I've been diving down the rabbit hole of convection heating techniques and I think there is a ton of cool stuff to talk about. So, this is an attempt to dump my thoughts and start some discussion.

This will only cover 100% convection heating. Everything changes when you introduce active conduction heating. Hybrid devices are relevant, but for the sake of keeping things simple I think it's best to omit them in this thread.

______

The convection process, in theory, is simple. You've got hot air flowing through a chamber that is packed with loose leaf/flower particles.

In an ideal world the flow of hot air would be totally uniform over each individual leaf particle, resulting in a perfectly even extraction of the entire packed chamber.

In reality, convection heating can often result in uneven extraction.

When convection goes right, It's absolutely sublime...... so what can we do to increase our chances of success?!

______

For the sake of this thread I think our goal could be to figure out what we can do to reach the highest possible "total extraction". Meaning the percentage of active compounds that end up in the vapor stream, relative to the weight of the extracted material.

This extraction should happen evenly throughout the entire chamber load.

And finally, that this extraction happens without manual stirring. (Perhaps it will be proven that stirring IS needed for absolute best results, but I am really hoping that is not the case) I'd still like to hear thoughts on stirring, as I know some people actually enjoy stirring.... but y'all are crazy. In my opinion, stirring is a sign that uneven extraction is happening. I believe it's better to treat the cause of that unevenness in the first place.

So, what are the variables that affect total/even extraction?

One obvious one is grind size.

______

For this first post, I am going to focus on the variable of grind size.

Theoretically, the finer the grind size the more surface area you have available to extract, and so the more extraction you should be able to achieve with a fixed volume of hot air. From my experience this doesn't translate into the real world.

With a fine grind I typically get very quick extraction. Vapor density is high, seemingly because of the large surface area of the small particles. But the evenness of the extraction can be poor if you try to extract too quickly. Since I prefer faster extractions, I often get uneven extraction.

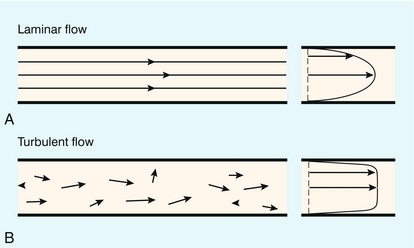

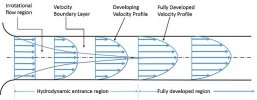

My working theory is that the fine particles restrict airflow, causing channels to open up where you get regions of high air flow, surrounded by regions of reduced airflow. This usually presents as "hot spotting", where one small area is over extracted.

______

I recently watched THIS video discussing an espresso extraction study. The main focus being grind size and how it relates to the extraction of coffee beans.

While this is all dealing with coffee beans and hot water, I felt like there were a lot of parallels between this process and the process of extracting loose leaf with hot air.

When you think about it, an espresso machine functions similarly to a convection vaporizer, just replace water with air. Instead of the pressure coming from a water pump or hand operated lever, the pressure comes from our lungs.

Since "Air behaves in a fluid manner, meaning particles naturally flow from areas of higher pressure to those where the pressure is lower" (wikipedia), we can likely still assume that there are useful bits of information to borrow from the espresso process, despite the fact that it's using water instead of air. Since espresso has been around for over 100 years, I feel like there are some insights that come with that maturity.

In short, the study found that total extraction (and more specifically the evenness of extraction) dropped with finer grind settings.

From the video,

As mentioned above, I seem to have the same experience with fine grinds. If pushed to extract quickly, uneven extraction is almost guaranteed.

Conversely, coarse grinds, in my experience, have the opposite effect, resulting in more even airflow over the entire herb load. Even when pushed to extract quickly, the airflow remains more even throughout the load.

The above video cites that water flows more evenly through a bed of coarser coffee grinds.... so it seems like my experiences are mirrored in the espresso world.

But... you can only go so coarse. At the extreme end, you can vaporize whole flower. I find that this can work fantastically... but it really depends on the density of your flower material. With dense flowers you've got a lot of nooks and crannies hidden away inside the flower that are not getting good exposure to the hot air flow. These whole flowers may require mid-session grinding and stirring to achieve a high total extraction.

From the video,

I think this pretty much sums up my thoughts on grind size and convection heating.

So, where is that crossover point?

I think it's somewhere in the medium - coarse grind size for my particle vaporizer and usage style. If I'm shooting for perfection, sifting the particles into uniform sizes will result in an incredibly even distribution of particles in the chamber. I use zero tamping, which is very important to preserve the air pockets around each particle.

Thoughts? What is your preferred grind size?

I also feel like it's worth mentioning what vaporizers you're using, so as to get an idea of how each device may affect these variables.

For future posts (and I invite anyone to start their own here) I think it'd be cool to discuss the other variables; chamber size/geometry, air speed, temperature, etc.. In fact, it might be useful to discuss exactly what variables exist in the first place, haha.

From the same creator of the above video, he has a series on "Understanding Espresso" where he outlines all the variables involved. He lists; Dose (weight of ground coffee), Ratio (coffee to water), Brew time, Grind size, Brew temperature, Pressure.

For our purposes, I'm not sure if we can use all those variables, or which ones make sense and how to translate them.. but I guess this is all a work in progress!

So, what variables do you find most important?

This will only cover 100% convection heating. Everything changes when you introduce active conduction heating. Hybrid devices are relevant, but for the sake of keeping things simple I think it's best to omit them in this thread.

______

The convection process, in theory, is simple. You've got hot air flowing through a chamber that is packed with loose leaf/flower particles.

In an ideal world the flow of hot air would be totally uniform over each individual leaf particle, resulting in a perfectly even extraction of the entire packed chamber.

In reality, convection heating can often result in uneven extraction.

When convection goes right, It's absolutely sublime...... so what can we do to increase our chances of success?!

______

For the sake of this thread I think our goal could be to figure out what we can do to reach the highest possible "total extraction". Meaning the percentage of active compounds that end up in the vapor stream, relative to the weight of the extracted material.

This extraction should happen evenly throughout the entire chamber load.

And finally, that this extraction happens without manual stirring. (Perhaps it will be proven that stirring IS needed for absolute best results, but I am really hoping that is not the case) I'd still like to hear thoughts on stirring, as I know some people actually enjoy stirring.... but y'all are crazy. In my opinion, stirring is a sign that uneven extraction is happening. I believe it's better to treat the cause of that unevenness in the first place.

So, what are the variables that affect total/even extraction?

One obvious one is grind size.

______

For this first post, I am going to focus on the variable of grind size.

Theoretically, the finer the grind size the more surface area you have available to extract, and so the more extraction you should be able to achieve with a fixed volume of hot air. From my experience this doesn't translate into the real world.

With a fine grind I typically get very quick extraction. Vapor density is high, seemingly because of the large surface area of the small particles. But the evenness of the extraction can be poor if you try to extract too quickly. Since I prefer faster extractions, I often get uneven extraction.

My working theory is that the fine particles restrict airflow, causing channels to open up where you get regions of high air flow, surrounded by regions of reduced airflow. This usually presents as "hot spotting", where one small area is over extracted.

______

I recently watched THIS video discussing an espresso extraction study. The main focus being grind size and how it relates to the extraction of coffee beans.

While this is all dealing with coffee beans and hot water, I felt like there were a lot of parallels between this process and the process of extracting loose leaf with hot air.

When you think about it, an espresso machine functions similarly to a convection vaporizer, just replace water with air. Instead of the pressure coming from a water pump or hand operated lever, the pressure comes from our lungs.

Since "Air behaves in a fluid manner, meaning particles naturally flow from areas of higher pressure to those where the pressure is lower" (wikipedia), we can likely still assume that there are useful bits of information to borrow from the espresso process, despite the fact that it's using water instead of air. Since espresso has been around for over 100 years, I feel like there are some insights that come with that maturity.

In short, the study found that total extraction (and more specifically the evenness of extraction) dropped with finer grind settings.

From the video,

....at very fine grinds you're inevitably gonna get channeling, water cannot pass evenly through that cake of coffee and so some water, quite a lot of water, is going to flow through just a little bit of coffee where channels form, you'll have a very high flow rate through a channel and the coffee around that channel won't see as much water. It won't be extracted as much and this is causing this drop in total extraction.

As mentioned above, I seem to have the same experience with fine grinds. If pushed to extract quickly, uneven extraction is almost guaranteed.

Conversely, coarse grinds, in my experience, have the opposite effect, resulting in more even airflow over the entire herb load. Even when pushed to extract quickly, the airflow remains more even throughout the load.

The above video cites that water flows more evenly through a bed of coarser coffee grinds.... so it seems like my experiences are mirrored in the espresso world.

But... you can only go so coarse. At the extreme end, you can vaporize whole flower. I find that this can work fantastically... but it really depends on the density of your flower material. With dense flowers you've got a lot of nooks and crannies hidden away inside the flower that are not getting good exposure to the hot air flow. These whole flowers may require mid-session grinding and stirring to achieve a high total extraction.

From the video,

....the finer you grind the more coffee you should be able to extract, but the coarser you grind the more evenly it's likely that the water will flow through the cake and so what you're looking for is kind of a crossover point. A point that's the best of both where you're going as fine as possible for an even flow rate

I think this pretty much sums up my thoughts on grind size and convection heating.

So, where is that crossover point?

I think it's somewhere in the medium - coarse grind size for my particle vaporizer and usage style. If I'm shooting for perfection, sifting the particles into uniform sizes will result in an incredibly even distribution of particles in the chamber. I use zero tamping, which is very important to preserve the air pockets around each particle.

Thoughts? What is your preferred grind size?

I also feel like it's worth mentioning what vaporizers you're using, so as to get an idea of how each device may affect these variables.

For future posts (and I invite anyone to start their own here) I think it'd be cool to discuss the other variables; chamber size/geometry, air speed, temperature, etc.. In fact, it might be useful to discuss exactly what variables exist in the first place, haha.

From the same creator of the above video, he has a series on "Understanding Espresso" where he outlines all the variables involved. He lists; Dose (weight of ground coffee), Ratio (coffee to water), Brew time, Grind size, Brew temperature, Pressure.

For our purposes, I'm not sure if we can use all those variables, or which ones make sense and how to translate them.. but I guess this is all a work in progress!

So, what variables do you find most important?