charcoal Vaporizer?

Last edited:

Nice suggestions!

I can appreciate the convenience of pre-loaded carts!

As for the O-rings, they would have to be so tiny to fit into a groove cut in the sidewalls that I don't think they will hold in place very well. With the "reverse" o-ring design you mentioned, there is no elastic pressure keeping the o-ring in place. The groove would have to be very shallow, and I'm afraid that the o-rings would be easily lost. Also, with an o-ring that small, degradation would be pretty fast, and they would probably have to be replaced relatively often... this sort of goes against my design plan for this...

If I were to use o-rings, i would have to make the diameter of the entire vape a bit larger, and if I did that..well..then we have all sorts of possibilities that open up... but, I am reallly trying to stay under 11.5mm outside diameter, if only for the pure aesthetics of it.

I do like the possibility of making the optional case however, that's a good idea.

Thinking about it more... I am sort of leaning towards a dispensing mechanism.

I can imagine a case design that allows for reloading faster, easier, and cooler than using multiple cartridges.

On top of that, there are less moving parts in the device itself, which means a long life with no need for repairs and no worries about lost little pieces. Just a solid object, simple.

Yes yes, I like this. I will update later with some drawings to better explain what I'm thinking....

This forum has been very helpful!

I can appreciate the convenience of pre-loaded carts!

As for the O-rings, they would have to be so tiny to fit into a groove cut in the sidewalls that I don't think they will hold in place very well. With the "reverse" o-ring design you mentioned, there is no elastic pressure keeping the o-ring in place. The groove would have to be very shallow, and I'm afraid that the o-rings would be easily lost. Also, with an o-ring that small, degradation would be pretty fast, and they would probably have to be replaced relatively often... this sort of goes against my design plan for this...

If I were to use o-rings, i would have to make the diameter of the entire vape a bit larger, and if I did that..well..then we have all sorts of possibilities that open up... but, I am reallly trying to stay under 11.5mm outside diameter, if only for the pure aesthetics of it.

I do like the possibility of making the optional case however, that's a good idea.

Thinking about it more... I am sort of leaning towards a dispensing mechanism.

I can imagine a case design that allows for reloading faster, easier, and cooler than using multiple cartridges.

On top of that, there are less moving parts in the device itself, which means a long life with no need for repairs and no worries about lost little pieces. Just a solid object, simple.

Yes yes, I like this. I will update later with some drawings to better explain what I'm thinking....

This forum has been very helpful!

Trogdor

Vapinating the peasants

Nice suggestions!

I can appreciate the convenience of pre-loaded carts!

As for the O-rings, they would have to be so tiny to fit into a groove cut in the sidewalls that I don't think they will hold in place very well. With the "reverse" o-ring design you mentioned, there is no elastic pressure keeping the o-ring in place. The groove would have to be very shallow, and I'm afraid that the o-rings would be easily lost. Also, with an o-ring that small, degradation would be pretty fast, and they would probably have to be replaced relatively often... this sort of goes against my design plan for this...

If I were to use o-rings, i would have to make the diameter of the entire vape a bit larger, and if I did that..well..then we have all sorts of possibilities that open up... but, I am reallly trying to stay under 11.5mm outside diameter, if only for the pure aesthetics of it.

I do like the possibility of making the optional case however, that's a good idea.

Thinking about it more... I am sort of leaning towards a dispensing mechanism.

I can imagine a case design that allows for reloading faster, easier, and cooler than using multiple cartridges.

On top of that, there are less moving parts in the device itself, which means a long life with no need for repairs and no worries about lost little pieces. Just a solid object, simple.

Yes yes, I like this. I will update later with some drawings to better explain what I'm thinking....

This forum has been very helpful!

something like a cereal dispenser except smaller maybe?

More like a six shooter cylinder. And instead of bullets, its just herbs in there.

cartridges stay hot, for quick change = burning fingers, rather do a quick loading baggy system. Load and dump out, load and dump out. No burning hands or fingers.

herbivore21

Well-Known Member

Interesting concept, not sure how it would work in practice, but I am sure I do not want to be carrying a smouldering piece of charcoal around with me anywhere!

marduk

daydreamer

Interesting concept, not sure how it would work in practice, but I am sure I do not want to be carrying a smouldering piece of charcoal around with me anywhere!

From what I can tell, the vaporizer and the case will work together. As soon as you're done with a session and want to move on, you put the vaporizer in the case and the charcoal will be extinguished immediately. Pop the case in your pocket and go about your business... there's no risk of the charcoal getting lit, there's not enough oxygen in the case to support that.

herbivore21

Well-Known Member

I appreciate this my friend, but still, I don't wanna be holding a smoldering piece of charcoal at any stage! I don't wanna risk burning myself, friends or belongings if I don't have to! Also not at all keen on letting off burning charcoal into the air around me, even if I'm not breathing it in directly.

marduk

daydreamer

Ah... well, apparently the properties of bamboo charcoal are different from your run-of-the-mill charcoal so it stays intact and doesn't release burning embers while lit. However, if you just don't like the idea of holding smoldering charcoal in your hand, then this is definitely not the vape for you.

On the other hand, if this vape comes together and works as promised, I know it will convert a ton of combusters. Because they like seeing that cherry when they inhale!

On the other hand, if this vape comes together and works as promised, I know it will convert a ton of combusters. Because they like seeing that cherry when they inhale!

cartridges stay hot, for quick change = burning fingers, rather do a quick loading baggy system. Load and dump out, load and dump out. No burning hands or fingers.

Agreed.

And Herbivore21 has a point, you do have to be careful with the burning ember, don't drop it on the carpet!