I have had customers remove the top seal from the bearing and submerge in iso to clean. Just be aware, there is a chance of the balls in the bearing flash rusting if you let them get dry for too long without some kind of oil on them. I recommend putting a drop of avocado, olive, veg oil in the bearing etc as its food safe. I personally would just dab some iso drenched Qtip around the lid to clean it when the time comes.Question for @OMD: if the OG as shipped can’t be immersed in ISO for cleaning, what are your recommendations for cleaning? Do you recommend switching to a ceramic bearing for this reason?

The other two “upgrades” seem unnecessary to me.

-

SCAM WARNING! See how this scam works in Classifieds.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

OLD MATE (formerly Medgrind)

- Thread starter Timps27

- Start date

I have purchased some ceramic bearings just now to test out. Thankyou for taking the risk and trying them in your grinder!He says to remove the bearing if you ever need to deep clean the unit.

If I could not work out how to remove the bearing I would simply use iso in a shallow dish with the teeth facing down so the iso level stays below the bearing for a good long soak if I did not own an ultrasonic cleaner or a ceramic bearing.

Ceramic bearings have a habit of breaking during installation compared to steel so that may be part of the reason along with wanting the magnetism would be the reason for the standard issue jobs. That said, Ben would happily install any bearing you like when made.

As part of me being open and honest with you all i need to share that i I have had some concerns from people regarding the bearing sliding on and off the post potentially causing metal dust. To alleviate any concerns i would like to offer ceramic bearings on my website.

I obviously need to test them out to make sure they dont break on install (might mean i need to hold a super dooper tight tolerance on the lid bearing pocket) and are fit for purpose.

Super keen to hear you guys thoughts on this?

Last edited:

jbm

Well-Known Member

I can’t determine from this whether you think this is an actual possibility or not. Should we be replacing the bearings after all?As part of me being open and honest with you all i need to share that i I have had some concerns from people regarding the the bearing sliding on and off the post potentially causing metal dust. To alleviate any concerns i would like to offer ceramic bearings on my website.

The minute amounts of black dust accumulate on the white ceramic bearing as well (probably worse but not sure as ceramics can be about 3x harder than S/S) and is also more noticeable than with s/s raced bearings due to the ceramics being white.To alleviate any concerns i would like to offer ceramic bearings on my website.

The ceramics only break if you do not have them lined up correctly when installing, the ceramics are unforgiving compared to steel and will not tolerate an uneven press.

Last edited:

I personally don't see this as a massive concern, the amount of residue is probably 0.1% compared to the safe limits of metal exposure. You would probably need to inhale the entire post to be a concern. Metal fabricators/ welders etc that are grinding/filing all day might be a different story.I can’t determine from this whether you think this is an actual possibility or not. Should we be replacing the bearings after all?

However my opinion is irrelevant!! If my customers have concerns i will do everything i can to help. I want you guys to be able to do whatever you like with your grinders. If you want to change the bearing then you should be able to imo. I created them using skateboard bearings so you can change them and make them your own.

The black dust accumulates on the white ceramic bearing as well (probably worse as ceramics are about 3x harder than S/S) and is also more noticeable than with s/s raced bearings due to the ceramics being white.

The ceramics only break if you do not have them lined up correctly when installing, the ceramics are unforgiving compared to steel and will not tolerate an uneven press.

I believe the new filleted post design should help with this as there is a lot less contact area, however its something i need to test!

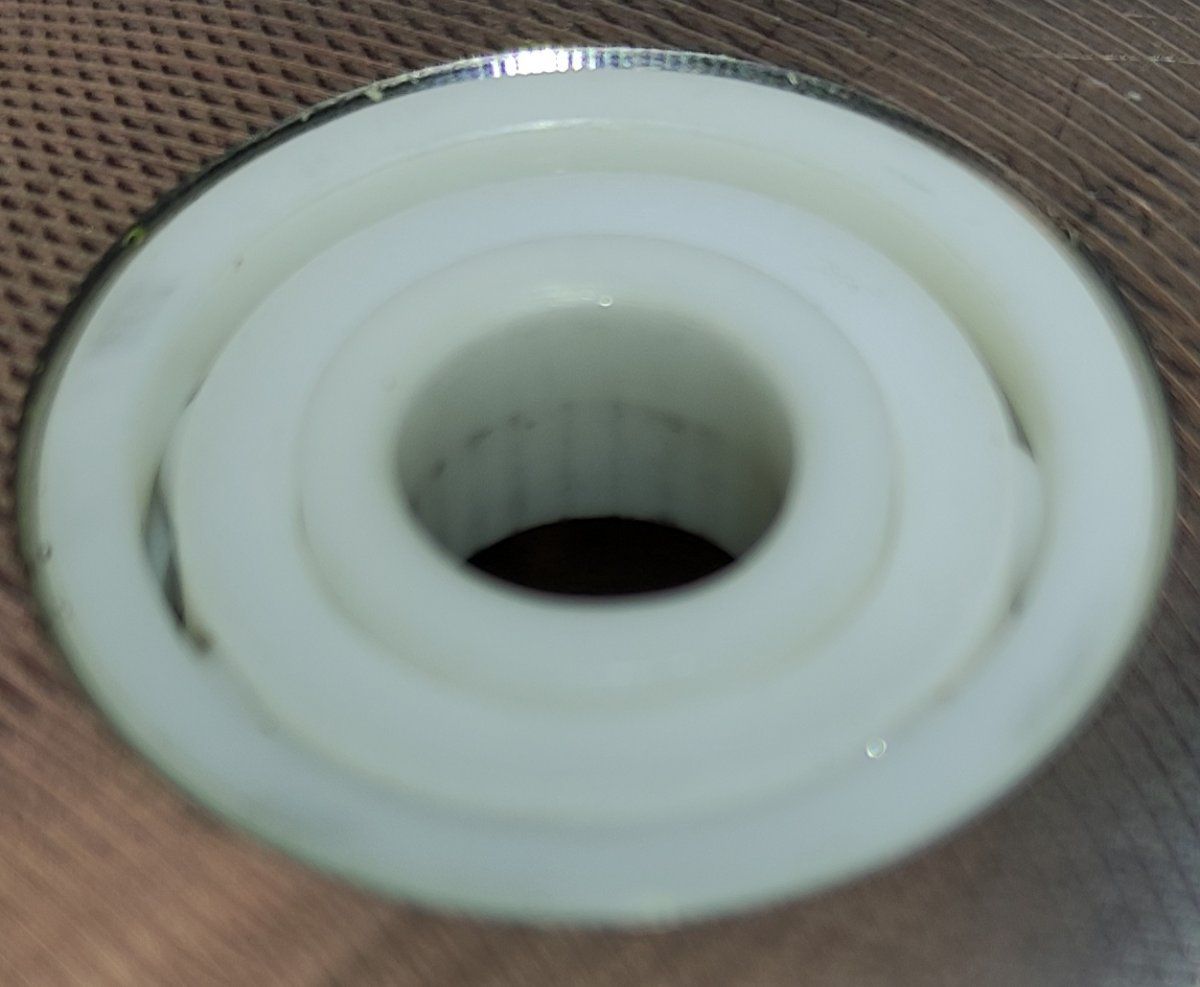

Do you mind sharing a photo of your inner race on your ceramic bearing?

Maybe pressing in a post of a different material will 100% eliminate this issue.

Excellent photo! Thankyou.The dark lines do not disappear completely once q-tipped so both surfaces seem to be wearing.

If this sort of thing concerns you a simple drop of cooking oil on your finger wiped over the top post occasionally may stop the wear?

Alrighty, I think any bearing would be fine if it was in conjunction with a post with a pressed in PEEK top section https://en.wikipedia.org/wiki/Polyether_ether_ketone would be absolutely ideal.

We machine peek for a lot of high demanding applications and it's quite awesome stuff! I know it would work well because its self lubricating and i have used it as a dry slide for a nickel plated aluminium bush to run it. It blew my mind how well it worked.

Thoughts on this?

EDIT:

Something like this is what im thinking.

Last edited:

I think this is a great idea. Personally, I feel you are addressing possible wear issues better than any of the other grinders that I have seen discussed.Excellent photo! Thankyou.

Alrighty, I think any bearing would be fine if it was in conjunction with a post with a pressed in PEEK top section https://en.wikipedia.org/wiki/Polyether_ether_ketone would be absolutely ideal.

We machine peek for a lot of high demanding applications and it's quite awesome stuff! I know it would work well because its self lubricating and i have used it as a dry slide for a nickel plated aluminium bush to run it. It blew my mind how well it worked.

Thoughts on this?

EDIT:

This is what im thinking.

Thankyou! I appreciate that. Instead of letting this get me down i will tackle it head on and make this product even better.I think this is a great idea. Personally, I feel you are addressing possible wear issues better than any of the other grinders that I have seen discussed.

Also guys, they make PEEK bearings. (that's how good the stuff is)

PEEK BEARING

This could be offered as a retrofit if you guys have any concerns with your current aroma-3?

11pm here. I need to get some sleep. Feel free to add any input guys

Thankyou!

jbm

Well-Known Member

How would these differ from the OG bearings or the ceramic bearings wrt performance and cleaning?This could be offered as a retrofit if you guys have any concerns with your current aroma-3?

Interesting, how do you use an ultrasonic cleaner with a grinder?He says to remove the bearing if you ever need to deep clean the unit.

If I could not work out how to remove the bearing I would simply use iso in a shallow dish with the teeth facing down so the iso level stays below the bearing for a good long soak if I did not own an ultrasonic cleaner or a ceramic bearing.

Ceramic bearings have a habit of breaking during installation compared to steel so that may be part of the reason along with wanting the magnetism would be the reason for the standard issue jobs. That said, Ben would happily install any bearing you like when made.

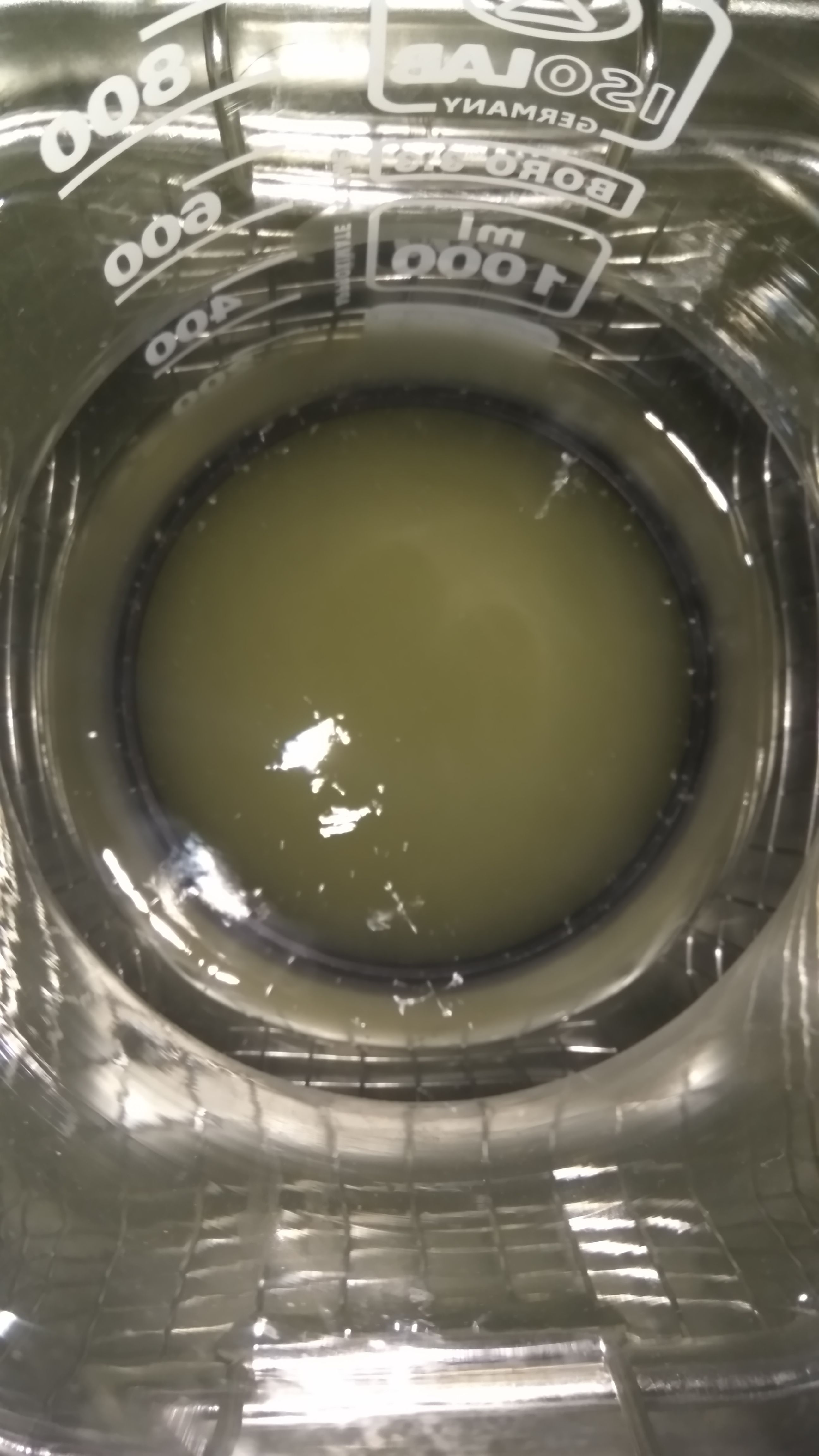

Beakers of iso suspended in the water bath (I also put a plastic lid over while cleaning),Interesting, how do you use an ultrasonic cleaner with a grinder?

There is a grinder in here with what was fresh iso at the start,

lapis

Well-Known Member

I applaud your efforts to make this grinder create as close to zero metal dust as possible, but I'm personally totally unconcerned about the absolutely minuscule amount of metal dust created by the bearing sliding onto and off of the post – and it's worth noting that a ceramic bearing could even create more dust than a metal bearing, due to, as mentioned by @LesPlenty, the fact that ceramic is a significantly harder material than SS.This could be offered as a retrofit if you guys have any concerns with your current aroma-3?

Wow, impressive cleaning setup. The ultrasonic cleaner looks like a professional one?Beakers of iso suspended in the water bath (I also put a plastic lid over while cleaning),

There is a grinder in here with what was fresh iso at the start,

I figured already that you would need quite some equipment to put a grinder in iso into an ultrasonic cleaner. I cleaned my Dynavap parts in the past in an ultrasonic cleaner for glasses. That was a lot easier cause you could just use bags. I was very impressed how much more residue from the dynavap tip the ultrasonic cleaner was able to remove compared to an iso soak.

Shit Snacks

Milaana. Lana. LANA. LANAAAA! (TM2/TP80/BAK/FW9)

I have had customers remove the top seal from the bearing and submerge in iso to clean. Just be aware, there is a chance of the balls in the bearing flash rusting if you let them get dry for too long without some kind of oil on them. I recommend putting a drop of avocado, olive, veg oil in the bearing etc as its food safe. I personally would just dab some iso drenched Qtip around the lid to clean it when the time comes.

Oh, I had no idea lubricating the bearings was a thing we would have to do at all until now... Not thrilled about the idea, I'm also not exactly sure where the lubrication should be going? It is all sealed up in there I wouldn't really feel comfortable just smearing oil all over personally... Like I'm someone who's always washing my hands from oils, I don't like lotions etc, I wouldn't really want loose oil around somewhere like that where I'll end up touching it and then feeling like I need to wash my hands?

I have purchased some ceramic bearings just now to test out. Thankyou for taking the risk and trying them in your grinder!

As part of me being open and honest with you all i need to share that i I have had some concerns from people regarding the bearing sliding on and off the post potentially causing metal dust. To alleviate any concerns i would like to offer ceramic bearings on my website.

I obviously need to test them out to make sure they dont break on install (might mean i need to hold a super dooper tight tolerance on the lid bearing pocket) and are fit for purpose.

Super keen to hear you guys thoughts on this?

Yes this is one of the things I was waiting for! Hoping you would offer these same ceramic bearings Les discovered, so I wouldn't even have to bother trying to change bearings, and I could get a second OMD from you with it (along with customized finer holed middle plate as I had mentioned previously so it would compliment my current OMD perfectly)

The minute amounts of black dust accumulate on the white ceramic bearing as well (probably worse but not sure as ceramics can be about 3x harder than S/S) and is also more noticeable than with s/s raced bearings due to the ceramics being white.

Oh I had no idea about this dust issue I suppose it is a concern but I didn't notice anything with mine, I do wonder if it would be better with the ceramic and the new post since you don't have that one yet either? Seemed like you wouldn't need it because the ceramics are non-magnetic already but if they are rubbing too much...?

I believe the new filleted post design should help with this as there is a lot less contact area, however its something i need to test!

Yeah I wonder how this improves more of these issues...

Alrighty, I think any bearing would be fine if it was in conjunction with a post with a pressed in PEEK top section

Oooh full peek protection now so my above comments may be irrelevant, more changes, but you could not soak it in alcohol at all if it had this now then?? I don't know tough to clean plastics sometimes even though peek is such high quality?

I trust you'll figure it all out!

How would these differ from the OG bearings or the ceramic bearings wrt performance and cleaning?

I imagine they would operate the same (ill test this), the plus is that you could submerge in iso /chuck in dishwasher and clean it no problems.

No no no! It's not something you have to do! This only applies if you have submerged your bearing in iso and washed the oil out. it's more of an advanced thing so i haven't really mentioned it for this reason. Sorry i should have been more clear. Some people are comfortable doing this, some aren't. You typically will never need to touch the bearing or service it in these grinders.Oh, I had no idea lubricating the bearings was a thing we would have to do at all until now... Not thrilled about the idea, I'm also not exactly sure where the lubrication should be going? It is all sealed up in there I wouldn't really feel comfortable just smearing oil all over personally... Like I'm someone who's always washing my hands from oils, I don't like lotions etc, I wouldn't really want loose oil around somewhere like that where I'll end up touching it and then feeling like I need to wash my hands?

Not everyone is getting this issue (over 350 out there now and only 3 reports so far). There are a heap of people on my discord showing they don't have this problem.Oh I had no idea about this dust issue I suppose it is a concern but I didn't notice anything with mine, I do wonder if it would be better with the ceramic and the new post since you don't have that one yet either? Seemed like you wouldn't need it because the ceramics are non-magnetic already but if they are rubbing too much...?

Oooh full peek protection now so my above comments may be irrelevant, more changes, but you could not soak it in alcohol at all if it had this now then?? I don't know tough to clean plastics sometimes even though peek is such high quality?

The idea is to be able to soak in iso with this peek bearing and it be no problem.

i will! thanks mate!I trust you'll figure it all out!

I don't know how to place photos here, just the link. sucks.

3oz through OM [no cleaning] in 4 weeks and it looks like this.

I used it till it became harmonically unbalanced and just to see

This thing .. still is .. the bomb.

My %70 ISO arrived today along with ma OM bearing press.

I take good care of ma things, this was an experiment.

3oz through OM [no cleaning] in 4 weeks and it looks like this.

I used it till it became harmonically unbalanced and just to see

This thing .. still is .. the bomb.

My %70 ISO arrived today along with ma OM bearing press.

I take good care of ma things, this was an experiment.

I get the same smear circle in mine!

feralcomprehension

Qualified Observer

1. I'm *super* impressed with the energy you devote to responding to your customers.Excellent photo! Thankyou.

Alrighty, I think any bearing would be fine if it was in conjunction with a post with a pressed in PEEK top section https://en.wikipedia.org/wiki/Polyether_ether_ketone would be absolutely ideal.

We machine peek for a lot of high demanding applications and it's quite awesome stuff! I know it would work well because its self lubricating and i have used it as a dry slide for a nickel plated aluminium bush to run it. It blew my mind how well it worked.

Thoughts on this?

EDIT:

Something like this is what im thinking.

2. If the addition of PEEK changes whether or not the unit can be cleaned in the dishwasher I would be sad- love that with my Herb Ripper.

3. In the cutaway image the engagement depth of the PEEK post into the ss looks proportionally too short for proper stability and retention.

I ended up just iso q-tipping the tips of the top plate row of teeth that made the smear on the lower part and had been spinning the heck out of my OM and only grinding in smaller amount each time instead of loading up as much as possible in the grinding area. The smear mark disappeared and my bearing was again spinning for over 3 minutes...then I installed my ABEC9 full ceramic and the smear reappeared and just cleaning the opposing teeth has not removed the smear...yet.I used it till it became harmonically unbalanced and just to see

Cloud McLongFoot

Well-Known Member

Hi guys,

Disappeared from the forum for a while since I got my grinder but decided to come check out the posts. I recently had an issue with my grinder getting stuck after a friend got some herb material caught between the bearing and post before grinding. I used a q tip and iso to clean it and got the a similar black residue off. Could this be from minute amounts fo herb getting stuck?

Too add, after looking at all the new changes and everything I am feeling the temptation to get a second. Will always love my founders edition but that new post and side grooves look nice

Disappeared from the forum for a while since I got my grinder but decided to come check out the posts. I recently had an issue with my grinder getting stuck after a friend got some herb material caught between the bearing and post before grinding. I used a q tip and iso to clean it and got the a similar black residue off. Could this be from minute amounts fo herb getting stuck?

Too add, after looking at all the new changes and everything I am feeling the temptation to get a second. Will always love my founders edition but that new post and side grooves look nice

Last edited:

Not in the pic I showed above.Could this be from minute amounts fo herb getting stuck?

Franco

is (most likely) vaping

TBH, I'm starting to be a little concerned about this black dust reports.

I've ordered one exactly three weeks ago, but I haven't received any order/shipping notification yet.

I really hope @OMD comes up with a solution that can be used to retrofit existing units, because at the moment I'm starting to have regrets for this purchase.

I've ordered one exactly three weeks ago, but I haven't received any order/shipping notification yet.

I really hope @OMD comes up with a solution that can be used to retrofit existing units, because at the moment I'm starting to have regrets for this purchase.